The intricate world of hydraulic machinery encompasses a variety of mechanisms that work together seamlessly to deliver efficient performance. In this section, we will explore the essential visual representations that assist in understanding the complexities of these systems. By delving into these schematics, users can gain insight into how various elements interact, ensuring optimal functionality and maintenance.

These visual aids serve as valuable tools for technicians and engineers alike, enabling them to identify specific features and configurations. The ability to interpret such illustrations is crucial for diagnosing issues and implementing effective solutions. Furthermore, these resources simplify the learning process, making it easier for newcomers to grasp the fundamentals of hydraulic operations.

Through a careful examination of these representations, one can appreciate the design and engineering excellence that underpins modern machinery. Each illustration provides a snapshot of the relationships between components, highlighting the importance of precision and accuracy in hydraulic systems. By enhancing our understanding of these connections, we can foster greater innovation and efficiency in the field.

Understanding Cat Pumps Components

This section delves into the intricate elements that comprise high-performance hydraulic systems. By examining each individual component, one can appreciate how they function collaboratively to enhance efficiency and reliability in various applications. Recognizing the significance of each piece is crucial for effective maintenance and troubleshooting.

Key Elements of Hydraulic Systems

Within these systems, several critical components play pivotal roles. The cylinders are responsible for generating motion, while the valves control fluid flow, ensuring optimal operation. Understanding the relationship between these elements is essential for maximizing system performance.

Maintenance and Longevity

Regular upkeep of the individual components is vital to prolonging the lifespan of the entire assembly. Identifying wear and tear early can prevent significant failures. Implementing a routine check-up of essential parts enhances overall functionality and guarantees reliability in demanding conditions.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and functionality in complex systems. Accurate illustrations serve as essential tools for understanding the intricate relationships and components involved. The clarity and detail provided by well-crafted visuals can significantly impact efficiency and reliability.

Here are several reasons why precise representations are vital:

- Enhanced Understanding: Clear visuals help users comprehend complex mechanisms easily, reducing the likelihood of errors.

- Improved Communication: Well-defined illustrations facilitate better discussions among teams, ensuring everyone is on the same page.

- Streamlined Maintenance: Accurate depictions guide technicians during repair and maintenance, minimizing downtime and costs.

- Increased Safety: Detailed visuals highlight critical components, promoting safe handling and operational practices.

- Efficient Training: High-quality representations are invaluable for educating new personnel, allowing for faster onboarding and proficiency.

In summary, the significance of precise visual aids cannot be overstated. They are foundational for successful operations, maintenance, and training across various industries.

Common Issues with Pump Parts

Understanding the frequent complications that arise in hydraulic mechanisms is essential for effective maintenance and longevity. Various factors can contribute to these challenges, including wear and tear, improper installation, and environmental influences. Addressing these issues promptly can prevent costly downtime and ensure optimal performance.

One prevalent concern involves leaks, often caused by degraded seals or gaskets. When these components fail, it can lead to significant loss of fluid, resulting in reduced efficiency and potential environmental hazards. Regular inspection and timely replacement of worn seals can mitigate this issue.

Another common problem is cavitation, which occurs when vapor bubbles form and collapse within the system. This phenomenon can cause severe damage to internal surfaces, leading to reduced functionality. Ensuring proper operating conditions and monitoring fluid levels can help prevent cavitation.

Additionally, contamination from foreign particles can obstruct flow and impair the overall efficiency of the system. Implementing effective filtration and routine cleaning can reduce the risk of contamination, ensuring smooth operation.

Lastly, misalignment during assembly can lead to excessive wear and premature failure of critical components. Regular alignment checks and adherence to manufacturer guidelines are vital to avoid such complications. Proactive measures in these areas can significantly enhance the reliability and performance of hydraulic systems.

