In the realm of high-performance engines, a well-optimized system can significantly enhance overall efficiency and power output. This section delves into the intricate elements that play a crucial role in the functioning of enhanced air supply mechanisms. A comprehensive understanding of these components is essential for anyone looking to improve engine performance or undertake maintenance.

By examining the various elements involved, enthusiasts and professionals alike can gain insight into how each piece contributes to the system’s efficiency. From the mechanisms that facilitate airflow to the structural components that support overall performance, this exploration will shed light on the critical factors that influence engine dynamics.

Equipped with this knowledge, individuals can make informed decisions regarding upgrades, replacements, and troubleshooting, ensuring that their engines operate at optimal levels. This exploration serves as a foundation for understanding the complex interplay of components that drive performance in modern engines.

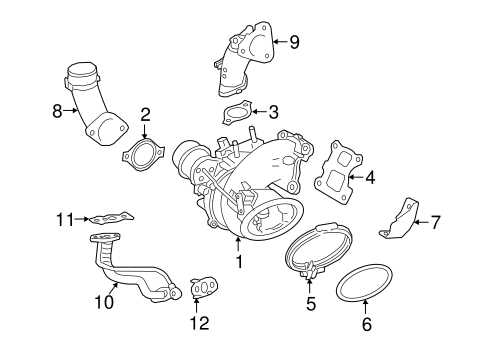

The system designed for enhancing engine performance through forced induction plays a crucial role in modern vehicles. Understanding its components helps in diagnosing issues and optimizing functionality. This section aims to provide a comprehensive overview of this sophisticated mechanism, highlighting its essential elements and their interactions.

| Component Name | Description |

|---|---|

| Compressor | Increases air intake to improve combustion efficiency. |

| Turbine | Utilizes exhaust gases to spin and create boost pressure. |

| Wastegate | Regulates exhaust flow to maintain optimal boost levels. |

| Intercooler | Cools the compressed air before it enters the engine. |

| Blow-off Valve | Releases excess pressure to prevent compressor surge. |

| Oil Supply Line | Delivers lubrication to prevent overheating and wear. |

| Exhaust Manifold | Collects exhaust gases from the engine cylinders. |

| Intake Manifold | Distributes the pressurized air to the engine cylinders. |

| Turbocharger Housing | Encloses the turbo components and directs airflow. |

| Electronic Control Unit (ECU) | Manages engine parameters and boost control for efficiency. |

Grasping the function of each element enables better maintenance practices and performance enhancements. This knowledge is invaluable for enthusiasts and professionals alike, leading to more informed decisions when addressing vehicle enhancements or repairs.

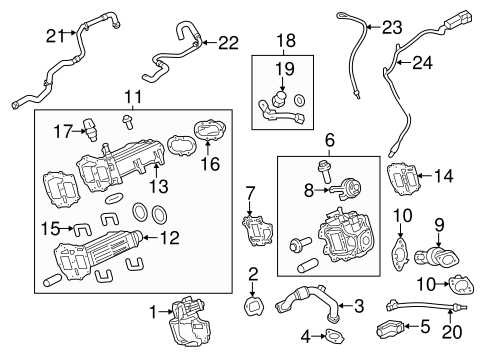

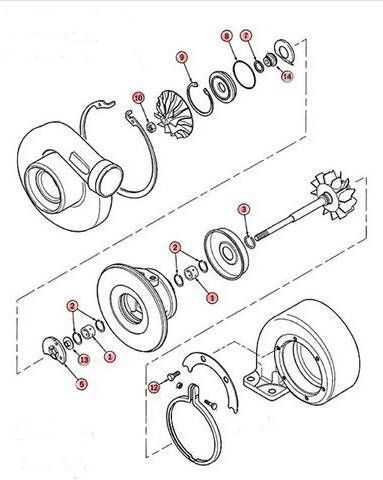

Key Components of Turbocharger Assembly

The efficiency and performance of forced induction systems heavily rely on various essential elements that work in unison. Understanding these components is crucial for grasping how these assemblies enhance engine capabilities. Each part plays a significant role in ensuring optimal functionality and longevity of the system.

