In the realm of liquid application, a thorough comprehension of the elements that contribute to functionality is essential. Each segment plays a crucial role in ensuring efficient delivery, affecting both performance and user experience. This section aims to illuminate the intricate relationships among these various components, providing a clearer picture of their interconnectedness.

Recognizing the individual roles of each element not only enhances operational efficiency but also aids in troubleshooting common issues that may arise during use. From the trigger mechanism to the sealing units, understanding these components can significantly impact the effectiveness of any dispensing activity.

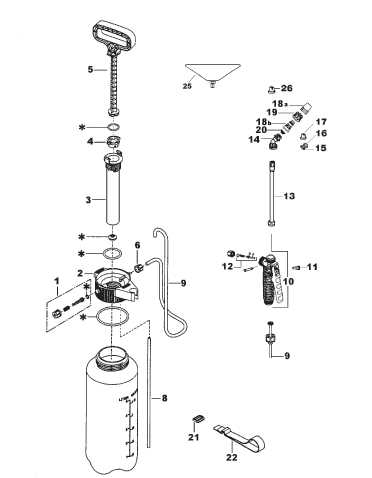

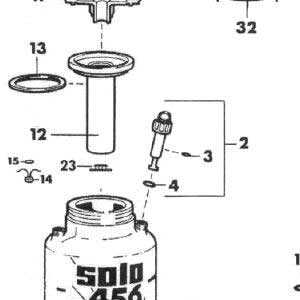

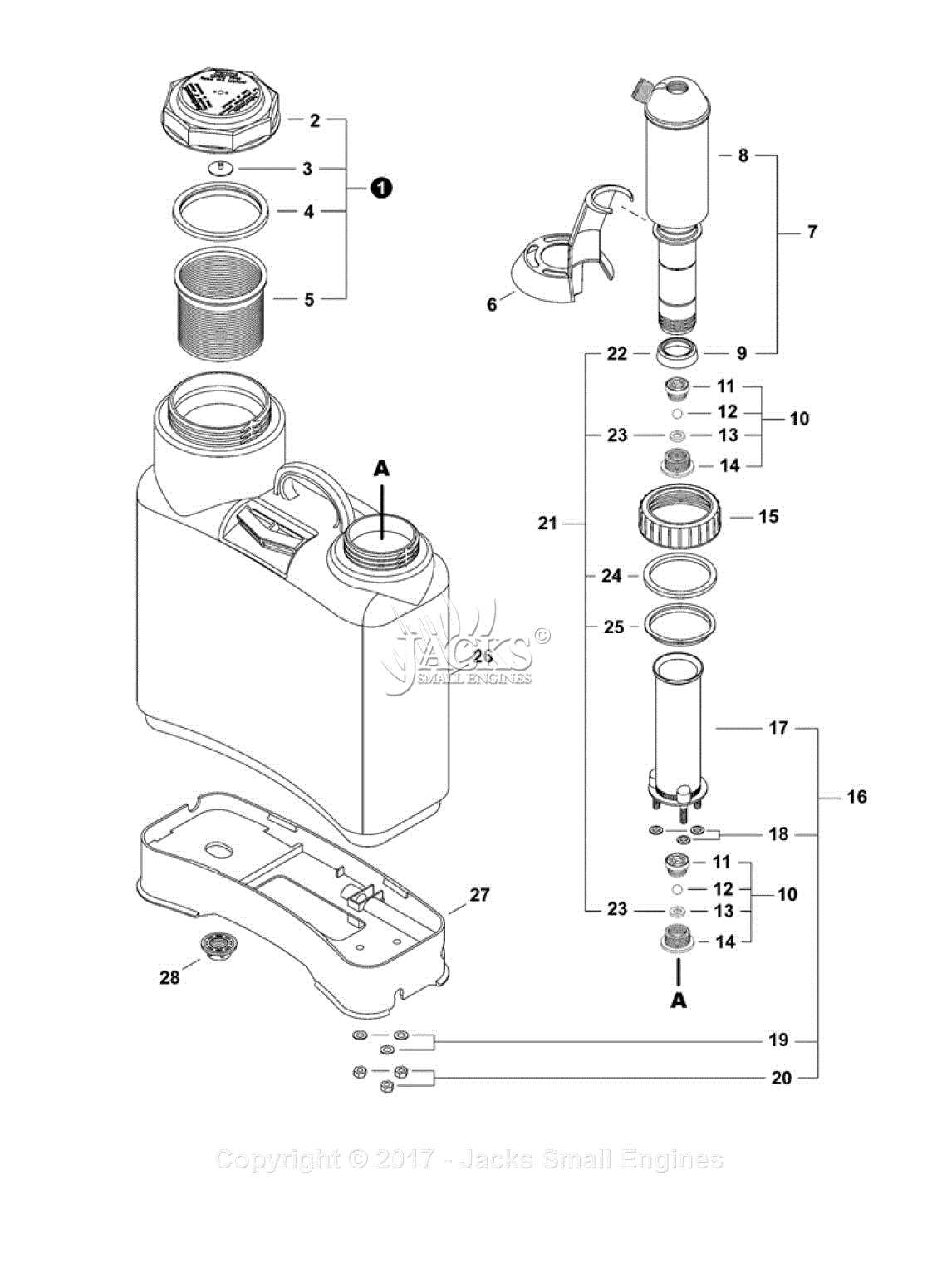

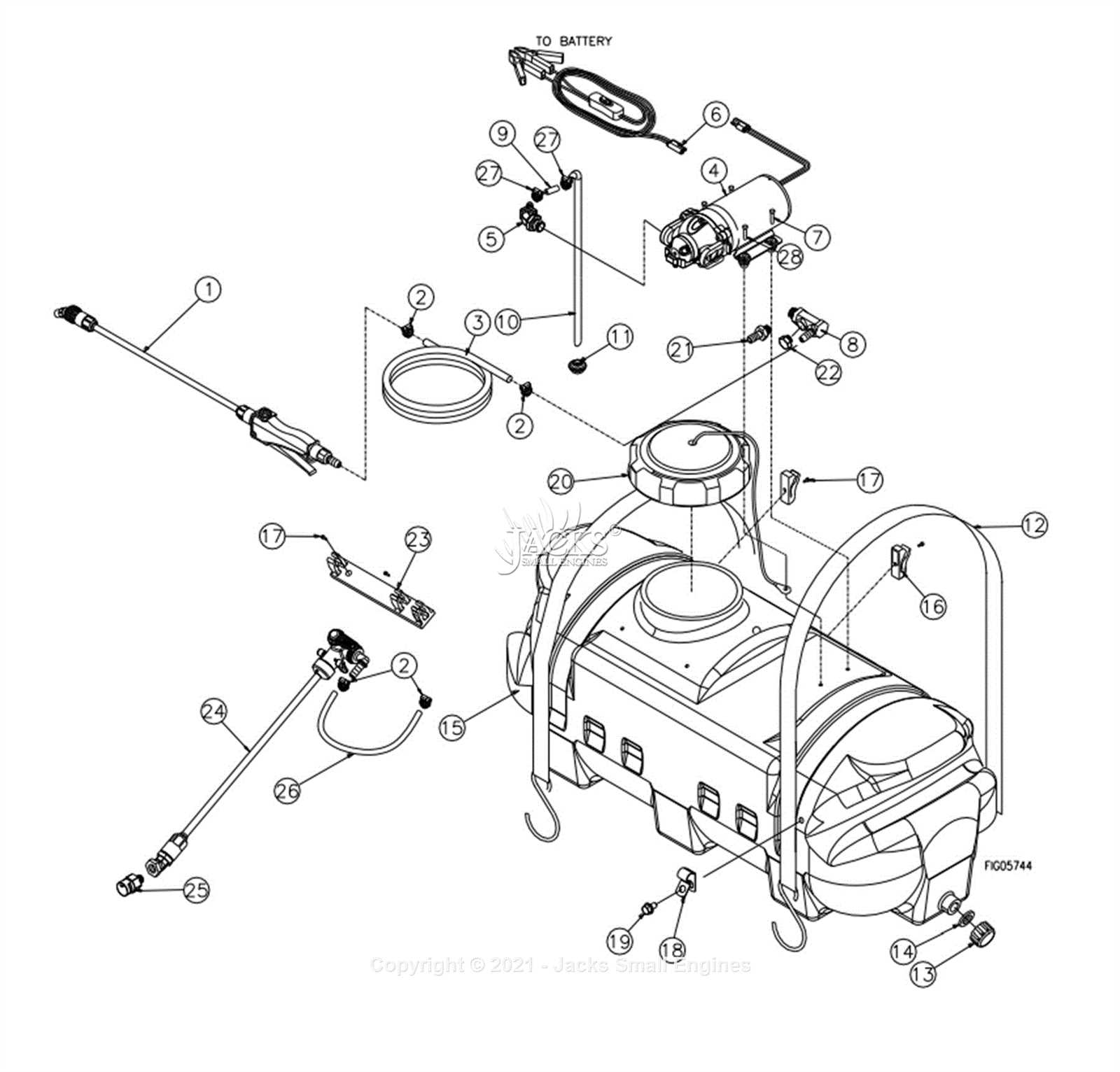

