When dealing with any mechanical or hydraulic system, it’s important to have a clear understanding of how the various elements work together. Each component plays a vital role in ensuring that the system operates efficiently and smoothly. Whether you’re handling maintenance, repairs, or simply learning about the system, knowing the function and position of each element is essential for optimal performance.

The layout of mechanical systems often follows a logical pattern, where individual pieces are interconnected to form a cohesive unit. By studying how these components are arranged, you can gain valuable insights into troubleshooting issues and enhancing the system’s functionality. Recognizing the

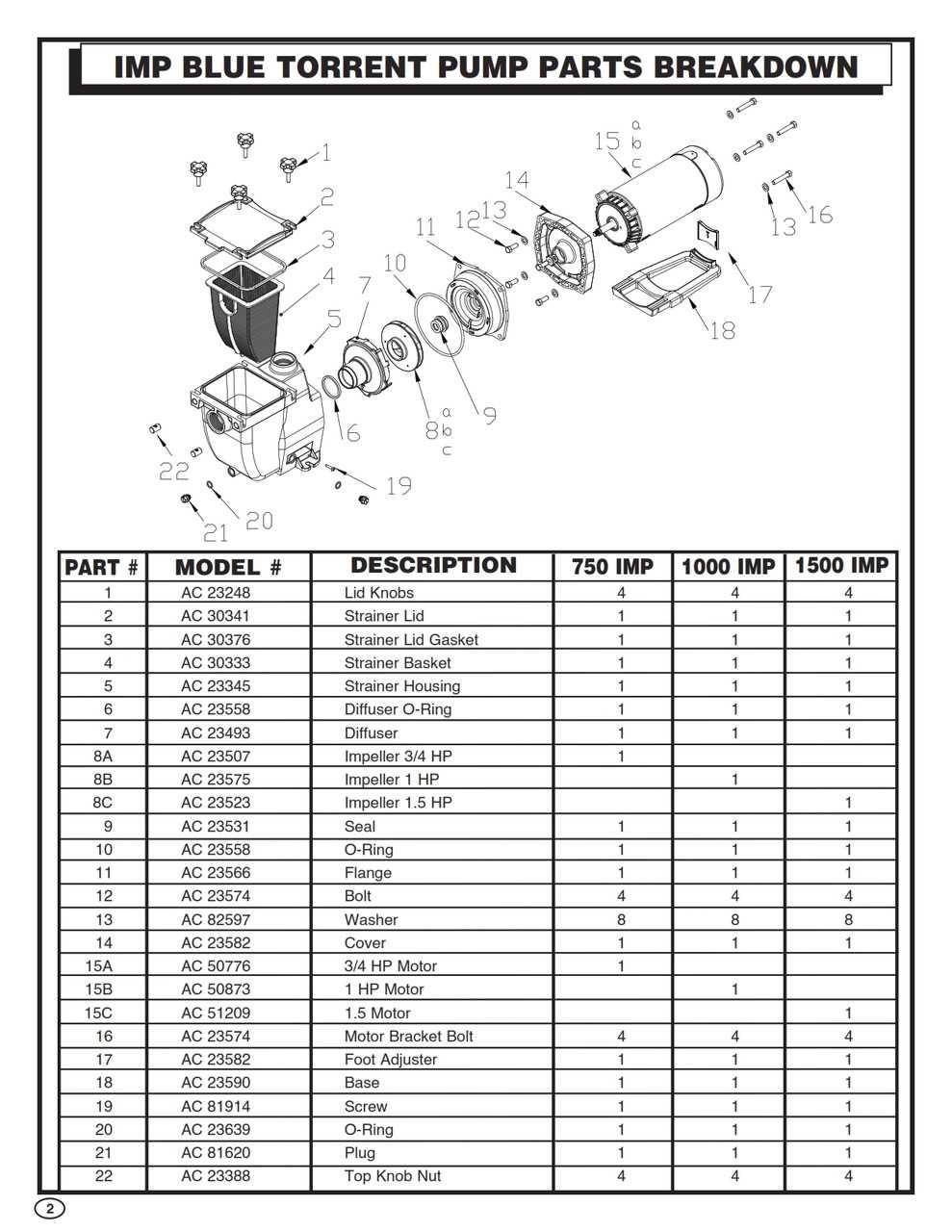

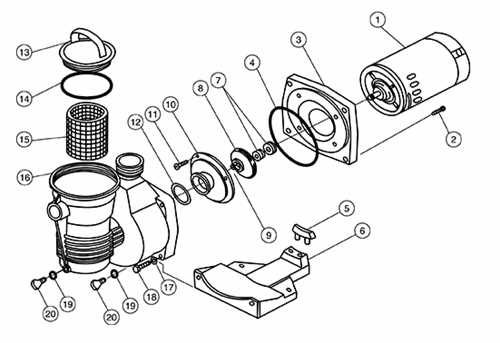

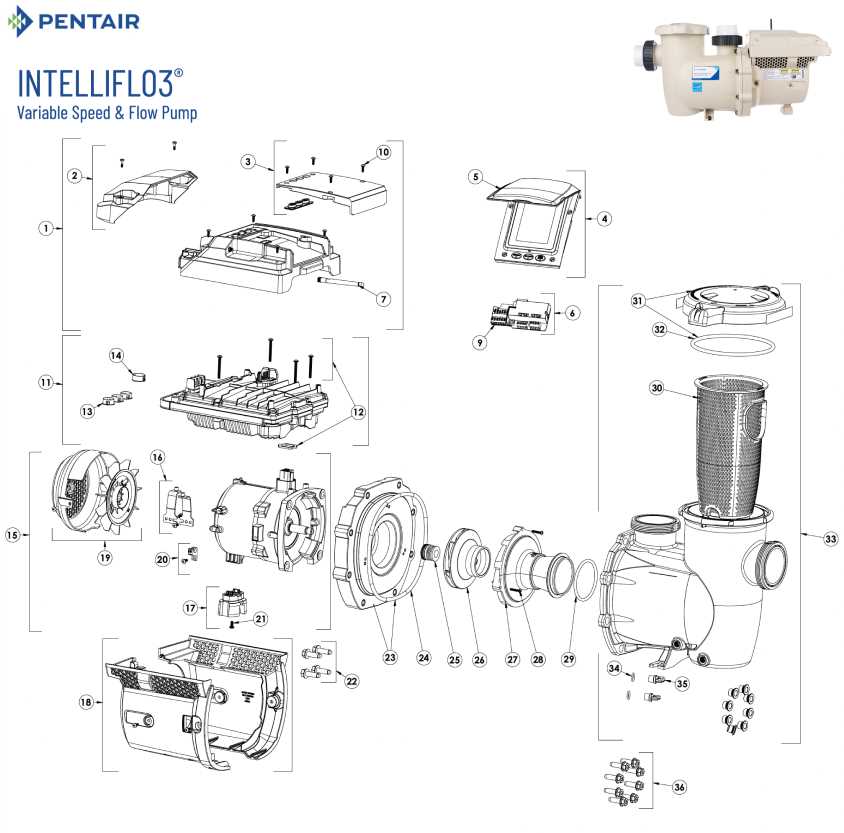

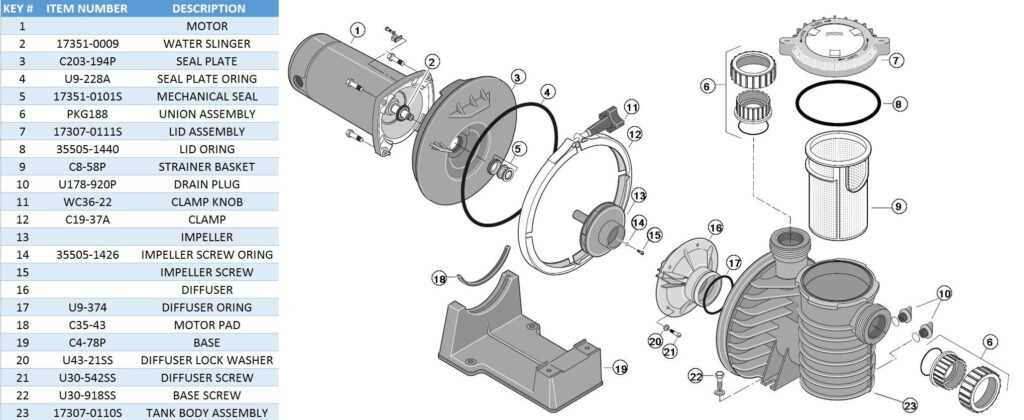

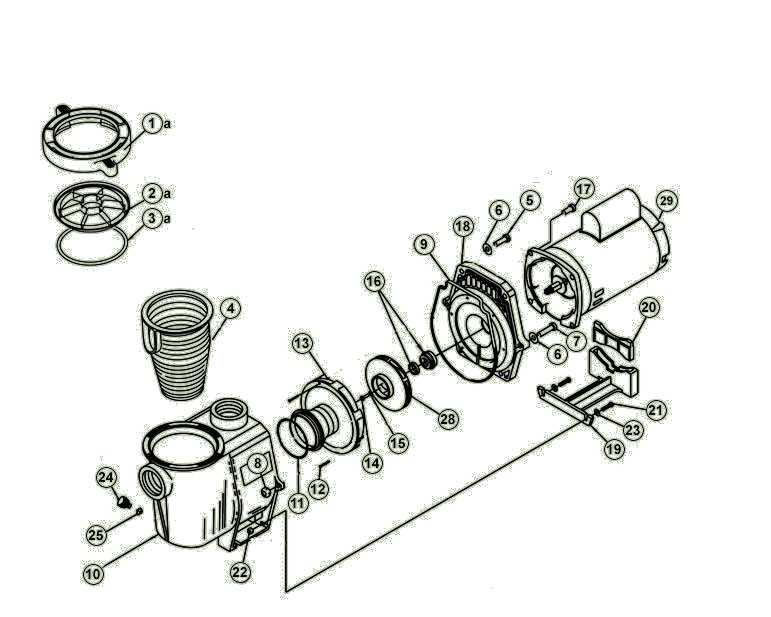

