When it comes to maintaining outdoor equipment, understanding how each element connects and functions together is key. Every machine is built with precision, and knowing how to interpret its structure can save both time and effort. In this guide, we will explore the fundamental components of a specific outdoor tool, delving into its intricate makeup.

Detailed insight into the inner workings of these machines allows users to quickly identify and address any issues that may arise. Whether you’re a seasoned technician or a beginner, understanding the complete assembly and structure is crucial for keeping your equipment in optimal condition.

From the smallest screws to the core mechanical systems, each part plays an essential role in ensuring reliable operation. This guide will help you familiarize yourself with the key elements of this equipment, enabling efficient repairs and routine maintenance.

Overview of Key Components for Snow Thrower Maintenance

Understanding the essential elements of your snow thrower is crucial for proper maintenance and efficient operation. Each component plays a specific role in ensuring the machine functions smoothly during heavy winter use. Regular inspection and timely replacement of worn-out elements will help extend the lifespan of your equipment.

Drive System: The drive system is responsible for the movement and propulsion of the machine. It includes gears, pulleys, and belts that work together to allow the snow thrower to maneuver easily over snowy surfaces.

Engine Mechanism: The power source of the machine, the engine mechanism, converts fuel into the energy required to operate the various moving parts. A well-maintained motor ensures reliable performance and quick start-up

Main Components of Poulan Pro PR241

The machine consists of several essential elements that ensure its efficient operation in various weather conditions. Understanding the structure and functionality of each part is crucial for maintaining and troubleshooting. Below is an overview of the core elements responsible for smooth and reliable performance.

Engine and Power System

The driving force behind the machine comes from its motor and related components. This system provides the necessary energy to handle tough tasks in challenging conditions.

- Engine block

- Fuel system

- Starter mechanism

Transmission and Drive

Critical for movement and control, the drive system allows for easy maneuvering and adaptability on different surfaces.

- Gear system

- Drive belt

- Axles and wheels

-

Engine Structure and Key Features

The engine plays a pivotal role in the overall performance and functionality of snow blowers. Understanding its structural components and essential characteristics helps users maintain and optimize their machines for maximum efficiency.

Core Components

The heart of the engine is built around several core elements that work together to generate power. These components are designed to ensure reliable operation in harsh winter conditions. Key parts include the crankshaft, piston, cylinder, and carburetor, each playing a crucial role in the smooth running of the engine.

Performance Enhancements

Several features are integrated to enhance the engine’s performance, such as fuel efficiency, easy ignition, and improved airflow. These improvements not only contribute to the longevity of the engine but also provide smooth operation, reducing the need for frequent maintenance

Auger System Breakdown

The auger mechanism is a crucial component responsible for moving material efficiently. It ensures smooth operation by rotating and directing the flow of snow or other substances through the machine. Understanding the arrangement and individual elements of this system helps maintain optimal performance and troubleshoot any potential issues.

Component Function Auger Blades Cut through and gather material for Drive System Components

The drive mechanism is a crucial part of ensuring smooth and efficient operation, responsible for transferring power to the machine’s moving parts. A well-maintained system guarantees reliability during use, making it essential to understand each component involved.

Transmission Assembly

The transmission directs the engine’s power to the wheels, enabling the movement. It works by adjusting the speed and torque as required, ensuring the machine moves at the correct pace depending on the task.

Belts and Pulleys

Belts and pulleys serve as the connection between various moving parts. The

Chassis and Frame Elements

The structural components of any outdoor power equipment play a vital role in ensuring durability and stability during operation. These essential elements provide the necessary support for various mechanisms, contributing to the overall efficiency and performance of the machine. Understanding the configuration and function of these parts is crucial for maintenance and repair.

Chassis refers to the framework that houses the engine and other vital systems. It acts as the backbone of the equipment, bearing the weight and absorbing stress during use. The design of the chassis can influence the maneuverability and balance of the machine, affecting user experience.

Similarly, the frame serves as the foundational structure, linking various components such as the wheels and the engine. A well-constructed frame ensures stability while operating on uneven terrain, making it easier to navigate obstacles. Moreover, frame elements often include features for easy assembly and disassembly, which aids in servicing and part replacement.

When considering the integrity of these components, it is essential to regularly inspect for signs of wear or damage. Maintaining these structures not only extends the lifespan of the equipment but also enhances safety for the user. Proper attention to the chassis and frame can significantly impact performance and reliability.

Fuel System Layout

The configuration of the fuel system is crucial for the optimal performance of any outdoor power equipment. It encompasses various components that work together to ensure a smooth supply of fuel to the engine. Understanding this arrangement aids in effective troubleshooting and maintenance, ensuring the machine operates efficiently.

