The functionality of a chilling device relies on various intricate elements working in harmony. Each component plays a pivotal role in ensuring optimal performance, regulating temperature, and maintaining efficiency. A thorough understanding of these key elements is essential for anyone seeking to grasp the mechanics behind modern refrigeration technology.

In this section, we will explore the fundamental mechanisms that contribute to the overall operation of a cooling unit. From the motor that drives the system to the intricate network of tubes and valves, every piece is vital for seamless functionality. Recognizing how these components interact can greatly enhance your knowledge and troubleshooting skills.

Additionally, visual representations of these essential units can provide clarity and foster a deeper comprehension of their arrangement and purpose. Whether you’re a DIY enthusiast or a professional technician, familiarizing yourself with these core aspects will empower you to tackle maintenance and repairs with confidence.

Understanding Refrigerator Compressors

This section explores the essential components that drive the cooling system of your appliance, highlighting their functions and importance in maintaining optimal performance.

- Function: Converts low-pressure gas into high-pressure gas, facilitating heat exchange.

- Components: Includes various elements such as valves, motors, and coils.

- Efficiency: A well-functioning unit ensures energy conservation and longevity.

Understanding the mechanics behind these systems can ultimately enhance troubleshooting and maintenance efforts.

- Identify the key components for better maintenance.

- Monitor performance to prevent potential failures.

- Regular servicing can extend lifespan significantly.

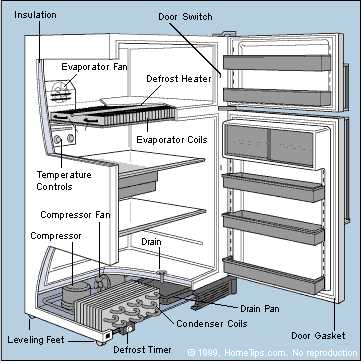

Key Components of Refrigerators

Understanding the essential elements that make up cooling appliances is crucial for effective maintenance and operation. These units are comprised of several critical components that work in unison to ensure optimal performance and efficiency. Each element plays a specific role in the cooling cycle, contributing to the overall functionality.

Main Elements

Among the primary components are the mechanisms responsible for heat exchange and temperature regulation. These elements facilitate the transfer of heat from the interior to the exterior, maintaining the desired coolness inside the unit. Below is a brief overview of these vital components:

| Component | Description |

|---|---|

| Evaporator | Absorbs heat from the interior, cooling the air inside. |

| Condenser | Dissipates heat to the outside environment, allowing the refrigerant to cool and condense. |

| Expansion Valve | Regulates the flow of refrigerant, reducing its pressure and temperature. |

| Fan | Circulates air over the evaporator and condenser to enhance heat exchange. |

Additional Features

Other significant elements include insulation materials that prevent heat transfer and maintain low temperatures within the appliance. The control system also plays a vital role in regulating temperatures and ensuring energy efficiency. By understanding these components, users can appreciate the intricate design and functionality of their cooling appliances.

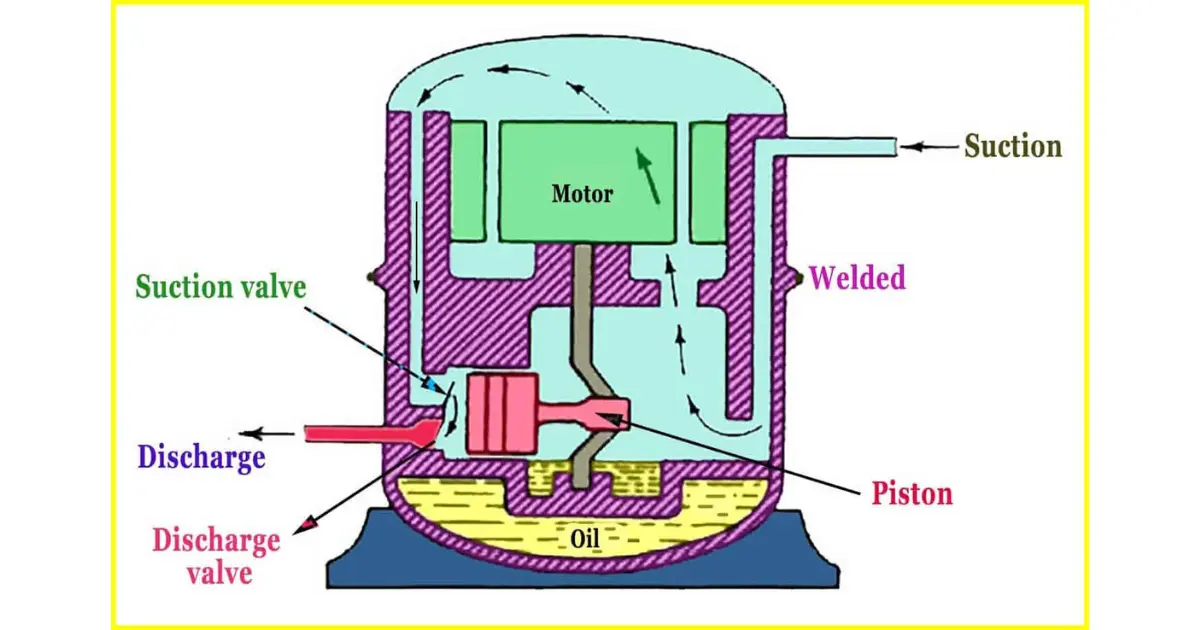

Function of Compressor in Cooling

The heart of any cooling system plays a crucial role in maintaining low temperatures. It operates by circulating a specific fluid that absorbs heat, thereby creating a chilled environment. This process is essential for the effective preservation of perishable items and contributes significantly to comfort in residential and commercial spaces.

