In modern agriculture, the efficiency and performance of tilling machinery play a crucial role in enhancing soil management practices. A thorough grasp of the various elements that contribute to these machines is essential for operators and technicians alike. This knowledge aids in the maintenance, repair, and optimization of agricultural implements, ensuring they operate at peak efficiency.

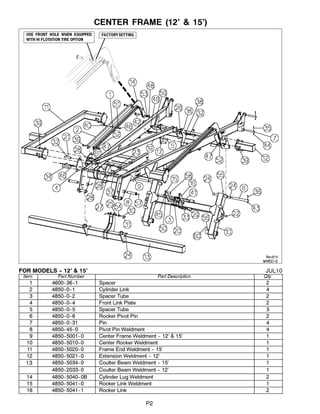

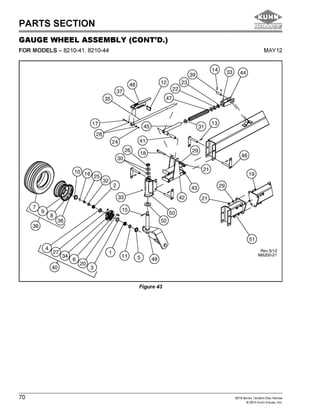

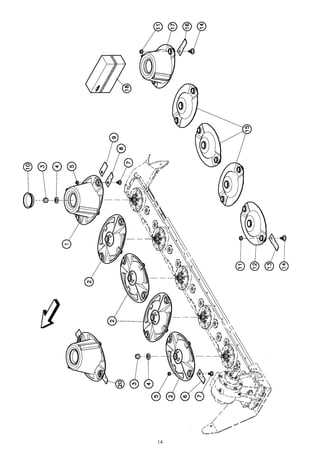

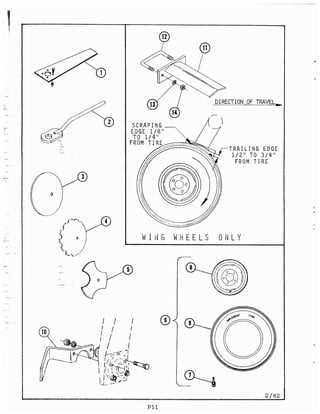

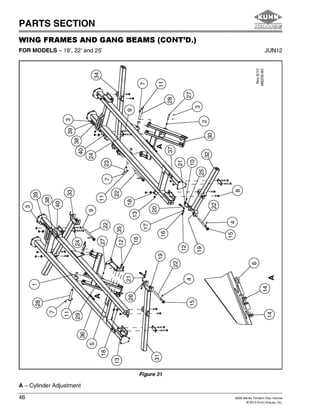

Each implement consists of several essential components that work together to achieve desired results. Understanding the layout and function of these elements allows users to identify issues quickly and implement effective solutions. From the frame to the working tools, each part serves a specific purpose, contributing to the overall functionality of the equipment.

For anyone involved in agricultural operations, being familiar with the intricate relationships among these components can lead to improved productivity and longevity of the machinery. Engaging with detailed visual representations of these elements fosters a deeper understanding, ultimately leading to more informed decisions regarding equipment usage and maintenance.

