Maintaining a clean and inviting swimming environment is essential for any pool owner. A crucial aspect of ensuring the efficiency of a cleaning device lies in comprehending its various elements and how they interact. This knowledge not only facilitates effective upkeep but also empowers users to troubleshoot any issues that may arise.

The intricate design of a cleaning apparatus involves a series of interconnected parts, each serving a specific purpose. Familiarity with these components can enhance performance and longevity. Additionally, understanding how each segment functions contributes to more effective maintenance practices.

In this section, we will explore the essential features of the device, offering insight into its operation. By gaining a deeper understanding of the individual elements, users can optimize their cleaning experience and ensure their pool remains pristine throughout the season.

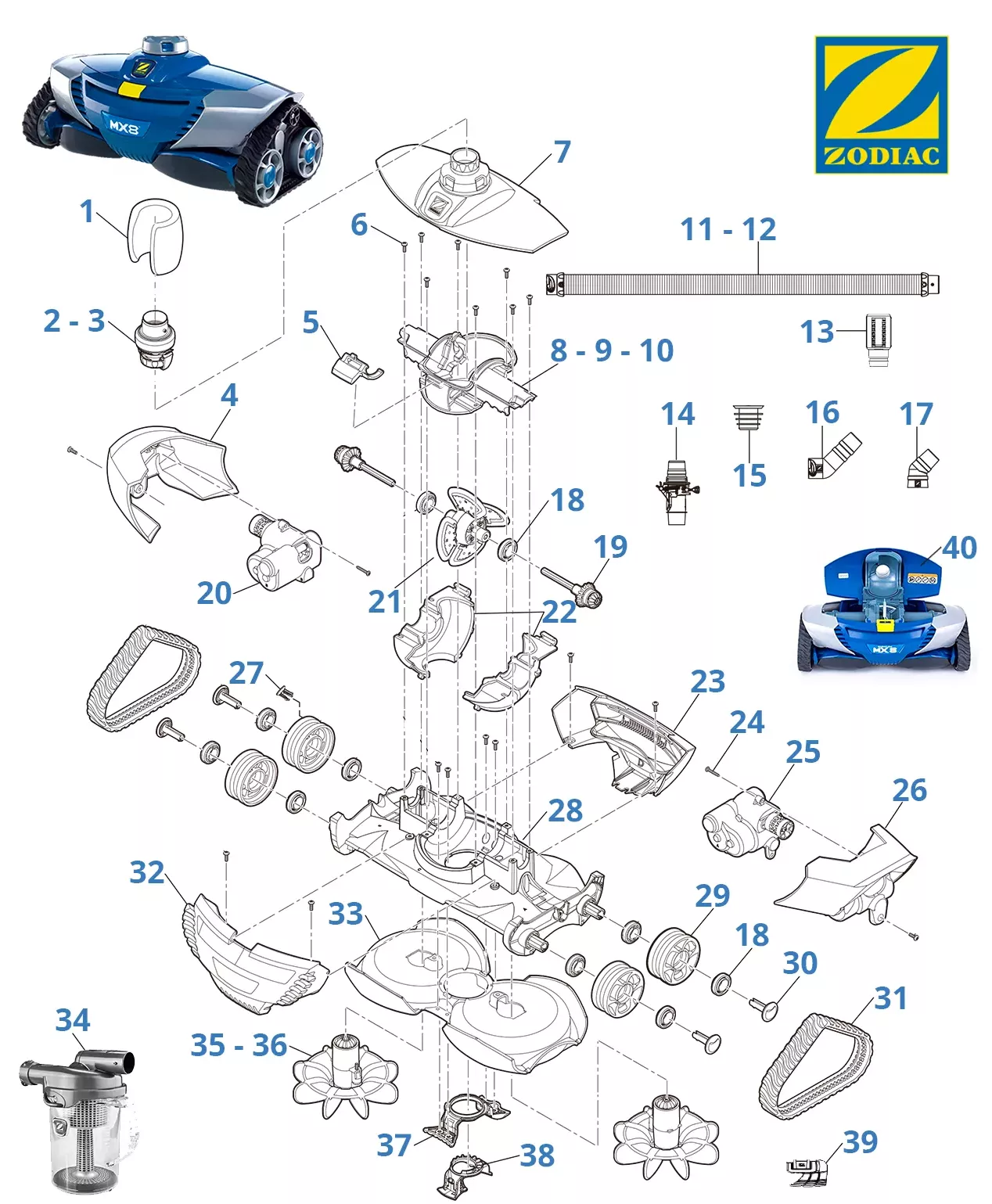

Overview of Key Components

This section provides an insight into the essential elements that contribute to the functionality of the equipment. Understanding these components is crucial for effective maintenance and operation.