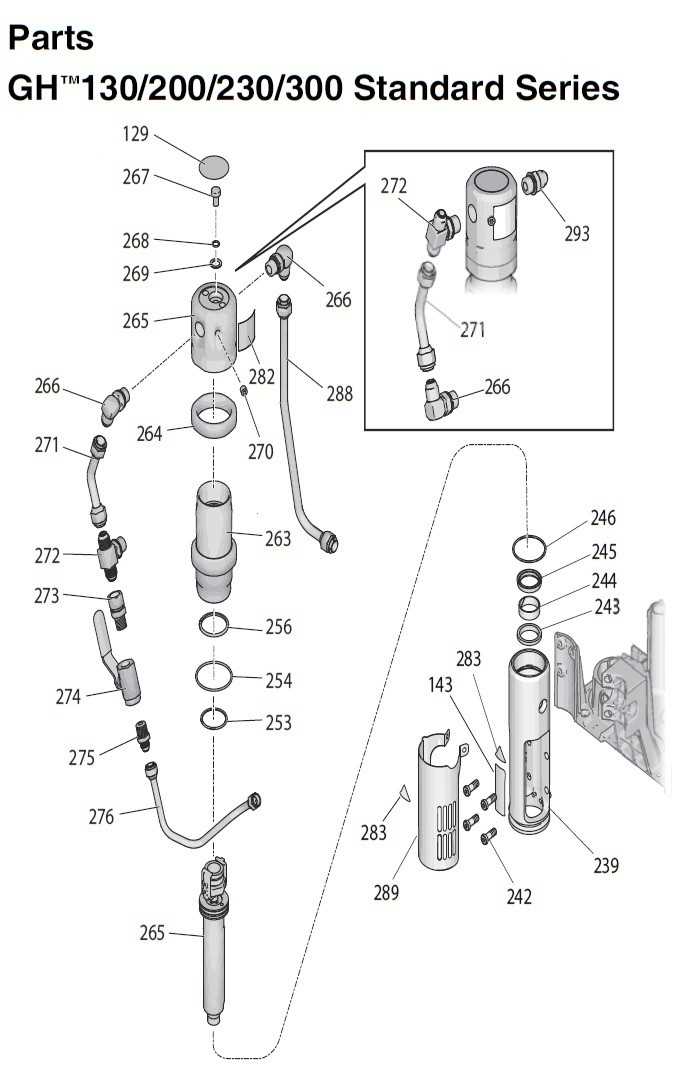

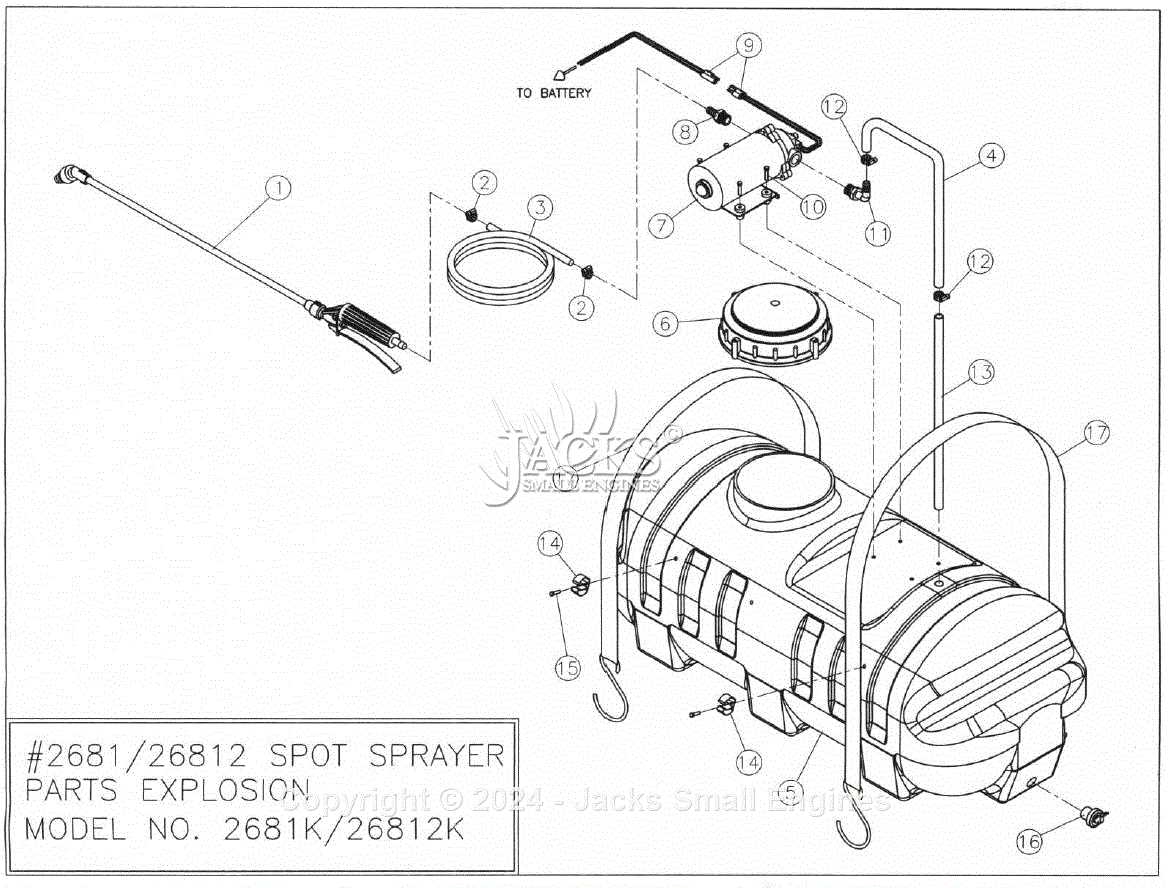

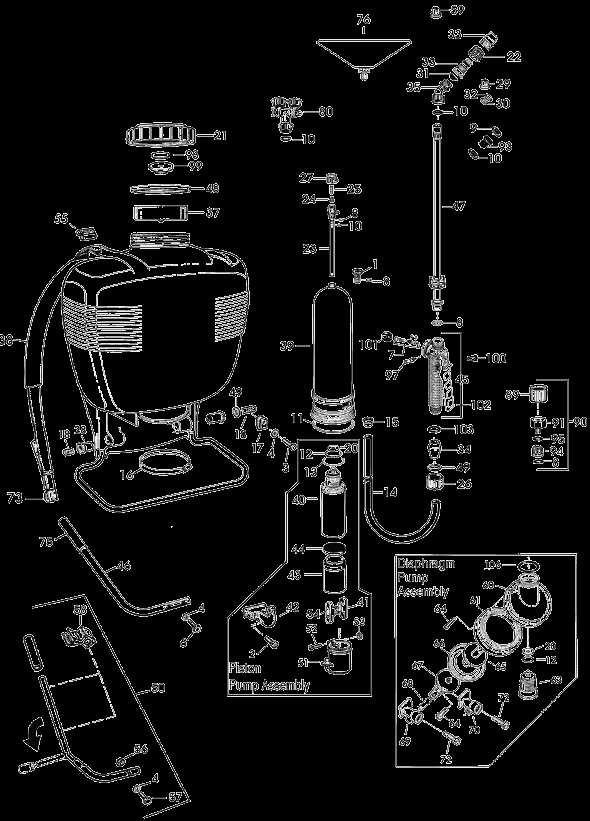

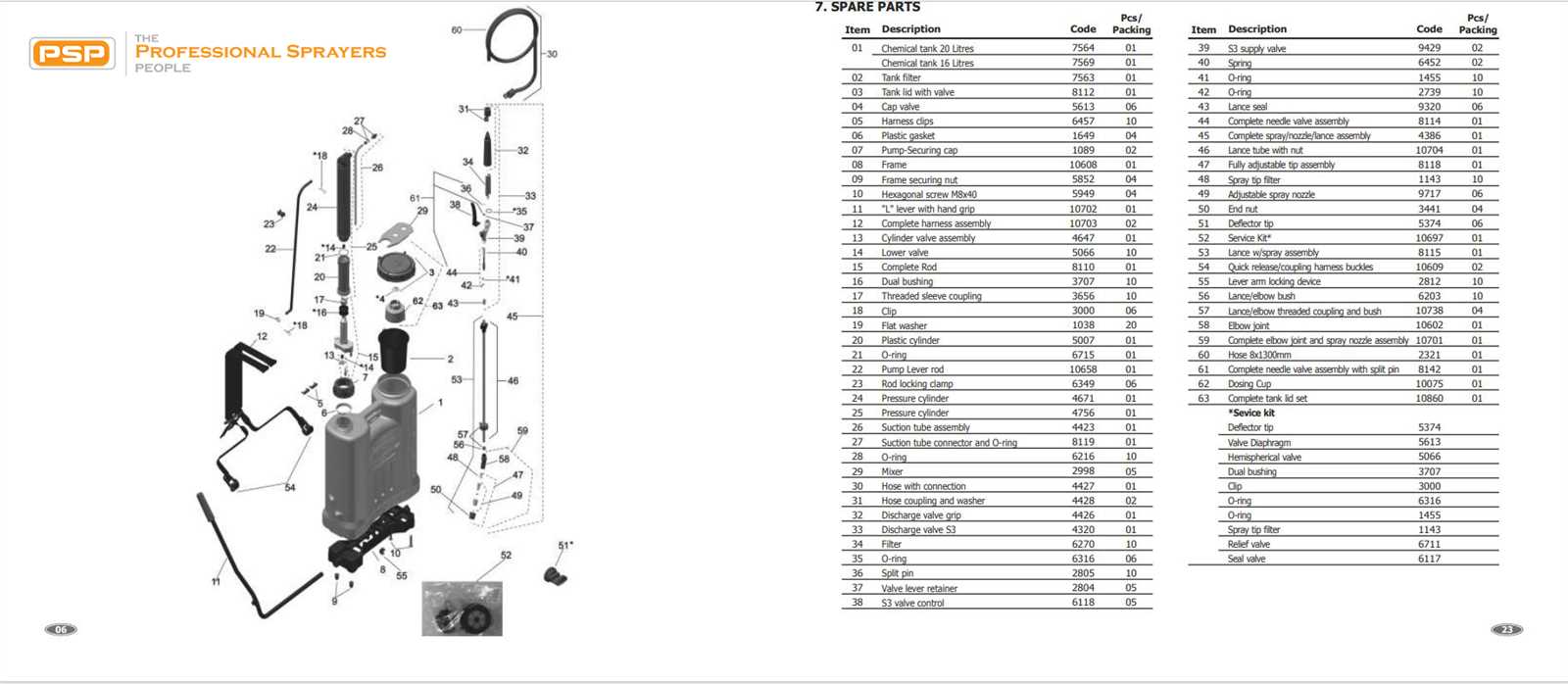

Moreover, having a visual representation of how these segments fit together serves as a valuable resource for maintenance and assembly. It allows users to quickly identify any potential shortcomings or wear, ensuring longevity and reliability in performance. Ultimately, a well-rounded knowledge of these essential parts is invaluable for anyone involved in liquid application tasks.

Understanding Pump Sprayers Basics

In the world of liquid application, a variety of mechanisms play a crucial role in delivering solutions efficiently. These devices rely on a series of components that work harmoniously to ensure optimal performance and ease of use. By familiarizing oneself with the fundamental elements, users can enhance their experience and achieve better results in various tasks.

