In the realm of fluid dynamics, the intricacies of various mechanisms play a crucial role in ensuring efficient operation. Grasping the relationship between each element is vital for maintaining optimal performance and reliability. This section aims to provide clarity on the essential elements that contribute to the smooth functioning of these systems.

By exploring the intricate connections and functionalities of individual components, users can better appreciate the overall system design. Identifying each element’s role not only enhances operational efficiency but also aids in troubleshooting and maintenance. Through this exploration, readers will gain insights that are ultimately beneficial for effective management.

Furthermore, understanding the layout and interactions between these components allows for more informed decision-making when it comes to repairs or upgrades. With this knowledge, one can delve deeper into the specifics, enhancing both performance and longevity. In the following sections, we will unravel these components in greater detail, equipping you with the information needed for successful engagement with your system.

Understanding Bell & Gossett Pumps

This section explores the intricacies of a renowned manufacturer specializing in fluid circulation solutions. Their equipment is essential in various applications, providing reliability and efficiency. A deeper understanding of these devices can enhance operational effectiveness and longevity.

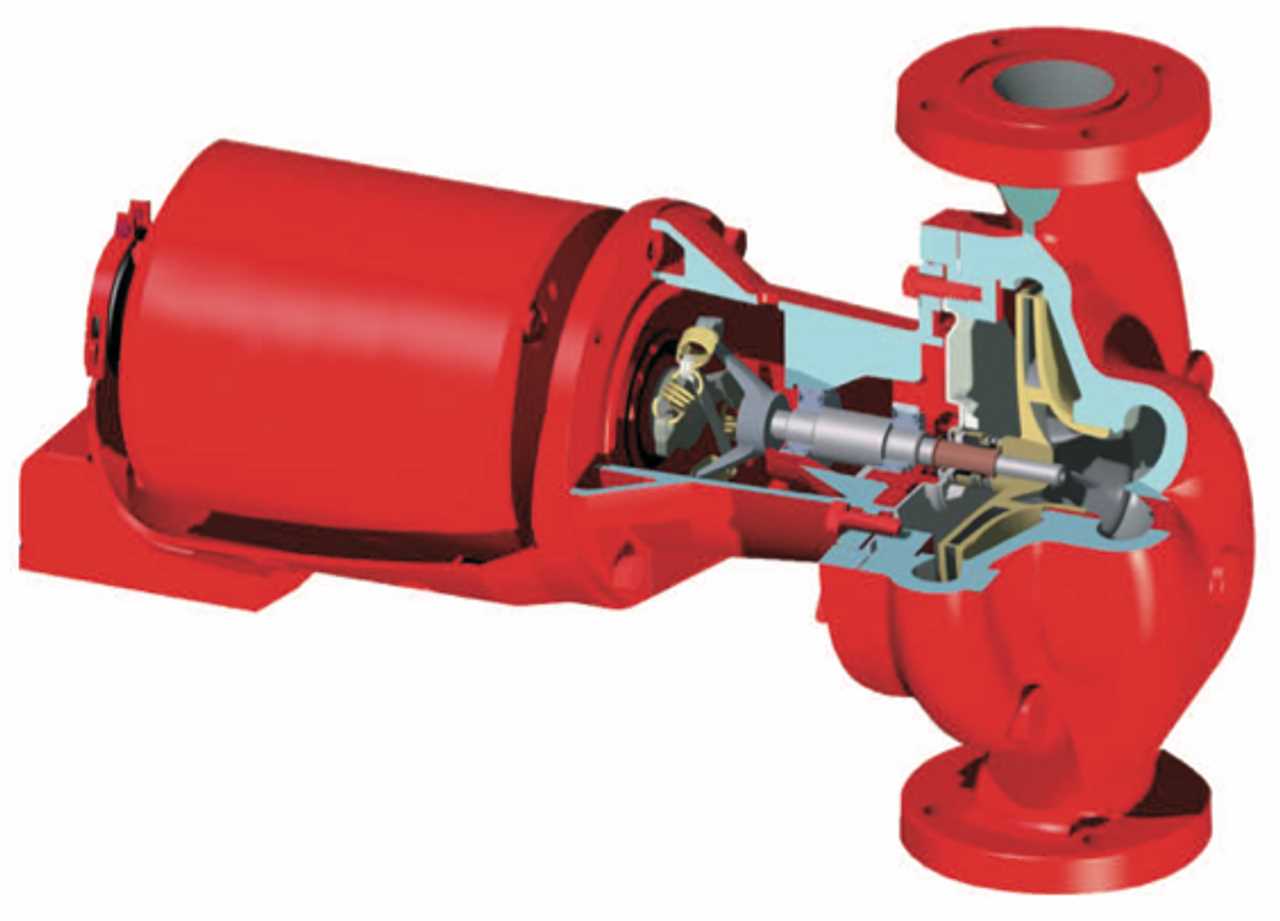

Key Components and Functionality

Each unit consists of several crucial elements that contribute to its overall performance. These components work harmoniously to facilitate fluid movement, ensuring optimal flow rates and pressure management.

