Understanding how various mechanical systems are assembled is crucial for maintaining and troubleshooting equipment. This guide provides a detailed look into the arrangement of key elements within a specific model, offering valuable insights into its functionality. By examining the connections and structure of the internal elements, users can enhance their knowledge and ensure optimal operation.

Each individual element within the system plays a significant role, working together to achieve smooth and reliable performance. This section focuses on providing a clear representation of how these elements are organized, allowing users to easily identify and understand their purpose within the larger mechanism.

Familiarity with these elements not only helps in identifying potential issues but also assists in preventive maintenance. It becomes easier to make informed decisions about replacements or adjustments when necessary, ensuring that the equipment continues to function efficiently.

Overview of Wayne PC4 Pump Components

The system consists of various interconnected elements designed to ensure efficient fluid movement. Each component plays a crucial role in maintaining the overall functionality and reliability of the equipment. By understanding the purpose of these individual parts, users can maintain and troubleshoot the system more effectively.

Main Structural Elements

At the core of the system lies the housing, which provides protection and support for other key elements. This casing is built to withstand environmental factors while ensuring the smooth operation of internal mechanisms. Inside, you’ll find a motor responsible for driving the system’s core operations, converting electrical energy into mechanical force.

Operational Mechanisms

To regulate flow, the assembly includes valves and seals that control fluid movement and prevent leaks. Additionally, a rotating impeller is installed, which facilitates the movement of liquid through the device, creating the necessary force for its displacement.

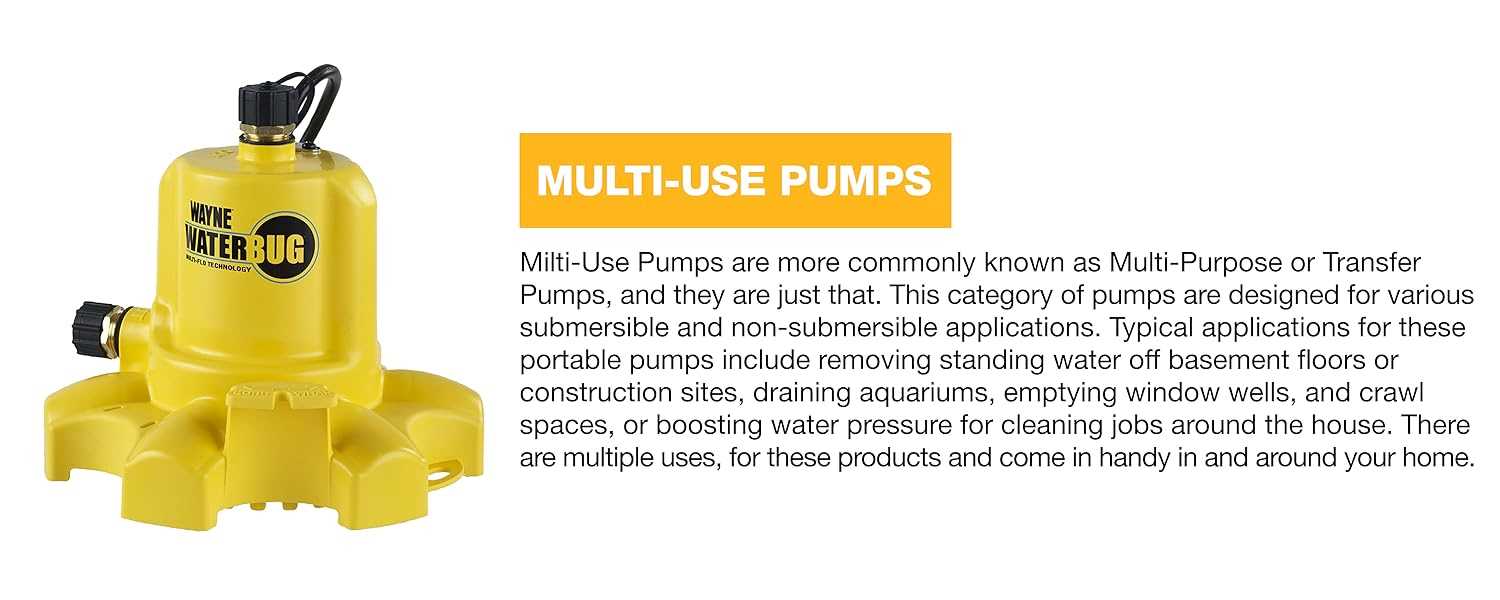

Main Features of the Wayne PC4 Model

The device is designed for efficient fluid management in various environments, offering users a versatile and robust solution for transferring liquids. It provides consistent performance with a structure that prioritizes durability and ease of operation. This model is suitable for diverse tasks that require reliable handling of different types of fluids.

