In the realm of efficient fluid management, comprehending the intricate assembly of mechanisms is crucial for optimal functionality. This section aims to illuminate the key elements involved in maintaining a seamless flow, ensuring the longevity and performance of the system.

Visualizing the Structure plays a pivotal role in troubleshooting and enhancing performance. By examining the relationships between various components, users can gain deeper insights into their operations and identify potential areas for improvement.

Delving into the specifics of these configurations allows for a more informed approach to maintenance and upgrades. Ultimately, a thorough understanding of these crucial elements is indispensable for anyone looking to optimize their setup.

Understanding Century Centurion Pool Pumps

In the realm of aquatic maintenance, a robust mechanism plays a vital role in ensuring optimal functionality and longevity. The intricate design and engineering of these devices are tailored to enhance water circulation and filtration, ultimately contributing to a pristine aquatic environment.

Key components of these systems work in harmony, creating an efficient workflow that caters to various needs. Understanding how each element operates can greatly improve overall performance and reliability.

Regular maintenance and awareness of potential issues can prevent malfunctions and extend the lifespan of the apparatus. This knowledge empowers users to make informed decisions regarding repairs and upgrades, enhancing their experience.

Key Components of Pool Pump Systems

The functionality of water circulation systems relies on several crucial elements that ensure efficient operation. Understanding these components can enhance maintenance and troubleshooting efforts, ultimately leading to a more effective system performance.

| Component | Description |

|---|---|

| Motor | The driving force behind the entire mechanism, converting electrical energy into mechanical motion. |

| Impeller | This rotating component moves water through the system, creating the necessary flow. |

| Strainer | Acts as a filter to prevent debris from entering the system, protecting internal components. |

| Volute | A casing that directs the flow of water from the impeller into the discharge pipe. |

| Seals | Prevent leaks and maintain pressure within the system, crucial for optimal performance. |

| Base | Provides stability and support for the entire assembly, ensuring safe operation. |

Recognizing these essential elements allows for better care and understanding of the entire water management setup, leading to improved longevity and efficiency.

Common Issues with Pool Pump Parts

Understanding frequent complications with aquatic circulation devices can enhance their longevity and efficiency. These challenges often arise from wear and tear, leading to diminished performance and increased energy consumption.

