In the world of recreational boating, having a comprehensive grasp of the various elements that make up marine propulsion systems is crucial for maintenance and optimization. This section delves into the intricate arrangement of key components, providing insights into their functions and interconnections. A thorough understanding can enhance performance and reliability while ensuring safe and enjoyable experiences on the water.

Exploring these essential components reveals not only their individual roles but also how they collectively contribute to the overall functionality of the system. Whether you are troubleshooting an issue or simply seeking to enhance your knowledge, familiarizing yourself with these vital parts empowers you to make informed decisions. This exploration serves as a valuable resource for both enthusiasts and professionals alike.

This section provides a comprehensive understanding of the essential elements that comprise a typical propulsion system for watercraft. Each component plays a critical role in ensuring optimal performance and reliability, contributing to the overall functionality of the vessel.

Key Elements

- Power Unit: The heart of the system, responsible for generating thrust and facilitating movement.

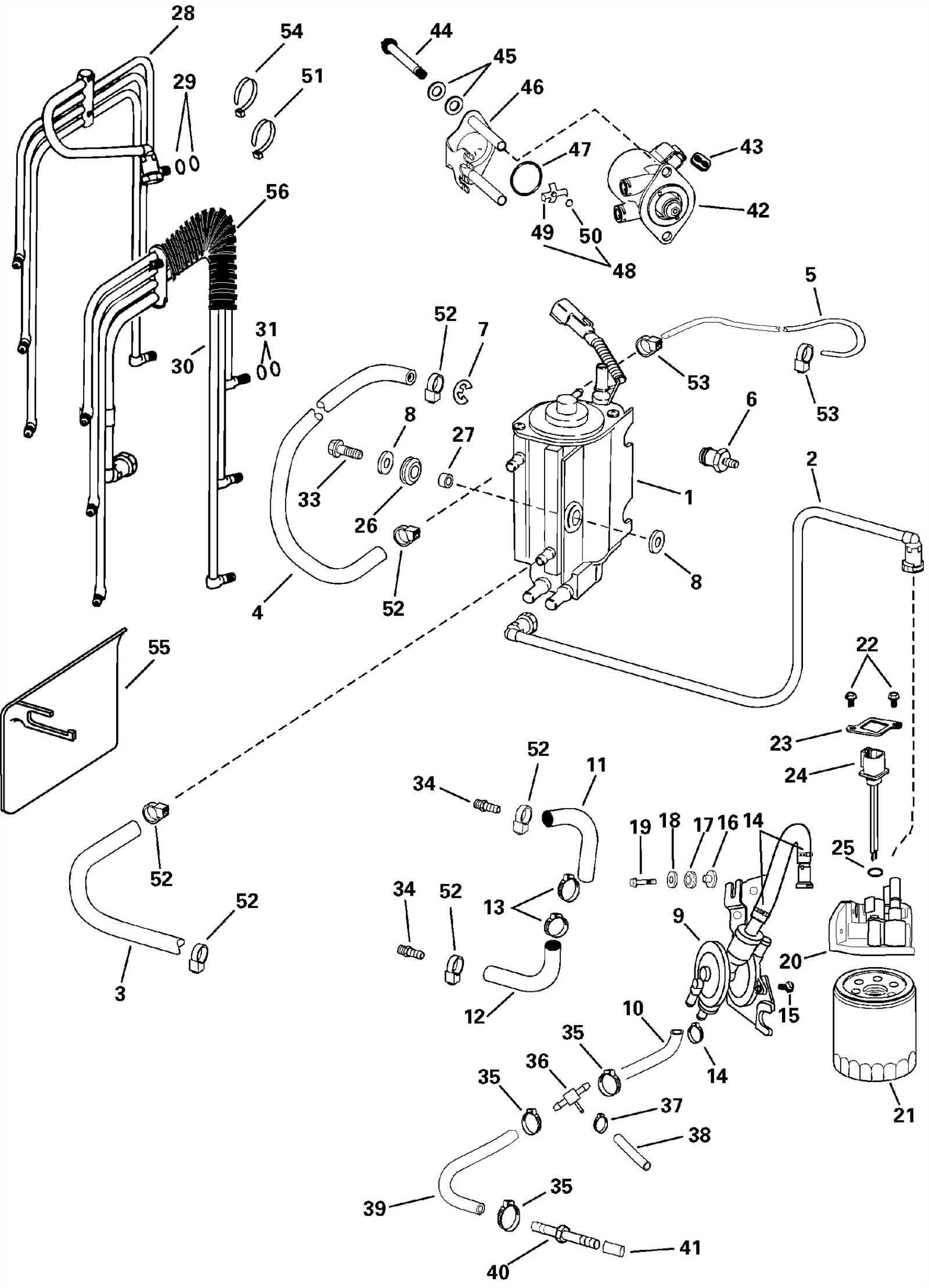

- Fuel System: Comprising tanks, pumps, and lines that deliver fuel to the engine efficiently.

