When it comes to maintaining or enhancing your aquatic vehicle, grasping the intricate arrangement of its components is essential. A well-structured overview of these elements can facilitate smoother repairs and upgrades, ultimately extending the lifespan of your vessel. This knowledge empowers owners to troubleshoot issues effectively and optimize performance.

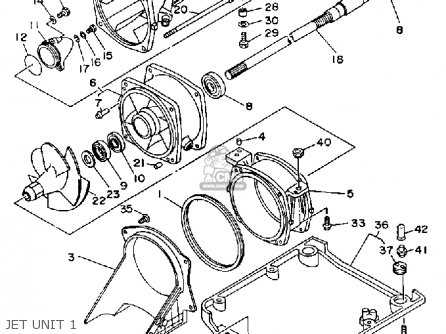

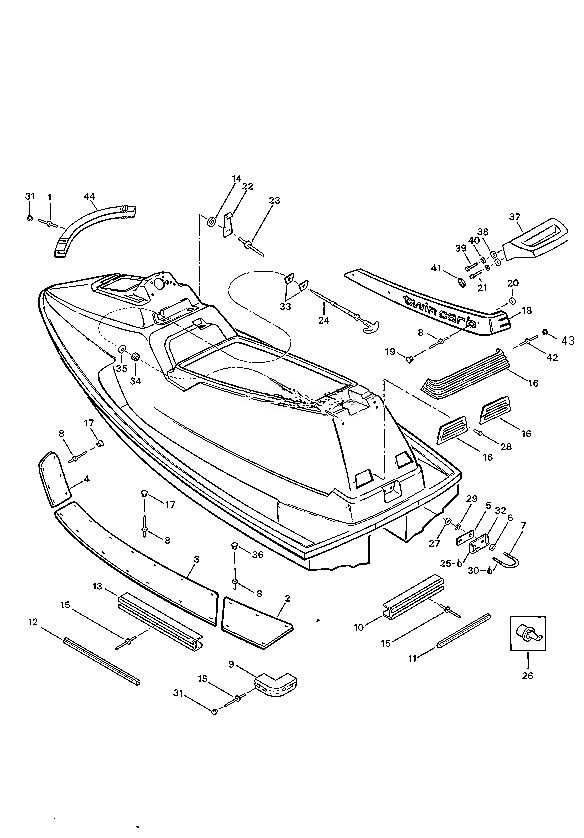

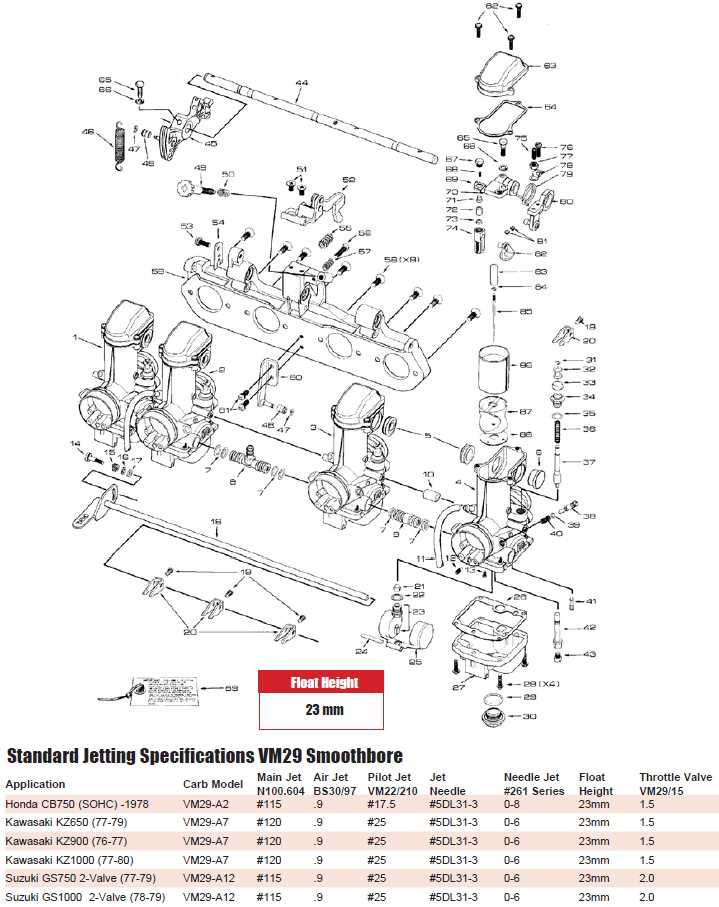

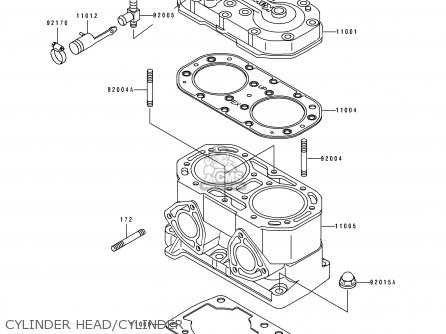

Detailed illustrations of the various sections reveal how each component interacts with the others. By examining these visuals, enthusiasts can gain insight into the assembly of their machines, identifying critical parts that contribute to overall functionality. Such familiarity not only enhances repair efficiency but also fosters a deeper appreciation for the engineering involved in aquatic design.

Moreover, having a clear representation of the intricate mechanisms involved aids in the understanding of maintenance protocols. This clarity can help users avoid common pitfalls, ensuring that their equipment operates at peak performance while providing an enjoyable experience on the water. Investing time in learning about these layouts is invaluable for any dedicated enthusiast.

Essential Parts of Polaris Watercraft

Watercraft are made up of various crucial components that ensure smooth operation and safety during use. Each element plays a significant role in maintaining balance, propulsion, and overall control, making the ride more enjoyable and secure. Understanding these components can help with proper maintenance and enhance the overall experience on the water.

- Hull: The structure that keeps the watercraft afloat and provides stability, especially when navigating waves.

- Engine: The core power source, responsible for driving the vessel and allowing for swift movement across the water.

- Impeller: A rotating component that draws in water and forces it out, generating thrust for forward movement.

- Steering System: Composed of handlebars and cables, this system directs the craft, enabling precise maneuvering.

- Fuel Tank: A reservoir

Maintenance Tips for Watercraft Components

