Every machine is a complex assembly of parts that work in harmony to achieve optimal performance. Understanding how these elements fit together is crucial for maintenance and repair. This section aims to provide clarity on the intricate relationships between various components, ensuring that you have a solid grasp of their functions and interactions.

To effectively manage and service your machinery, it’s essential to have a visual representation of its structure. By examining an illustrative layout, users can quickly identify each segment, simplifying troubleshooting and repairs. This not only enhances efficiency but also prolongs the lifespan of the equipment.

Whether you are a seasoned technician or a novice user, familiarizing yourself with the layout and specifics of the machine can greatly improve your overall experience. Recognizing the role of each part allows for informed decisions during servicing and can prevent common pitfalls associated with improper handling.

Poulan Pro 300EX Overview

This section provides an insight into a specific model of outdoor power equipment, highlighting its features, functionality, and user benefits. This machine is designed for efficiency and ease of use, making it an excellent choice for both novice and experienced users.

Key attributes include:

- Robust engine performance

- User-friendly design

- Durability for various landscaping tasks

Notable features that enhance usability encompass:

- Lightweight construction for easy maneuverability

- Ergonomic handle for comfort during extended use

- Versatile attachments for multiple applications

Overall, this equipment stands out in the market due to its reliable performance and adaptability to various outdoor tasks, making it a valuable addition to any toolkit.

