When it comes to maintaining marine machinery, having a comprehensive understanding of the various elements that make up the engine is essential. This section delves into the intricate arrangement of mechanical components, offering insight into their functionality and interrelationships. Whether for troubleshooting, repairs, or routine upkeep, grasping the layout is a fundamental aspect of effective maintenance.

Each element plays a crucial role in the overall performance of the machinery. From the propulsion system to the fuel management components, understanding how these elements interact can lead to improved efficiency and longevity of the equipment. This guide aims to illuminate the key features and connections between these crucial parts, empowering users with the knowledge needed for optimal operation.

By familiarizing oneself with the configuration of these essential components, one can enhance both the functionality and reliability of the vessel. Gaining this knowledge not only aids in repairs but also fosters a deeper appreciation for the engineering behind marine technology.

This section delves into the various components of small marine engines, offering a comprehensive overview of their functions and interactions. By understanding these elements, enthusiasts and users can better maintain and troubleshoot their equipment, ensuring optimal performance during use.

Key Components of Marine Engines

Marine engines consist of several critical parts that work together to propel watercraft efficiently. Familiarizing oneself with these components can aid in proper maintenance and repairs.

| Component | Function |

|---|---|

| Powerhead | Generates power through combustion. |

| Lower Unit | Transfers power to the propeller. |

| Fuel System | Supplies fuel to the engine for combustion. |

| Ignition System | Initiates combustion for engine operation. |

| Cooling System | Regulates engine temperature during operation. |

Importance of Regular Maintenance

Routine upkeep is vital for ensuring the longevity and efficiency of these marine machines. Regular checks can prevent common issues, enhancing reliability during excursions.

Troubleshooting Common Issues

Understanding the typical problems that may arise with marine engines can empower users to address issues promptly. Early detection and resolution can save time and resources in the long run.

Essential Components of Eska Outboards

The functionality and efficiency of a marine engine rely on several key elements that work in unison. Understanding these fundamental components is vital for proper maintenance and operation.

Each unit consists of various essential elements that contribute to its overall performance. Here are some of the most crucial components:

- Powerhead: This is the heart of the unit, housing the engine and vital mechanical parts.

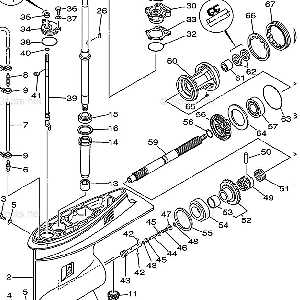

- Gearcase: It contains the gears that transfer power to the propeller, playing a critical role in propulsion.

- Propulsion Unit: Responsible for moving the vessel through the water, its design significantly impacts speed and handling.

- Fuel System: This includes the tank, lines, and pump, ensuring a steady supply of fuel to the engine.

- Cooling System: Essential for maintaining optimal operating temperatures and preventing overheating.

- Electrical Components: These include the battery, wiring, and ignition system, all of which are necessary for starting and operating the engine.

Familiarity with these components will aid in troubleshooting issues and performing effective maintenance, ultimately enhancing the longevity and reliability of your marine engine.