Key components involved in these mechanisms include:

- Container: Holds the liquid and is often designed for easy handling.

- Handle: Facilitates operation and provides control over the application.

- Nozzle: Adjusts the flow and pattern of the liquid being dispensed.

- Sealing Mechanism: Ensures no leakage occurs during use.

- Pressure System: Generates the necessary force for effective dispersion.

Understanding how these components function together is essential for selecting the right device for specific needs. Users should consider the intended application, as different tasks may require varying features and specifications.

Additionally, maintenance plays a vital role in the longevity and efficiency of these mechanisms. Regular cleaning and inspection can prevent malfunctions and ensure consistent performance. By mastering the basics, individuals can make informed decisions and maximize the utility of their equipment.

Key Components of Pump Sprayers

Understanding the essential elements of liquid application devices is crucial for effective usage and maintenance. Each component plays a vital role in ensuring optimal performance and longevity.

Main Elements

- Container: Holds the liquid solution.

- Pressure mechanism: Creates the force needed to expel the liquid.

- Nozzle: Directs and controls the flow of the solution.

- Hose: Connects the container to the nozzle for efficient delivery.

Supporting Features

- Filter: Prevents clogging by trapping debris.

- Handle: Provides a grip for ease of use.

- Cap: Seals the container to maintain pressure.

