The intricate operation of a water-based relaxation system relies on multiple interconnected elements that ensure a smooth and efficient flow of liquid throughout the structure. Each element plays a vital role in maintaining the balance and functionality of the system, allowing users to experience optimal performance and comfort. By delving into the specific components responsible for these functions, we can gain a deeper appreciation for the complexity and precision behind the design.

From energy conversion to fluid movement, the system’s core elements are designed to work in unison. Each piece, regardless of its size or complexity, contributes to the overall operation. This section will explore these essential components, offering insight into their functions and how they work together to create a seamless water flow experience.

As we navigate through the various elements, it becomes evident that even minor adjustments or replacements can have a significant impact on the overall functionality. This guide serves as a detailed exploration of the essential parts, helping to identify and understand their roles in maintaining efficient operation.

Understanding the Key Components of a Water Circulation System

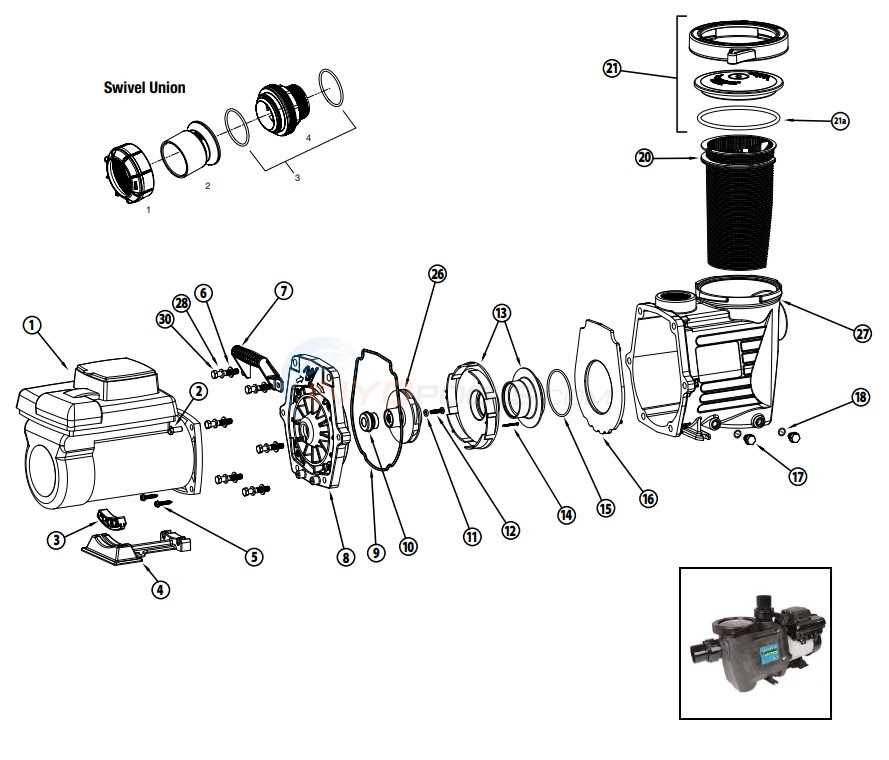

Efficient movement of water is essential in maintaining the balance and functionality of any aquatic setup. Each element within the circulation framework works together to ensure smooth flow, consistent pressure, and proper filtration. Understanding how these parts work together is crucial for optimal performance and longevity of the system.