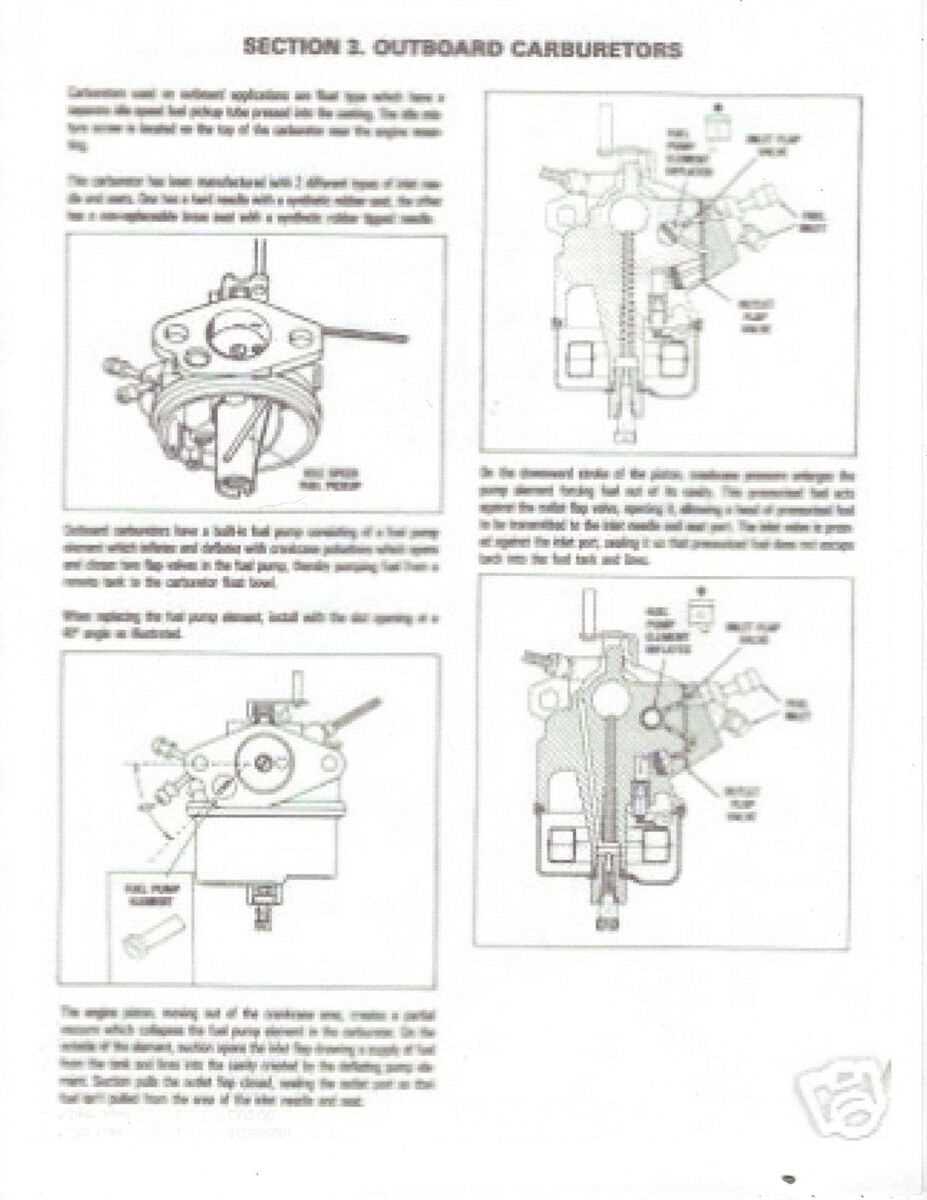

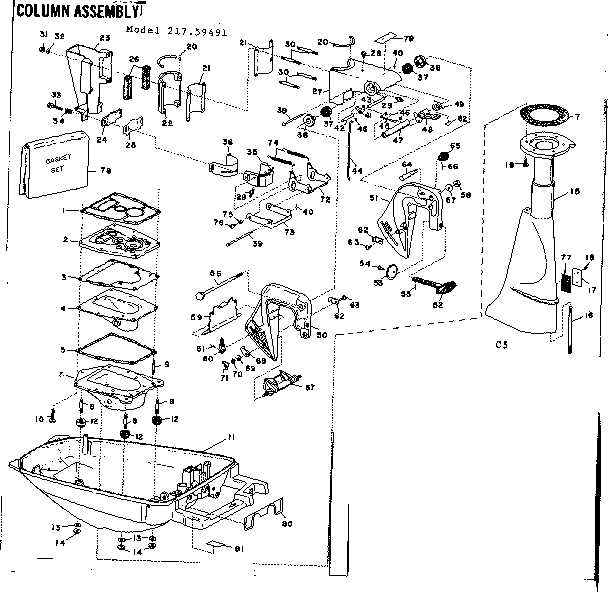

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide provides insights into interpreting the schematic, allowing for efficient identification of each element within the assembly. A clear grasp of this information can enhance your ability to troubleshoot and order the correct components.

Familiarizing with Symbols and Labels

The illustration utilizes various symbols and labels to denote specific components and their functions. Each symbol corresponds to a particular part, while labels provide additional information such as part numbers or specifications. Familiarizing yourself with these elements is crucial for effective interpretation.