- Adjustable settings: Allows customization of spray patterns.

How Pump Sprayers Function

These devices operate through a simple yet effective mechanism that allows for the controlled application of liquids. By generating pressure within a chamber, they enable a fine mist or steady stream to be released through a nozzle. This process is essential for various tasks, from gardening to cleaning, ensuring that liquids are distributed evenly and efficiently.

Basic Mechanism

The core of the operation lies in the creation of pressure. When the user engages a trigger or lever, it compresses air within a container. This action forces the liquid upward through a tube and out of the nozzle. The design of the nozzle influences the flow rate and pattern, allowing for versatility in application.

Maintenance and Care

To ensure longevity and optimal performance, regular maintenance is crucial. Cleaning the nozzle and the container after use prevents clogging and buildup of residues. Additionally, inspecting seals and valves for wear can help maintain the effectiveness of the device, allowing for consistent results in future applications.

Types of Pump Sprayers Available

In the realm of liquid application, various models cater to distinct needs, each with unique features and benefits. Understanding these categories allows users to select the most suitable option for their tasks.

Handheld Options

Compact and easy to maneuver, handheld devices are perfect for small projects. They offer portability and are often designed for quick usage, making them ideal for gardens and household chores.

Backpack Models

For larger areas, backpack configurations provide comfort and efficiency. These units distribute weight evenly, enabling prolonged use without fatigue, thus enhancing productivity for extensive applications.

Common Applications for Pump Sprayers

Devices designed for the efficient application of liquids are utilized in various settings, serving multiple purposes. Their versatility makes them essential tools in gardening, maintenance, and industrial processes. Understanding their applications can help users maximize their effectiveness.

| Application | Description |

|---|---|

| Gardening | Ideal for distributing fertilizers, pesticides, and herbicides evenly across plants and soil. |

| Cleaning | Useful for applying cleaning solutions to surfaces in homes, offices, and public spaces. |

| Automotive | Employs liquids for detailing, such as waxes and tire shines, ensuring a polished finish. |

| Food Industry | Facilitates the even coating of oils, marinades, or flavorings during food preparation. |

| Disinfection | Enables the application of sanitizing solutions in healthcare settings to maintain hygiene. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any equipment. Regular care not only enhances performance but also prevents premature wear and tear. By following a few key practices, you can ensure optimal functionality and durability.

1. Regular Cleaning: After each use, make it a habit to clean the device thoroughly. Remove any residue or debris that may cause blockages or damage over time.

2. Inspect Components: Periodically check for any signs of wear or damage. Addressing minor issues promptly can prevent more significant problems later.

3. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and enhance performance. This will contribute to smoother operation and prolong the device’s life.

4. Store Properly: Ensure that the equipment is stored in a cool, dry place away from direct sunlight. Proper storage conditions can prevent material degradation and maintain functionality.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance. Adhering to these guidelines will provide the best results and ensure longevity.