- Cooling Mechanism: Ensures that the engine operates within safe temperature limits, preventing overheating.

- Transmission: A system that transmits power from the engine to the propeller, allowing for speed adjustments.

- Steering System: Provides maneuverability and control over the direction of travel.

Auxiliary Components

- Ignition System: Responsible for starting the engine and maintaining its operation.

- Electrical System: Powers various electronic devices and systems, enhancing functionality.

- Trim and Tilt Mechanism: Adjusts the angle of the propulsion unit for improved performance and handling.

- Exhaust System: Safely directs exhaust gases away from the engine and vessel.

- Propulsion Unit: Converts the engine’s power into thrust to move the craft through the water.

Common Evinrude Models Explained

This section provides insights into various popular engine types produced by a renowned manufacturer known for its reliability and performance on the water. Understanding these models can help enthusiasts choose the right fit for their boating needs, ensuring optimal performance and enjoyment.

The following are some notable examples:

- 150 HP – Known for its powerful output, this engine is ideal for larger vessels requiring speed and efficiency.

- 115 HP – A versatile option suitable for a range of recreational boats, offering a balance between power and fuel efficiency.

- 75 HP – This engine is perfect for smaller crafts, providing ample thrust while maintaining a lightweight design.

- 40 HP – Often favored for fishing boats, this model combines sufficient power with exceptional fuel economy.

- 30 HP – A compact choice, this engine is well-suited for dinghies and small watercraft, ensuring easy handling and maneuverability.

Each of these models is designed to cater to specific needs and preferences, making them popular among boating enthusiasts. When selecting an engine, it’s essential to consider factors such as vessel size, intended use, and performance expectations.