Major Elements

- Compressor Housing: This encases the compressor wheel and directs air into the engine.

- Turbine Housing: Encloses the turbine wheel and facilitates exhaust gas flow.

- Center Housing: Connects the compressor and turbine sections while providing lubrication.

- Wastegate: Regulates exhaust flow to maintain optimal pressure levels.

Supporting Components

- Intercooler: Cools compressed air before it enters the engine.

- Oil Feed Line: Supplies lubrication to the rotating assembly.

- Exhaust Manifold: Collects exhaust gases from the engine and directs them to the turbine.

Recognizing these key components allows for better maintenance and understanding of how to maximize performance. Each element contributes significantly to the overall efficiency of the system, ensuring reliable operation over time.

Understanding Turbocharger Functionality

A key component in enhancing engine performance, a specific device significantly boosts air intake, resulting in improved efficiency and power output. By optimizing the combustion process, this mechanism allows for greater energy extraction from the fuel, ultimately leading to enhanced overall performance. Understanding its operation reveals the intricacies of modern automotive engineering.

How It Works

The device operates by harnessing exhaust gases to spin a turbine. As the turbine rotates, it compresses incoming air, forcing it into the combustion chamber at a higher density. This increased airflow enables more fuel to be burned, creating a more potent explosion and delivering more power to the engine. The process is cyclical, continuously feeding exhaust gas to maintain the momentum of the turbine.

Benefits of Enhanced Airflow

Enhanced airflow contributes to better throttle response and increased horsepower, making the vehicle more responsive and enjoyable to drive. Additionally, improved combustion efficiency can lead to reduced emissions, aligning with modern environmental standards. The integration of this device has become essential in the pursuit of performance without compromising sustainability.

Common Issues with Turbo Parts

In high-performance vehicles, certain components can experience wear and tear over time, leading to various complications. Understanding these common challenges can help in maintaining optimal functionality and extending the lifespan of the system.

One frequent problem is the accumulation of carbon deposits. These deposits can obstruct airflow and reduce efficiency, ultimately affecting performance. Additionally, inadequate lubrication often leads to increased friction, which can cause severe damage to critical components.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Carbon Build-up | Reduced performance, increased emissions | Regular cleaning, use of quality fuel |

| Oil Leaks | Low oil levels, engine noise | Inspect seals, replace damaged components |

| Overheating | Loss of power, warning lights | Check cooling system, ensure proper airflow |

| Excessive Noise | Unusual sounds, vibrations | Inspect bearings, replace worn-out elements |

By being aware of these potential issues and taking proactive measures, vehicle owners can ensure their systems operate smoothly and efficiently.

Benefits of Upgrading Turbo Components

Enhancing the performance of engine accessories can lead to significant improvements in efficiency and power output. By investing in superior components, enthusiasts can optimize their vehicles for better acceleration, fuel economy, and overall responsiveness. This approach not only boosts performance but also contributes to the longevity of the engine.

One of the primary advantages of upgrading these components is the increased airflow that can result from advanced designs. Improved airflow enhances combustion, leading to more efficient energy conversion and reduced exhaust emissions. Additionally, higher-quality materials used in these components often lead to better durability and reduced maintenance costs over time.

| Advantage | Description |

|---|---|

| Improved Performance | Enhanced responsiveness and acceleration, resulting in a more thrilling driving experience. |

| Increased Efficiency | Optimized fuel consumption due to better airflow and combustion processes. |

| Enhanced Durability | High-quality materials reduce wear and tear, leading to lower maintenance requirements. |

| Lower Emissions | Improved combustion efficiency results in reduced harmful emissions, benefiting the environment. |

Overall, upgrading these components can lead to a more robust and efficient vehicle, making it a worthwhile investment for anyone looking to enhance their engine’s capabilities.