How to Read Diagrams Effectively

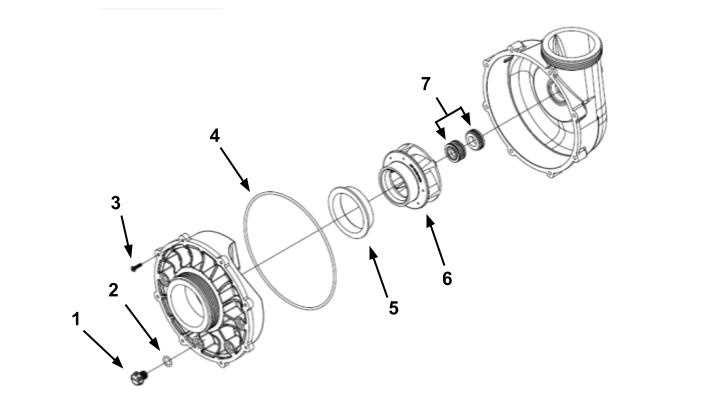

Understanding visual representations is essential for anyone working with mechanical systems. These illustrations provide a detailed overview of components and their relationships, allowing for better maintenance and troubleshooting. Grasping how to interpret these visuals can significantly enhance your efficiency and accuracy when performing tasks.

Start by familiarizing yourself with the symbols and notations used in the illustration. Each representation has a specific meaning, and knowing these will help you decipher the information more quickly. Look for a legend or key that explains the various symbols, as this will serve as your guide.

Next, focus on the layout. Most visuals are organized in a logical manner, often indicating flow or sequence. Pay attention to how components are arranged and connected; this can reveal how they interact with each other and the overall system. Note the orientation and direction indicated by arrows or lines, as these are crucial for understanding functionality.

Lastly, practice makes perfect. The more you work with these visuals, the more proficient you will become at interpreting them. Regular review and application of the knowledge gained from these illustrations will lead to improved comprehension and confidence in handling mechanical systems.

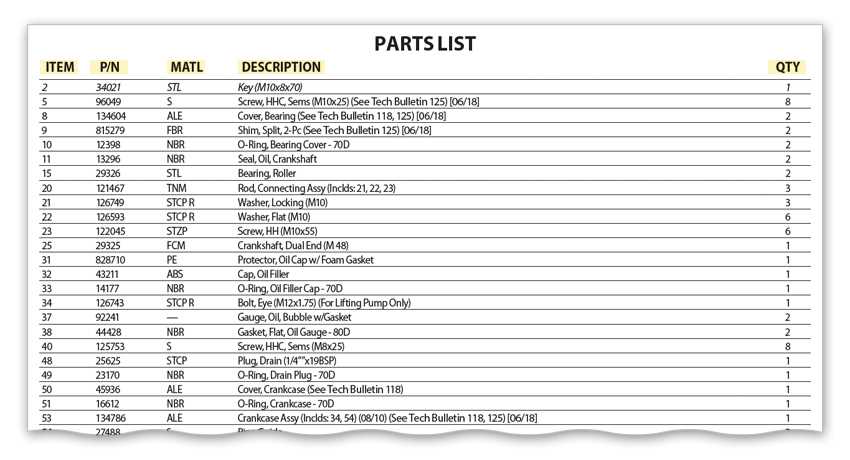

Identifying Key Components in Pumps

Understanding the essential elements within pumping mechanisms is crucial for effective maintenance and troubleshooting. Each component plays a pivotal role in the functionality and performance of these systems. By recognizing and comprehending these integral parts, technicians can ensure optimal operation and longevity.

| Main Mechanism | Core Structure |

| Primary Unit | Central Framework |

| Key Elements | Essential Framework |

Within the operational context of pumps, these components collectively contribute to the seamless function of fluid transfer and pressure generation. Each piece, whether foundational or supplementary, serves a distinct purpose in the overall assembly. Recognizing these elements empowers maintenance personnel to diagnose issues accurately and execute targeted repairs efficiently.

Maintenance Tips for Cat Pumps

Regular upkeep of hydraulic equipment is essential for ensuring optimal performance and longevity. Implementing a few straightforward strategies can prevent malfunctions and enhance efficiency, leading to a smoother operation and reduced downtime.

Routine Inspection

- Check seals and gaskets for wear and tear.

- Examine hoses for leaks or damage.

- Inspect the pressure relief valve to ensure it functions correctly.

Cleaning and Lubrication

- Clean the exterior regularly to prevent dust accumulation.

- Apply appropriate lubricants to moving parts as per the manufacturer’s guidelines.

- Ensure all lubrication points are easily accessible and maintained.

By adhering to these maintenance practices, operators can significantly extend the lifespan of their hydraulic systems and maintain optimal operational standards.