Typical Problems

- Clogs due to debris accumulation

- Seal leaks causing fluid loss

- Motor overheating from overuse

- Noisy operation indicating mechanical failure

Preventive Measures

- Regular cleaning to prevent blockages

- Inspecting seals for wear

- Monitoring motor performance

- Scheduling routine maintenance checks

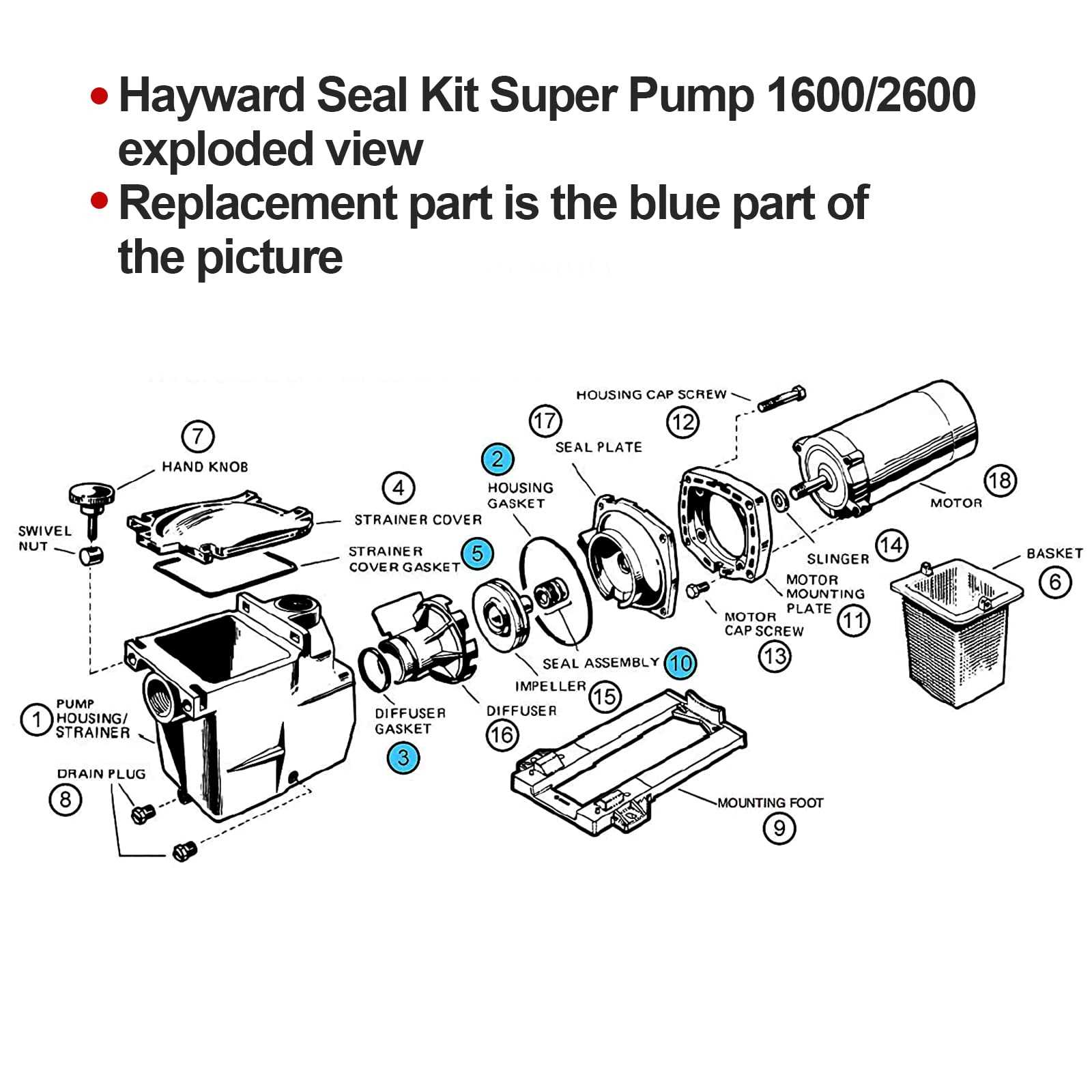

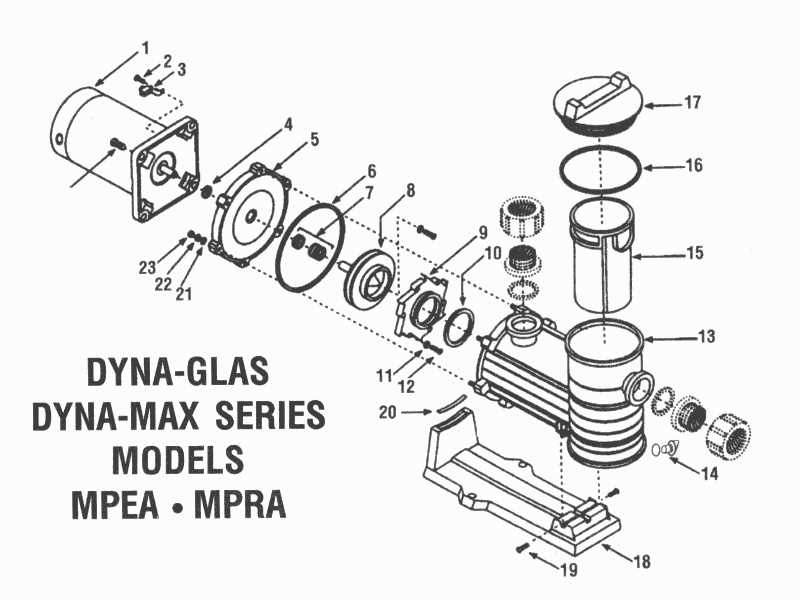

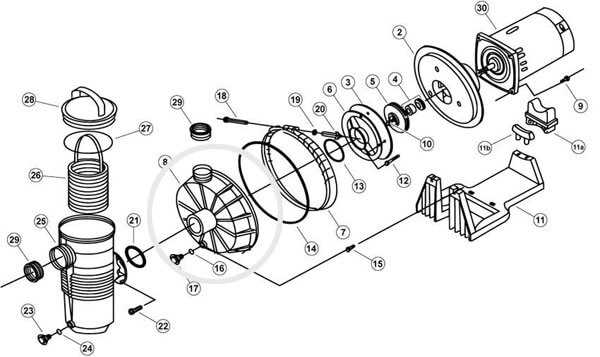

Identifying Parts on Pump Diagrams

Understanding the components depicted in technical illustrations is essential for effective maintenance and troubleshooting. Familiarity with these schematics enables users to quickly locate and address issues within the system, ensuring optimal performance.

Key Components to Recognize

- Motor: The driving force behind the operation.

- Impeller: Responsible for moving fluid through the system.

- Housing: The outer shell that protects internal mechanisms.

- Seal: Prevents leaks and maintains pressure.

Tips for Effective Identification

- Familiarize yourself with common terminology.

- Use a magnifying glass for clearer details in complex diagrams.

- Refer to manufacturer resources for specific illustrations.

- Practice by sketching parts to reinforce memory.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires regular attention and care. By following a systematic maintenance routine, you can significantly extend its lifespan and improve efficiency. This section outlines essential practices that will help you maintain optimal functionality and avoid premature wear and tear.

First, regularly inspect all components for signs of damage or wear. Identifying issues early can prevent costly repairs down the line. Cleanliness is also crucial; removing debris and buildup not only enhances performance but also reduces the risk of malfunction. Make it a habit to check and clean filters as part of your routine maintenance.