Installation Guide for Turbo Parts

Properly integrating performance components is essential for enhancing engine efficiency and output. This section outlines the necessary steps to successfully install these key elements, ensuring optimal performance and reliability. Adhering to the guidelines will not only facilitate a smoother installation process but also contribute to the longevity of your vehicle.

1. Preparation: Before commencing the installation, gather all required tools and components. Ensure that the engine is cool and the vehicle is securely lifted. Disconnect the battery to avoid any electrical issues during the process.

2. Disassembly: Carefully remove any existing components that may obstruct access to the area where the new elements will be installed. Take your time to avoid damaging any surrounding parts, and keep track of all fasteners and connections.

3. Installation: Follow the specific instructions for each component meticulously. Ensure that all seals and gaskets are in place to prevent leaks. Tighten all fasteners to the manufacturer’s specifications, using a torque wrench for accuracy.

4. Reassembly: Once everything is in position, reattach any removed parts in the reverse order of disassembly. Double-check that all connections are secure and that there are no leftover components.

5. Testing: After reassembly, reconnect the battery and start the engine. Allow it to idle for a few minutes while checking for any irregularities or leaks. It’s crucial to monitor performance during initial testing to ensure everything operates smoothly.

By following these steps diligently, you can ensure a successful installation that enhances your vehicle’s performance and reliability.

Maintenance Tips for Turbo Systems

Ensuring optimal performance of forced induction systems requires diligent upkeep and attention to detail. Regular maintenance helps to prevent common issues that can arise from wear and tear, extending the lifespan and efficiency of the entire setup.

- Regular Inspections: Frequently check components for signs of wear, such as cracks or leaks. Pay special attention to seals and connections.

- Clean Air Filters: Ensure that air intake filters are clean and free from obstructions. This improves airflow and overall system performance.

- Monitor Oil Quality: Regularly assess engine oil quality and replace it according to manufacturer recommendations. Clean oil is essential for lubrication and cooling.

- Check Coolant Levels: Maintain proper coolant levels to prevent overheating. This is crucial for sustaining performance during extended operation.

- Inspect Exhaust Components: Examine exhaust systems for blockages or damage that could restrict flow. Proper exhaust flow is vital for optimal operation.

By following these maintenance practices, users can ensure that their forced induction systems operate efficiently and reliably over time.

Diagnostic Tools for Turbo Performance

Ensuring optimal functionality of a forced induction system is essential for maintaining engine efficiency and power output. Various diagnostic instruments can assist in evaluating the performance of these systems, enabling mechanics to identify potential issues and enhance overall performance.

One crucial tool is the boost pressure gauge, which measures the pressure within the intake manifold. This device helps determine whether the system is achieving the desired pressure levels, indicating if the compressor is functioning correctly. Another important instrument is the exhaust gas temperature (EGT) gauge. Monitoring EGT can reveal excessive temperatures that might signify issues with the air-fuel mixture or insufficient cooling, allowing for timely adjustments to prevent damage.

Additionally, scan tools are invaluable for reading trouble codes and monitoring various engine parameters. These devices can provide insights into the performance of the engine and its components, making it easier to pinpoint problems related to airflow and fuel delivery. Regularly using these diagnostic tools not only aids in troubleshooting but also helps maintain peak performance over time.

Aftermarket vs. OEM Turbo Parts

The choice between original equipment manufacturer components and alternatives available in the market is a crucial consideration for many vehicle owners. Each option presents unique advantages and potential drawbacks that can significantly impact performance, reliability, and overall value. Understanding these differences can aid in making an informed decision tailored to specific needs and preferences.