| Feature | Description |

|---|---|

| Material Quality | Constructed with high-grade materials that ensure longevity and resistance to wear. |

| Motor Power | Equipped with a powerful motor, enabling fast and efficient operation in demanding conditions. |

| Portability | Designed with a compact structure, making it easy to transport and set up in different locations. |

| Application Versatility | Ideal for a variety of fluid transfer applications, making it a flexible tool for both professionals and casual users. |

Exploring the Internal Mechanisms of the PC4 Pump

The intricate systems inside this device are designed to move liquid efficiently and reliably. Understanding how these components interact can help improve performance and troubleshooting. By analyzing each internal element, one can gain insights into the mechanical principles that make the device operate smoothly under various conditions.

At the core, the mechanism consists of a motor-driven assembly that ensures continuous fluid flow. Key elements work in harmony to regulate pressure, control movement, and maintain consistent operation. Precision engineering allows these parts to function seamlessly, reducing wear and enhancing durability.

Examining the detailed structure reveals the importance of balance between power input and fluid output. The careful alignment of moving parts ensures that energy is efficiently transferred, minimizing energy loss and maximizing output. Regular maintenance of these components can significantly extend the lifespan of the entire system.

How the Wayne PC4 Enhances Efficiency

Achieving greater productivity and reducing operational strain are critical in any mechanical system. This particular model is designed to deliver consistent performance while optimizing energy use and minimizing wear over time. It effectively balances the workload, ensuring smoother operations even under demanding conditions.

Key Features that Improve Functionality

- Streamlined energy consumption for prolonged usage.

- Enhanced flow control to meet varying operational demands.

- Durable construction designed to resist fatigue.

Optimized for Longevity

The engineering behind this device ensures that components endure for longer periods with minimal need for maintenance. Its design promotes uniform distribution of operational loads, preventing overuse of critical parts, which contributes to the system’s extended lifespan.

- Reduced maintenance cycles save time and costs.

- Optimized performance leads to less downtime.

- Energy-efficient operation helps lower overall expenses.

Key Differences in PC4 Pump Parts

Understanding the distinctions between various components in this model is essential for ensuring proper operation and maintenance. Each element serves a specific function, and recognizing the variations can help with troubleshooting and replacements when needed.

Main Internal Components

- Motor assembly – Key for driving the device, differences in power ratings may affect overall performance.

- Seals – Different types of seals are used based on the liquid being transferred, affecting durability and leakage prevention.

- Impeller – Variations in design and material directly impact flow rate and efficiency.

External Features

- Inlet and outlet ports – Size and shape can vary depending on the connection type required.

- Housing – Differences in material used for the casing provide varying levels of protection against environmental factors.

These differences in internal and external features play a crucial role in determining how the system functions in different conditions and for different tasks.

Maintenance Tips for Wayne PC4 Systems

Ensuring the longevity and efficiency of your fluid transfer system requires regular upkeep and attention. By implementing a few key maintenance practices, you can prevent issues and enhance the performance of your setup. The following tips will help you maintain optimal operation and extend the lifespan of your equipment.

Regular inspections are crucial to identify any potential wear or damage early on. Look for signs of leakage, unusual vibrations, or abnormal noises. Additionally, ensuring that all connections are secure and free of debris will help maintain a smooth operation.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks, cracks, and signs of wear. |

| Cleaning | Every 3 Months | Remove dust and debris from exterior components. |

| Fluid Level Check | Monthly | Ensure fluid levels are within recommended ranges. |

| Filter Replacement | Every 6 Months | Replace filters to prevent clogs and maintain efficiency. |

| Lubrication | Quarterly | Apply appropriate lubricant to moving parts as needed. |

By following these maintenance tips and adhering to a regular schedule, you can ensure your system operates efficiently and reliably, minimizing downtime and costly repairs.

Replacement Guide for Wayne PC4 Components

Maintaining the efficiency of your equipment often requires replacing specific elements over time. Understanding the replacement process for various components can help ensure that your system runs smoothly and effectively. This guide outlines key considerations and steps for replacing essential components.

Before proceeding with any replacements, it is crucial to follow a systematic approach:

- Identify the components that require replacement.