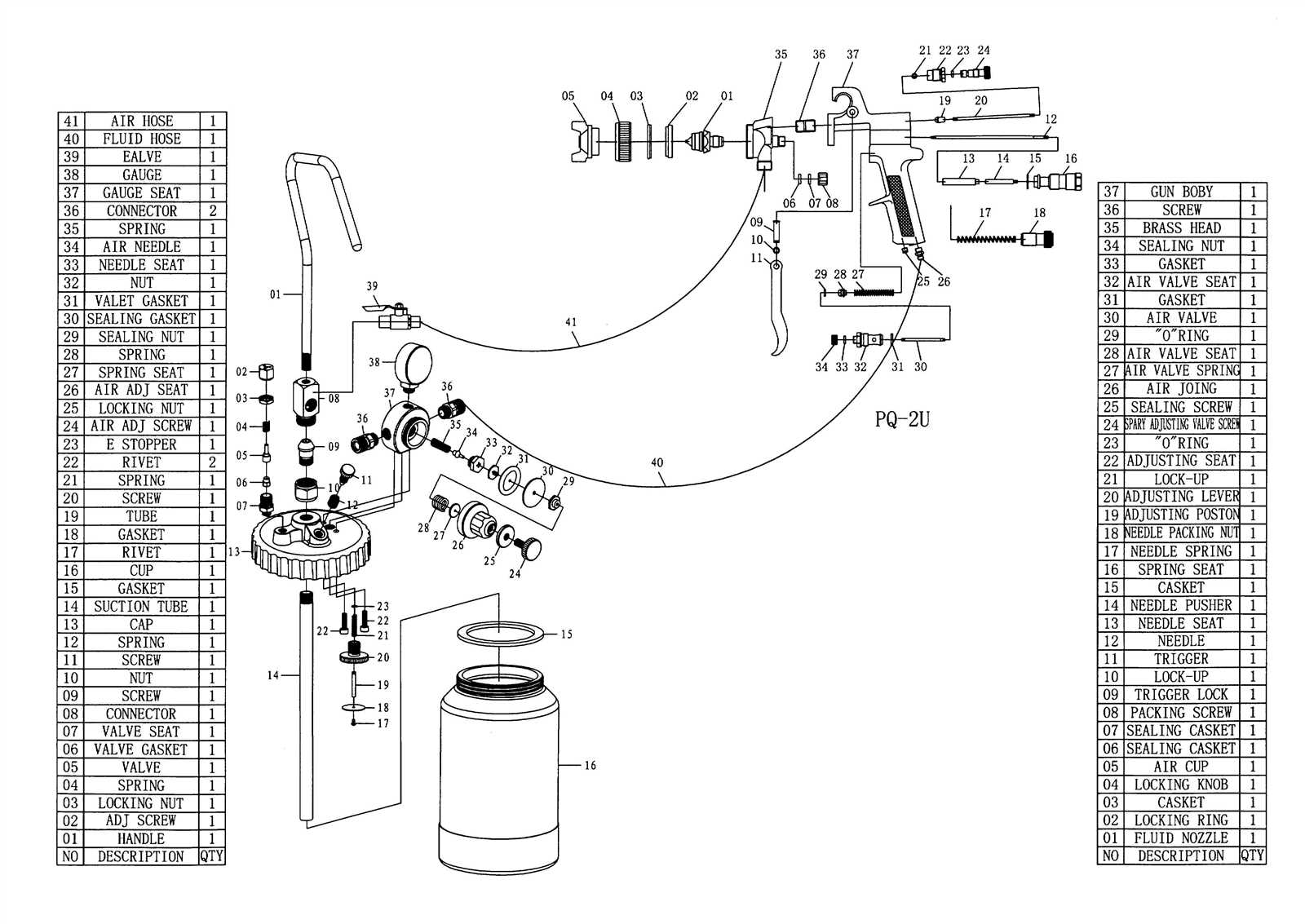

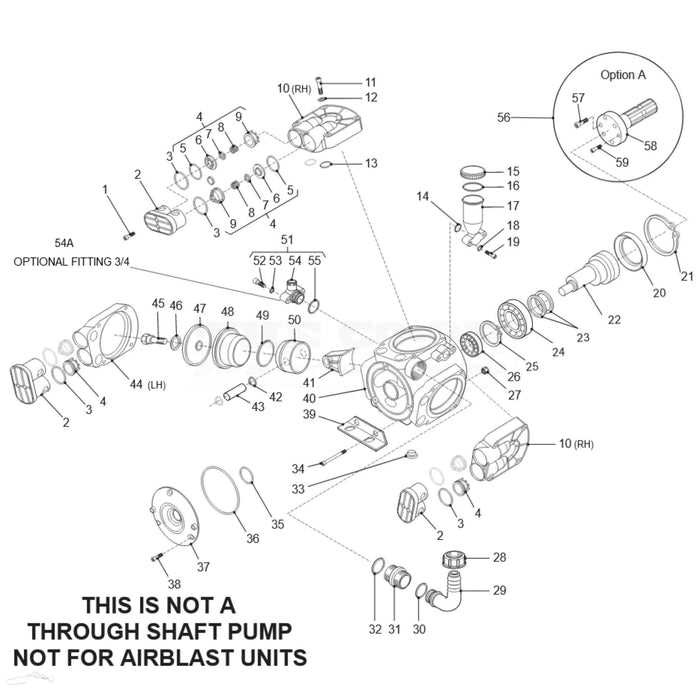

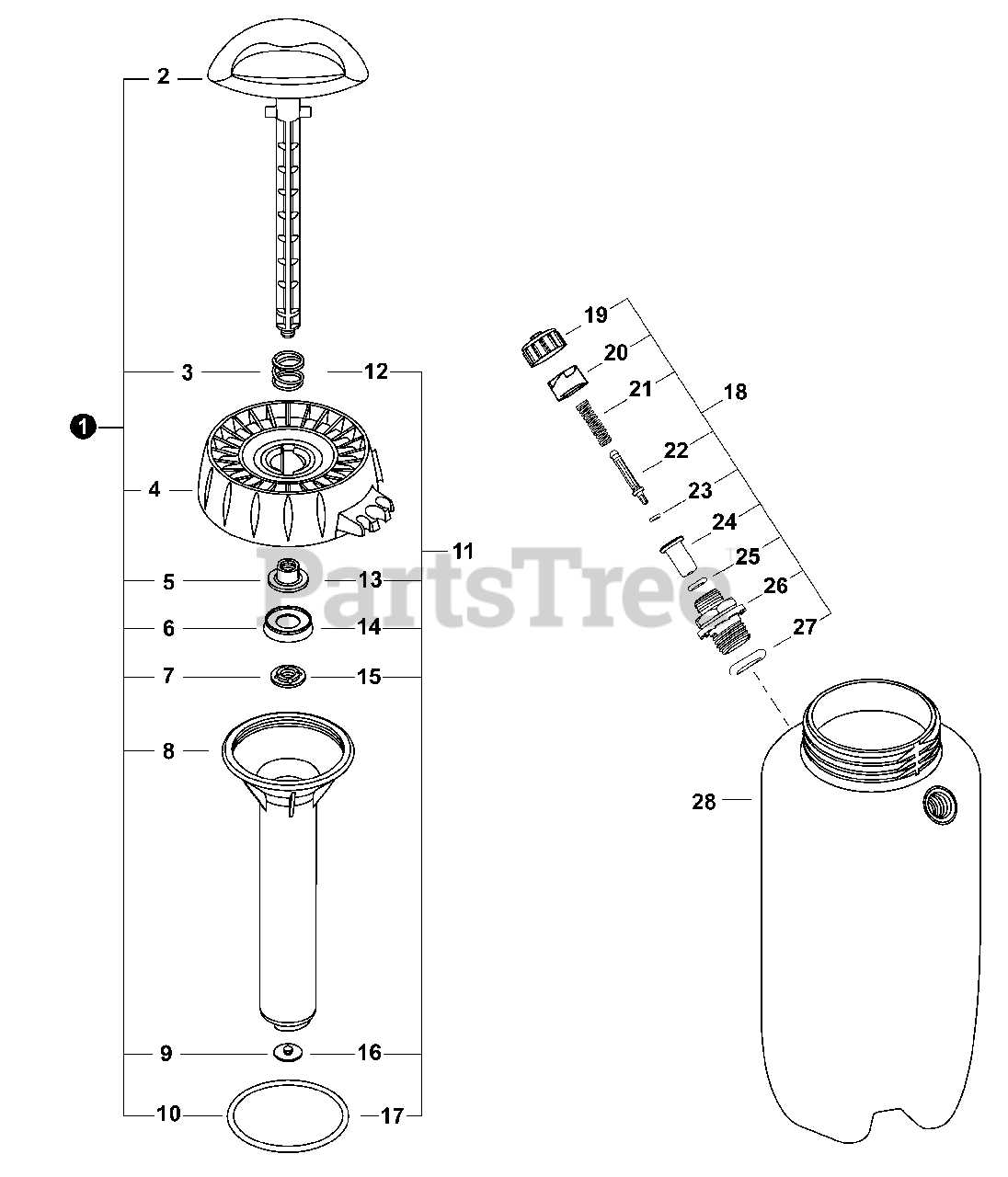

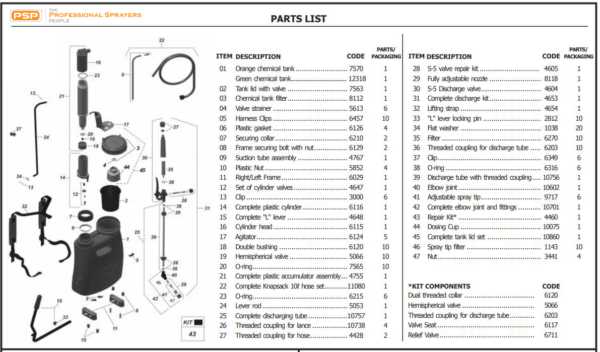

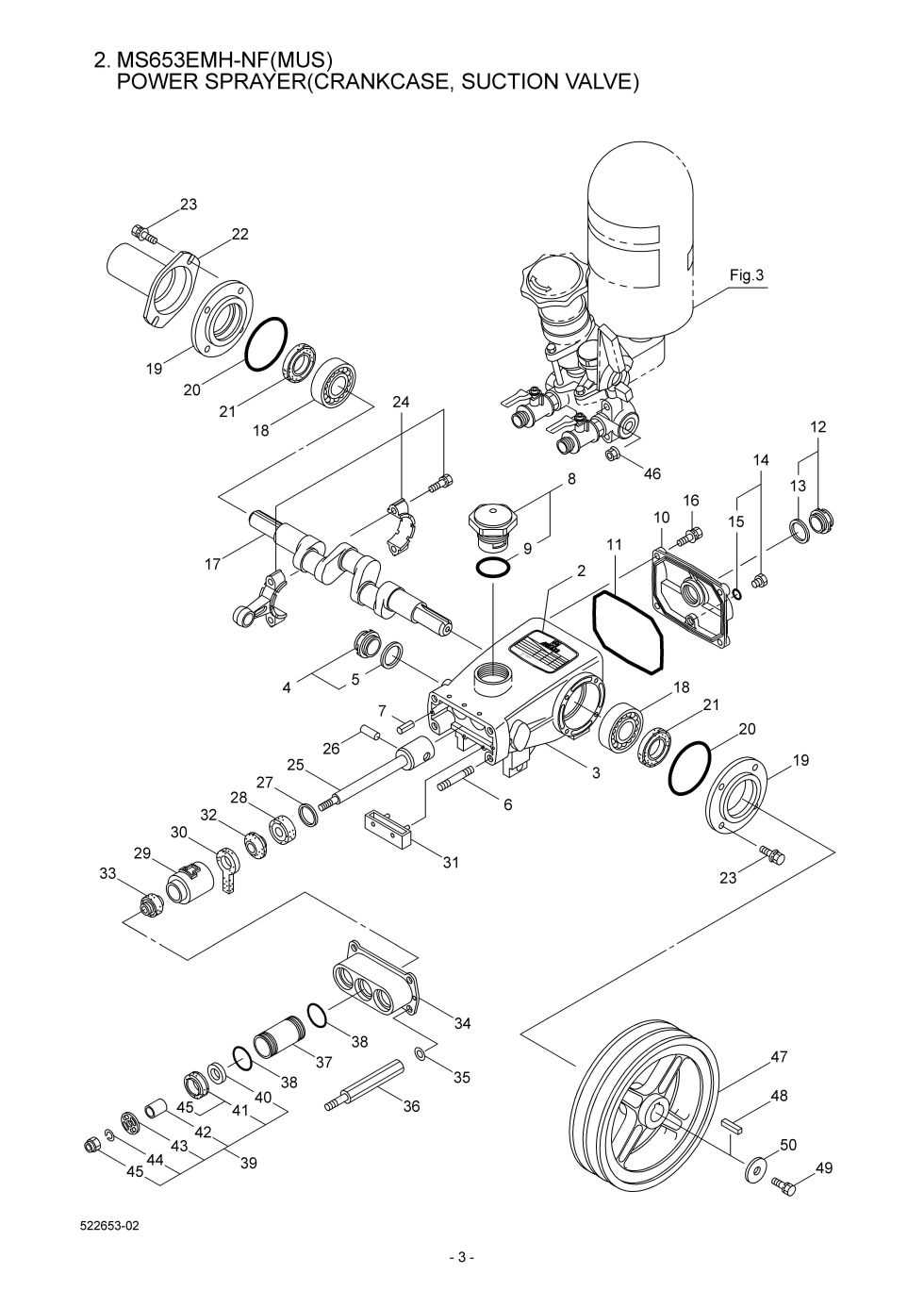

Identifying Parts in Diagrams

Understanding the various components of a device can enhance efficiency and facilitate maintenance. This section explores how to recognize and differentiate elements within technical illustrations, ensuring that users can effectively navigate the information presented.