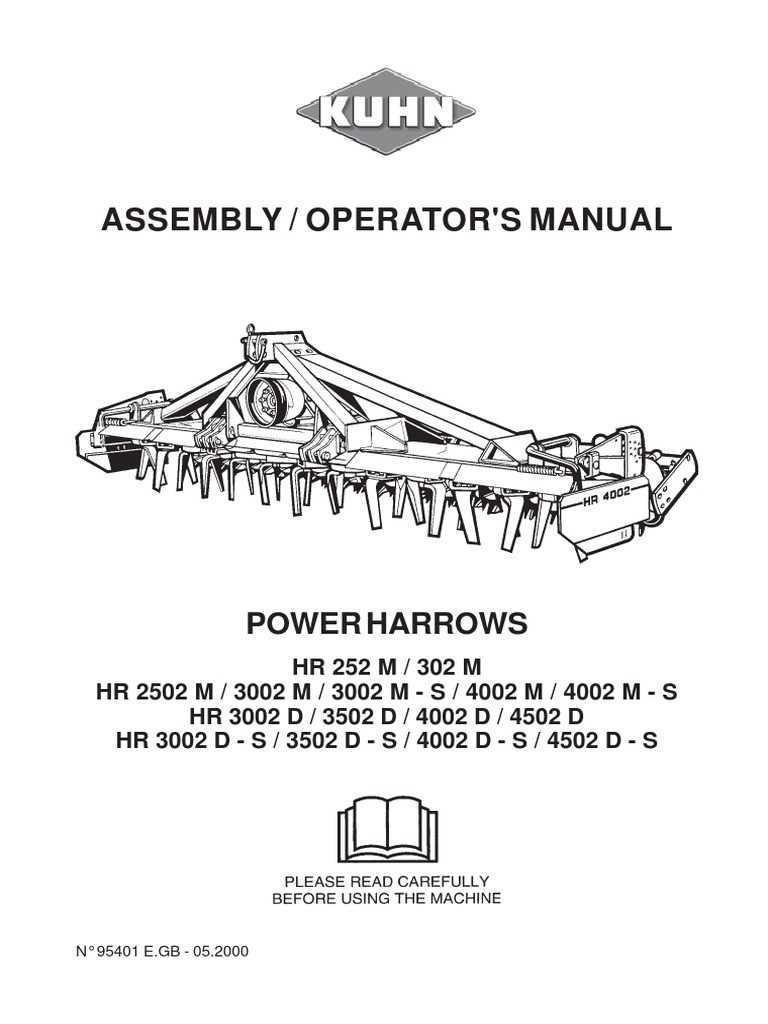

Understanding Kuhn Power Harrow Components

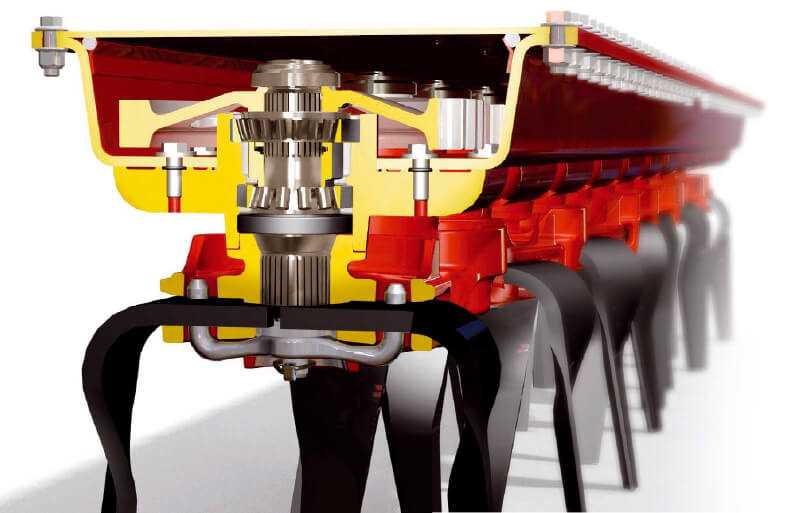

Effective soil preparation is essential for optimal crop growth. A well-designed tool for tilling the earth is composed of various essential elements that work together to enhance efficiency and productivity. Each component plays a significant role in ensuring the tool operates smoothly and meets agricultural needs.

Main Elements of the Tilling Equipment

The primary components include rotating blades that break up the soil, providing aeration and incorporating organic matter. Additionally, robust frames support these blades, ensuring durability under various conditions. The mechanism responsible for adjusting the depth of tillage is crucial for adapting to different soil types and moisture levels.

Importance of Regular Maintenance

To maintain optimal performance, regular inspections and timely replacements of worn components are vital. Proper upkeep not only prolongs the lifespan of the equipment but also guarantees consistent results in soil preparation. Understanding the functionality of each element fosters better decision-making regarding maintenance and upgrades.

Key Features of the Harrow Design

This section explores the essential characteristics that define an effective soil preparation implement. The design elements play a crucial role in enhancing efficiency and performance during agricultural tasks.

| Feature | Description |

|---|---|

| Durability | Constructed from high-quality materials to withstand rigorous conditions and extend lifespan. |

| Adjustable Depth | Allows customization of working depth to suit various soil types and conditions. |

| Efficient Tillage | Designed for optimal soil mixing and aeration, promoting healthy crop growth. |

| Versatility | Compatible with various tractors and can be utilized for different agricultural tasks. |

| Easy Maintenance | Features designed for straightforward servicing to minimize downtime. |

Functionality of Each Part Explained

This section delves into the essential components of tilling machinery, highlighting their individual roles and contributions to overall performance. Understanding these elements aids in appreciating the intricate design and efficiency of agricultural equipment.