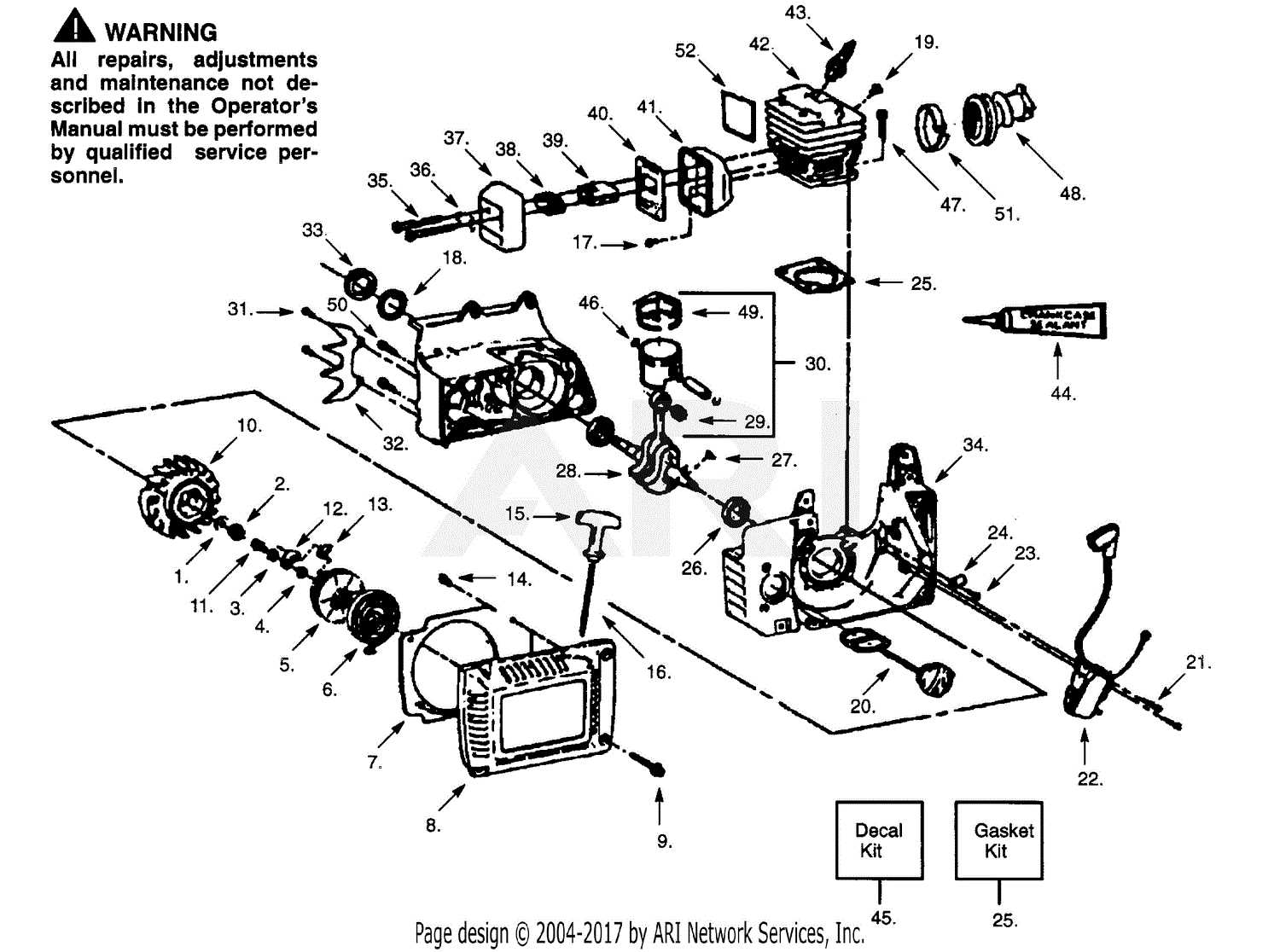

Understanding Parts Diagrams

Exploring the intricacies of equipment can be challenging, but visual representations simplify this process. These illustrations serve as a crucial tool for identifying components and understanding their relationships within a system.

Such representations offer several benefits:

- Enhanced clarity in locating specific elements.

- Facilitated troubleshooting and maintenance.

- Improved communication when discussing repairs or replacements.

To make the most of these visuals, consider the following tips:

- Familiarize yourself with the symbols and labels used in the illustration.

- Refer to the guide alongside the visual for detailed descriptions.

- Use the image as a reference point during disassembly or reassembly.

By understanding how to interpret these illustrations, you can streamline repairs and ensure the longevity of your equipment.

Essential Components of the 300EX

Understanding the fundamental elements of any outdoor power equipment is crucial for maintenance and performance. Each component plays a specific role in ensuring the machine operates efficiently and reliably. Below is a breakdown of the key parts that make up this model.

- Engine: The heart of the machine, responsible for powering all operations.

- Fuel System: This includes the fuel tank, lines, and filter, which ensure the engine receives the necessary fuel.

- Ignition System: Comprising the spark plug and ignition coil, this system ignites the fuel-air mixture for combustion.

- Cutting Mechanism: A critical feature that encompasses the blades and drive system, enabling effective cutting.

- Transmission: This component transfers power from the engine to the wheels or cutting mechanism, affecting speed and performance.

- Chassis: The frame that houses all parts, providing structural integrity and support.

- Control System: Includes levers and switches that allow the operator to control various functions easily.

- Cooling System: Essential for maintaining optimal engine temperature during operation.

Each of these components must be maintained properly to ensure the longevity and efficiency of the equipment. Regular checks and replacements can prevent common issues and enhance performance.

Benefits of Using Original Parts

Utilizing genuine components in machinery and equipment offers numerous advantages that enhance performance and longevity. These authentic items are specifically designed to fit perfectly, ensuring seamless operation and reducing the risk of malfunction.

- Quality Assurance: Original items are manufactured under strict quality control standards, guaranteeing reliability and durability.

- Optimal Performance: Genuine components are engineered to work harmoniously with your equipment, maximizing efficiency.

- Warranty Protection: Using authentic parts often preserves warranty coverage, protecting your investment in the long run.

- Safety: Genuine components are tested for safety standards, reducing the risk of accidents or failures during operation.

- Resale Value: Equipment maintained with original components tends to retain higher resale value, as potential buyers often prefer authenticity.

In summary, opting for authentic components ensures that your machinery operates at its best, provides peace of mind, and supports a longer service life.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a clear view of how different elements fit together, allowing users to identify specific items and their functions within a machine. Mastering this skill can significantly enhance your ability to troubleshoot and replace necessary components.