Lubrication plays a vital role in reducing friction and wear. Ensure that moving parts are adequately lubricated according to the manufacturer’s recommendations. Additionally, monitoring operational sounds can alert you to potential problems; unusual noises often indicate that something requires attention.

Lastly, consider seasonal maintenance checks to prepare your system for changes in usage. This proactive approach helps identify any necessary adjustments or repairs, ensuring that your equipment operates smoothly throughout the year. By committing to these maintenance practices, you can enjoy reliable service for years to come.

How to Replace Pump Components

Maintaining the efficiency of your equipment often requires swapping out various elements. Understanding the process of component replacement can significantly enhance performance and longevity. Here’s a concise guide to help you navigate this task effectively.

Before you start, ensure you have the necessary tools and replacement items. It’s crucial to follow the manufacturer’s guidelines closely for a successful operation.

| Step | Description |

|---|---|

| 1 | Turn off the power supply to the unit to ensure safety. |

| 2 | Remove the housing cover using a screwdriver or appropriate tool. |

| 3 | Identify the component that needs replacing and detach it carefully. |

| 4 | Install the new element, ensuring it fits snugly in place. |

| 5 | Replace the housing cover and secure it properly. |

| 6 | Restore the power supply and test the system for functionality. |

By following these steps, you can effectively maintain the operational standards of your machinery and ensure its ultimate efficiency.