Core Components

The primary elements of the machinery work in harmony to ensure optimal soil preparation. Each segment plays a crucial role, from initiating soil disturbance to ensuring consistent mixing and leveling.

Supportive Elements

Additional features enhance the functionality of the main components. These elements provide stability, control, and adaptability, making the equipment suitable for various terrains and conditions.

| Component | Function |

|---|---|

| Blade Assembly | Engages the soil, breaking it up for better aeration. |

| Frame | Holds all components together, providing structural integrity. |

| Hitch | Connects the machinery to the tractor, facilitating movement. |

| Adjustable Wheels | Allows for height modification and maneuverability. |

Benefits of Using Kuhn Equipment

Utilizing advanced agricultural machinery offers numerous advantages that enhance productivity and efficiency on the farm. These innovative tools are designed to streamline various tasks, allowing farmers to achieve optimal results with less effort.

Durability is a key feature of these implements, ensuring they withstand the rigors of daily use in diverse conditions. Farmers can rely on their longevity, reducing the need for frequent replacements.

The efficiency of operations is significantly improved with these machines, as they are engineered to maximize performance while minimizing resource consumption. This results in lower operational costs and better environmental sustainability.

Additionally, the precision offered by such equipment contributes to more accurate fieldwork, leading to improved crop yields. The integration of advanced technology enhances the ability to monitor and adjust processes in real-time.

Lastly, investing in high-quality machinery provides users with peace of mind through robust support and service options. Farmers can focus on their core activities, knowing they have reliable tools at their disposal.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your agricultural equipment, regular upkeep is essential. Proper maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns, thereby saving time and resources.

Regular Inspections: Conduct frequent checks on all components to identify wear and tear. Look for signs of damage or misalignment that could hinder functionality.

Lubrication: Keep moving parts well-lubricated to reduce friction and prevent premature wear. Use the recommended lubricants and apply them according to the manufacturer’s guidelines.

Cleaning: Remove debris and buildup from all surfaces. Regular cleaning helps prevent corrosion and maintains optimal performance in various working conditions.

Adjustments: Ensure all settings are correctly calibrated for specific tasks. Regular adjustments can improve efficiency and enhance the quality of work produced.

Replacement of Worn Parts: Stay proactive by replacing any components that show signs of significant wear. Timely replacements can prevent larger issues down the line.

By following these tips, you can maximize the effectiveness and lifespan of your machinery, leading to more productive outcomes.

Common Issues and Troubleshooting Steps

Operating agricultural machinery can lead to a variety of challenges that may affect performance. Identifying these issues promptly is essential for maintaining efficiency and productivity. Below are some common problems and practical solutions to help mitigate them.

- Uneven Soil Preparation:

- Check the adjustment settings to ensure uniformity.

- Inspect for wear on blades or tines that may require replacement.

- Loss of Power:

- Examine the connection to the power source for any loose fittings.

- Ensure that filters are clean and not obstructed.

- Strange Noises During Operation:

- Listen for unusual sounds that may indicate mechanical issues.

- Inspect for any loose or damaged components that need tightening or replacing.

- Frequent Jamming:

- Clear any debris or clogs that may be obstructing movement.

- Adjust the speed settings to avoid overloading the equipment.

By systematically addressing these common concerns, operators can enhance the functionality of their equipment and ensure a smoother workflow.

How to Access Replacement Parts

Obtaining components for agricultural machinery is essential for maintaining efficiency and performance. Understanding the best approaches can simplify the process and ensure you find the necessary elements without unnecessary delays.

Research Online: Begin by exploring manufacturer websites or trusted retailers that specialize in agricultural equipment. Many platforms offer extensive catalogs, making it easier to identify what you need.

Consult the Manual: Refer to the user guide for detailed information on specific components. This resource typically provides valuable insights into compatible items and their specifications.

Contact Local Dealers: Engaging with local distributors can yield beneficial results. They often have firsthand knowledge and can assist in ordering the right items.

Utilize Community Resources: Join forums or social media groups dedicated to machinery enthusiasts. Members frequently share their experiences and can recommend where to source specific elements.

Keep a Maintenance Log: Documenting maintenance activities helps track when replacements are needed. This practice can prompt timely orders and reduce equipment downtime.

