When it comes to marine vehicles, comprehending the intricate arrangements of their mechanical elements is essential for maintenance and repair. This section aims to provide a comprehensive overview of the various components that contribute to the functionality of these vessels. Familiarity with the layout and interrelation of these elements can enhance your ability to troubleshoot and optimize performance.

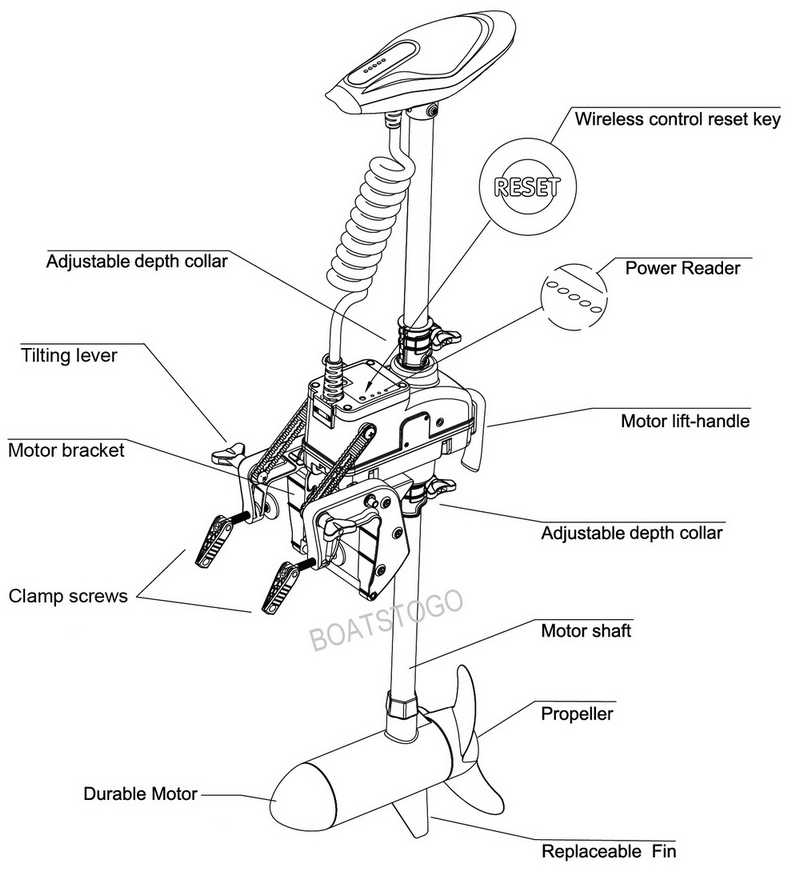

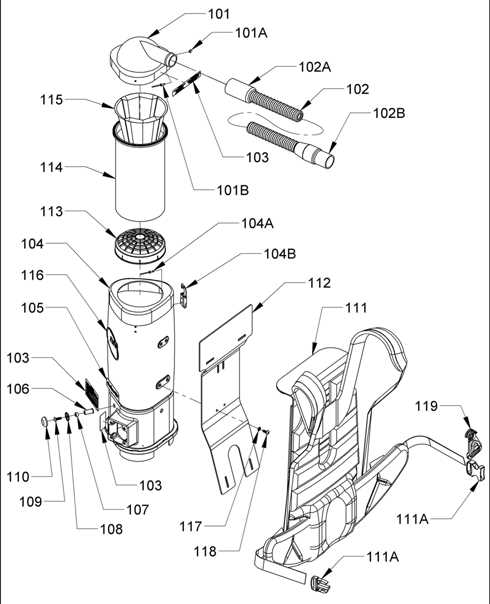

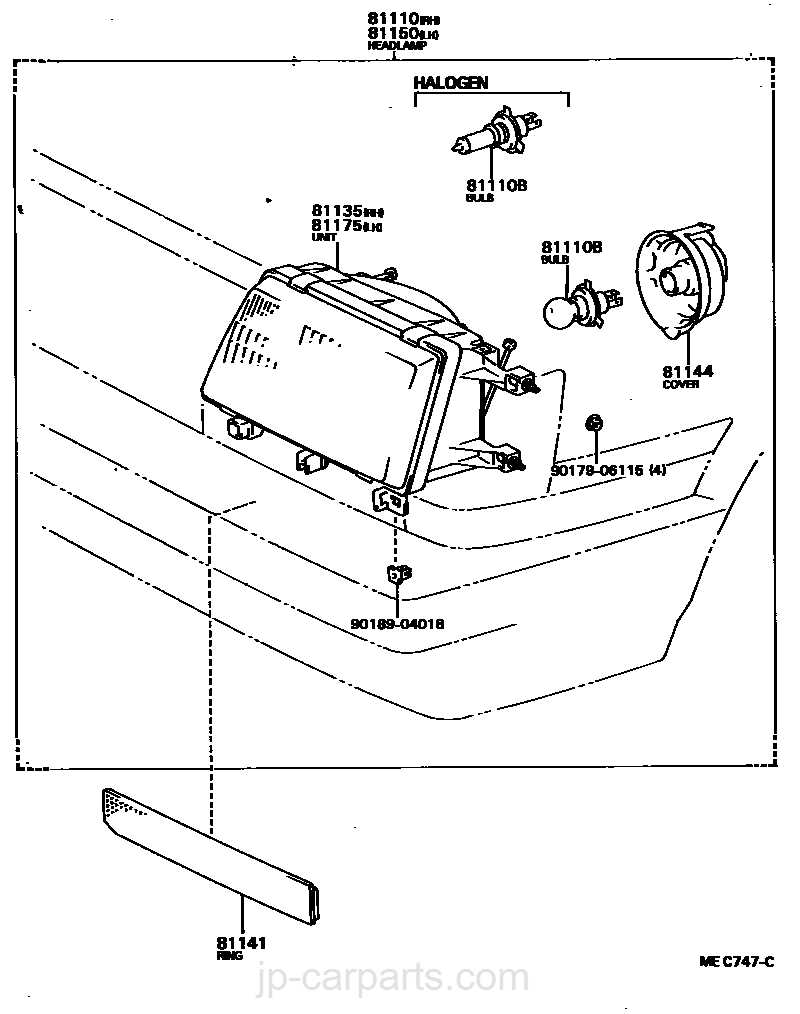

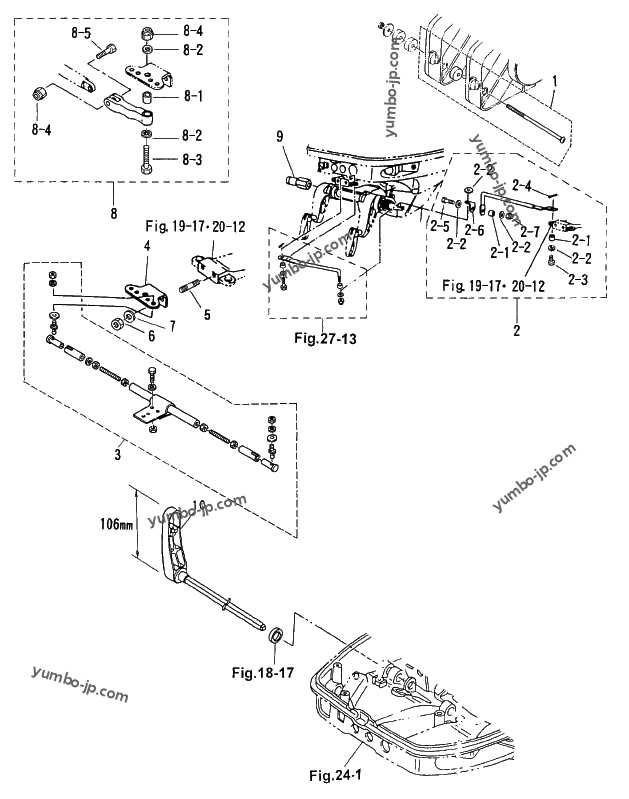

Through visual representations, one can gain valuable insights into how each section operates within the entire system. These illustrations serve as guides, enabling users to identify specific features and their roles in the overall machinery. By examining these depictions, individuals can develop a clearer understanding of how to maintain and repair their equipment effectively.

In this exploration, emphasis will be placed on the significance of each component while highlighting their collective contribution to the vessel’s efficiency. Whether for educational purposes or practical application, mastering this knowledge is a vital step towards achieving a deeper connection with marine engineering.