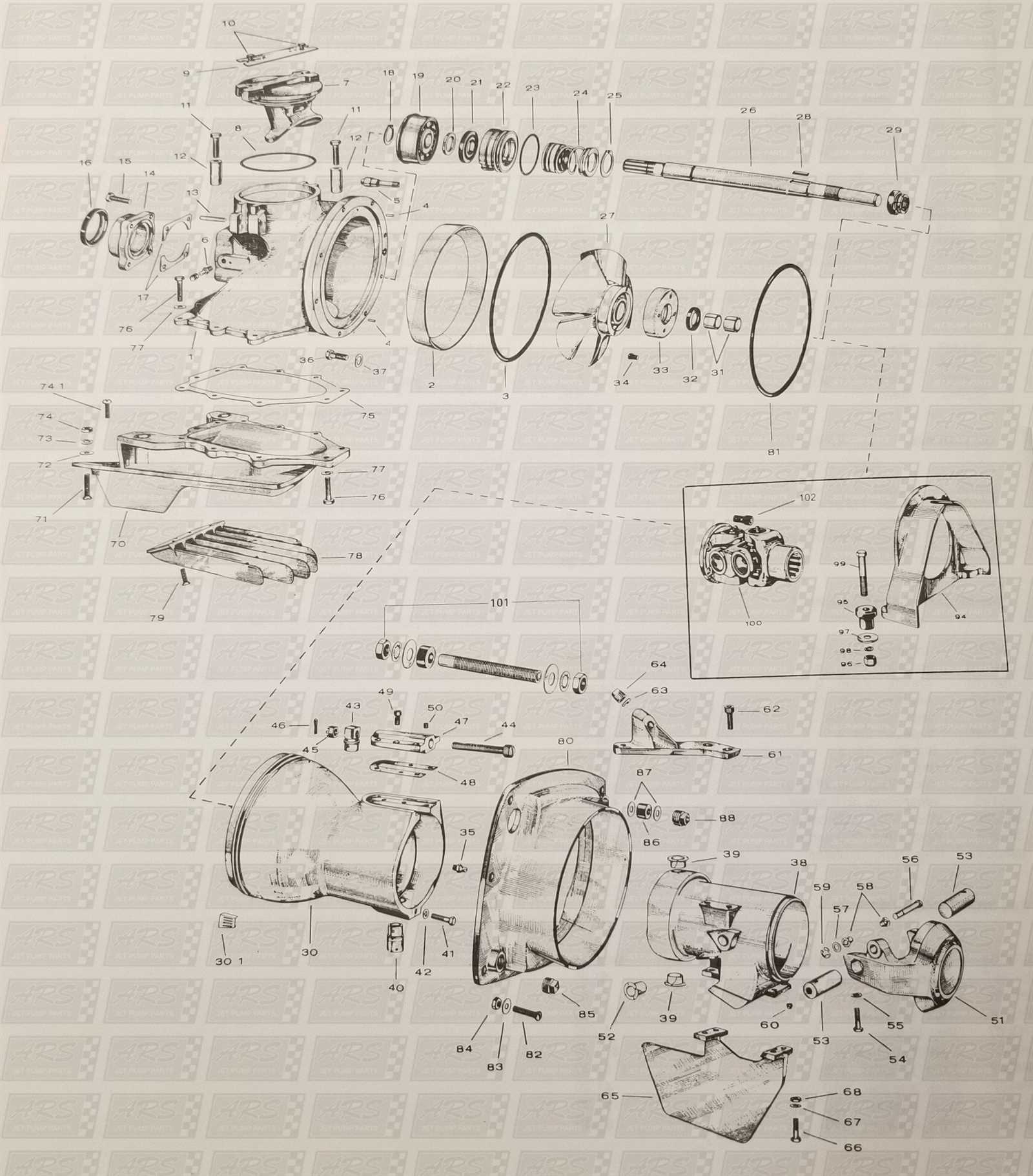

Flow Control Mechanism

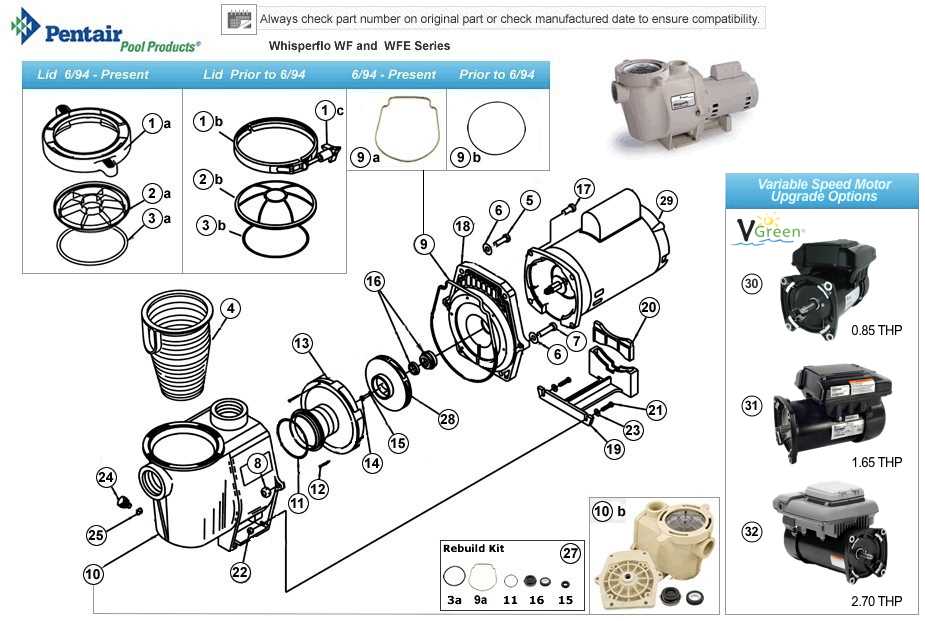

The primary component responsible for directing the flow of water is the control mechanism. This element regulates the speed and volume of water moving through the system, ensuring that the flow is neither too slow nor too fast. By maintaining an optimal pace, it helps prevent overheating and ensures the water reaches all necessary areas evenly.

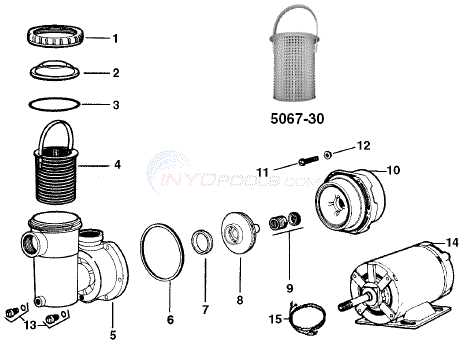

Filtration and Purification

Clean water is critical for the health and efficiency of the system. Filtration units play a pivotal role in removing debris and impurities from the circulating water. These units often include several layers of media that trap unwanted particles, allowing only clean water to continue through the circuit. In addition to debris re