Comparison with Other Brands

When evaluating various equipment options in the agricultural sector, it’s essential to consider the differences in design, functionality, and overall performance among competing manufacturers. Each brand offers unique features that cater to specific needs, influencing user experience and efficiency in operations.

Build Quality often varies significantly between brands. While some emphasize durability and robust construction, others may focus on lightweight materials that enhance maneuverability. This choice can impact long-term maintenance and operational costs.

Technology Integration is another critical factor. Some manufacturers incorporate advanced technology to improve precision and ease of use, while others may rely on more traditional designs. This divergence affects the adaptability of the equipment to modern farming practices.

Cost Efficiency is always a concern. Prices can fluctuate widely, influenced by the features and innovations each brand offers. It is important for buyers to assess not only the initial investment but also the potential return through increased productivity.

Ultimately, understanding these differences enables informed decisions, ensuring the right choice aligns with specific agricultural requirements and enhances operational efficiency.

Innovations in Harrow Technology

Recent advancements in tillage implements have transformed the way soil is prepared for planting. These innovations focus on enhancing efficiency, reducing soil compaction, and improving crop yield. Manufacturers are now incorporating cutting-edge materials and designs that cater to the diverse needs of modern agriculture.

Enhanced Durability and Performance

Modern implements utilize high-strength alloys and innovative engineering techniques, resulting in greater durability and performance. Improved resistance to wear and tear ensures that these tools can withstand rigorous use, ultimately leading to lower maintenance costs for farmers.

Smart Technology Integration

The incorporation of smart technology has revolutionized the approach to soil management. Features like automated depth control and real-time monitoring systems allow for precise adjustments, ensuring optimal soil conditions. This technological shift not only boosts productivity but also promotes sustainable farming practices.

Cost Considerations for Owners

Understanding the financial implications of maintaining and upgrading agricultural equipment is crucial for operators. Various factors influence overall expenses, making it essential to evaluate all aspects before making significant investments.

- Initial Investment: Assess the upfront costs associated with purchasing new machinery versus maintaining existing units.

- Maintenance Costs: Regular upkeep is necessary to ensure optimal performance. Consider both scheduled services and unexpected repairs.

- Replacement Parts: Evaluate the availability and pricing of components. Higher-quality parts may come with a premium but can lead to long-term savings through enhanced durability.

- Fuel Efficiency: Analyzing the fuel consumption of equipment can significantly impact operational costs. Opting for models with better efficiency can reduce overall expenditure.

- Resale Value: Consider how the investment will retain value over time. Equipment that is well-maintained typically fetches a higher price in the resale market.

By carefully analyzing these factors, owners can make informed decisions that align with their financial goals while ensuring effective operation in the field.

Expert Recommendations for Usage

When operating machinery designed for soil preparation, it’s crucial to follow best practices to ensure efficiency and longevity. Proper handling not only maximizes productivity but also minimizes wear on equipment.

Regular Maintenance: Conduct frequent checks and maintenance to keep all components in optimal condition. This includes inspecting for wear, ensuring lubricants are at appropriate levels, and tightening loose parts.

Adjusting Settings: Tailor the machine settings based on the specific conditions of the field. Soil type, moisture level, and crop requirements can influence the necessary adjustments for effective performance.

Safe Operation: Prioritize safety by wearing appropriate gear and ensuring that all operators are well-trained. Understanding the equipment’s capabilities and limitations will enhance safety and operational effectiveness.

Timely Usage: Utilize the machinery during the recommended seasons and under suitable weather conditions. This timing can significantly impact the success of soil preparation efforts.

Testimonials from Kuhn Users

This section highlights experiences and feedback from individuals who utilize a specific brand’s agricultural equipment. Their insights offer valuable perspectives on performance, reliability, and overall satisfaction with the machinery.

Users frequently mention the following aspects in their testimonials:

- Efficiency: Many operators appreciate how effectively the equipment enhances productivity in their farming tasks.

- Durability: Users often commend the robust build quality, noting that the machines withstand rigorous conditions and extended use.

- Ease of Use: Feedback indicates that many find the machinery user-friendly, allowing for straightforward operation even for those new to agricultural practices.

- Customer Support: Several testimonials highlight the excellent service and support provided, making maintenance and troubleshooting less daunting.

Overall, the shared experiences reflect a high level of satisfaction among users, reinforcing the equipment’s reputation in the industry.