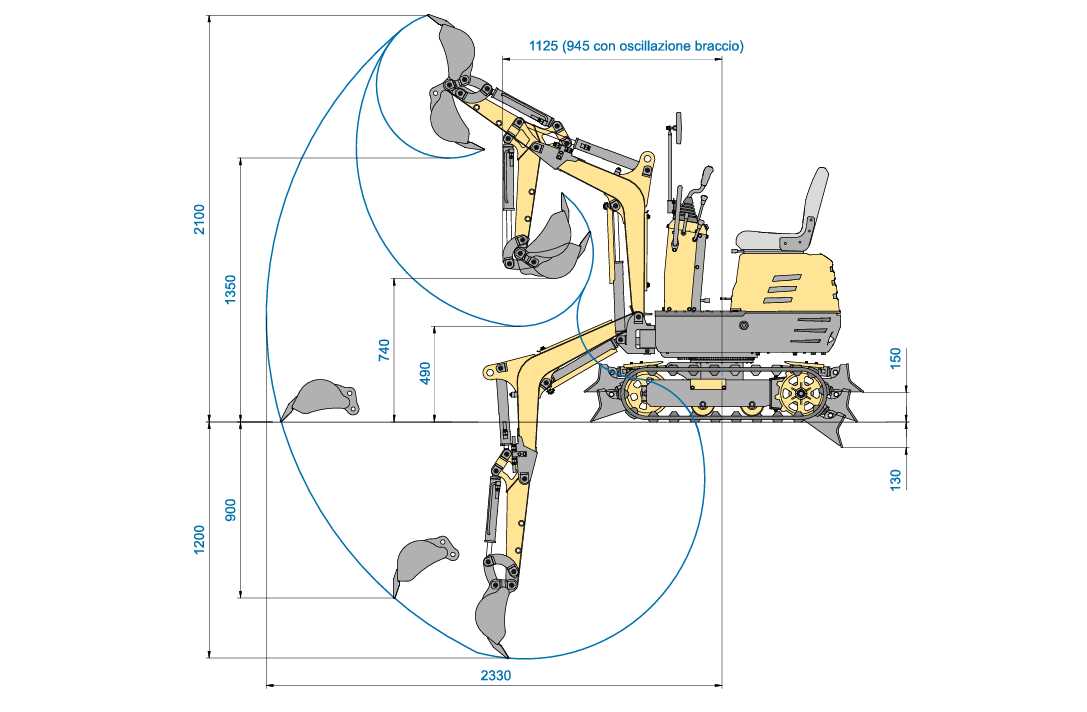

Maintaining a well-kept lawn requires a variety of specialized tools, each designed for specific tasks that help achieve a clean and professional finish. One of the most important devices in this process features a collection of essential elements working together to ensure effective and efficient turf care.

Understanding how each element contributes to the overall functionality of the equipment is key to keeping your machine in top condition. By familiarizing yourself with the structure and connections, you can ensure that the necessary upkeep is performed, avoiding unnecessary issues and extending the life of your tool.

In this guide, we will explore the essential details of various components and their roles in creating a smooth, effective operation.

Comprehensive Guide to Bluebird Power Rake

This section provides an in-depth overview of an essential landscaping tool designed to maintain healthy and vibrant lawns. It effectively removes unwanted materials from the soil’s surface, improving the overall condition of grass and preparing the ground for new growth. By utilizing this equipment, users can achieve better results in lawn care and maintenance.

Key Features of the Device

- Motor: Provides the necessary force to run the machine efficiently.