Maintenance and Best Practices

Regular upkeep is vital for sustained efficiency. Implementing best practices in care can prevent unexpected failures and extend the lifespan of these sophisticated devices. Monitoring and regular inspections are essential for identifying potential issues before they escalate.

Importance of Pump Parts Diagram

Understanding the intricate elements of a mechanical system is crucial for optimal functionality and maintenance. Visual representations of components enhance comprehension and facilitate efficient repairs, ensuring longevity and reliability in operations.

Here are several reasons why such visual aids are essential:

- Enhanced Clarity: Diagrams provide a clear view of the arrangement and interaction between various elements, making it easier for technicians to understand complex assemblies.

- Improved Troubleshooting: When issues arise, having a visual reference allows for quicker identification of faulty components, reducing downtime and improving response times.

- Streamlined Maintenance: Regular upkeep becomes more efficient when one can easily identify parts that require attention, leading to better overall performance.

- Training Resource: New employees benefit from visual aids, which serve as effective tools for learning about the system’s structure and operation.

- Documentation Support: Accurate representations assist in maintaining records, ensuring that modifications and repairs are well-documented for future reference.

In summary, the use of visual guides for mechanical components is vital for effective management, facilitating understanding, maintenance, and operational efficiency.

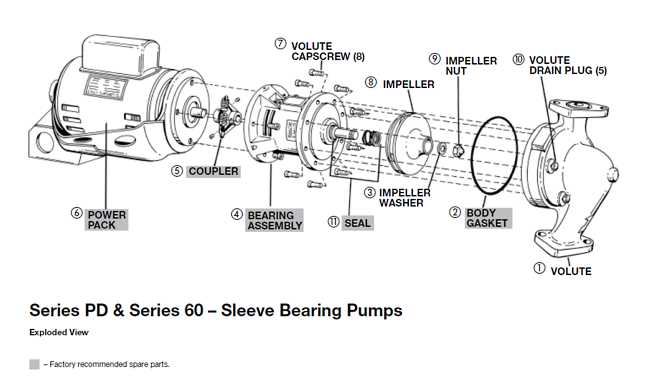

Common Components of Bell & Gossett

Understanding the key elements of a fluid transfer system is essential for efficient operation. These components play a vital role in ensuring reliability and performance.

- Impeller: Responsible for moving the fluid through the system.

- Motor: Powers the impeller and drives the entire mechanism.

- Volute: Directs the flow of the fluid efficiently from the impeller.

- Seals: Prevent leaks and maintain pressure within the system.

- Bearing: Supports the rotating shaft and reduces friction.

Each of these components contributes to the ultimate functionality and effectiveness of the system, making their understanding crucial for maintenance and troubleshooting.