Utilizing the Reference Table

Alongside the visual representation, a reference table often accompanies it. This table serves as a key to match symbols with their corresponding parts. Here’s an example of what such a table may look like:

| Symbol | Component Name | Part Number |

|---|---|---|

| Connector | 12345 | |

| ⚙️ | Gear Assembly | 67890 |

| Screw | 11121 |

Common Issues with Outboard Parts

Understanding frequent problems that can arise with marine engines is crucial for maintaining optimal performance. These issues can affect functionality, leading to inefficient operation and potential safety hazards. Identifying these common challenges can help users take proactive measures to ensure reliability.

Frequent Mechanical Failures

Mechanical components are often subjected to significant wear and tear. Common failures include issues with the ignition system, fuel delivery, and cooling mechanisms. Regular inspection and maintenance are essential to detect signs of deterioration early, thus preventing more severe damage and costly repairs.

Electrical Malfunctions

Electrical failures can lead to engine malfunctions and operational challenges. Problems often arise from corroded connections, faulty wiring, or dead batteries. Ensuring proper maintenance of electrical systems, including cleaning terminals and securing connections, can mitigate these issues and enhance overall reliability.

Maintenance Tips for Eska Motors

Proper upkeep of marine engines is essential for ensuring longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and reliability during use. Here are some key recommendations to consider for keeping your engine in excellent condition.

Routine Inspections

Conducting frequent checks on your engine is crucial. Look for signs of wear and tear, such as leaks or corrosion. Inspect the fuel system, electrical connections, and cooling system components. Identifying potential issues early can save time and money in repairs.

Fluid Management

Regularly change the oil and check the levels of coolant and fuel. Maintaining the correct fluid levels is vital for preventing overheating and ensuring smooth operation. Always use the recommended types of fluids to avoid damaging the engine.

By following these guidelines, you can ensure your marine engine operates efficiently and lasts for many years.

Identifying Replacement Parts Easily

Locating suitable components for your marine engine can be a straightforward process when you know what to look for. Understanding the specific attributes and functionalities of each element can significantly streamline your search for suitable substitutes. By familiarizing yourself with the various characteristics, you can enhance your efficiency in identifying the right items needed for maintenance or repair.

Begin by consulting reliable resources that provide detailed illustrations and descriptions of the components involved. These guides can offer valuable insights into the dimensions, shapes, and connection points of each piece, enabling you to make informed decisions. Furthermore, utilizing online databases or forums can facilitate discussions with fellow enthusiasts who may share their experiences and recommendations regarding the most effective replacements.

When examining your equipment, ensure you take note of any identifying numbers or specifications printed on the components themselves. This information can serve as a crucial reference point when searching for compatible alternatives. Remember to verify compatibility with your specific model to avoid any discrepancies that could lead to installation issues.

Safety Precautions When Servicing

Ensuring safety during maintenance tasks is crucial for both the individual performing the service and the equipment involved. Adopting proper measures can prevent accidents, injuries, and damage to components. This section highlights essential precautions to observe while working on your motor.

Before starting any maintenance work, it’s important to gather the necessary tools and materials. Ensure that your workspace is clean and well-lit, minimizing the risk of accidents. Additionally, wearing appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, is highly recommended to safeguard against potential hazards.

| Precaution | Description |

|---|---|

| Disconnect Power Source | Always disconnect the battery or remove the ignition key to prevent accidental starts during servicing. |

| Check for Leaks | Inspect all fluid levels and connections for leaks before commencing work to avoid spills and slips. |

| Secure Components | Ensure all parts are secured and stable before starting any repairs to avoid injury from falling objects. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s recommendations for servicing to ensure correct procedures are followed. |

By adhering to these guidelines, you can create a safer environment for both yourself and the machinery. Always prioritize safety to enhance the longevity and performance of your equipment.

Tools Needed for Repairs

When undertaking maintenance or fixing issues with marine equipment, having the right tools is essential for a smooth and efficient process. Proper instruments not only simplify the task but also ensure safety and precision while working on the machinery.

Essential Tools

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for removing and securing different types of screws.

- Wrenches: Both adjustable and socket wrenches are vital for loosening and tightening nuts and bolts.

- Pliers: Needle-nose and slip-joint pliers can help in gripping, twisting, and cutting wires or small components.

- Socket Set: A comprehensive socket set allows for efficient work on various fasteners.

- Torque Wrench: Ensuring that fasteners are tightened to the correct specifications is crucial for the integrity of the equipment.

Additional Instruments

- Multimeter: Useful for diagnosing electrical issues and ensuring components are functioning correctly.

- Marine Grease: Essential for lubricating moving parts and preventing corrosion.