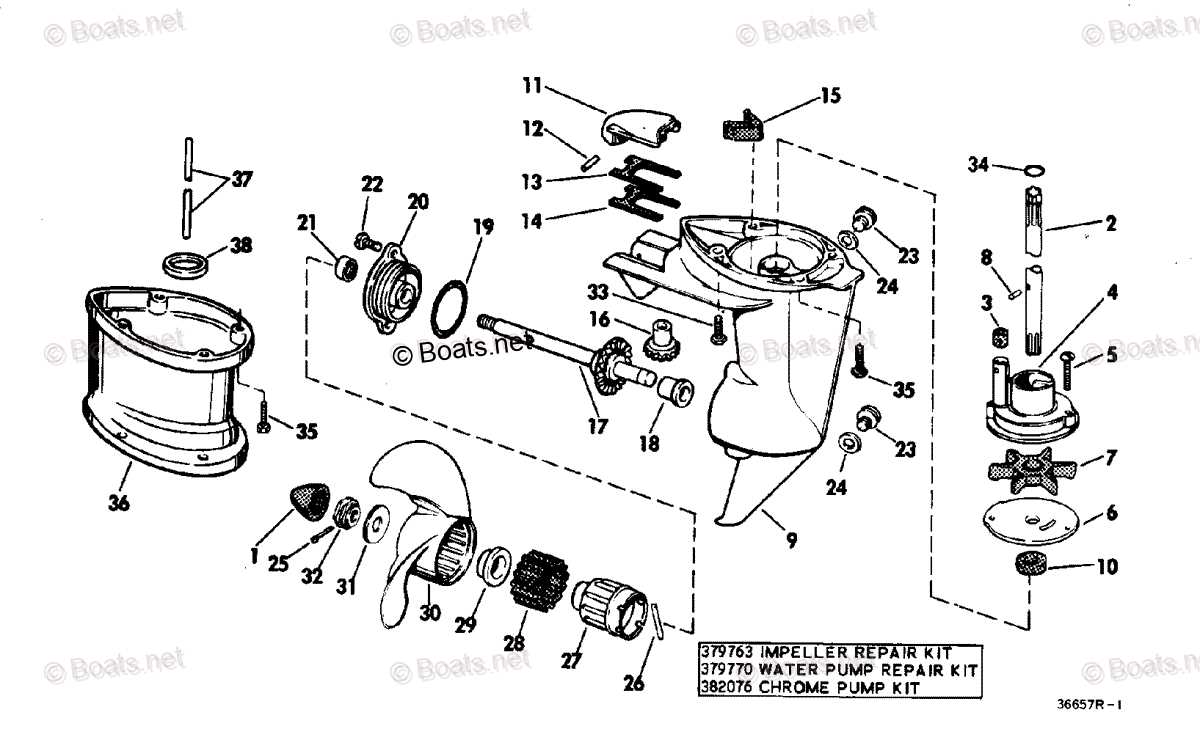

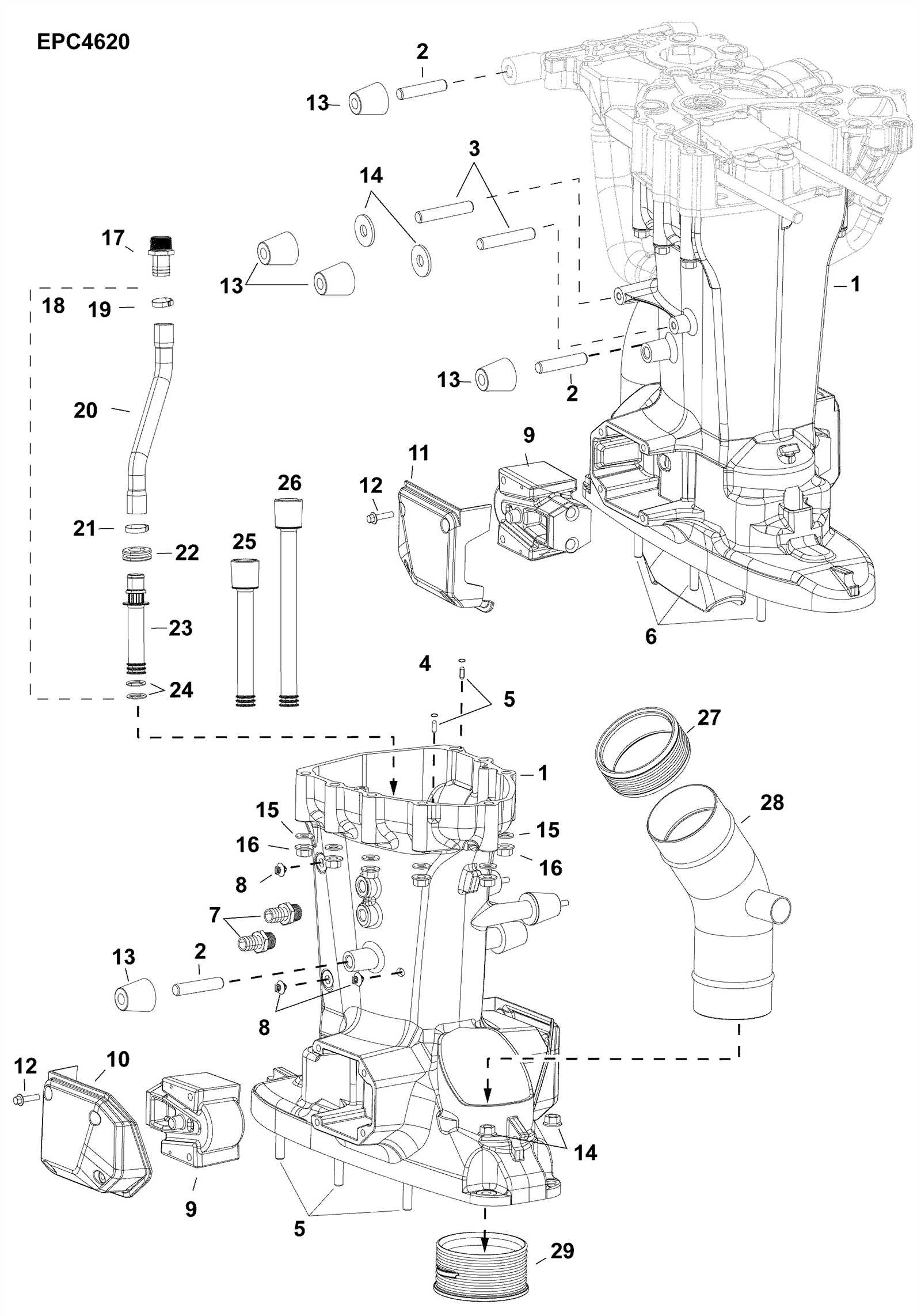

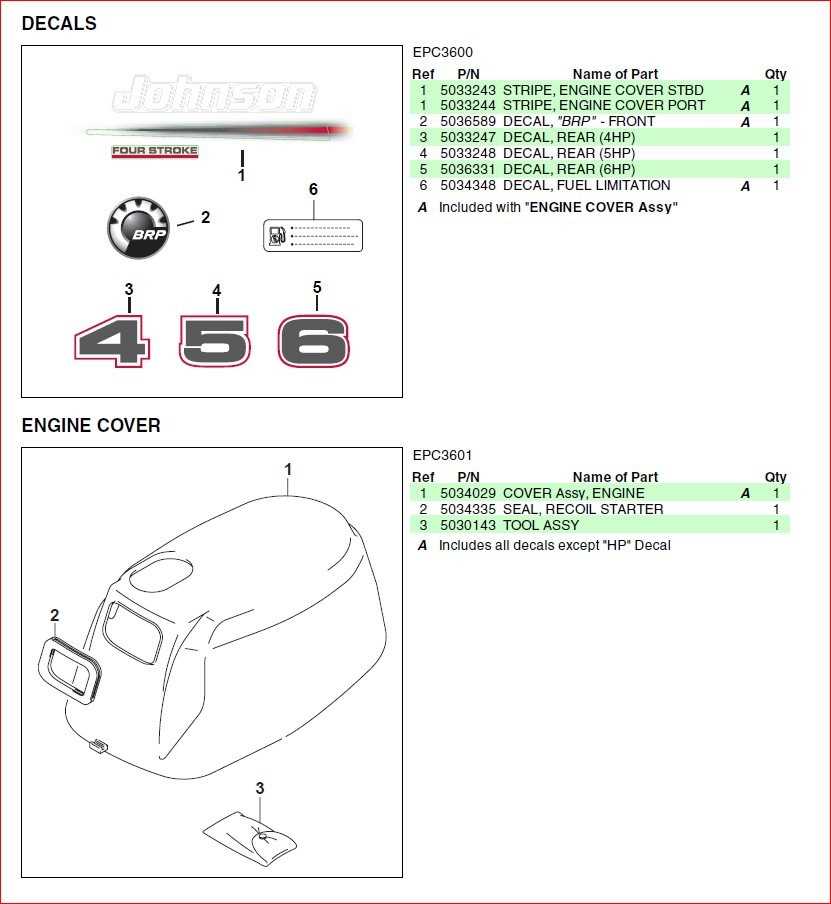

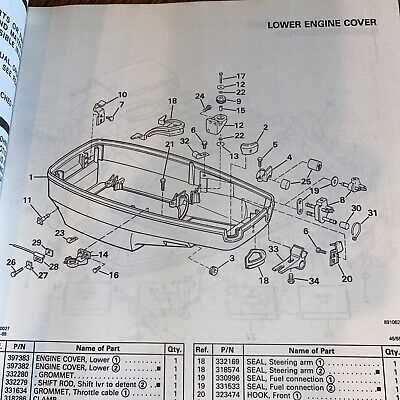

Importance of Parts Diagrams

Understanding the layout and components of mechanical systems is crucial for effective maintenance and repairs. Visual representations provide a clear overview of various elements, helping users identify and address issues efficiently. This clarity enhances the troubleshooting process, making it easier to locate problems and understand how different parts interact.

These illustrations serve as valuable references for both novices and experienced technicians. By offering a comprehensive view, they facilitate accurate reassembly and ensure that no critical components are overlooked during repairs. Furthermore, they assist in ordering the correct replacements, thereby reducing downtime and improving overall functionality.

In addition, such visuals foster a deeper understanding of the machinery, empowering users to perform preventive maintenance. Familiarity with the arrangement of elements enables proactive measures, extending the lifespan of equipment and enhancing performance. Overall, these representations are indispensable tools for anyone involved in the upkeep and operation of mechanical systems.

Key Components in Outboard Motors

Understanding the fundamental elements that make up marine propulsion systems is essential for both enthusiasts and professionals. Each segment plays a vital role in ensuring optimal performance, reliability, and longevity. Here, we delve into the critical components that contribute to the functionality of these systems.

Essential Elements

- Powerhead: This is the heart of the system, housing the engine and providing the necessary power for propulsion.

- Lower Unit: Located below the powerhead, this component contains gears and other mechanisms that transmit power to the propeller.

- Propeller: A crucial element for movement, the propeller converts rotational energy into thrust, pushing the vessel through the water.