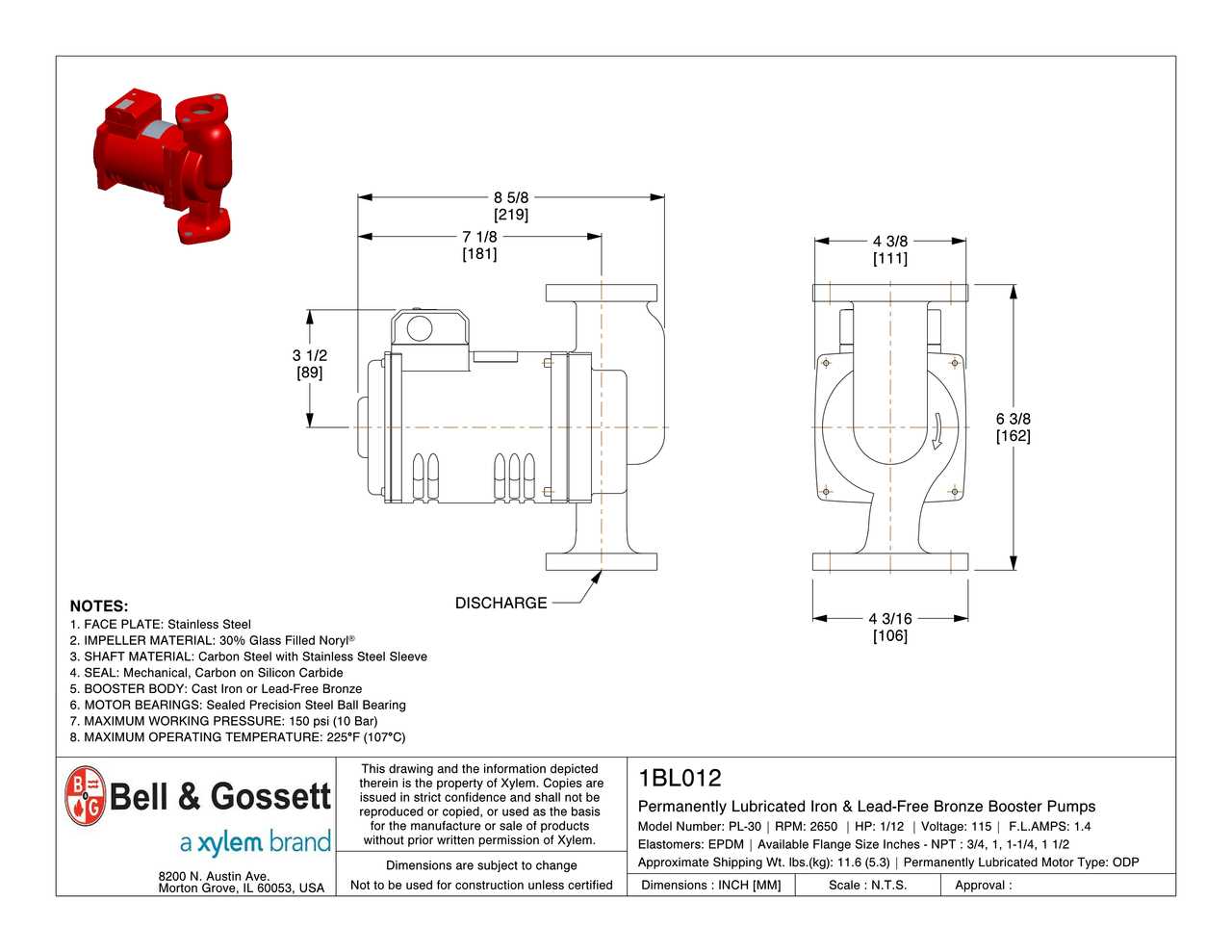

How to Read Pump Diagrams

Understanding schematic representations is essential for effective maintenance and troubleshooting in various mechanical systems. These visual aids provide crucial information about the components and their interconnections, enabling users to analyze and resolve issues efficiently.

Key Elements to Identify

When examining a schematic, it’s important to recognize several core elements:

- Symbols: Each component is represented by a specific symbol, often standardized across the industry.

- Labels: Annotations indicate the names, specifications, and functions of the components.

- Connections: Lines and arrows illustrate how different elements are linked, showing the flow of operation.

Steps for Effective Interpretation

- Familiarize Yourself: Review the legend or key to understand the symbols used in the representation.

- Trace the Flow: Follow the pathways indicated by arrows to understand the sequence of operation.

- Note Specifications: Pay attention to any listed data, such as sizes and capacities, for each component.

- Identify Critical Components: Recognize which parts are essential for the system’s functionality and may require more attention.

By mastering these aspects, one can navigate through schematics with confidence, enhancing both repair and operational processes.

Maintenance Tips for Pump Longevity

Ensuring the extended lifespan of your machinery requires regular attention and proper care. By adopting systematic maintenance practices, you can prevent potential issues and enhance efficiency. Here are some essential recommendations to keep your system in optimal condition:

- Regular Inspections: Schedule frequent evaluations to detect wear and tear early.

- Keep Components Clean: Remove dust and debris to prevent clogging and overheating.

- Check Seals and Gaskets: Inspect for leaks and replace any worn seals promptly.

- Monitor Operating Conditions: Ensure temperature and pressure remain within recommended ranges.

By implementing these practices, you can significantly reduce the likelihood of unexpected breakdowns and maintain operational efficiency.

- Lubricate Moving Parts: Use appropriate lubricants to minimize friction and wear.

- Replace Filters Regularly: Ensure optimal fluid flow by maintaining clean filters.

- Calibrate Sensors: Regularly check and adjust sensors for accurate readings.

- Train Personnel: Educate operators on proper handling and troubleshooting techniques.

Consistent adherence to these guidelines will help you achieve a reliable and efficient system, ultimately extending its life cycle and performance.

Troubleshooting Pump Issues

Identifying and resolving challenges in fluid-moving machinery is crucial for maintaining efficiency and extending equipment lifespan. Common issues can manifest in various forms, often indicating underlying problems that need addressing. This section outlines key steps to diagnose and rectify typical complications.

Common Symptoms and Their Causes

- No Flow: Check for blockages, closed valves, or issues with the power source.

- Strange Noises: Unusual sounds may indicate wear or misalignment. Inspect bearings and connections.

- Overheating: Assess for low fluid levels, improper installation, or excessive wear on components.

- Vibrations: Examine for imbalance, loose fittings, or foundation issues.