- Safety Gear: Gloves, goggles, and other protective equipment should always be used to ensure personal safety during repairs.

Locating Eska Parts Suppliers

Finding reliable sources for marine engine components is essential for maintaining performance and ensuring longevity. Many options are available for individuals seeking to purchase essential items for their watercraft, including authorized dealers, online marketplaces, and specialty retailers. By exploring various channels, one can identify the most suitable suppliers for their needs.

Authorized Dealers and Service Centers

One of the most dependable ways to obtain components is through authorized dealers and service centers. These establishments often have direct access to official stock and can provide expert advice on compatibility and installation. Additionally, they may offer warranties on the items purchased, ensuring peace of mind for the buyer.

Online Marketplaces and Forums

The internet has revolutionized the way people acquire marine accessories. Online marketplaces host numerous vendors offering a wide selection of components, often at competitive prices. Furthermore, online forums and communities dedicated to boating enthusiasts can be invaluable resources for recommendations and reviews, helping buyers make informed decisions.

Compatibility of Eska Parts

This section focuses on the interchangeability and suitability of components for various models. Understanding how different elements work together can enhance performance and ensure reliability.

When considering the compatibility of components, it is essential to take into account several factors:

- Model Variations: Different designs may require specific elements that fit their unique configurations.

- Year of Manufacture: Components produced in varying years might have modifications that affect their interchangeability.

- Specifications: Each unit has particular specifications that dictate which elements can be used without compromising functionality.

To maximize compatibility, it is advisable to:

- Consult detailed manuals for each model to identify compatible components.

- Engage with experts or forums to gather insights on successful component matches.

- Perform visual inspections to confirm compatibility before installation.

By taking these steps, users can ensure that their selected elements will perform optimally together.

How to Assemble Outboard Components

Assembling marine engine components is a crucial task that ensures optimal performance and reliability. This process involves various steps that require precision and attention to detail. Understanding the essential elements and following a structured approach will lead to successful assembly and maintenance of your equipment.

Preparation and Tools Required

Before beginning the assembly, gather the necessary tools and components. This preparation will streamline the process and minimize errors.

- Screwdrivers (flathead and Phillips)

- Wrenches (various sizes)

- Torque wrench

- Grease and lubricant

- Cleaning cloths

Assembly Steps

- Begin by laying out all components in an organized manner to ensure easy access during assembly.

- Follow the specific sequence of assembly as outlined in the manufacturer’s guidelines.

- Apply grease to moving parts to ensure smooth operation.

- Secure each component using the appropriate fasteners, ensuring they are tightened to the specified torque settings.

- After completing the assembly, double-check all connections and fittings for any signs of looseness or misalignment.

Upgrading Your Eska Outboard Motor

Enhancing the performance and reliability of your marine engine can significantly improve your boating experience. This section focuses on key strategies to elevate your motor’s efficiency and functionality, ensuring you enjoy smoother rides and better handling on the water.

Consider the following steps to effectively upgrade your engine:

- Assess Current Performance: Start by evaluating the current state of your motor. Identify any issues that may hinder performance, such as sluggish acceleration or poor fuel efficiency.

- Research Available Upgrades: Investigate various modifications that can enhance engine output. This may include improved carburetors, high-performance fuel pumps, or advanced ignition systems.

- Consult with Experts: Seek advice from marine specialists who can provide insights into the most effective upgrades for your specific engine model. They can recommend reliable brands and components.

- Implement Upgrades Gradually: Prioritize upgrades based on budget and urgency. Implementing changes step-by-step allows for better assessment of each modification’s impact on performance.

- Regular Maintenance: Keep up with routine maintenance to ensure all upgraded components function optimally. Regular checks can prevent future issues and extend the lifespan of your engine.

By following these guidelines, you can effectively enhance your marine engine’s capabilities, ensuring a more enjoyable and efficient boating experience.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their functionalities. Understanding these aspects can enhance the maintenance and operation of your marine equipment.

What are the key elements to consider when selecting components?

When choosing elements for your machinery, it’s essential to consider compatibility, quality, and durability. Ensuring that the selected items meet the required specifications will significantly impact performance and longevity.

How can I identify the right component for my needs?

To accurately determine the appropriate item for your machinery, consult the manufacturer’s guidelines or reference materials. Additionally, seeking assistance from knowledgeable professionals can provide valuable insights into the best options available.