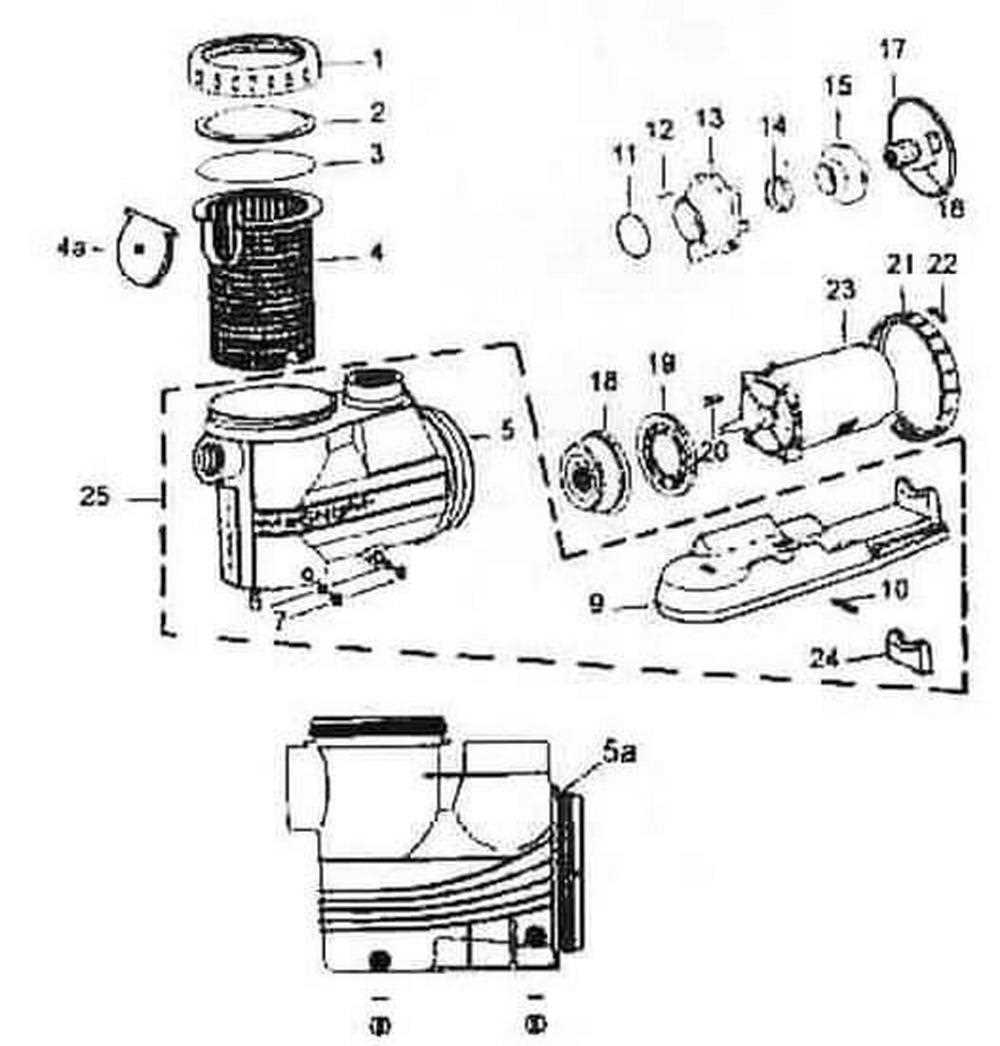

The Role of the Motor in Maintaining Flow

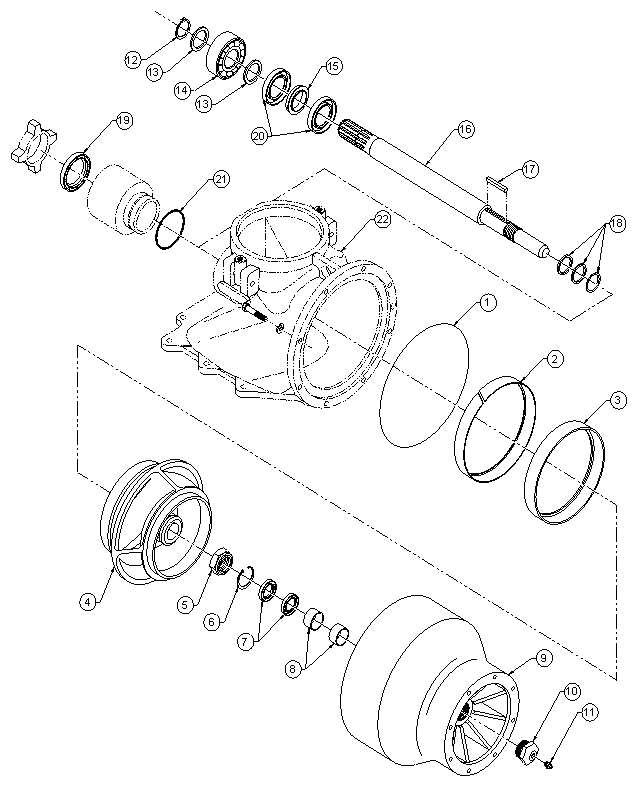

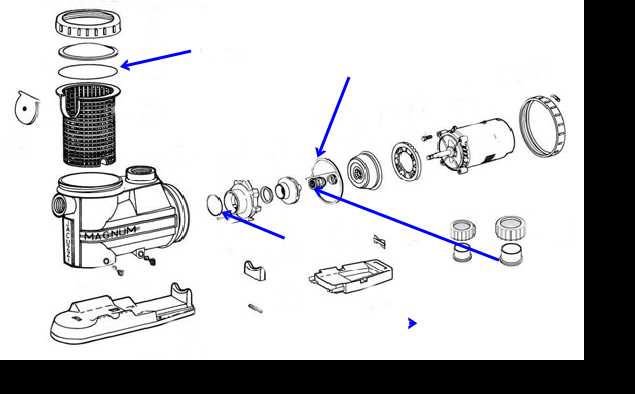

The motor is a crucial component responsible for sustaining a steady movement of water through the system. It converts electrical energy into mechanical power, driving the mechanism that ensures continuous circulation, which is essential for consistent performance and comfort. Understanding the function of the motor helps in recognizing its importance in the overall operation of the system.

How the Motor Powers Circulation