Regular upkeep of key components is essential to ensure the smooth operation of your watercraft. Proper care not only extends the life of individual elements but also enhances overall performance on the water. By focusing on timely inspections and maintenance routines, you can prevent potential issues and keep everything in optimal condition.

Check and Clean Mechanical Elements

One of the most important aspects of maintenance is to regularly inspect and clean the mechanical parts. Look for any signs of wear or damage, such as rust or cracks, and address them immediately. Make sure to remove any debris that may affect the performance, especially in moving parts like the engine or drive system.

Lubrication and Tight

How to Read Parts Diagrams

Understanding how to interpret component schematics is essential for anyone looking to identify or replace elements of a complex machine. These schematics offer a clear overview of how various pieces fit together, providing a visual reference that simplifies the repair or maintenance process.

Key Symbols and Notations

Each schematic uses specific symbols and notations to represent different elements. Learning what these symbols mean is the first step in deciphering the diagram. Typically, you will see labels for fasteners, connectors, and various parts, each with unique markers.

- Labels: Numbers or codes that correspond to specific components in a list.

- Lines: These indicate connections or relationships between elements, showing how they fit or work together.

- Arrows: Often used to

Common Issues with Jet Propulsion Watercraft Components

Watercraft components can experience a variety of issues over time, affecting performance and reliability. Understanding the common problems with these mechanical parts can help identify solutions and maintain smooth operation.

- Engine Overheating: One of the most frequent issues is related to engine cooling. Blockages in the cooling system or a malfunctioning pump can cause the engine to overheat.

- Fuel Delivery Problems: Clogged fuel filters or malfunctioning injectors can restrict fuel flow, leading to poor engine performance or even stalling.

- Electrical Malfunctions: Issues with the battery, ignition, or wiring can disrupt the electrical system, preventing the watercraft from starting or running consistently.