Understanding Force Outboard Motors

Exploring the intricacies of marine propulsion systems reveals a fascinating world of engineering and design. These devices are essential for enhancing the performance of watercraft, enabling smooth navigation across various water bodies. Gaining insight into their functionality aids in better appreciation and effective maintenance.

Key Components and Functionality

Each system consists of several critical elements that work in harmony to produce thrust and maneuverability. Understanding these components is vital for users who seek to optimize their experience on the water. The interaction between the various parts determines the overall efficiency and effectiveness of the mechanism.

Importance of Maintenance

Regular upkeep plays a crucial role in ensuring the longevity and reliability of these devices. Familiarity with the internal structure allows operators to identify potential issues early, thereby avoiding costly repairs. By prioritizing maintenance, enthusiasts can enhance their aquatic adventures significantly.

Essential Components of Outboard Engines

The functionality of marine propulsion systems relies on several critical elements, each contributing to the overall performance and efficiency of the vessel. Understanding these fundamental components is vital for effective maintenance and troubleshooting.

Among the most important parts is the powerhead, which houses the engine and is responsible for converting fuel into mechanical energy. This section is pivotal, as it directly influences the propulsion capabilities of the craft.

Another key component is the gear case, which houses the transmission system. This unit plays a crucial role in transferring the engine’s power to the propeller, enabling smooth navigation through water.

The fuel system is also essential, as it ensures the engine receives the correct mixture of air and fuel for combustion. Proper functioning of this system is necessary for optimal performance and fuel efficiency.

Lastly, the cooling system prevents the engine from overheating, maintaining an ideal operating temperature. This component is vital for longevity and reliability, ensuring that the engine operates efficiently over extended periods.