Identifying Components

Begin by familiarizing yourself with the various symbols and labels used in the visual representation. Each part is typically numbered or coded, corresponding to a list that describes its specifications. Pay attention to the arrangement; components are often displayed in a way that reflects their assembly order or relationship to one another.

Using the Key and Legend

Most illustrations come with a key or legend that explains the meanings of different symbols. This section is essential for accurate interpretation, as it clarifies any shorthand used in the representation. Always refer back to this key as you work through the image to ensure you’re on the right track in understanding the layout and functionalities of the various pieces.

Common Repairs for Poulan Pro 300EX

Regular maintenance and timely repairs are essential for ensuring the longevity and efficiency of outdoor power equipment. Over time, wear and tear can lead to common issues that may affect performance. Understanding these typical repairs can help owners keep their machines in optimal condition and avoid costly replacements.

One frequent concern is the engine not starting. This problem may arise due to a drained battery, clogged fuel lines, or issues with the ignition system. Checking the fuel levels, replacing the spark plug, and ensuring proper battery charge are crucial steps in troubleshooting this issue.

Another common repair involves the cutting mechanism. Dull blades can result in inefficient performance, so regular sharpening or replacement is necessary. Additionally, inspecting the drive belt for wear and proper tension can prevent further complications and ensure smooth operation.

Fuel system maintenance is also vital. Over time, fuel filters can become clogged, leading to decreased engine performance. Regularly replacing these filters and ensuring clean fuel lines will help maintain optimal flow and efficiency.

Lastly, ensuring that all nuts and bolts are tightened and free from corrosion can prevent mechanical failures. Regular inspections can help identify loose components before they lead to more serious issues, ultimately saving time and resources in repairs.

Where to Find Replacement Parts

When it comes to maintaining and repairing your outdoor equipment, sourcing the right components is essential for optimal performance. Fortunately, there are various avenues to explore for acquiring the necessary items to keep your machinery running smoothly.

Online Retailers: The internet is a treasure trove for finding specific components. Numerous websites specialize in outdoor tools and machinery, offering a wide range of options. Make sure to check customer reviews and ratings to ensure reliability.

Local Hardware Stores: Visiting nearby hardware or garden supply stores can be beneficial. Many of these establishments carry essential components or can order them for you. Speaking directly with staff can provide insights into compatible items.

Manufacturer’s Websites: The official sites of the equipment’s manufacturer often have dedicated sections for replacement components. Here, you can find detailed information and specifications to ensure you select the correct items.

Forums and Community Groups: Engaging with fellow enthusiasts through online forums or social media groups can be a valuable resource. Members often share their experiences and can recommend where to find specific components.

Salvage Yards: For those looking to save money, visiting salvage yards or recycling centers can yield unexpected finds. You might discover used components that are still in good condition at a fraction of the cost.

By exploring these options, you can efficiently locate the components you need to keep your outdoor equipment in peak condition.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires consistent care and attention. By following a few essential practices, you can significantly extend the life of your machinery and enhance its performance.

Regular Cleaning

Keeping your equipment clean is vital for its optimal functioning. Dirt and debris can accumulate and cause various issues. Here are some cleaning tips:

- Wipe down surfaces after each use to remove dust and grass clippings.

- Inspect and clear the air filter regularly to prevent clogging.

- Check the blades for any buildup of sap or residue, and clean them as necessary.

Routine Inspections

Conducting regular inspections helps identify potential problems before they escalate. Consider these steps:

- Examine all moving parts for signs of wear and tear.

- Ensure all connections and fasteners are secure to avoid accidents.

- Monitor fluid levels and replace or refill as needed, especially oil and fuel.

By incorporating these maintenance tips into your routine, you can promote the longevity and reliability of your outdoor equipment, ensuring it remains a dependable tool for years to come.

Comparing Aftermarket vs. OEM Parts

When maintaining or repairing equipment, choosing between original components and alternative options can be a pivotal decision. Each type offers distinct advantages and potential drawbacks that can affect performance, longevity, and cost. Understanding these differences is essential for making an informed choice.

Original components are typically manufactured by the same company that produced the equipment. They are designed to meet specific standards, ensuring compatibility and reliability. Conversely, alternative options are produced by third-party manufacturers and can vary widely in quality and price.