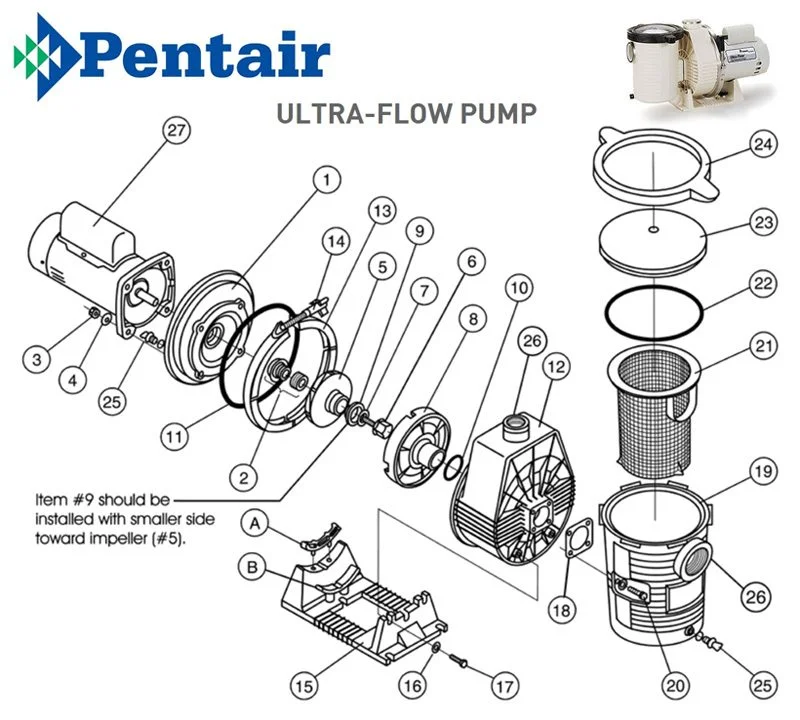

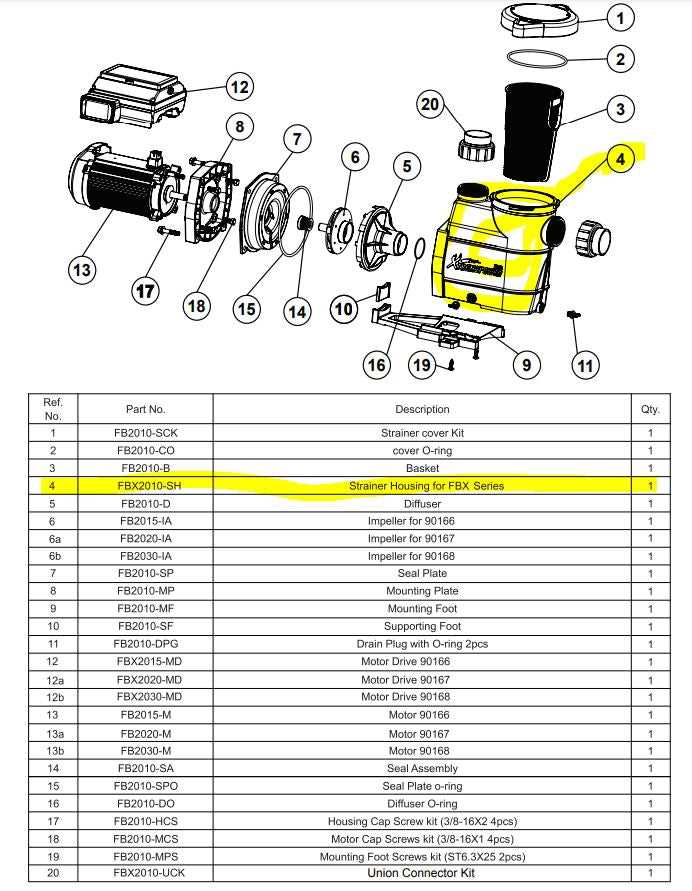

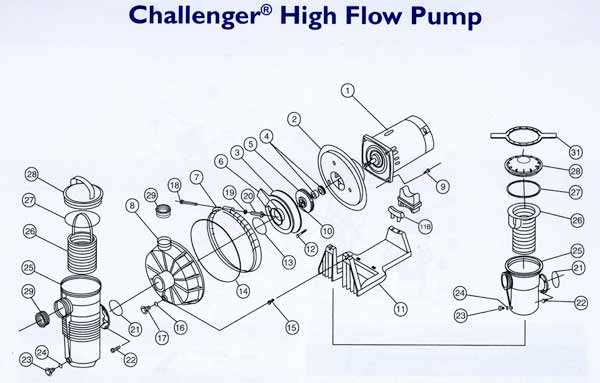

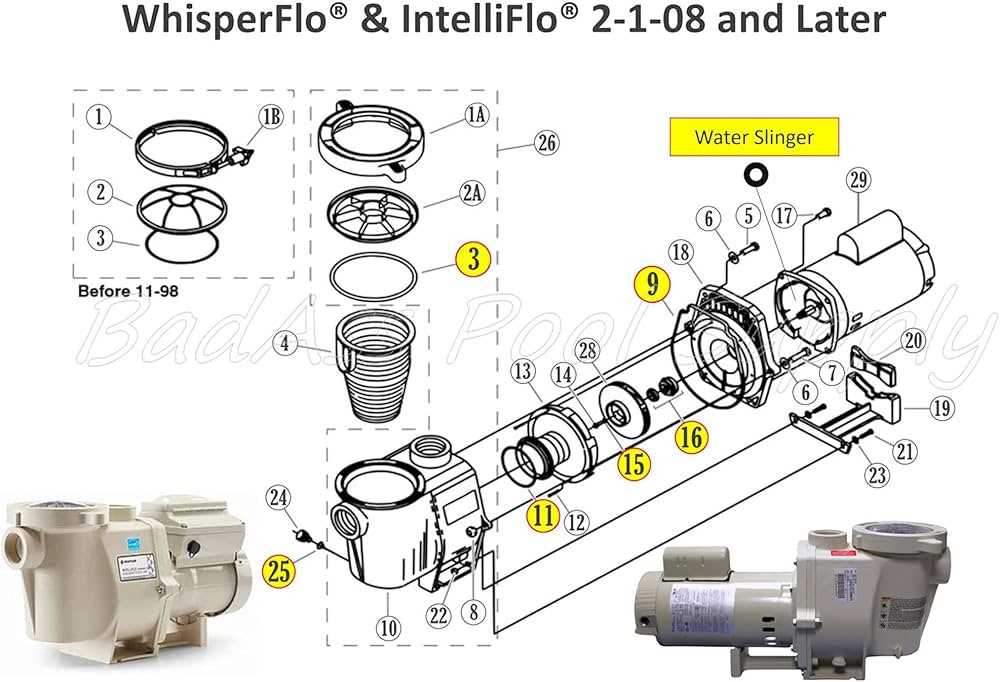

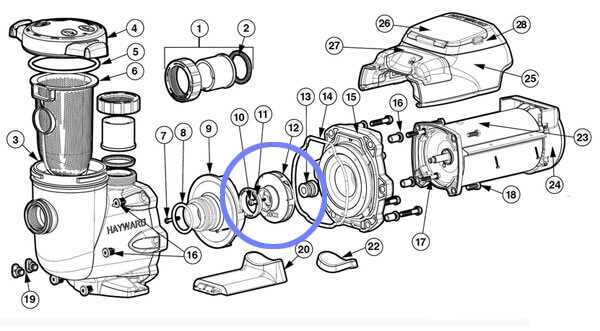

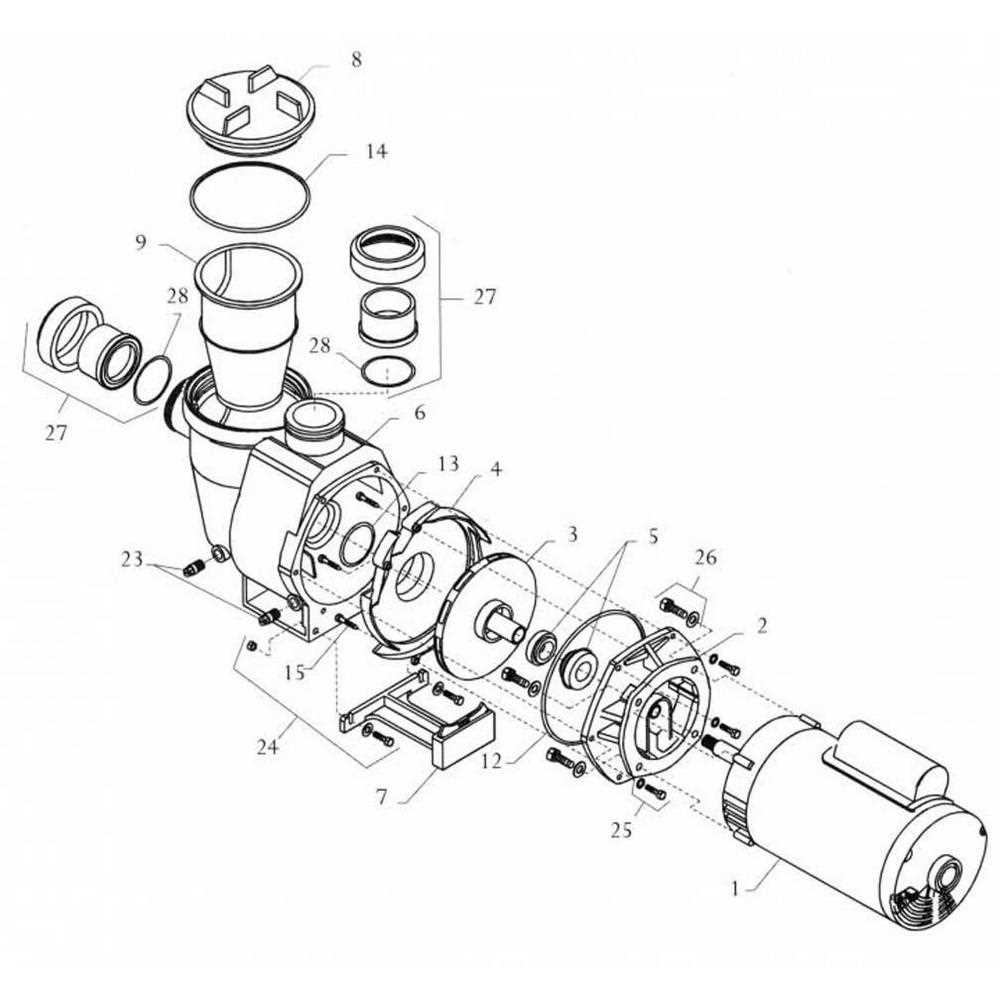

Pool Pump Parts Diagram Overview

Understanding the structure of this equipment is essential for maintaining its efficient operation. Each element works together to ensure smooth functionality and durability. This section provides a detailed look at the various components involved in the system, focusing on their roles and how they interconnect to create an effective solution for moving water.

- The main housing serves as the core of the mechanism, protecting internal elements from external damage.

- A rotating mechanism is responsible for driving the entire process, converting electrical energy into mechanical motion.