Advantages of OEM Components

Original equipment manufacturer components are designed and tested to meet the exact specifications set by the vehicle manufacturer. This ensures compatibility and reliable performance. Additionally, they often come with a warranty, providing peace of mind regarding their longevity and effectiveness. For individuals prioritizing reliability and quality assurance, OEM offerings can be the preferred choice.

Benefits of Aftermarket Alternatives

Aftermarket alternatives often provide a cost-effective solution without compromising on quality. Many manufacturers focus on enhancing performance or offering additional features that OEM components may lack. This flexibility allows vehicle owners to customize their experience according to personal preferences and performance goals. However, it is essential to research and select reputable brands to avoid inferior products.

Turbocharger Performance Enhancements

Enhancing the efficiency and output of forced induction systems is crucial for achieving optimal engine performance. Various strategies and modifications can be implemented to maximize the capabilities of these components, ensuring a balance between power and reliability. Understanding these enhancements allows enthusiasts to elevate their vehicles to new performance levels while maintaining engine integrity.

Upgraded Components

Replacing factory-installed elements with high-performance alternatives can significantly improve efficiency. Options include larger compressors and turbine housings, which facilitate increased airflow. Additionally, improving the intercooler setup can lead to lower intake temperatures, enhancing overall engine performance.

Tuning and Calibration

Proper tuning is essential for unlocking the full potential of modified systems. Advanced calibration methods ensure that fuel maps and boost levels are optimized, leading to improved throttle response and overall drivability. Utilizing performance tuning software can help achieve a well-rounded power increase while maintaining engine safety.

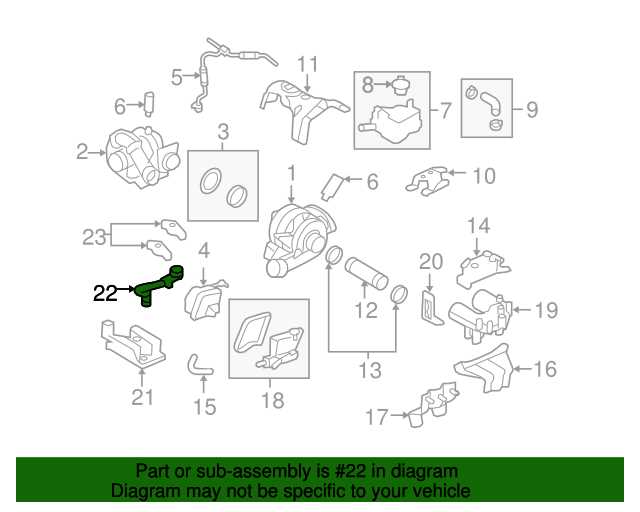

Resources for Turbo Parts Diagrams

When it comes to understanding the components of forced induction systems, having access to reliable information is crucial. Numerous platforms provide valuable insights into the various elements involved in these systems. These resources can assist enthusiasts and professionals alike in grasping the intricate details and functionality of each component.

Online Forums: Participating in automotive forums dedicated to performance modifications can yield a wealth of knowledge. Members often share their experiences, provide recommendations, and post detailed visuals that can enhance understanding of component arrangement and functionality.

Manufacturer Websites: Many manufacturers offer detailed catalogs and technical documentation on their websites. These documents often include comprehensive illustrations that clarify the specifications and configurations of the different components, making it easier to identify the necessary elements for any installation or maintenance task.

Repair Manuals: Investing in repair manuals specific to certain models can prove beneficial. These manuals usually feature clear illustrations and step-by-step guides, allowing users to familiarize themselves with the setup and maintenance procedures for the forced induction systems.

YouTube Channels: Numerous automotive YouTube channels focus on performance upgrades and maintenance. Many of these channels provide visual walkthroughs and explanations that can significantly aid in understanding how each part interacts within the system.

Community Groups: Joining local or online automotive clubs can connect you with fellow enthusiasts who possess knowledge and resources related to performance enhancements. Sharing insights and diagrams within these groups can foster a deeper understanding of the system’s intricacies.