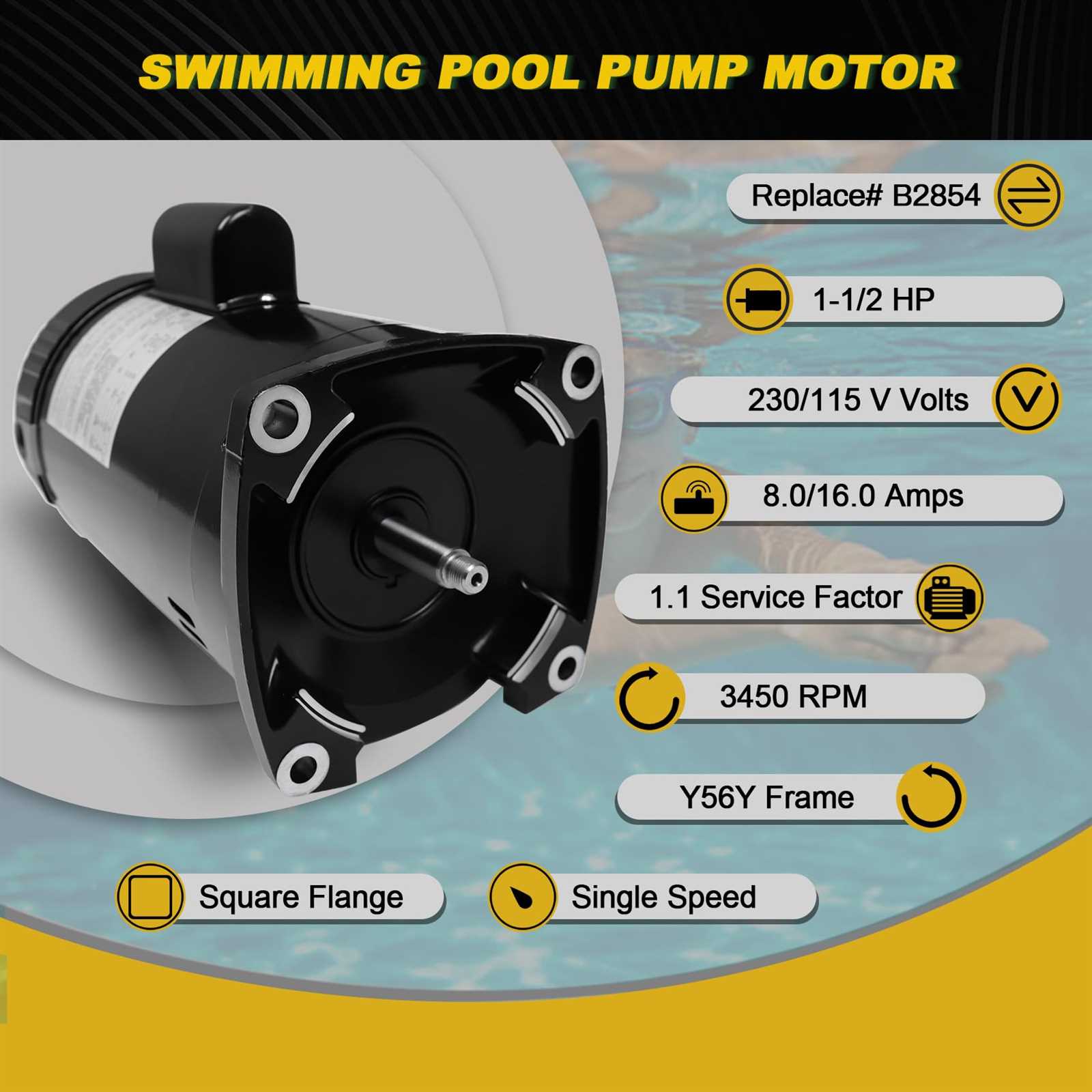

Choosing the Right Replacement Parts

Selecting suitable components for your equipment is crucial for ensuring optimal performance and longevity. Making informed decisions can help prevent future issues and maintain efficiency. Here are some key considerations when evaluating your options.

- Compatibility: Ensure the replacement items match your existing system specifications to avoid functionality problems.

- Quality: Opt for high-quality materials that can withstand wear and tear, reducing the need for frequent replacements.

- Manufacturer Reputation: Research brands known for reliability and durability, as these often provide better support and warranties.

- Cost: While budget is important, weigh the price against quality. Sometimes, spending a bit more upfront can save money in the long run.

By focusing on these aspects, you can effectively choose components that enhance performance and extend the life of your system. Always consult with a professional if you’re unsure about your selections.

