When it comes to high-performance cooking tools, understanding the individual elements that make up the device is crucial for both maintenance and effective use. Each section of the equipment plays a distinct role in ensuring efficiency and durability, from the external controls to the internal mechanisms that work behind the scenes.

Delving deeper into the structure, one can uncover a variety of integral parts that contribute to the overall functionality. Identifying and learning about these specific elements can significantly improve the user’s ability to troubleshoot and optimize the appliance.

This guide aims to provide a detailed look at how various components interact and support the seamless operation of the entire system, giving users an informed perspective on maintaining and enhancing their kitchen tool.

Understanding the Structure of Your Pressure Cooker

To make the most of your culinary tool, it’s essential to become familiar with its key elements. A deeper understanding of its construction will help ensure safe and efficient operation during meal preparation. Each component plays a vital role in regulating the cooking process, contributing to both performance and safety.

Key Components Explained

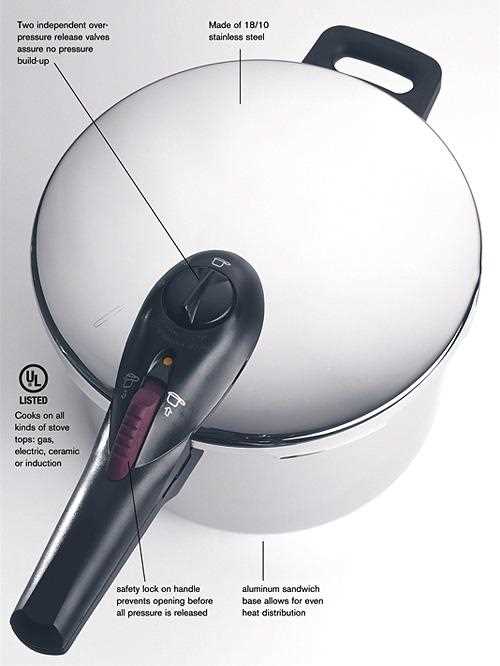

- Main Body: The primary vessel where ingredients are placed for cooking. Designed to withstand high temperatures, it supports the overall function of the device.

- Lid Mechanism: This vital part ensures that the pot remains securely sealed during use, allowing for efficient heat retention and cooking processes.

- Sealing Ring: A flexible material fitted around the lid, ensuring no heat or moisture escapes, maintaining the necessary environment inside.

- Release Valve: This mechanism regulates internal conditions by allowing for controlled escape when needed, ensuring safety during operation.

- Base Structure: The foundation of the pot, designed for even heat distribution and stability while cooking.

- Handle Design

Exploring the Sealing Mechanism for Safety

The reliability of the sealing process is crucial for ensuring the safe operation of any kitchen equipment. This section delves into how this feature works to prevent mishaps during cooking, focusing on its role in maintaining a secure and airtight environment. A well-functioning closure system not only improves performance but also enhances the overall safety of the device.

Below are the key elements that contribute to an effective sealing system:

- Gasket: A flexible ring that sits snugly around the lid, creating a tight seal to trap heat and moisture within the pot.

- Locking mechanism: This component ensures that the lid remains tightly closed throughout the cooking process, preventing accidental openings.

- Venting system: An integral feature that allows excess steam to escape, regulating internal pressure and enhancing

The Role of the Pressure Release Valve

The safety mechanism at the heart of any efficient cooking device plays a crucial role in managing internal forces and ensuring smooth operation. Its function is to regulate the buildup of energy within the system, releasing it when needed to prevent any potential risks. By controlling this process, the system remains both secure and effective, safeguarding the user during food preparation.

How It Maintains Balance

The valve’s primary purpose is to maintain a consistent level of internal conditions, allowing for the gradual release of excess pressure. This balance ensures that cooking remains efficient without compromising safety. Without this essential feature, the system could experience fluctuations, leading to uneven results or malfunctions.

Importance of Timely Release

By allowing controlled release, the valve prevents over-accumulation, which could otherwise strain the device. This timely adjustment not only enhances safety but also preserves the integrity of the cooking process

Why the Gasket is Crucial for Functionality

The sealing component plays a vital role in maintaining the overall effectiveness and safety of the cooking process. Without this essential part, achieving optimal performance becomes difficult, as it ensures that the internal environment remains stable during operation. A proper seal helps to prevent potential issues and maintains consistency in the cooking process.