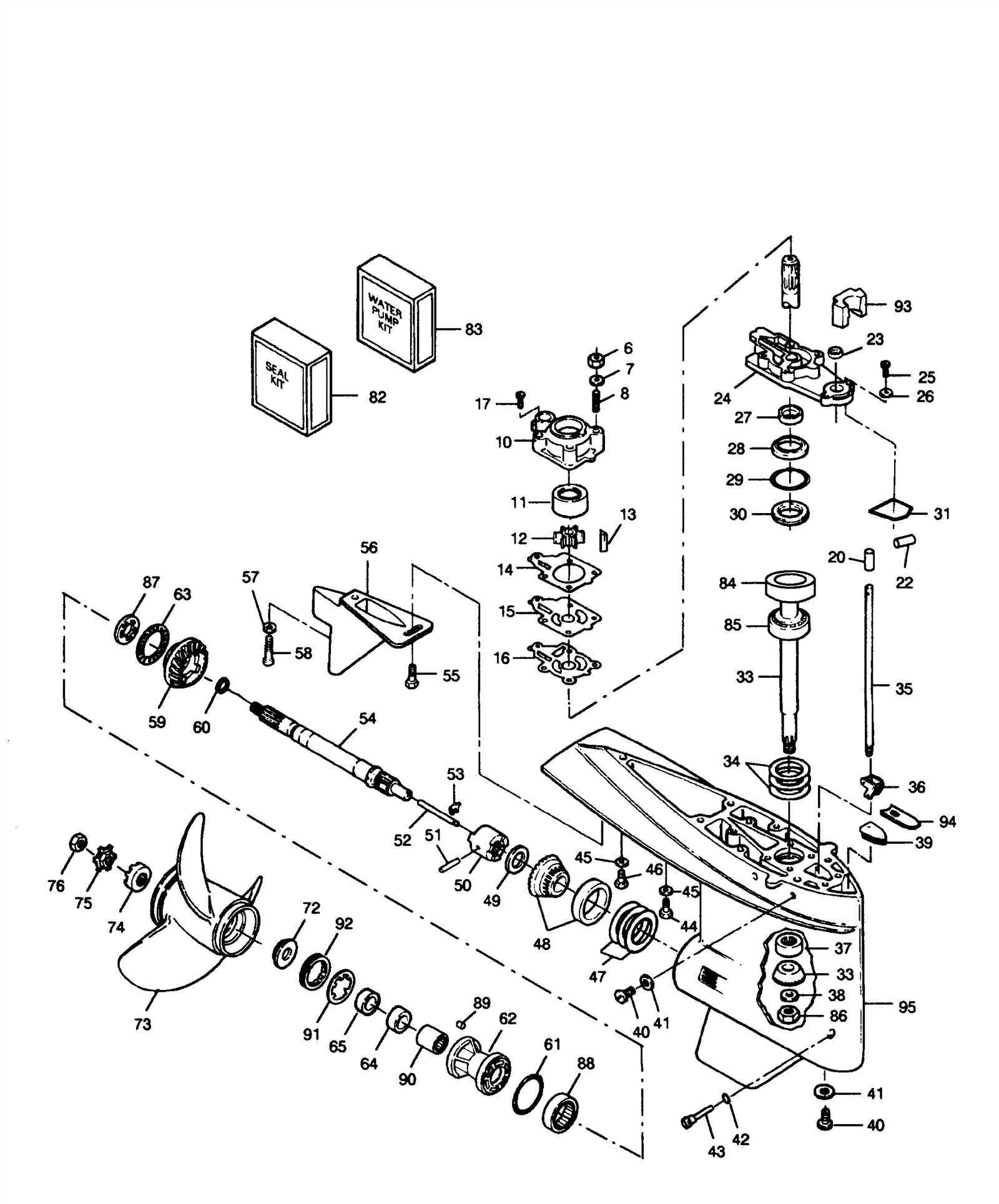

Diagram Overview for Force Motors

This section provides a comprehensive visual representation of essential components associated with a specific marine propulsion system. The illustrations aim to facilitate understanding of the various elements involved in the functionality of the system.

Key Elements Included

- Identification of main components

- Connections and interactions between elements

- Visual cues for assembly and maintenance

Importance of Understanding Components

Grasping the layout and function of each element is crucial for effective operation and troubleshooting. Knowledge of these components allows users to optimize performance and ensure longevity of the system.

Functionality of Outboard Motor Parts

This section explores the essential roles played by various components of a marine propulsion system. Understanding how these elements interact is crucial for maintaining optimal performance and efficiency.

Each component serves a specific purpose that contributes to the overall functionality of the system:

- Power Source: This is the engine that generates the necessary force for propulsion.

- Transmission: This mechanism transfers power from the engine to the propeller, enabling movement.

- Cooling System: This system prevents overheating by circulating water around the engine.

- Fuel Delivery System: This assembly ensures that the engine receives the right amount of fuel for combustion.

- Propulsion Unit: This is the part that converts engine power into thrust, propelling the vessel forward.

Each of these components must work in harmony to ensure reliable operation on the water. Regular maintenance and understanding of their functions can significantly enhance the longevity and performance of the equipment.

Maintenance Tips for Force Motors

Proper upkeep of your watercraft’s propulsion system is essential for ensuring longevity and optimal performance. Regular attention to various components will help prevent issues and enhance the overall functionality of your vessel.

Regular Inspections

Conduct routine checks on all key elements to identify wear or potential failures early. Focus on the following areas:

- Examine the fuel system for leaks or blockages

- Inspect electrical connections and wiring for corrosion

- Check the cooling system for obstructions

- Assess the integrity of the propeller and associated components

Seasonal Maintenance Tasks

Adhering to a seasonal maintenance schedule can significantly improve reliability. Consider the following tasks:

- Change the oil and replace filters regularly

- Flush the cooling system to eliminate debris

- Clean and lubricate moving parts to reduce friction

- Store your equipment in a dry, safe environment during off-seasons

Identifying Common Issues in Motors

Understanding frequent complications in propulsion systems is essential for maintaining performance and reliability. By recognizing symptoms early, one can prevent more significant malfunctions and extend the lifespan of the equipment.

Common problems that may arise include:

- Overheating

- Unusual noises during operation

- Difficulty starting the engine

- Erratic performance or power loss

- Fuel leaks or poor fuel efficiency

Each of these issues can stem from various underlying causes, such as:

- Poor maintenance practices

- Wear and tear of components

- Improper fuel usage

- Electrical system malfunctions

By staying vigilant and addressing these common signs promptly, operators can ensure smooth and efficient operation of their equipment.

How to Replace Outboard Parts

Replacing components of your marine propulsion system can seem daunting, but with the right approach and guidance, it can be a straightforward process. Understanding the key elements and techniques involved in the replacement procedure can enhance the performance and longevity of your vessel.