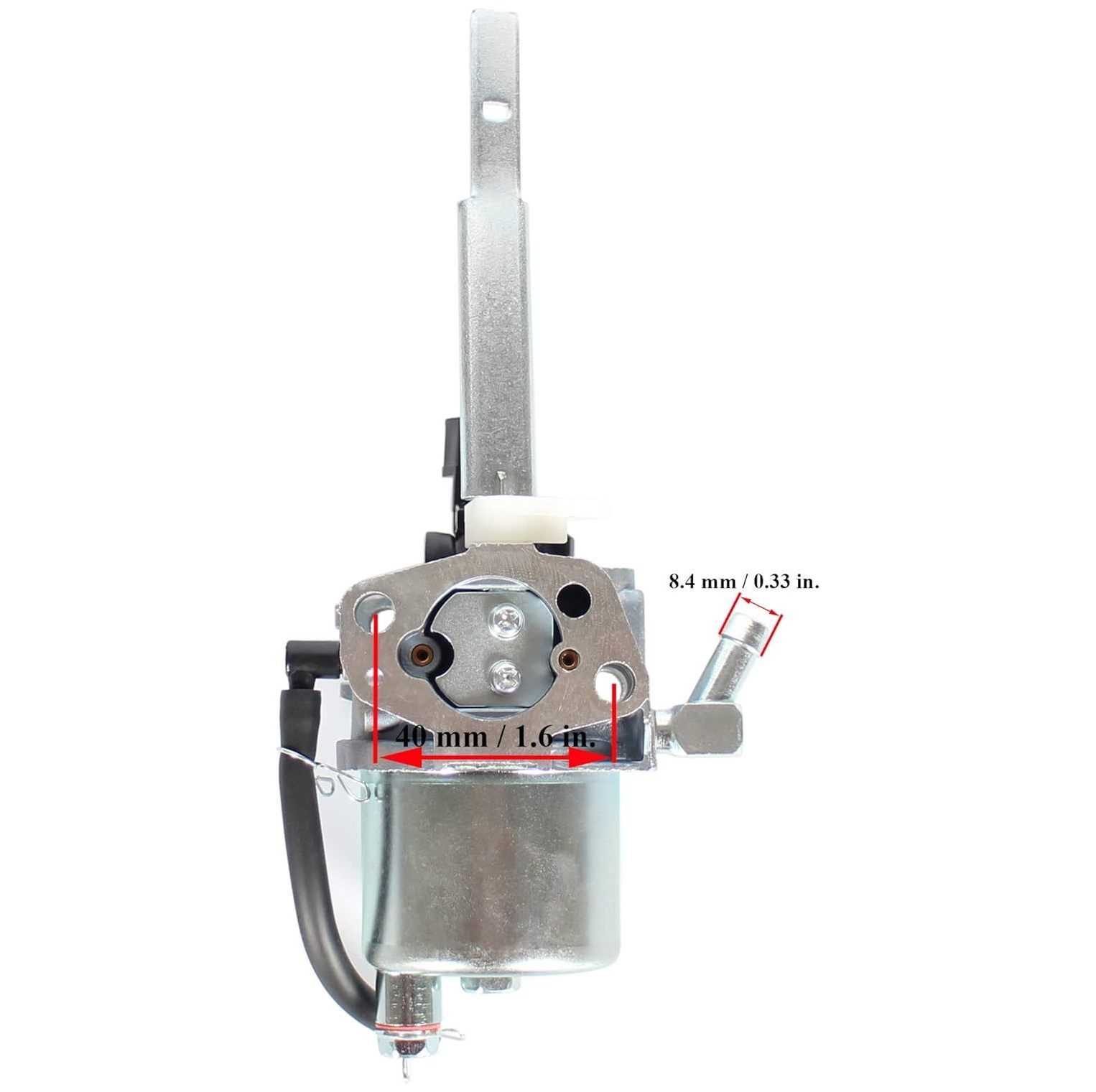

The carburetor plays a pivotal role in mixing the fuel with air, creating a vaporized mixture that is essential for ignition. This component is often equipped with adjustable settings to optimize performance based on environmental conditions. Additionally, the presence of a primer bulb can facilitate easier starting by drawing fuel into the carburetor.

Finally, various gaskets and seals ensure that the entire system remains airtight, preventing leaks and maintaining pressure. By comprehensively understanding this layout, users can identify issues more swiftly and ensure their equipment remains in peak condition.

Electrical Components of Poulan Pro PR241

The electrical system in outdoor power equipment plays a crucial role in ensuring optimal performance and functionality. This section focuses on the essential electrical components that contribute to the efficient operation of these machines. Understanding these elements is vital for both maintenance and troubleshooting, enabling users to address issues effectively.

One of the key elements is the ignition system, which is responsible for starting the engine and ensuring reliable operation. It typically includes components such as the ignition coil and spark plug, which work together to generate the necessary spark for combustion.

Another important part is the electrical wiring, which connects various components and allows for the transfer of power throughout the equipment. Proper wiring is essential for preventing electrical faults and ensuring that each part receives the correct voltage.

The starter motor is also a critical component, as it provides the initial torque needed to start the engine. This motor must function efficiently to ensure quick and smooth starts, especially in challenging conditions.

Additionally, switches and connectors facilitate user control and secure connections between different parts of the system. Ensuring these components are in good condition is vital for safe and effective operation.