Advantages of OEM Components

- Guaranteed compatibility with the equipment.

- Often backed by warranties or guarantees from the manufacturer.

- Maintains resale value due to use of authentic components.

Advantages of Aftermarket Options

- Typically more affordable than original components.

- May offer enhanced features or improved performance.

- Wider variety of choices to suit specific needs.

Considerations

- Evaluate the quality of the alternative components, as they can vary greatly.

- Check warranty terms for both options to understand potential long-term costs.

- Consider how each choice aligns with your maintenance goals and budget.

Ultimately, the decision between original and alternative components will depend on individual needs, priorities, and budget constraints. Balancing quality and cost is key to achieving the best results in equipment upkeep.

Tools Needed for Repairs

To ensure efficient and effective maintenance of your equipment, having the right tools is essential. Each repair task may require a specific set of implements to tackle various components successfully. Below is a list of essential tools that can facilitate smooth repair processes.

- Wrenches: A set of both standard and adjustable wrenches will help you loosen or tighten bolts and nuts.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for handling different types of screws.

- Socket Set: This tool is useful for quickly removing or installing nuts and bolts in hard-to-reach areas.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Pliers: Useful for gripping, twisting, or cutting wires and small components.

- Utility Knife: Ideal for cutting through materials such as tape, plastic, or insulation.

- Cleaning Supplies: Brushes, rags, and cleaners are vital for maintaining a clean work area and ensuring proper equipment function.

Having these tools readily available not only simplifies the repair process but also contributes to the longevity of your equipment. Always remember to follow safety protocols while using any tools.

Assembly Instructions for Components

This section provides essential guidelines for the correct assembly of various components. Following these instructions will ensure that each part fits together seamlessly, enhancing the overall performance and durability of the equipment. Proper assembly is crucial for achieving optimal functionality and longevity.

Preparation Steps

Before beginning the assembly process, gather all necessary tools and components. Ensure that your workspace is clean and organized to prevent the loss of small parts. Review the instruction manual to familiarize yourself with each component’s role and placement. It is advisable to lay out the parts in the order of assembly to streamline the process.

Assembly Process

Start by connecting the main components as indicated in the instructions. Use the appropriate fasteners to secure each piece, ensuring they are tightened adequately without overtightening, which can cause damage. As you progress, check alignment frequently to avoid complications later. Once all parts are assembled, perform a final inspection to confirm that everything is in place and secure.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users who have interacted with the product. Understanding customer perspectives is crucial for potential buyers to make informed decisions. Feedback can range from performance insights to durability assessments, providing a comprehensive view of what to expect.

User Experiences

Many users appreciate the reliability and efficiency of the equipment. One reviewer noted, “The performance exceeded my expectations, especially during extended use.” Another mentioned the ease of maintenance, stating, “I found it straightforward to service, which is a huge plus.”

While the feedback is largely positive, some customers have pointed out areas needing enhancement. For instance, one user remarked, “The initial setup was a bit confusing, but I managed to get through it.” Additionally, a few reviews indicated a desire for more detailed instructions to aid first-time users. Overall, the collective insights are valuable for refining future models.

Troubleshooting Common Issues

When operating outdoor equipment, users may encounter various challenges that can hinder performance. Identifying and resolving these issues is essential for maintaining efficiency and prolonging the lifespan of the machinery. This section outlines some typical problems and their potential solutions to help users navigate troubleshooting effectively.

Engine Won’t Start

If the engine fails to ignite, several factors could be at play. First, check the fuel level and ensure that the fuel is fresh and uncontaminated. A clogged fuel filter can also impede flow, so inspect it for any blockages. Additionally, verify that the spark plug is clean and functioning properly; replacing it may resolve ignition issues.

Excessive Vibrations

Unusual vibrations can indicate a problem with the machinery’s balance or components. Begin by examining the blades or cutting elements for damage or misalignment. Ensure that all fasteners are securely tightened and that there are no foreign objects lodged in moving parts. If the issue persists, consider consulting a professional for a thorough inspection.