Exploring Pump Motor Types

Understanding the various motor types is essential for optimizing performance and efficiency in any water circulation system. Each motor variant offers unique advantages, influencing the overall effectiveness of the machinery it powers. A thorough grasp of these differences enables users to make informed choices, ensuring that the selected motor aligns with specific operational requirements.

Induction motors are among the most prevalent due to their reliability and low maintenance needs. They operate by creating a magnetic field that induces rotation, making them suitable for continuous use in many applications. Conversely, brushless motors provide enhanced energy efficiency and quieter operation, appealing to those seeking reduced energy costs and noise levels.

Variable speed motors offer the flexibility to adjust performance based on demand, which can lead to significant energy savings. Their ability to adapt to changing conditions makes them ideal for systems requiring variable flow rates. In contrast, single-speed motors are simpler and often more cost-effective but may not offer the same level of energy efficiency or adaptability.

When selecting a motor, considerations such as application type, energy consumption, and desired lifespan should guide the decision-making process. By exploring the characteristics and benefits of each motor type, users can enhance their systems and achieve optimal results.

Benefits of Using Quality Parts

Utilizing high-grade components in any system ensures optimal performance and longevity. Quality materials contribute significantly to the overall functionality, providing reliable operation and reducing the likelihood of failures.

- Durability: Superior components withstand wear and tear, extending the lifespan of the entire system.

- Efficiency: High-quality elements enhance performance, leading to better energy use and cost savings.

- Safety: Reliable materials minimize risks associated with malfunctions, ensuring safer operation.

- Warranty Support: Many manufacturers provide guarantees for top-tier products, offering peace of mind.

- Enhanced Performance: Quality components often lead to smoother operation and improved overall results.

Investing in superior materials ultimately leads to a more dependable and effective system, making it a wise choice for long-term satisfaction.