- Fuel System: Comprising the fuel tank, lines, and pump, this system delivers fuel to the engine for combustion.

- Cooling System: This system ensures that the engine remains within optimal temperature limits, preventing overheating during operation.

Supporting Structures

- Steering Mechanism: Allows for directional control, enabling the operator to navigate effectively.

- Electrical System: This includes the battery, wiring, and ignition components essential for starting the engine and powering electronic accessories.

- Trim and Tilt System: Facilitates adjustments in the angle of the propulsion unit, improving efficiency and performance based on water conditions.

Identifying Evinrude Part Numbers

Understanding how to pinpoint specific identification numbers is essential for effective maintenance and repairs of watercraft engines. These alphanumeric codes play a crucial role in ensuring that the correct components are sourced, enabling optimal performance and longevity of the equipment.

To begin with, each identification number typically consists of a combination of letters and numbers that indicate the specific component, its model, and sometimes the manufacturing year. Recognizing these sequences can simplify the process of locating replacements or upgrades.

It’s important to note that many manufacturers provide a parts catalog, which can be invaluable when searching for these identification numbers. Such resources often include visual references and descriptions that aid in accurately identifying the necessary components.

Furthermore, consulting with authorized dealers or knowledgeable mechanics can provide insights and assistance in decoding these numbers, especially when dealing with older models. This collaborative approach can significantly enhance the chances of acquiring the right items for repairs.

In conclusion, familiarizing oneself with the identification numbers associated with watercraft engine components is vital for maintaining the functionality and reliability of the equipment. By utilizing catalogs, seeking expert advice, and paying attention to the specific codes, users can ensure they are well-equipped to address any repair or replacement needs.

Maintenance Tips for Evinrude Motors

Regular upkeep is essential for ensuring the longevity and performance of your marine engine. By adhering to proper care procedures, you can prevent common issues and enhance reliability on the water. This guide provides essential strategies to keep your vessel’s propulsion system running smoothly.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace the oil to ensure optimal engine performance and prevent wear and tear. |

| Fuel System Inspection | Before each use | Check for leaks and ensure fuel lines are in good condition to maintain efficiency. |

| Cooling System Check | Every season | Inspect the cooling system for clogs and ensure proper water flow to prevent overheating. |

| Battery Maintenance | Monthly | Examine battery connections and clean terminals to guarantee reliable starts. |

| Propeller Examination | Every outing | Inspect for damage or debris that could affect performance and efficiency. |

Implementing these maintenance practices will help ensure your vessel remains in peak condition, ready for any adventure on the water.

How to Use Parts Diagrams

Understanding how to utilize schematic representations of components is essential for effective maintenance and repair tasks. These visual aids provide a clear overview of the various elements within a system, allowing users to identify individual pieces and their relationships with one another. This can streamline troubleshooting processes and enhance the overall efficiency of repairs.

Identifying Components

To begin, carefully examine the illustration to familiarize yourself with the layout and organization of the elements. Each section typically includes labels and reference numbers that correspond to specific items. Take note of these identifiers, as they will be invaluable when sourcing replacements or seeking additional information about each element.

Understanding Relationships

In addition to identifying individual components, it is crucial to understand how they interact within the system. The schematic will often illustrate connections and configurations, highlighting how parts work together to achieve functionality. This knowledge will aid in diagnosing issues and ensuring that any replacements are installed correctly for optimal performance.

Common Troubleshooting Issues

Troubleshooting is an essential skill for ensuring optimal performance and longevity of your aquatic propulsion equipment. Users often encounter various challenges that can hinder functionality, and recognizing these issues is the first step toward resolution. This section outlines frequent complications that may arise, helping enthusiasts maintain efficiency in their aquatic activities.

Starting Difficulties: One of the most common problems faced is the inability to initiate the engine. This may stem from issues such as insufficient fuel, electrical faults, or blocked air intakes. Thoroughly inspecting the ignition system and fuel delivery components can help pinpoint the cause.

Overheating: Excessive heat can lead to significant damage if not addressed promptly. This condition often arises from a malfunctioning cooling system or blocked water passages. Regular checks of the cooling components are crucial to prevent this issue.

Unusual Noises: Strange sounds during operation can indicate mechanical problems. Rattling or grinding noises may suggest loose components or wear. Conducting a careful examination of moving parts can help identify and rectify these concerns.

Performance Loss: A noticeable decrease in speed or acceleration can be frustrating. This may result from fuel quality issues, propeller damage, or other mechanical failures. Evaluating the fuel system and checking for obstructions are effective troubleshooting measures.