The motor works by rotating a specific internal element, which creates pressure that pushes the liquid through the system. The speed and strength of the motor directly influence the rate of circulation, allowing for the adjustment of flow intensity based on the needs of the setup. A well-functioning motor ensures smooth and uninterrupted water movement.

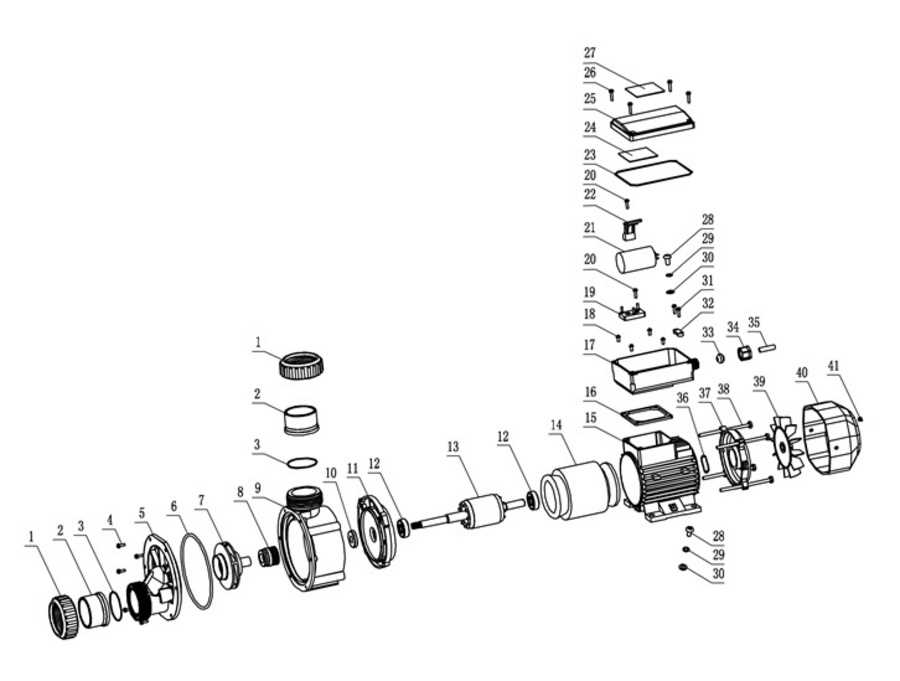

Key Components of the Motor

| Component | Function | ||||

|---|---|---|---|---|---|

| Rotor | Spins to create movement, converting electrical input into mechanical action. | ||||