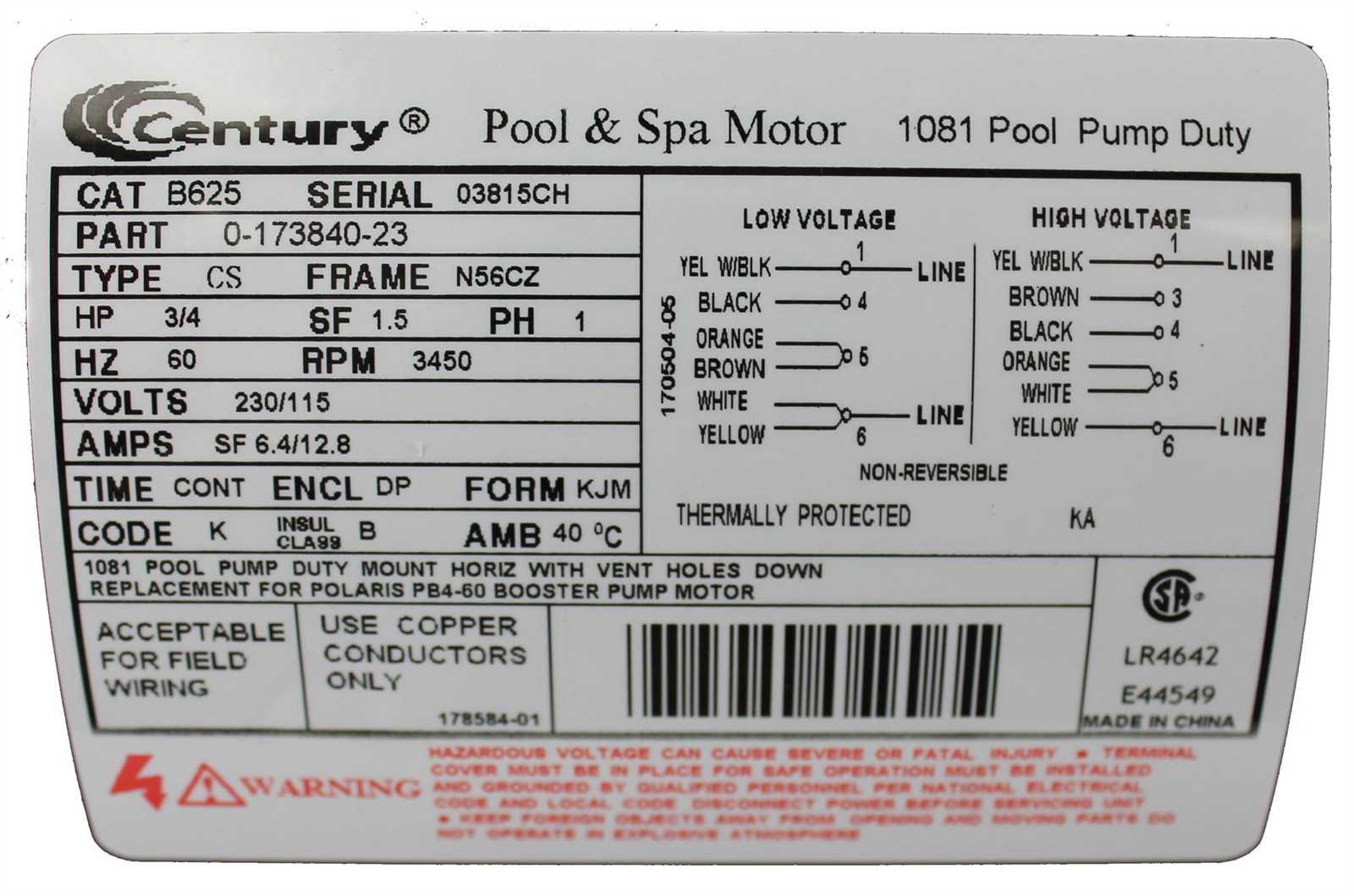

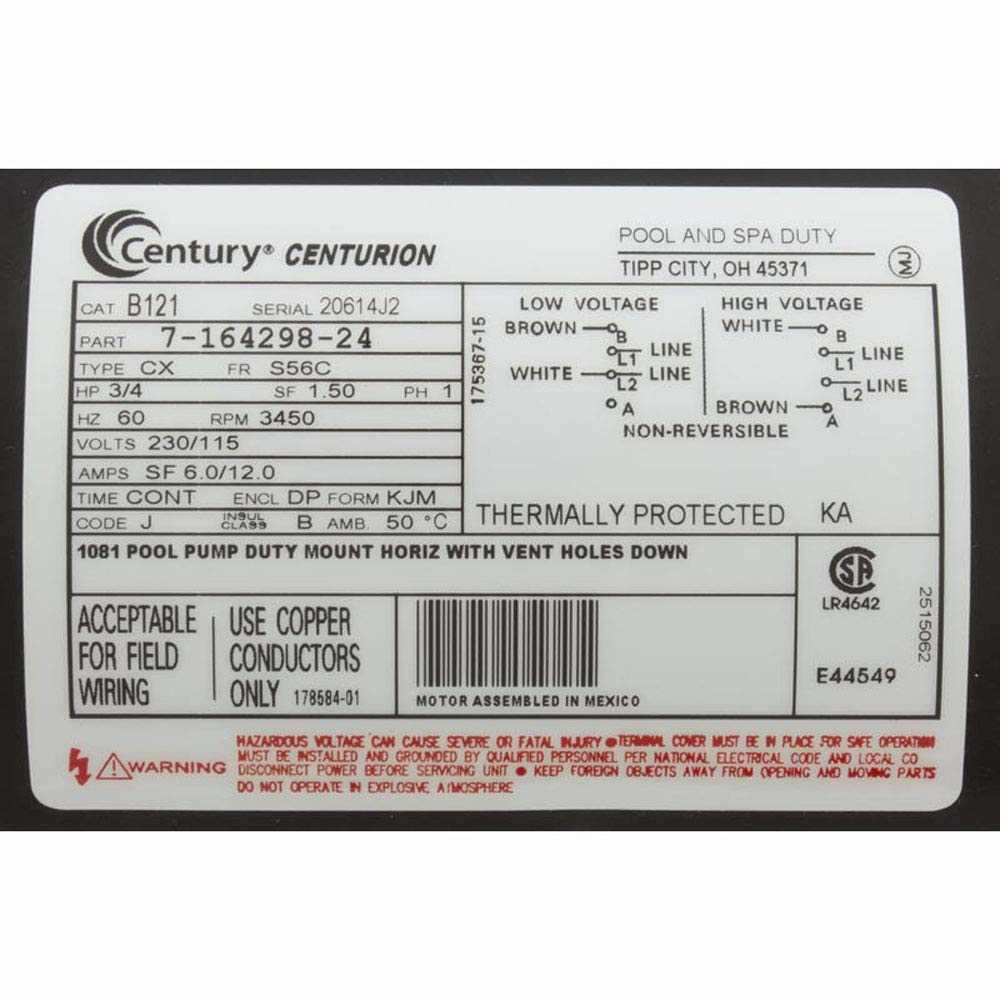

Wiring Diagram for Century Pumps

This section provides essential information regarding the electrical configurations for various water circulation devices. Understanding these layouts is crucial for effective installation, maintenance, and troubleshooting. Proper wiring ensures optimal performance and safety, preventing potential issues during operation.

The following table outlines the typical connections and their respective functions, which can guide users in managing their equipment efficiently.

| Connection | Function |

|---|---|

| Power Supply | Provides electrical energy to the unit. |

| Ground Wire | Ensures safety by preventing electrical shocks. |

| Control Switch | Allows the user to start and stop the device. |

| Capacitor | Assists in starting the motor efficiently. |

| Motor Leads | Connects to the motor for operation. |

Referencing these configurations can help in identifying issues and performing necessary repairs or upgrades effectively, ensuring that the device operates smoothly over time.

Reading the Manufacturer’s Manual

Understanding the documentation provided by the creator is essential for effective maintenance and operation of your equipment. This guide contains vital information that can enhance longevity and efficiency, ensuring that you get the most out of your investment.

Importance of the Manual

The manual serves multiple purposes:

- Instructions for setup and installation

- Troubleshooting guidelines

- Maintenance recommendations

- Safety precautions

How to Utilize the Manual Effectively

To make the most of the information available:

- Read thoroughly before starting any work.

- Refer to specific sections as needed.

- Keep the manual accessible for future reference.

- Highlight key points or procedures for quick access.