Vibration Issues: Excessive vibrations can be a sign of an unbalanced propeller or misalignment in the drive system. Addressing these vibrations promptly can enhance performance and reduce wear on critical components.

Where to Find Replacement Parts

When it comes to maintaining marine equipment, sourcing quality components is essential for optimal performance and longevity. There are several avenues available for individuals seeking to procure new or refurbished items for their vessels. Understanding where to look can save time and ensure reliability.

Online Retailers

The internet offers a wealth of options for acquiring necessary items. Numerous websites specialize in marine supplies, providing an extensive selection and the convenience of home delivery. Many platforms also feature user reviews, helping buyers make informed choices.

Local Dealers and Service Centers

Visiting nearby dealerships and authorized service centers can provide direct access to genuine components. These establishments often maintain a stock of essential items and can offer expert advice on the best options for your specific requirements.

| Source | Description | Advantages |

|---|---|---|

| Online Marketplaces | Websites like eBay and Amazon that feature various sellers. | Wide selection, user reviews, competitive pricing. |

| Marine Supply Stores | Physical stores specializing in marine-related products. | Expert assistance, ability to inspect items before purchase. |

| Manufacturer Websites | Official sites of brands offering direct sales. | Guaranteed authenticity, detailed product information. |

DIY Repairs for Evinrude Motors

When it comes to maintaining your watercraft engine, tackling repairs on your own can be both rewarding and cost-effective. Understanding the basic components and their functions empowers you to address common issues without the need for professional assistance. With a little patience and the right approach, many repairs can be successfully managed at home.

Assessing the Problem: Before diving into any repairs, it’s crucial to diagnose the issue accurately. Start by observing the symptoms and checking for visible damage. Listen for unusual noises and pay attention to performance inconsistencies, which can provide valuable clues about the root cause of the problem.

Gathering Tools and Supplies: Having the right tools at your disposal is essential for any DIY project. Basic tools such as wrenches, screwdrivers, and pliers are often sufficient for minor repairs. Additionally, make sure to have replacement components on hand, as well as maintenance supplies like oil and cleaning agents.

Performing Basic Maintenance: Regular upkeep can prevent many common issues from arising. Tasks such as changing the oil, inspecting the fuel system, and cleaning the cooling components are straightforward and can enhance the longevity of your engine. Following a scheduled maintenance routine will keep your equipment in optimal condition.

Documenting Your Work: Keeping a record of repairs and maintenance performed is beneficial. Note the dates and details of each task to create a comprehensive history. This documentation can assist you in future troubleshooting and ensure that you remain organized.

Resources for Further Learning

Expanding your knowledge about marine propulsion systems can enhance your understanding and maintenance skills. Numerous resources are available for enthusiasts and professionals alike, offering valuable insights into various components and their functions.

Online Platforms

- Forums and Community Groups: Engaging with fellow enthusiasts can provide practical advice and tips.

- Video Tutorials: Platforms like YouTube host countless instructional videos demonstrating maintenance and repair procedures.

- Manufacturer Websites: Many brands provide manuals, specifications, and product information that can aid in your learning.

Books and Publications

- Technical Manuals: Comprehensive guides often include troubleshooting tips and detailed illustrations.

- Magazines: Industry publications feature articles on the latest innovations and best practices in marine technology.

- Online Courses: Various educational platforms offer structured courses covering different aspects of marine engineering.

Comparing Evinrude to Other Brands

This section explores the differences and similarities between a well-known manufacturer and its competitors in the field of marine propulsion systems. Understanding these distinctions can help consumers make informed decisions when selecting a suitable option for their boating needs.

When evaluating various brands, several factors come into play:

- Performance: Different brands offer varying levels of efficiency, speed, and handling, which can significantly impact the overall boating experience.

- Durability: The longevity and resilience of a brand’s products are crucial for users who frequently engage in water activities. Comparing the materials and construction techniques can reveal which options stand up to wear and tear.

- Maintenance: Ease of maintenance varies among manufacturers. Some systems are designed for straightforward upkeep, while others may require specialized knowledge or tools.

- Customer Support: Reliable after-sales service and availability of replacement components are essential considerations. A brand with strong support can enhance the overall ownership experience.

- Cost: Price ranges differ widely across brands, impacting consumer choices. It’s vital to weigh the initial investment against long-term value and performance.

In conclusion, a thorough comparison of the prominent players in the market can guide potential buyers toward a decision that aligns with their expectations and requirements.