Step-by-Step Troubleshooting Process

- Begin with a visual inspection to identify obvious problems.

- Check fluid levels and ensure all valves are functioning correctly.

- Listen for abnormal sounds and observe any unusual vibrations.

- Review operational parameters against manufacturer specifications.

- Consult the maintenance manual for specific diagnostic procedures.

Choosing Replacement Parts Wisely

When it comes to maintaining equipment, selecting the right components is crucial for ensuring optimal performance and longevity. Informed decisions can prevent costly breakdowns and enhance efficiency. This section outlines key considerations for making smart choices when sourcing new elements for your system.

Firstly, understanding compatibility is vital. Not all components are created equal; hence, knowing which ones fit your specific model can save time and resources. It’s advisable to consult manuals or seek expert advice to ensure that the new pieces will integrate seamlessly with your existing setup.

| Consideration | Description |

|---|---|

| Quality | Opt for high-grade materials that promise durability and reliability. |

| Manufacturer Reputation | Research the suppliers and prioritize those known for excellence in production. |

| Warranty | Look for products that come with a guarantee, indicating confidence in their performance. |

| Cost | Balance affordability with quality; the cheapest option may not always be the best choice. |

Additionally, staying informed about advancements in technology can lead to better alternatives. Newer models may offer enhanced functionality or energy efficiency, making them a worthwhile investment. Always consider future needs to ensure that selected components will serve you well in the long run.

By prioritizing these aspects, you can enhance the reliability and efficiency of your system while avoiding common pitfalls associated with subpar replacements.

Installation Guide for New Parts

Ensuring proper assembly of components is crucial for optimal performance and longevity of your system. This guide outlines the essential steps for effectively integrating new elements into your existing setup, emphasizing safety and precision throughout the process.

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and new components required for the installation. |

| 2 | Turn off power and ensure the system is completely safe to work on. |

| 3 | Carefully remove the old components, taking note of their configuration. |

| 4 | Install the new elements in accordance with the specifications provided. |

| 5 | Double-check all connections and ensure everything is secure before restoring power. |

Following these steps will help guarantee a successful integration, leading to improved functionality and reliability in your operations.

Understanding Pump Performance Metrics

Evaluating the efficiency and reliability of a fluid-moving device requires a clear understanding of its performance indicators. These metrics serve as critical benchmarks, helping users assess functionality, optimize operations, and anticipate maintenance needs.

Key performance indicators include:

- Flow Rate: The volume of fluid transported over a specified period, typically measured in gallons per minute (GPM) or liters per second (L/s).

- Head Pressure: The height to which the fluid is elevated, indicating the energy imparted to the fluid, usually expressed in feet or meters.

- Efficiency: The ratio of the useful work output to the energy input, reflecting how effectively the device converts energy into fluid movement.

- NPSH (Net Positive Suction Head): A critical value that ensures adequate pressure at the inlet to prevent cavitation, expressed in feet or meters.

Understanding these metrics allows operators to:

- Make informed decisions regarding equipment selection.

- Monitor performance over time to detect inefficiencies.

- Implement strategies for improved operational efficiency.

- Reduce the risk of equipment failure and extend service life.

In summary, grasping these essential metrics is vital for anyone involved in the management and operation of fluid transport systems, ensuring optimal performance and longevity.

Innovations in Pump Technology

Recent advancements in fluid transfer mechanisms have significantly transformed the industry, enhancing efficiency, reliability, and sustainability. The evolution of these systems incorporates cutting-edge materials and smart technologies that optimize performance and reduce energy consumption.

Smart Technologies

- Integration of IoT for real-time monitoring

- Predictive maintenance to minimize downtime

- Automation features for improved control

Material Innovations

- Use of corrosion-resistant composites

- Lightweight alloys for improved durability

- Eco-friendly options to reduce environmental impact

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of fluid movement systems and their components. Various sources provide in-depth information, practical insights, and expert advice, allowing you to delve deeper into the subject.

Online Courses: Numerous platforms offer specialized courses focusing on mechanical systems, fluid dynamics, and related technologies. These courses often include interactive elements and assessments to solidify your knowledge.

Technical Manuals: Comprehensive guides published by manufacturers can be invaluable. They typically cover specifications, installation procedures, and maintenance tips, serving as essential references.

Forums and Community Groups: Engaging with professionals in dedicated online communities allows for the exchange of experiences and solutions to common challenges. This collaboration can lead to a greater understanding of practical applications.

Webinars and Workshops: Attending live sessions hosted by industry experts can provide real-time insights and updates on the latest technologies and best practices, making learning more dynamic.

Books and Publications: Reading authoritative texts on the principles of mechanical engineering and system design can build a strong theoretical foundation, helping you grasp complex concepts.