- The filtration system ensures that debris and impurities are removed, maintaining a clean environment.

- Seals and gaskets prevent leaks, ensuring that the fluid remains contained within the system.

- Pipes and

Main Components of a Pool Pump

Understanding the essential mechanisms of this equipment is crucial for maintaining efficient water circulation and ensuring the longevity of the system. These elements work together, creating the flow that moves the liquid through the filtration and heating systems, allowing for a clean and balanced aquatic environment. Below is a breakdown of the most important sections and their functions, which contribute to the overall operation of the device.

Motor

The motor is the driving force behind the system. It converts electrical energy into mechanical movement, which powers the entire process. Typically, it’s an electric model that operates at different speeds, providing flexibility for energy efficiency and performance depending on the needs of the system.

Impeller and Housing

The impeller is

Internal Mechanisms and Their Functions

Understanding the inner workings of any mechanical system requires a clear focus on the core components that drive functionality. These intricate parts collaborate to maintain consistent operations, ensuring the overall performance of the system remains stable. Each element, no matter its size, contributes to the larger framework by performing a specific role, which is vital for seamless coordination.

Rotational Elements are at the heart of mechanical movement, converting energy into motion. These components ensure that mechanical processes remain smooth and uninterrupted, transmitting force effectively across the system.

Flow Controllers regulate the internal dynamics, allowing materials or energy to pass through at controlled rates. Their function is to maintain balance and prevent any overload that could disrupt the system’s efficiency.

Sealing Mechanisms play a crucial role in maintaining pressure and preventing leaks. By ensuring that all connections are tightly secured

Key Sections of the Pump Housing

The main structure of the equipment casing is essential for ensuring the integrity and functionality of the entire system. It not only provides a protective barrier but also serves as a central hub where various components are mounted and interconnected. Understanding the different areas of this enclosure can help with maintenance and troubleshooting, as each section plays a distinct role in regulating the flow and pressure within the mechanism.

Intake Chamber: This area is designed to control the initial entry of fluid into the system. Its primary purpose is to manage the rate at which liquid enters, helping to prevent excessive buildup or disruptions in flow.

Flow Regulator: Positioned after the intake, this part of the casing ensures a smooth and consistent distribution of fluid through the entire assembly. It helps to maintain stable pressure levels, which is critical for overall performance.

Discharge Outlet: This section allows the controlled release of fluid from the system. It is shaped to direct

Understanding the Pump’s Motor Structure

The motor is a key component responsible for converting electrical energy into mechanical motion. Its design is crucial for ensuring efficient performance and reliability over time. In this section, we will explore the primary features and structural components of the motor that contribute to its overall function, without delving into specific technical terms. By understanding the internal setup, you can gain insights into how various forces and movements are generated within the system.