| Stator | Provides the magnetic field that interacts with the rotor to produce

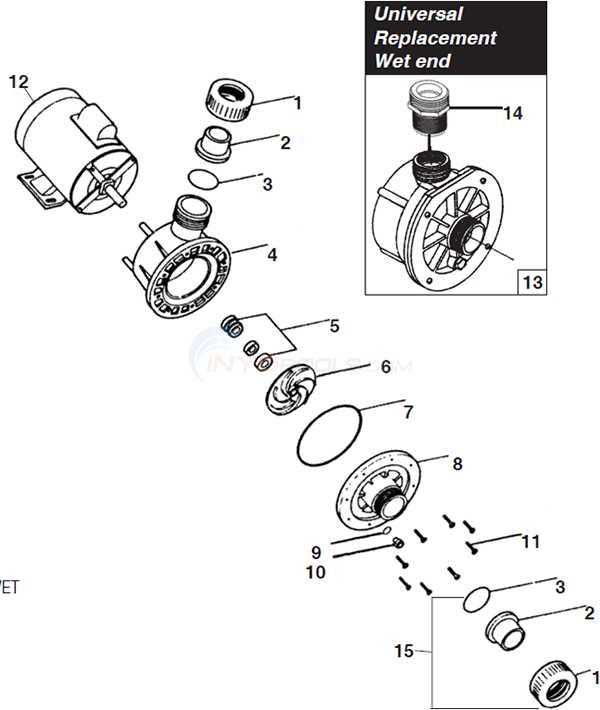

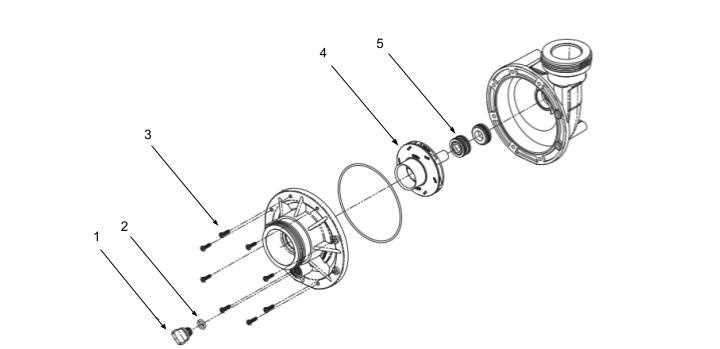

Impeller Mechanics and Their Impact on Water PressureThe efficiency of fluid movement in systems that rely on circulation is heavily influenced by the design and operation of key rotating components. The manner in which these components interact with water directly determines how pressure is generated and maintained. Understanding the principles behind these rotating mechanisms is essential for optimizing performance and ensuring consistent flow.

By adjusting these mechanical aspects, the overall fluid dynamics can be finely tuned, allowing for precise control of the flow and pressure within the system. This ensures that even under varying conditions, the mechanism can sustain optimal performance. Seal and Gasket Functions for Leak Prevention

Effective sealing mechanisms are essential in ensuring the longevity and functionality of various fluid-based systems. Their primary role is to prevent leakage by maintaining a tight boundary between moving and stationary components, particularly in areas exposed to pressure and varying temperatures. Without proper sealing, even the most well-constructed systems could suffer from performance degradation or irreversible damage. Key Roles of Seals