Tools Needed for Repairs

In order to effectively perform maintenance tasks on your equipment, it’s essential to have the right tools at hand. Proper tools not only streamline the repair process but also ensure precision and safety throughout. Below is a comprehensive list of equipment necessary for conducting repairs on machinery:

- Adjustable wrenches for versatile tightening and loosening tasks

- Screwdrivers of various sizes, both flathead and Phillips, for accessing and securing components

- Socket and ratchet sets for efficiently handling bolts and nuts

- Pliers, including needle-nose and locking types, for gripping and manipulating small parts

- Allen wrenches for fastening socket head screws

- Hammer and mallet for gentle tapping and adjusting

- Torque wrench for precise tightening according to manufacturer specifications

- Wire cutters and strippers for electrical work

- Multimeter for testing electrical components and circuits

- Lubricants and penetrating oils to aid in disassembly and prevent corrosion

By ensuring you have these tools readily available and properly maintained, you can enhance the efficiency and reliability of your repair work, contributing to the longevity and performance of your machinery.

Safety Precautions During Servicing

When conducting maintenance on machinery, adhering to safety measures is paramount. These protocols not only protect the technician but also ensure the longevity and efficiency of the equipment. Understanding the potential hazards and implementing the appropriate precautions can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is essential during maintenance tasks. This includes gloves, safety goggles, and ear protection. Gloves shield hands from sharp edges and hazardous substances, while safety goggles protect the eyes from debris and splashes. Ear protection is crucial in loud environments to prevent hearing damage.

Tool and Equipment Handling

Proper handling of tools and machinery is vital for safe servicing. Ensure that all tools are in good condition and suitable for the task at hand. Always follow the manufacturer’s instructions for tool usage. Additionally, disconnect the equipment from its power source before commencing any repair work to prevent accidental start-up.

Where to Find Official Resources

Accessing accurate and reliable information is crucial for effective maintenance and operation of machinery. Numerous sources offer official documentation and guidance, ensuring that users can find the necessary materials to support their equipment. This section outlines where to locate these valuable resources.

Manufacturer’s Website

One of the most direct methods for obtaining authentic materials is through the manufacturer’s official website. Most manufacturers provide comprehensive sections dedicated to support, where users can download manuals, view technical specifications, and access troubleshooting guides. Regularly checking this platform can keep users informed about the latest updates and product enhancements.

Authorized Distributors and Dealers

Another excellent avenue for finding credible information is through authorized distributors and dealers. These entities often have exclusive access to proprietary materials and can provide personalized assistance based on specific equipment needs. Engaging with these professionals not only ensures access to authentic documentation but also opens the door to expert advice and support.

Differences Between Model Variants

Understanding the distinctions among different variants of equipment is essential for selecting the most suitable option for specific applications. Each version offers unique features and specifications that cater to diverse operational requirements, influencing efficiency and performance in various environments.

Key Variations

The models available in the market often vary in design, functionality, and adaptability. These differences can significantly affect their suitability for particular tasks. Below are some of the primary aspects where variants differ:

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Output Pressure | 2000 PSI | 2500 PSI | 3000 PSI |

| Flow Rate | 3 GPM | 4 GPM | 5 GPM |

| Weight | 50 lbs | 55 lbs | 60 lbs |

| Materials | Aluminum | Stainless Steel | Brass |

Application Suitability

Each variant is designed with specific applications in mind. While one may excel in high-pressure tasks, another may be better suited for larger flow requirements. Evaluating the intended use can guide users in choosing the most effective model.

Best Practices for Diagram Usage

Utilizing visual representations effectively can significantly enhance understanding and facilitate communication in various technical fields. By adhering to established methods, users can maximize the benefits derived from these visual tools, leading to improved efficiency and clarity.

1. Ensure Clarity and Simplicity

To promote comprehension, it is essential to maintain clarity in visual representations. Follow these guidelines:

- Use straightforward language and labels.

- Avoid clutter by focusing on essential elements.

- Employ a consistent style and format throughout the visuals.

2. Keep the Audience in Mind

Tailor visual aids to the audience’s level of expertise and familiarity. Consider the following:

- Identify the primary users and their specific needs.

- Incorporate relevant examples that resonate with the target group.

- Provide additional explanations or resources for those needing further assistance.