Main Components of the Motor

At the heart of the motor are several essential parts that work together to create rotational energy. These include the rotor, stator, and the winding system. Each of these elements has a unique role in transferring energy and ensuring smooth operation. The rotor is the rotating part, while the stator remains

Impeller Design and Its Importance

The design of an impeller plays a crucial role in the efficiency and effectiveness of fluid movement systems. It serves as a vital component that facilitates the transfer of energy to the fluid, thereby impacting overall performance. Understanding its design is essential for optimizing functionality and ensuring longevity in various applications.

Key Features of Impeller Design

- Blade Shape: The configuration and curvature of blades directly influence fluid dynamics, allowing for smooth flow and minimal turbulence.

- Material Selection: Choosing the right material enhances durability and resistance to wear, which is critical in environments with varying temperatures and chemical exposure.

- Diameter and Width: These dimensions determine the flow rate and pressure, making precise measurements essential for specific applications.

Importance of Proper Design

- Efficiency: An optimally designed impeller maximizes energy transfer, reducing operational costs.

- Performance: Effective impeller design enhances the system’s ability to maintain desired flow rates and pressures, improving overall functionality.

- Longevity: A well-constructed impeller minimizes wear and tear, extending the life span of the equipment and reducing maintenance needs.

O-rings and Seals in Pump Operation

In any fluid-moving system, the efficiency and reliability of operation significantly depend on the integrity of various sealing components. These elements are crucial in preventing leaks, maintaining pressure, and ensuring smooth functionality. Understanding their role can help in optimizing performance and extending the lifespan of the entire assembly.

Importance of Sealing Components

Sealing elements serve multiple functions in fluid transport systems:

- They create barriers against unwanted fluid leakage.

- They maintain the internal pressure required for effective operation.

- They protect internal components from environmental factors and contaminants.

Types of Seals and Their Functions

Different types of sealing components are used in these systems, each designed for specific functions:

- O-rings: Commonly used to create a tight seal in joints and connections, preventing fluid escape.

- Gaskets: These flat sealing components are typically placed between surfaces to prevent leaks in flange connections.

- Mechanical seals: Often found in rotating equipment, these seals minimize leakage between moving and stationary parts.

Proper selection and maintenance of these sealing elements are essential to ensure optimal performance and longevity of the entire fluid-moving system.

Role of Diffusers in Water Flow

Diffusers play a crucial role in enhancing the efficiency of fluid movement within a system. They are designed to manage the flow characteristics, transforming the velocity of water and ensuring a smooth transition through various components. By optimizing this flow, diffusers contribute significantly to the overall performance of the system.

The main functions of diffusers include:

- Reducing turbulence: By gradually expanding the flow area, diffusers minimize disruptive turbulence, promoting a more streamlined movement of water.

- Increasing pressure: The design of diffusers allows for a rise in pressure as water slows down, facilitating effective circulation within the system.

- Enhancing efficiency: With improved flow characteristics, diffusers ensure that energy is used effectively, reducing wear on other components.

In addition to these benefits, diffusers contribute to:

- Maintaining consistent flow rates, which is essential for reliable system operation.

- Preventing cavitation, a phenomenon that can cause significant damage if left unchecked.

- Improving the longevity of the entire system by reducing stress on components.

Overall, the strategic incorporation of diffusers within fluid systems is vital for achieving optimal performance and durability.

Identifying the Pump’s Strainer Basket

Understanding the function and location of the filtration component is crucial for effective maintenance. This essential element plays a significant role in ensuring that debris and contaminants are filtered out before they can affect the overall system performance.

The filtration device is typically situated near the intake area of the motor. It is designed to trap leaves, dirt, and other particles that may enter the system, helping to prevent clogs and damage. To locate it, look for a removable cover, often secured with screws or latches, which allows for easy access during cleaning or inspection.

Recognizing this component is important for anyone involved in system upkeep. Regular checks and maintenance of the filtration element will enhance the efficiency and longevity of the entire setup, making it a vital part of routine care.