- Transmission

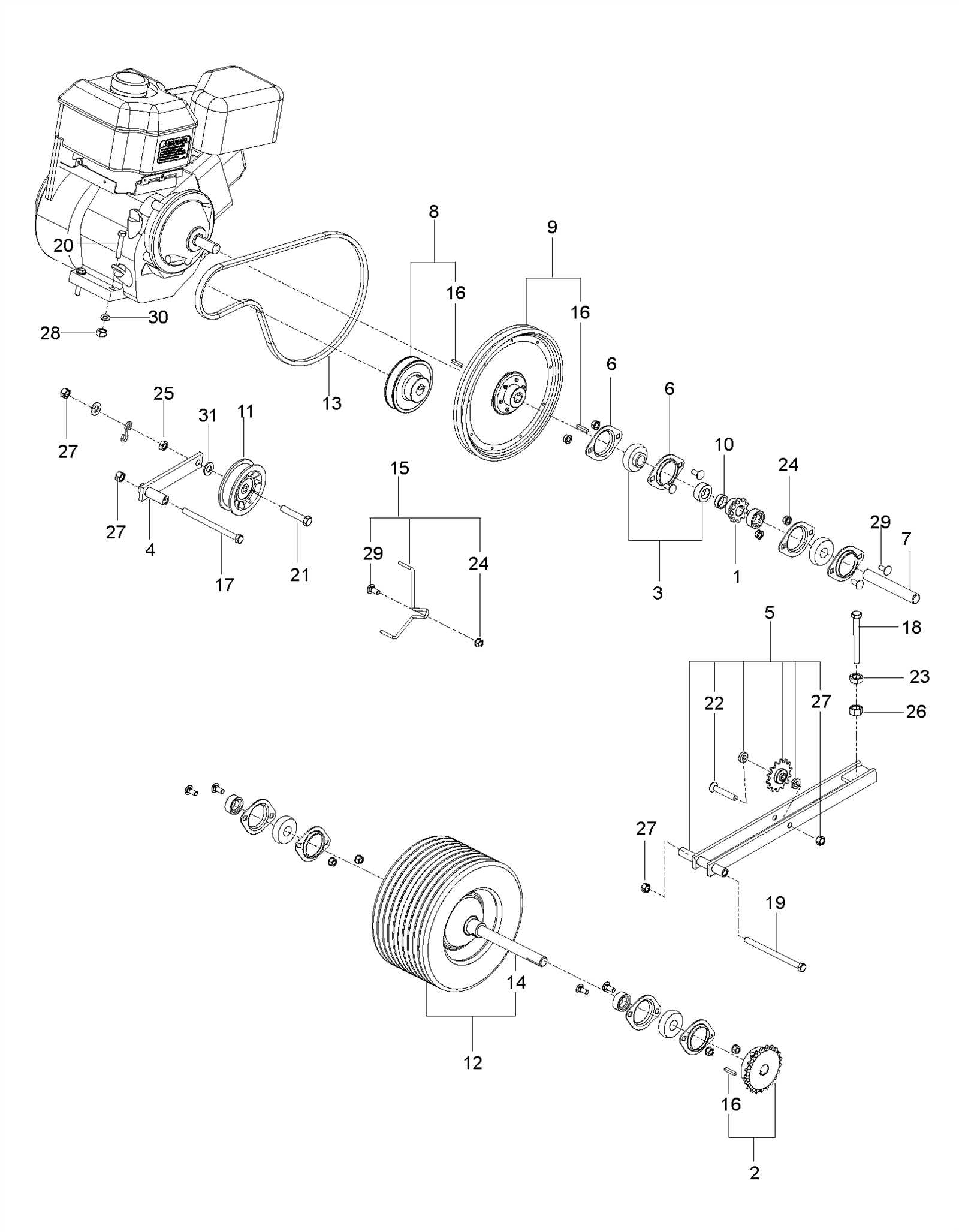

Understanding the Drive Mechanism

The drive system in a machine like this plays a crucial role in converting energy into motion. It ensures that the moving parts operate smoothly and efficiently, allowing the entire device to perform its function effectively. Understanding how this mechanism works is key to both troubleshooting and maintaining the equipment.

Main Components of the Drive System

The drive mechanism consists of several interconnected elements that work together. These include belts, pulleys, and gears, each of which contributes to the overall movement. Belts are responsible for transferring motion, while pulleys help in redirecting force, ensuring efficient energy distribution.