Maintaining a Secure Seal

A well-functioning gasket ensures that no air escapes during the cooking process. This secure seal is critical to sustaining the necessary conditions inside the appliance. Any defects in this element can lead to reduced efficiency and compromise the entire cooking experience.

Prolonging the Lifespan of Your Appliance

Regular inspection and replacement of the gasket are key to keeping your kitchen tool in optimal condition. Ensuring that this sealing component is intact not only improves safety but also extends the lifespan of the entire system, allowing you to enjoy consistent results over time.

How the Lid Lock Enhances Security

The mechanism designed to secure the top of a cooking appliance plays a crucial role in ensuring safe operation. By preventing accidental opening during the cooking process, this feature minimizes the risk of mishaps and enhances the overall user experience. Understanding how this locking system works can provide valuable insights into its importance for safety in the kitchen.

Functionality and Design

The locking mechanism is engineered to engage automatically, creating a tight seal that withstands high temperatures and pressure. This design not only protects against spills but also ensures that steam remains contained, allowing for efficient cooking. Users can have peace of mind knowing that the lid will remain securely in place until it is safe to open.

Safety Benefits

By incorporating this essential feature, manufacturers prioritize user safety. The lock acts as a safeguard against unintended openings, which could lead to burns or other injuries. Additionally, it encourages proper usage by making it clear when the appliance is ready for lid removal. Overall, this component is vital in promoting safe cooking practices in the kitchen.

Pressure Indicator and Its Importance

The functionality of any cooking device relies heavily on various components working in harmony. One of the most crucial elements in ensuring optimal performance and safety is the mechanism that signals the internal condition of the vessel. This feature not only enhances efficiency but also plays a vital role in user safety, allowing for precise control during the cooking process.

Role of the Indicator in Cooking

This signaling device serves as a reliable gauge, providing real-time feedback on the vessel’s status. By clearly displaying changes in internal conditions, it helps users make informed decisions about cooking times and techniques. Without this feature, one could easily encounter overcooking or undercooking, leading to unsatisfactory results.

Safety Considerations

Moreover, the presence of a functional signaling device is paramount for maintaining safety standards. It prevents dangerous situations that could arise from excessive buildup within the vessel. Understanding the importance of this component can significantly enhance the overall cooking experience by ensuring that the user is always aware of the device’s condition, thereby reducing the risk of accidents.

Identifying the Steam Venting System

The steam venting mechanism is crucial for regulating pressure and ensuring safe operation during cooking. Understanding its components and functions can enhance the overall cooking experience by providing insights into how steam is released and how to maintain optimal performance. This section will guide you through the key elements of this essential system.

Key Components of the Venting System

The venting system comprises several vital components that work together to manage steam release effectively. Familiarity with these parts can aid in troubleshooting and maintenance.

Component Function Steam Vent Allows steam to escape during cooking, preventing pressure buildup. Vent Valve Controls the flow of steam, ensuring precise pressure regulation. Sealing Ring Ensures a tight fit between the lid and body, preventing steam leakage. Importance of Proper Functionality

Ensuring the steam venting system operates correctly is vital for achieving desired cooking results and maintaining safety. Regular checks and maintenance can prevent issues related to pressure buildup and improve the efficiency of the cooking process.

Maintenance Tips for Long-Lasting Parts

Ensuring the longevity of essential components in your cooking appliance requires regular care and attention. Proper maintenance not only enhances performance but also extends the lifespan of the device. By implementing a few simple practices, you can keep the key elements functioning efficiently and safely.

Regular Cleaning Practices

Maintaining cleanliness is crucial for optimal performance. After each use, take the time to clean the inner chamber and any accessories thoroughly. This prevents the buildup of residue that could affect functionality. Use mild detergents and soft cloths to avoid damaging surfaces.

Routine Inspection and Replacement

Periodically inspect the components for signs of wear or damage. Look for cracks, fraying, or other issues that may indicate the need for replacement. Keeping an eye on these elements ensures that you can address any problems before they escalate.

Maintenance Task Frequency Notes Clean the inner chamber After each use Use mild soap and water Inspect sealing elements Monthly Replace if damaged Check valves and vents Every 3 months Ensure no obstructions Lubricate moving parts Annually Use recommended lubricants

Key Components Inside the Cooking Pot

The interior of a modern cooking vessel is composed of several crucial elements that work together to ensure smooth operation and efficient performance. Understanding these components can help in the maintenance and optimal use of the device.