Gathering Necessary Tools and Materials

Before starting the replacement, ensure you have all required tools and components on hand. Basic tools such as wrenches, screwdrivers, and pliers are essential. Additionally, having a repair manual specific to your device will provide valuable information about specifications and procedures.

Step-by-Step Replacement Process

Begin by carefully removing the existing component, taking note of how it is installed. This can help when you are ready to install the new piece. Follow the manufacturer’s guidelines for installing the new item, ensuring it fits securely and operates correctly. After installation, conduct a thorough inspection to confirm everything is functioning as intended. Remember to keep safety in mind throughout the process.

Regular maintenance is crucial for optimal performance, so consider checking related components while you are at it. Taking the time to replace essential elements can significantly improve your marine experience.

Performance Enhancements for Outboard Engines

Boosting the capabilities of marine propulsion systems involves various strategies that can significantly improve speed, efficiency, and overall responsiveness. By implementing specific modifications and upgrades, enthusiasts can experience enhanced performance while navigating waterways.

- Weight Reduction: Minimizing unnecessary weight can lead to improved acceleration and handling. Consider removing excess equipment or using lightweight materials for certain components.

- Propeller Optimization: Choosing the right propeller type and size can maximize thrust and minimize resistance, enhancing the vessel’s speed and maneuverability.

- Fuel System Improvements: Upgrading fuel injectors or filters can ensure optimal fuel delivery, resulting in better combustion and increased power output.

- Exhaust Modifications: Adjusting the exhaust system can enhance airflow, improving engine efficiency and performance.

- Regular Maintenance: Keeping the engine well-maintained, including timely oil changes and inspections, ensures optimal performance over time.

By focusing on these enhancements, boaters can achieve significant improvements in their propulsion systems, allowing for a more enjoyable and efficient experience on the water.

Safety Features in Force Motors

Ensuring the protection of users and enhancing operational reliability are paramount in modern vehicle design. Innovative systems are integrated to minimize risks and improve the overall experience for operators and passengers alike.

One essential aspect is the implementation of robust shielding mechanisms that prevent accidental contact with moving elements. These safeguards are crucial for maintaining a secure environment, especially in high-activity scenarios.

Additionally, emergency shutdown systems are a vital feature. They allow for immediate cessation of operation in unforeseen situations, providing an extra layer of security. Such systems are designed to activate swiftly, ensuring quick response times in critical moments.

Moreover, stability control technologies play a significant role in preventing capsizing or loss of balance. These features analyze environmental conditions and adjust performance accordingly, significantly enhancing safety during navigation.

Lastly, comprehensive user training programs are essential. Proper education on the operation and safety protocols fosters a culture of awareness, empowering users to make informed decisions while using the equipment.

Choosing the Right Parts for Repairs

Selecting appropriate components for maintenance is crucial for ensuring optimal performance and longevity of your vessel. Making informed choices can prevent further complications and enhance the overall efficiency of your equipment.

When considering replacements, it is essential to assess compatibility with your existing system. Look for components that not only fit perfectly but also meet the quality standards necessary for reliable operation. Utilizing reputable suppliers can significantly impact the success of your repair efforts.

Additionally, understanding the specific requirements of your equipment will help you make better decisions. Researching and comparing different options can provide insights into which components offer the best value and reliability. Prioritize durability and performance to ensure your repairs stand the test of time.

Resources for Force Outboard Owners

For enthusiasts and caretakers of marine propulsion systems, access to quality resources is essential for maintaining performance and longevity. Comprehensive information can empower users to ensure their vessels operate smoothly and efficiently. This section highlights various platforms and materials that can support owners in their maintenance journey.

Online Communities and Forums

Engaging with fellow enthusiasts through online platforms can provide invaluable insights. Numerous forums and social media groups offer a space for sharing experiences, troubleshooting issues, and exchanging tips. Participating in these communities fosters a sense of camaraderie and enhances knowledge through collective expertise.

Manufacturer’s Manuals and Guides

Official documentation from manufacturers often serves as a primary source of information. These manuals typically include detailed instructions, maintenance schedules, and troubleshooting advice tailored to specific models. Accessing these resources ensures that owners are well-informed about best practices and can perform necessary upkeep with confidence.