- Propulsion System: This element ensures smooth movement across the surface, facilitating efficient navigation.

- Cleaning Mechanism: A critical aspect responsible for maintaining cleanliness, utilizing brushes or similar tools.

- Filtration Unit: This component works to remove debris and impurities from the water, enhancing overall performance.

- Power Supply: An essential part that provides the necessary energy for operation, affecting efficiency and runtime.

- Control Panel: The interface that allows users to manage settings and monitor performance, ensuring ease of use.

Each of these elements plays a vital role in the overall effectiveness, and familiarity with them aids in troubleshooting and optimizing functionality.

Understanding the Inner Mechanics

The intricate workings of cleaning devices involve a variety of components that contribute to their overall functionality. Each element plays a crucial role, ensuring that the equipment operates efficiently and effectively. Understanding how these pieces interact can enhance both maintenance and performance.

Components such as propulsion systems and filtration units are designed to work in harmony, facilitating seamless movement and effective debris capture. The propulsion mechanism typically consists of rotating brushes and suction elements that navigate through various surfaces, while the filtration system ensures that collected particles are properly contained and disposed of.

In addition to these primary parts, there are also control systems that regulate the device’s operations. These systems allow for user inputs to be translated into specific actions, enhancing usability and adaptability. Understanding the interplay between these different elements is essential for troubleshooting and optimizing the device’s performance.

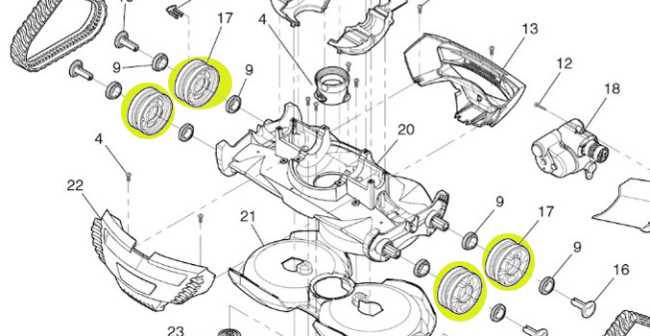

Drive System Parts Breakdown

The drive mechanism of a pool cleaner is essential for its efficient operation and maneuverability. Understanding the components involved in this system can enhance maintenance efforts and improve performance. Below is an overview of the key elements that constitute the drive system.

Key Components

- Motor Assembly: Powers the entire cleaning unit and facilitates movement.

- Gears: Transmit power from the motor to the wheels, allowing for smooth navigation.

- Wheels: Provide traction and stability on the pool surface.

- Drive Belts: Connect various parts of the system, ensuring synchronized movement.

- Friction Discs: Aid in controlling speed and traction, preventing slippage.

Maintenance Tips

- Regularly inspect the motor assembly for any signs of wear.

- Check gears for proper alignment and lubrication.

- Ensure wheels are free from debris and maintain optimal grip.

- Replace worn drive belts to avoid performance issues.

- Monitor friction discs for degradation and replace as needed.

Flow Control System Elements

The effectiveness of any aquatic cleaning device relies heavily on its flow regulation components. These elements are crucial for ensuring that water circulation is optimized, allowing for efficient debris removal and overall functionality.

Among the key components are valves and pumps, which play a significant role in managing the flow rate and pressure within the system. Valves are responsible for directing water through various pathways, while pumps generate the necessary force to move water throughout the device.

Additionally, filters are essential for capturing contaminants, contributing to the clarity and cleanliness of the water. The integration of these elements creates a harmonious balance that enhances the operational performance of the equipment.