- Impeller Damage: The impeller,

Upgrading Your Watercraft Components

Enhancing your water vehicle’s performance can significantly improve both its reliability and speed on the water. When considering an upgrade, it’s essential to focus on areas that directly affect handling, stability, and power. Modern enhancements can elevate the overall experience, ensuring smoother rides and greater control in various water conditions.

Performance Enhancements

By upgrading the propulsion and control systems, you can achieve more efficient acceleration and responsiveness. Swapping out older components for high-quality replacements can reduce drag and optimize energy use, leading to a better balance of speed and fuel efficiency.

Durability Improvements

Investing in stronger, more durable materials for your watercraft can s

Finding OEM Parts for Polaris Models

Locating genuine components for watercraft models is essential to maintain optimal performance and ensure longevity. The availability of original equipment manufacturer (OEM) components provides a reliable solution for replacing worn-out or damaged parts, as they are specifically designed to fit the unique specifications of each model.

To simplify the search process, you can follow multiple avenues to identify the exact components you need. Below is a comparison of some of the most common approaches to sourcing these components.

Method Advantages Challenges Official Distributors Guaranteed authenticity, full range of options Higher prices, limited availability in some regions Online Marketplaces Convenience, wide selection Risk of counterfeit products, variable quality Tools Needed for Jet Ski Repairs

When working on watercraft repairs, having the right set of tools is crucial for ensuring a smooth and efficient process. Whether performing routine maintenance or addressing more complex issues, proper equipment allows you to complete tasks safely and effectively.

Basic Hand Tools such as screwdrivers, wrenches, and pliers are essential for handling most small adjustments. These tools help with removing covers, tightening bolts, and accessing hard-to-reach components.

For more specialized tasks, socket sets and torque wrenches are necessary. These allow for precise tightening of bolts to manufacturer specifications, ensuring that everything is securely fastened.

Additionally, lubricants and cleaning supplies are often needed to prevent corrosion and ensure the longevity of the

Safety Guidelines for Jet Ski Maintenance

Regular upkeep of personal watercraft is crucial to ensure both performance and safety. To avoid potential hazards during maintenance, it’s important to follow established precautions and understand the proper procedures. Careful attention to safety reduces the risk of accidents and prolongs the vessel’s operational life.

Use Protective Gear: Always wear appropriate protective equipment, including gloves and eye protection, to prevent injury when handling mechanical components or fluids.

Disconnect Power Sources: Before working on any system, make sure to disconnect the battery and other electrical sources to eliminate the risk of electric shock or accidental engine activation.

Work in a Well-Ventilated Area: Ensure you are in a space with good ventilation, especially when dealing with fuel, oils, or chemicals. Fumes can be hazardous if inhaled in confined

Exploring Aftermarket Parts Options

When it comes to maintaining and improving your watercraft, aftermarket components offer a versatile solution for enhancing both performance and durability. These alternatives provide an array of choices for different budgets and preferences, allowing owners to customize their vehicle to fit their specific needs. Whether you’re aiming to upgrade functionality or replace worn-out elements, aftermarket options can deliver great value and reliability.

Benefits of Aftermarket Components

One of the primary advantages of aftermarket solutions is the ability to choose from a broader range of products that may not be available through original manufacturers. This opens up the opportunity to find items that are more affordable, durable, or even better suited to your specific riding conditions. Additionally, many aftermarket manufacturers focus on optimizing the performance of specific components, making them ideal for those looking to improve their overall experience.

Comparison of

Connecting with Watercraft Enthusiast Communities

Engaging with communities of watercraft enthusiasts offers a fantastic opportunity to exchange knowledge, share experiences, and learn about the latest trends. These groups often consist of individuals passionate about aquatic adventures and eager to help others by providing advice and tips. Participating in these discussions can help broaden your understanding and offer solutions to various challenges.

Many enthusiasts join forums or social media groups where they can ask questions, seek recommendations, or simply share their latest experiences on the water. Whether you’re new to the activity or have been involved for years, these communities foster a welcoming and collaborative environment for everyone. By staying connected, you can enhance your knowledge and enjoy the support of fellow watercraft lovers.