Gasket Contributions to System Integrity

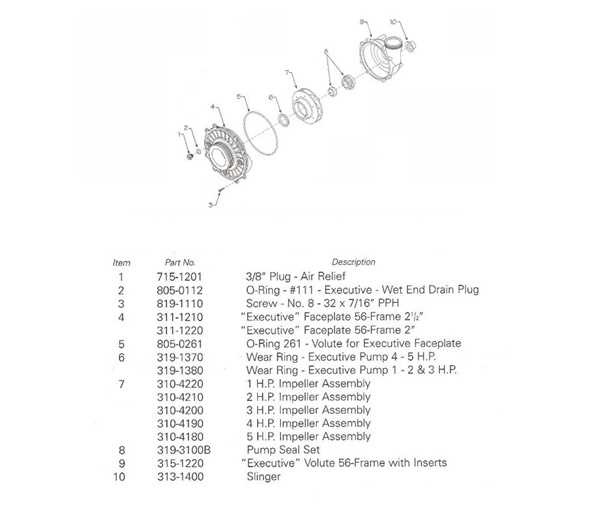

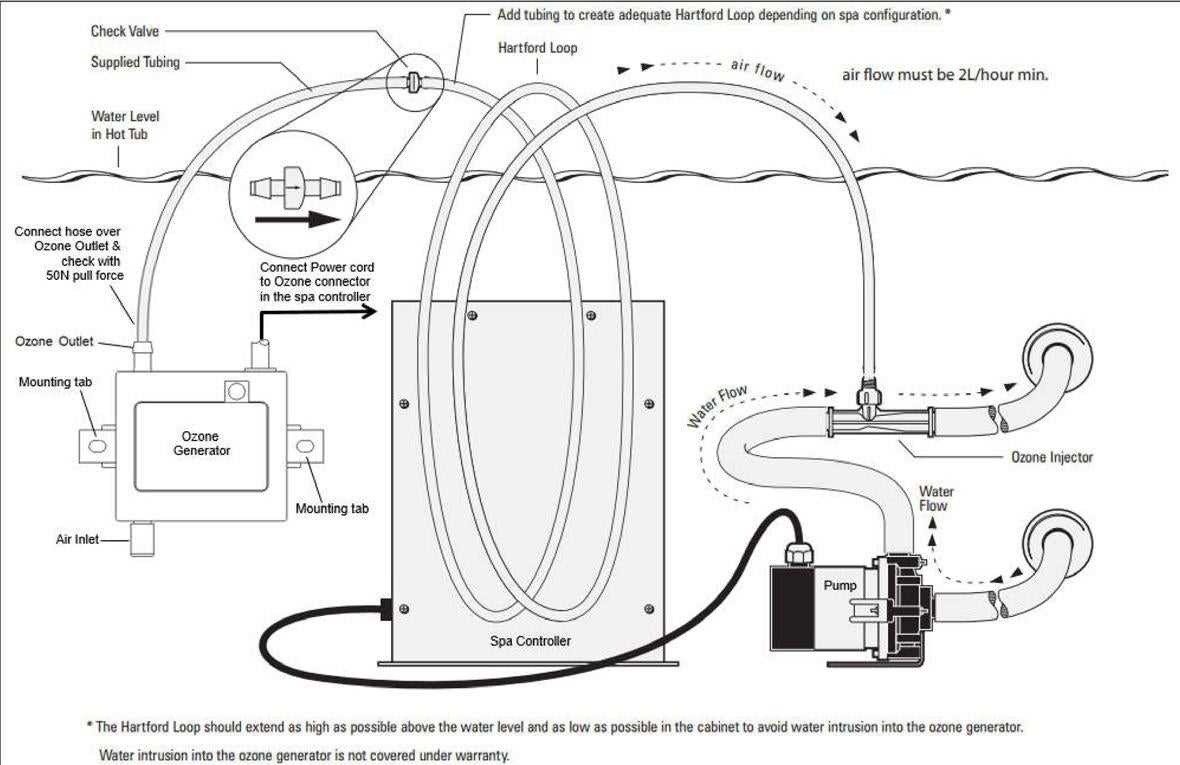

Together, seals Air Bleed Valves and Pressure Regulation

Proper control of fluid flow and maintaining balanced internal conditions is essential for the efficient operation of any system. An important component in achieving this is the use of devices designed to release trapped air and maintain consistent pressure. These mechanisms ensure smooth operation by preventing air pockets and balancing forces within the system. One common mechanism allows excess air to be vented while regulating internal forces, thereby reducing the risk of pressure build-up. These devices are typically designed with simple functionality, allowing automatic or manual adjustments to suit specific needs. Their implementation enhances the overall performance and longevity of the system.

|