Understanding Components

Each illustration typically includes labels and symbols that represent different features. Familiarizing oneself with these can significantly ease the identification process. Look for numbered annotations or highlighted areas that correspond to a legend, as these often provide crucial details about each segment’s function.

Practical Tips for Recognition

When analyzing illustrations, start by isolating sections of interest. Focus on the shape and arrangement of elements, as these can give hints about their roles. Additionally, cross-reference with user manuals or guides for more context on how each feature interacts within the overall system.

DIY Repairs for Pump Sprayers

Maintaining your equipment can be a fulfilling experience that not only saves money but also enhances your understanding of how it operates. Many common issues can be addressed with a little knowledge and some basic tools. This guide will help you tackle typical repairs, ensuring that your device remains functional and effective for various tasks.

Identifying Common Issues

Before diving into repairs, it’s essential to recognize the most frequent problems that may arise. Leaks, pressure loss, and clogged nozzles are just a few of the challenges you might face. By systematically inspecting each component, you can pinpoint the source of the malfunction. For example, a leaky seal often indicates wear and may need replacement to restore functionality.

Simple Repair Techniques

Once you’ve identified the issue, applying straightforward repair techniques can make a significant difference. Start by disassembling the device, taking care to note how each piece fits together. Cleaning components with warm soapy water can often resolve clogs. Additionally, replacing worn-out seals or gaskets will help maintain pressure and prevent leaks. For those uncomfortable with disassembly, consult the user manual for guidance on troubleshooting and maintenance.

Choosing the Right Sprayer Size

When selecting the appropriate size for your application, it’s crucial to consider the area you intend to cover and the specific tasks at hand. The correct dimensions ensure efficiency, effective coverage, and optimal performance during use.

| Size | Best For | Coverage Area |

|---|---|---|

| Small | Detail work and small gardens | Up to 1,000 sq ft |

| Medium | Residential lawns and landscaping | 1,000 – 5,000 sq ft |

| Large | Commercial use and larger properties | 5,000+ sq ft |

Ultimately, choosing the right size is about balancing capacity and convenience, ensuring you have the right tool for every job.

Comparing Manual vs. Electric Models

This section explores the differences between two prevalent types of dispensing devices. Each model offers distinct advantages and limitations, influencing user choice based on specific needs and applications.

Advantages of Manual Models

- Cost-effective and budget-friendly.

- Lightweight and portable, easy to transport.

- Requires no electricity, ideal for remote areas.

- Simple to operate with minimal maintenance.

Benefits of Electric Models

- Consistent and efficient performance for larger tasks.

- Time-saving with faster application rates.

- Reduced physical effort, suitable for extensive use.

- Advanced features like adjustable settings for precision.

Ultimately, the choice between these models depends on the user’s specific requirements, budget constraints, and intended use.

Safety Precautions When Using Sprayers

Ensuring safety during the application of various substances is essential to prevent accidents and injuries. Following specific guidelines can significantly reduce risks associated with the equipment and the materials being utilized.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks, to safeguard against harmful chemicals.

- Read the manufacturer’s instructions carefully before operation to understand the equipment’s functionality and safety features.

- Ensure proper ventilation in the area of use to avoid inhaling toxic fumes or vapors.

Before starting, it is vital to check the equipment for any damage or leaks. Regular maintenance can help identify issues early.

- Conduct a thorough inspection of hoses and connections.

- Test the pressure settings to ensure they are within safe limits.

- Store materials and equipment in a cool, dry place away from direct sunlight.

Finally, always have an emergency plan in place. Familiarize yourself with first aid procedures and have appropriate materials ready for quick response in case of accidental exposure.

Upgrades and Accessories for Efficiency

Enhancing the functionality of your equipment can significantly improve performance and user experience. By incorporating innovative tools and components, you can achieve optimal results in various applications. Consider the following upgrades to elevate your efficiency.

| Upgrade/Accessory | Benefits |

|---|---|

| Extended Nozzles | Provide better reach and precision for targeted application. |

| Pressure Regulators | Maintain consistent output and reduce wastage. |

| Ergonomic Handles | Enhance comfort and reduce fatigue during prolonged use. |

| Replacement Filters | Ensure clean fluid delivery and protect components. |

| Quick-Connect Fittings | Facilitate faster setup and easy switching between tasks. |

Troubleshooting Common Issues

Addressing typical problems that may arise during operation is essential for maintaining efficiency and effectiveness. By understanding the underlying causes, users can implement practical solutions to enhance functionality.

Leaking Fluid: If you notice unwanted fluid escaping, check for damaged seals or loose connections. Replacing worn components can often resolve this issue.

Insufficient Pressure: Low pressure can result from clogs in the nozzle or hoses. Ensure all pathways are clear, and inspect for any blockages that could impede flow.

Difficulty in Activation: If activation is challenging, examine the trigger mechanism for debris or damage. Cleaning or replacing the trigger may restore proper function.

Uneven Dispersion: For inconsistent output, ensure that the nozzle settings are correctly adjusted. Additionally, verify that the liquid is properly mixed if applicable.

By following these guidelines, users can effectively troubleshoot and maintain their equipment, ensuring optimal performance during use.