Common Materials Used in Pump Construction

The construction of various fluid-moving devices relies on a selection of materials that enhance durability, efficiency, and resistance to environmental factors. Understanding these materials is essential for ensuring optimal performance and longevity in any application.

Typically, the following materials are utilized:

- Stainless Steel: Known for its excellent corrosion resistance, this alloy is often employed in environments where exposure to moisture or chemicals is a concern.

- Cast Iron: Renowned for its strength and ability to withstand high pressures, this material is commonly used in heavy-duty machinery.

- Plastic: Lightweight and resistant to corrosion, various polymers are used in smaller or more cost-effective designs.

- Bronze: This alloy provides good resistance to wear and is frequently used in components that experience friction.

- Aluminum: Valued for its lightweight properties and resistance to oxidation, this metal is often found in portable models.

Each of these materials offers distinct advantages, making them suitable for specific applications and environments. The choice of material significantly impacts the overall functionality and reliability of the device.

How a Filter Works

Understanding the operation of a filtration system is essential for maintaining clean and clear water in recreational facilities. This device plays a crucial role in removing debris and impurities, ensuring the quality of the liquid remains at optimal levels. By using a combination of physical and chemical processes, the filtration unit effectively keeps the environment safe and pleasant for users.

Mechanism of Filtration

The filtration system utilizes various components to trap unwanted particles. Water flows through the device, passing through different stages of filtering media designed to capture dirt, leaves, and other contaminants. The primary function is to ensure that only clean liquid is recirculated, promoting hygiene and safety.

Types of Filtering Media

Different types of filtering materials are employed to enhance the efficiency of the filtration process. Common options include sand, cartridges, and diatomaceous earth, each offering unique advantages. The selection of the appropriate media is vital for achieving desired results.

Type of Media Advantages Sand Cost-effective and durable Cartridges Easy to replace and maintain Diatomaceous Earth High filtration efficiency Replacing and Maintaining Pump Parts

Ensuring the longevity and efficiency of your water circulation system requires regular attention to its components. Periodic inspection and timely replacement of worn-out elements can prevent significant issues and enhance performance. Understanding the specific functionalities of various elements will aid in the maintenance process, allowing for seamless operation and extending the life of the equipment.

When it comes to upkeep, being familiar with common components is crucial. The following table outlines the primary elements, their functions, and maintenance tips:

Component Function Maintenance Tips Motor Drives the mechanism to circulate water. Inspect for unusual noises and overheating; clean the exterior regularly. Seal Prevents leaks around the motor shaft. Check for wear and replace if leaking; ensure proper lubrication. Strainer Traps debris and prevents clogging. Clean frequently to ensure unobstructed flow; replace if damaged. Impeller Moves water through the system. Inspect for cracks or wear; replace if performance diminishes. Regularly assessing these components and performing maintenance tasks can greatly improve the efficiency and durability of your water system. Stay proactive to avoid larger issues down the line.

Signs of Wear in Pump Components

Identifying deterioration in essential elements is crucial for maintaining efficiency and extending the lifespan of the system. Various symptoms indicate that the components may be experiencing wear and require attention. Regular inspections can help in catching issues early, ensuring optimal performance.

Common Indicators of Deterioration

- Unusual Noises: Sounds such as grinding, rattling, or excessive vibration may suggest that internal components are worn or damaged.

- Reduced Efficiency: A noticeable decrease in operational effectiveness can be a sign of worn-out parts, leading to increased energy consumption.

- Leakage: Visible fluid leaks around seals or connections can indicate wear and may compromise the integrity of the system.

Visual Signs to Look For

- Cracks or Fractures: Examine components for any visible cracks or fractures, which can significantly affect performance.

- Discoloration: Changes in color or texture on surfaces may signal overheating or other types of damage.

- Corrosion: Rust or corrosion on metallic parts can lead to failure if not addressed promptly.

Being aware of these indicators allows for proactive maintenance, reducing the likelihood of unexpected failures and costly repairs.