Upgrading vs. Repairing Your Pump

When faced with the choice of enhancing or fixing your equipment, several factors come into play. The decision can impact performance, longevity, and overall efficiency, leading to different outcomes depending on the route taken. Understanding the benefits and drawbacks of each option is essential to making an informed choice.

| Aspect | Upgrading | Repairing |

|---|---|---|

| Cost | Often higher initial investment | Generally lower immediate cost |

| Performance | Enhanced functionality and efficiency | May restore original performance |

| Longevity | Longer lifespan with modern technology | Short-term solution; risk of future failures |

| Time | Potentially longer installation period | Quicker fix, less downtime |

FAQs About Pool Pump Parts

This section addresses common inquiries regarding components essential for efficient water circulation systems. Understanding these elements can enhance performance and longevity, ensuring a seamless experience for users.

| Question | Answer |

|---|---|

| What are the main components of a water circulation system? | The primary elements include the motor, impeller, strainer basket, volute, and seal assembly. |

| How often should I replace the motor? | Typically, a motor can last several years, but it’s wise to inspect it annually for signs of wear. |

| What signs indicate a faulty impeller? | Common indicators include reduced flow, unusual noises, or visible damage. |

| How can I maintain the strainer basket? | Regular cleaning is essential; remove debris and rinse it with water to prevent clogs. |

| What is the purpose of the volute? | The volute helps direct water flow efficiently from the impeller to the discharge outlet. |

| When should I replace the seal assembly? | Replace the seal if you notice leaks or if it shows signs of deterioration. |