- Gather the necessary tools and replacement elements.

- Refer to the manufacturer’s guidelines for specific instructions.

Here is a list of common elements that may need to be replaced:

- Seals and gaskets

- Valves and fittings

- Motor components

- Filters and strainers

- Hoses and connections

When replacing any component, ensure that you adhere to safety protocols and use the correct specifications for each element. Regular maintenance and timely replacements will prolong the life of your equipment and enhance its overall performance.

Understanding the Wayne PC4 Motor Assembly

The motor assembly is a critical component in various fluid transfer systems, serving as the driving force behind efficient operation. This section delves into the intricate workings and essential elements that make up the motor unit, highlighting its functionality and significance in the overall mechanism.

At the heart of the assembly lies the electric motor, responsible for converting electrical energy into mechanical energy. This transformation is vital for initiating the movement of fluids. The motor’s design often incorporates various components such as the rotor and stator, which work in unison to generate rotational force.

Another crucial element is the drive mechanism, which typically includes a series of gears or belts that transmit power from the motor to the impeller. This transfer of energy ensures that the system can effectively move liquids with the desired flow rate and pressure.

Additionally, the assembly may feature thermal protection devices to prevent overheating, thereby prolonging the life of the motor. These safeguards are essential for maintaining operational efficiency and preventing potential failures.

Overall, understanding the structure and operation of the motor assembly is vital for anyone involved in maintenance or troubleshooting of fluid movement systems. A comprehensive grasp of its components and their interactions can greatly enhance performance and reliability.

Best Practices for Wayne PC4 Pump Installation

Ensuring optimal functionality and longevity of your fluid transfer system begins with proper setup. A systematic approach to installation not only enhances performance but also minimizes potential issues down the line. This section outlines essential guidelines that will help you achieve a successful configuration.

Preparation and Planning

Before commencing the installation, it is crucial to conduct thorough research. Familiarize yourself with the specific requirements of the model you are working with. Assess the installation location for accessibility, ventilation, and proximity to power sources. Additionally, ensure that you have all necessary tools and components at hand to streamline the process.

Proper Alignment and Mounting

Achieving correct alignment is vital to prevent undue stress on components. Ensure that the unit is mounted on a stable and level surface to avoid vibrations that could lead to damage. Follow manufacturer guidelines closely during this stage, as proper positioning will contribute significantly to the efficiency and reliability of the system.

Signs of Wear in Wayne PC4 Parts

Identifying the indicators of deterioration in mechanical components is crucial for maintaining optimal performance. Over time, various elements can exhibit signs of fatigue, which can lead to reduced efficiency and potential failures. Recognizing these signs early can save time and resources in the long run.

Common signs that suggest wear includes:

- Unusual Noises: Any unexpected sounds during operation can indicate that components are no longer functioning smoothly.

- Leaks: Fluid leaks around connections often signify that seals or gaskets are compromised.

- Increased Vibration: Excessive movement can point to loose or damaged parts, affecting overall stability.

- Decreased Performance: A noticeable decline in operational efficiency is a key indicator of wear.

- Visual Damage: Cracks, rust, or other visible defects can suggest serious underlying issues.

Regular inspection and maintenance are vital to prolonging the lifespan of mechanical systems. Addressing these indicators promptly can prevent costly repairs and ensure reliable operation.

Improving Longevity of the Wayne PC4 Pump

Ensuring the extended life of your water-moving device involves several crucial maintenance practices and careful usage strategies. By focusing on specific aspects of operation and upkeep, users can significantly enhance the efficiency and durability of their equipment. Implementing regular maintenance checks, using quality components, and adhering to operational guidelines are key factors in achieving longevity.

Regular Maintenance Checks

Consistent inspections are vital for identifying potential issues before they escalate. Schedule routine evaluations to check for wear and tear on critical components. Early detection of problems can save time and costs associated with major repairs.

Quality Components and Proper Usage

Utilizing high-quality materials and following manufacturer recommendations are essential. Ensure that replacement components meet the required specifications to maintain optimal performance. Additionally, adhering to usage guidelines can prevent unnecessary strain on the equipment, thereby prolonging its lifespan.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Inspection of seals and gaskets | Monthly | Look for signs of wear or leaks. |

| Cleaning of filters | Every 3 months | Clogged filters can reduce efficiency. |

| Checking motor performance | Every 6 months | Listen for unusual sounds during operation. |

| Lubrication of moving parts | Annually | Use recommended lubricants to avoid friction. |