Overall, the electrical components of this equipment work in harmony to provide the necessary power and control, making it essential for users to understand their functions for proper maintenance and troubleshooting.

Handle Assembly and Control Mechanisms

The handle assembly plays a crucial role in the operation and maneuverability of outdoor equipment. This section delves into the various components that make up the handle assembly, focusing on their functions and the mechanisms that control the machine’s performance. Understanding these elements is essential for efficient maintenance and effective operation.

Components of the Handle Assembly

The handle assembly typically consists of grips, control levers, and connecting rods. The grips are designed for comfort and stability, allowing the operator to maintain a secure hold during use. Control levers serve as the interface for adjusting settings, such as speed and power, facilitating seamless operation. Connecting rods link these components, ensuring precise communication between the operator’s actions and the machine’s responses.

Functionality and Adjustment Mechanisms

Proper functionality of the handle assembly is vital for effective control. Adjustment mechanisms allow users to tailor the handle’s position for optimal ergonomics, enhancing comfort during prolonged use. Regular inspection of these components ensures they remain functional, preventing wear and tear that could lead to decreased performance or safety hazards.

Wheels and Steering Mechanisms

The wheel and steering systems are essential components of any outdoor equipment, influencing both maneuverability and overall performance. These mechanisms work in tandem to ensure smooth navigation and control during operation. A thorough understanding of their construction and functionality is vital for maintaining optimal efficiency and safety.

Typically, wheels are designed to support the weight of the machine while providing traction on various terrains. Their materials and tread patterns are carefully selected to enhance grip and durability. The steering mechanism, on the other hand, facilitates directional control, allowing the operator to navigate tight spaces or uneven ground with ease. Components such as steering links and pivot points play a crucial role in translating the operator’s input into precise movements.

Regular inspection and maintenance of these systems are necessary to prevent wear and tear, ensuring the longevity of the equipment. By understanding the intricacies of wheel and steering assemblies, users can make informed decisions regarding repairs or replacements, ultimately enhancing the functionality and lifespan of their machinery.

Blade and Cutting System Details

The cutting mechanism of a lawn maintenance tool is crucial for achieving an even and efficient lawn finish. This section explores the essential components and functionalities of the blade and cutting assembly, highlighting how they contribute to optimal performance.

The primary elements of the cutting system include:

- Blades: Sharp, durable blades are essential for clean cuts. They are designed to slice through grass without tearing, promoting healthier growth.

- Blade Height Adjustment: This feature allows the user to modify the height of the cut, accommodating various grass types and preferences.

- Cutting Deck: The cutting deck houses the blades and is engineered for efficient airflow, which helps in elevating and directing grass clippings.

- Drive Mechanism: This component facilitates the rotation of the blades, powered by the engine, ensuring consistent cutting speed and power.

Proper maintenance of these components is vital for achieving peak efficiency and extending the lifespan of the equipment. Regularly inspecting the blades for wear and ensuring they are correctly sharpened can significantly enhance performance and results.

Additionally, understanding the layout and operation of the cutting assembly can aid users in troubleshooting and optimizing their lawn care tasks. Familiarity with these details empowers users to make informed decisions regarding replacements and upgrades.

Exhaust System Configuration

The exhaust system plays a crucial role in ensuring optimal engine performance by effectively directing combustion gases away from the engine. A well-designed exhaust configuration contributes not only to power output but also to noise reduction and emissions control.

Key components of the exhaust system include:

- Muffler: Reduces noise produced by the engine during operation.

- Exhaust Pipe: Channels gases from the engine to the outside atmosphere.

- Exhaust Manifold: Collects gases from the engine cylinders and directs them into the exhaust pipe.

- Catalytic Converter: Converts harmful emissions into less toxic substances before they exit the vehicle.

When configuring the exhaust system, consider the following factors:

- Material Selection: Use corrosion-resistant materials to ensure longevity and durability.

- Diameter of Pipes: Adjusting the diameter can affect backpressure and overall performance.

- Mounting Position: Proper placement is essential to avoid damage and ensure efficiency.

- Compatibility: Ensure all components work well together for optimal performance.

In summary, a properly configured exhaust system not only enhances engine efficiency but also contributes to a quieter and more environmentally friendly operation.

Maintenance and Replacement Parts

Proper upkeep and timely substitution of components are essential for the longevity and performance of outdoor equipment. Regular checks and the use of quality replacements ensure that the machinery operates efficiently and safely. This section discusses key maintenance practices and necessary replacements to keep your device running smoothly.

Component Maintenance Tips Replacement Frequency Air Filter Clean regularly and replace when damaged or clogged. Every 25 hours of use or annually. Spark Plug Inspect for wear and replace if fouled or damaged. Every 50 hours of operation. Fuel Line Check for cracks or leaks; replace as needed. Annually or at signs of wear. Blade Sharpen regularly and replace if excessively worn. Every 20 hours of use or as needed. Belt Inspect for fraying or damage; replace if necessary. Every season or at signs of wear.