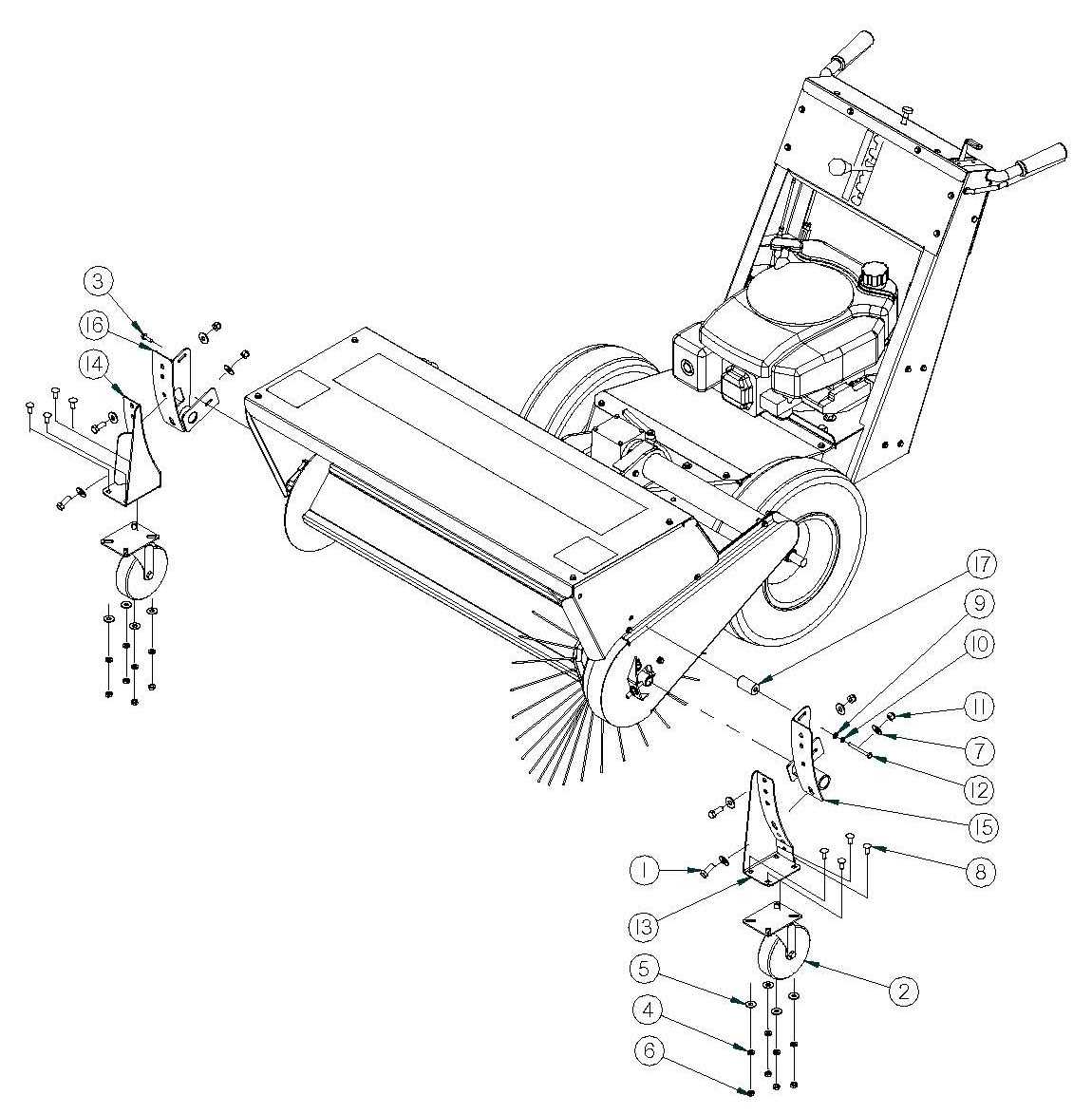

Parts Breakdown for Blade Assembly

The blade mechanism consists of several key components that work together to ensure effective performance. Understanding the individual elements that form this assembly can help in maintenance and replacement when necessary. Below is a detailed breakdown of the elements involved in the blade system, highlighting their function and importance.

Main Blade Components

- Cutting Blade: The primary element responsible for the cutting action. It is crucial for efficient material processing.

- Mounting Bolts: These secure the blade to the main frame and must

How the Tine Bar Functions

The tine bar is a key component in ensuring effective soil engagement and surface treatment. It plays a vital role in loosening compacted soil, making it easier for air, water, and nutrients to penetrate deeper. This mechanism is critical for maintaining healthy soil conditions.

Mechanical Motion

The movement of the tine bar is driven by a rotational system, which causes the tines to move in a coordinated pattern. This movement allows the tines to dig into the soil, creating the necessary disturbance for loosening hardened ground.

Durability and Adjustment

Made from durable materials, the tine bar is designed to withstand

Identifying Key Engine Parts

Understanding the essential components of a motor is crucial for effective maintenance and repair. Each element plays a significant role in the overall functionality and performance of the machine. Recognizing these parts helps users troubleshoot issues and ensure optimal operation.

1. Cylinder Block: This is the main structure of the engine, housing the cylinders where combustion occurs. Its durability is vital for maintaining engine integrity.

2. Crankshaft: This component converts the linear motion of the pistons into rotational motion, ultimately driving the machine’s wheels or blades. It is pivotal for energy transfer within the system.

3. Camshaft: This part controls the opening and closing of the engine’s valves, allowing the intake of air and fuel while expelling exhaust gases. Its precise timing is essential for efficient engine performance.

4. Piston: The piston moves up and down within the cylinder, compressing the fuel-air mixture for combustion. Its movement is a critical aspect of the engine’s power generation.

5. Carburetor: This component mixes air and fuel in the right proportions for combustion. Proper functioning of the carburetor is vital for engine efficiency and power output.

By familiarizing oneself with these crucial components, users can enhance their understanding and capability in maintaining their machinery effectively.

Maintaining the Belt and Pulley System

Ensuring the proper functionality of the drive mechanism is crucial for optimal performance. This system plays a vital role in transferring power efficiently. Regular maintenance helps to extend its lifespan and prevent costly repairs.

To maintain this system effectively, consider the following steps:

- Inspect belts regularly for signs of wear or damage.

- Check for proper tension in the belts to ensure efficient operation.

- Examine pulleys for any misalignment or buildup of debris.

- Lubricate the pulleys as needed to reduce friction.

- Replace any worn or damaged components promptly to prevent further issues.

By following these maintenance tips, you can ensure a reliable and efficient drive system, enhancing the overall functionality of your equipment.

Main Components of Bluebird Power Rake

This equipment is designed to handle a variety of tasks, using a combination of essential mechanisms that work together to ensure smooth operation. Each element contributes to the efficiency and effectiveness of the machine, making it ideal for preparing surfaces and removing unwanted layers.

Engine and Drive System

The core of the machinery is its motor, which powers the entire unit. Connected to the drive mechanism, it ensures that the machine can move across different terrains with ease and precision.