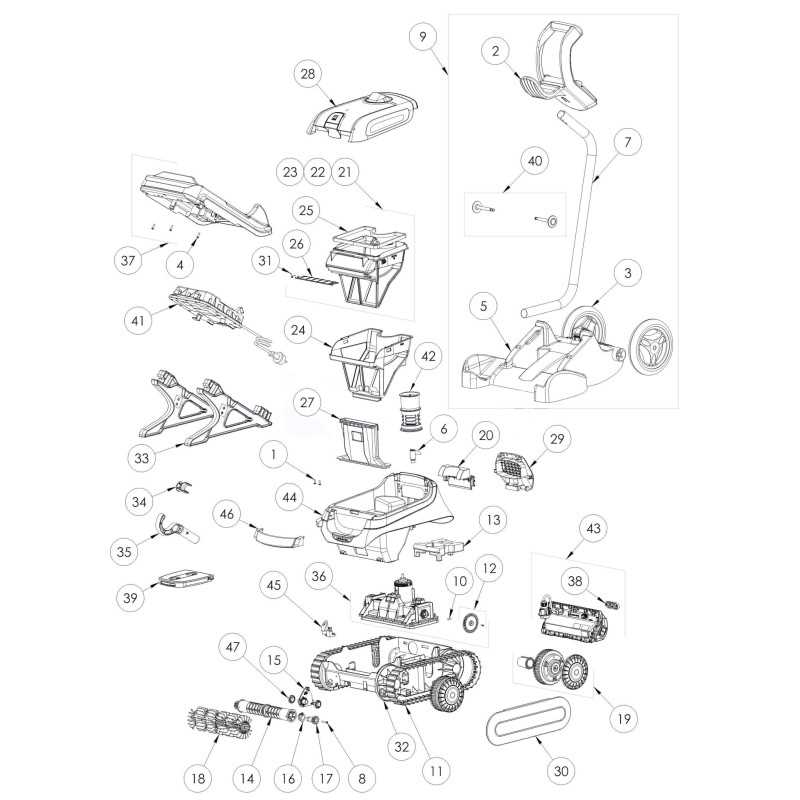

Hoses and Connections Diagram

This section focuses on the arrangement and interrelation of various tubes and fittings that play a crucial role in the efficient functioning of the system. Understanding the layout is essential for troubleshooting and maintenance, as each component contributes to the overall performance.

The connections are typically designed to facilitate the smooth flow of water, ensuring that all elements work harmoniously. Proper installation and inspection of these components can prevent leaks and enhance durability.

Identifying the different hoses and their respective positions allows for a comprehensive approach to servicing and optimizing the equipment. Regular checks on these connections can lead to improved efficiency and longevity.

Suction and Filtration Structure

The suction and filtration system is crucial for maintaining a clean and efficient operation. This mechanism is designed to draw in debris and contaminants from the water, ensuring optimal performance and longevity.

Key components of this structure include:

- Intake Valve: Responsible for controlling the flow of water into the system.

- Filter Cartridge: Captures dirt and particles to keep the water clear.

- Impeller: Enhances the suction power by generating flow.

- Strainer: Prevents larger debris from entering the system, protecting sensitive parts.

Effective maintenance of these elements is essential for optimal functioning. Regular cleaning and replacement of filters can significantly improve performance and efficiency.

Motor Unit Parts Explained

This section delves into the components of the propulsion system, which plays a crucial role in ensuring efficient performance and functionality. Understanding these elements can enhance maintenance efforts and optimize the overall operation.

Key Components

- Drive Motor: The main component responsible for providing the necessary power to propel the device.

- Impeller: A rotating part that moves water, creating the necessary flow for the unit to function effectively.

- Housing: The protective shell that encases the internal mechanisms and components, safeguarding them from damage.

- Seal: Ensures that water does not enter the motor housing, maintaining the integrity of the internal components.

- Wiring Harness: A collection of electrical connections that enable power distribution and communication between components.

Functionality Overview

Each element of the propulsion assembly plays a distinct role in maintaining optimal performance. The drive motor energizes the system, while the impeller effectively circulates water, facilitating cleaning and other tasks. Proper maintenance and awareness of these components can significantly extend the life of the equipment.

Replacement Parts and Compatibility

Ensuring that components are suitable for your device is essential for maintaining optimal performance and longevity. When considering the substitution of individual elements, it is vital to understand the specifications and requirements of the unit in question. Compatibility plays a significant role in achieving seamless operation and functionality.

Identifying Suitable Components

To find appropriate replacements, begin by consulting the manufacturer’s guidelines or technical documents. These resources often provide valuable insights into compatible elements and their respective features. Additionally, reaching out to authorized retailers or experts can offer assistance in sourcing the right items.

Benefits of Using Compatible Components

Utilizing suitable replacements can enhance the efficiency and reliability of your device. Quality components are designed to meet the same standards as the originals, ensuring proper integration and performance. Moreover, opting for compatible alternatives often results in cost savings without compromising on quality or durability.

Maintenance Tools and Accessories

Proper upkeep of your equipment ensures optimal performance and longevity. Utilizing the right tools and supplementary items is essential for effective maintenance. This section outlines the essential implements and accessories that aid in the care and preservation of your device.

Essential Maintenance Tools

- Cleaning Brushes: Designed to remove debris and dirt from hard-to-reach areas.

- Screwdrivers: A variety of sizes to assist with assembling and disassembling components.

- Wrenches: Useful for tightening and loosening various fittings.

- Pressure Gauges: To monitor and maintain proper pressure levels.

Recommended Accessories

- Protective Covers: Shields your device from environmental damage.

- Replacement Filters: Ensures clean operation and efficient performance.

- Lubricants: Reduces friction and wear on moving parts.

- Storage Bins: Keeps tools organized and readily accessible.

Guide to Seals and Gaskets

Understanding the importance of seals and gaskets is crucial for maintaining the efficiency and longevity of various mechanical systems. These components play a vital role in preventing leaks and ensuring that fluids and gases remain contained within their designated areas. Proper installation and selection of these elements are essential to avoid operational failures and enhance performance.

Types of Seals and Gaskets

There are various types of seals and gaskets, each designed to suit specific applications and materials. Common types include O-rings, flat gaskets, and spiral wound gaskets. O-rings are typically used in dynamic applications, while flat gaskets are ideal for static sealing in flanged joints. Spiral wound gaskets provide excellent resistance to high pressures and temperatures, making them suitable for demanding environments.

Choosing the Right Seal or Gasket

Selecting the appropriate seal or gasket involves considering factors such as temperature, pressure, and chemical compatibility. It is essential to consult manufacturer specifications and guidelines to ensure that the chosen component will perform effectively in the intended application. Regular inspections and timely replacements can help prevent leaks and extend the service life of machinery.

Common Wear and Tear Parts

In any mechanical system, certain components are more susceptible to wear over time. Understanding these elements is crucial for maintaining optimal performance and longevity. Regular inspection and timely replacement of these parts can help prevent costly repairs and ensure smooth operation.

The following are frequently encountered components that may require attention:

- Seals and O-rings

- Hoses and tubing

- Filters

- Brushes and scrapers

- Drive belts

Monitoring the condition of these components can greatly enhance the reliability and efficiency of the entire system. It is advisable to replace worn-out items promptly to avoid further damage and maintain overall functionality.

Troubleshooting Mechanical Failures

When dealing with mechanical issues in aquatic cleaning devices, identifying and resolving malfunctions can be critical to maintaining performance. Understanding the common symptoms and their underlying causes allows for effective solutions to restore functionality.

Common Symptoms and Their Causes

Mechanical failures may manifest in various ways, such as irregular movement, reduced suction power, or unusual noises during operation. Recognizing these signs early can help pinpoint the problem more efficiently.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Irregular movement | Obstruction in the movement system | Inspect and clear any debris |

| Reduced suction power | Clogged intake or filter | Clean or replace the filter |

| Unusual noises | Worn or damaged components | Examine parts for wear and replace as needed |

Steps for Effective Troubleshooting

To address mechanical failures, begin by conducting a thorough inspection of the device. Follow a systematic approach to eliminate potential issues, starting from the simplest solutions, such as cleaning filters and checking for obstructions. If problems persist, consider consulting the user manual for further guidance on component inspection and replacement procedures.