Heat Absorption and Transfer

Initially, the system draws in the warm vapor from the surrounding area. This vapor is then transformed into a high-pressure state, allowing it to release the absorbed heat outside. The transition from low to high pressure not only enhances the efficiency of heat exchange but also prepares the fluid for the next cycle of cooling. Without this essential mechanism, maintaining desired temperatures would be nearly impossible.

Cycle Efficiency and Performance

The efficiency of the entire cooling process depends on the optimal functioning of this central component. Regular maintenance ensures that the system operates smoothly, preventing potential breakdowns and prolonging its lifespan. By maximizing energy usage, it not only reduces operational costs but also minimizes environmental impact, making it a vital aspect of modern cooling solutions.

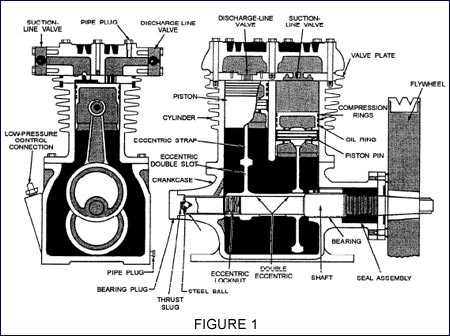

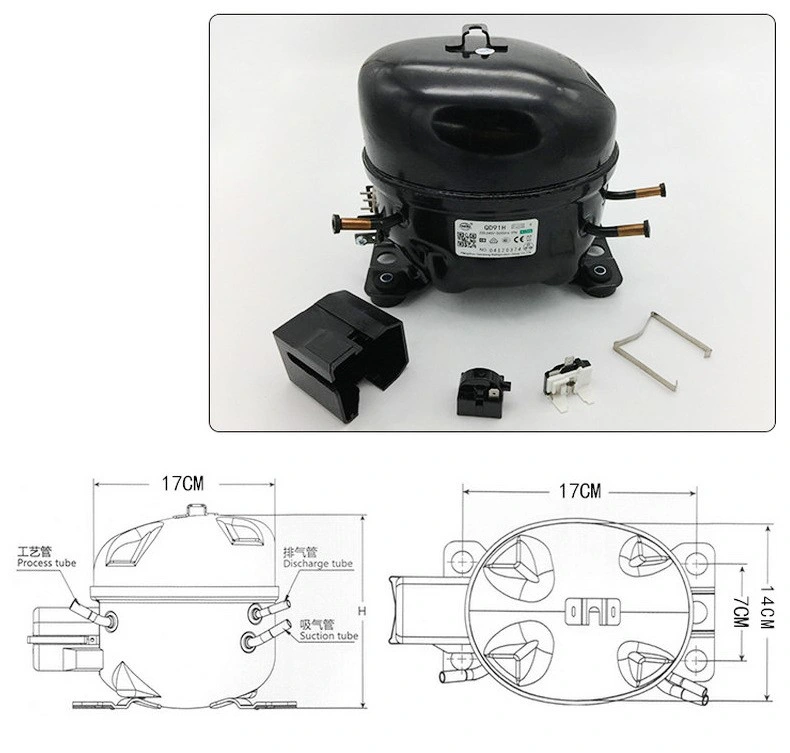

Diagram Breakdown of Compressor Parts

This section delves into the intricate components of a key element in cooling systems, exploring their functions and interrelationships. Understanding how these elements work together can enhance troubleshooting and maintenance efforts.

The primary element is the motor, which drives the mechanism and is essential for the unit’s operation. Coupled with this is the housing, designed to protect and encase the internal mechanisms while ensuring efficient heat dissipation. Additionally, the intake and discharge valves play crucial roles in regulating the flow of refrigerant, allowing for optimal pressure management.

Moreover, the piston serves as a vital part of the compression process, moving within the cylinder to facilitate the transformation of refrigerant from gas to liquid. A connecting rod links the piston to the crankshaft, converting rotary motion into linear movement. Furthermore, the crankshaft itself is pivotal, as it provides the necessary rotational force derived from the electric motor.

Finally, various seals and gaskets ensure that the system remains airtight, preventing leaks and maintaining efficiency. By comprehensively understanding these components, one can gain insights into the operational dynamics of cooling mechanisms and ensure their effective performance.

How to Identify Compressor Issues

Recognizing malfunctions in your cooling unit can save you time and money. Early detection of irregularities ensures that you can address potential failures before they escalate. Common signs include unusual noises, inefficient cooling, and fluctuating temperatures.

Start by listening for odd sounds, such as clicking or buzzing, which may indicate mechanical problems. Next, check for temperature inconsistencies inside the unit; if items aren’t as cold as they should be, it could point to an underlying issue. Lastly, observe the energy consumption–significant increases may signal that the unit is struggling to operate efficiently.

Maintenance Tips for Compressor Longevity

Ensuring the durability of your cooling system requires attention and care. By following some essential practices, you can extend its lifespan and enhance its efficiency, ultimately saving on energy costs and repairs.

Regular Inspections

- Check for any unusual noises during operation.

- Inspect the area for dust and debris accumulation.

- Ensure all connections are secure and free of leaks.

Optimal Operating Conditions

- Maintain appropriate ambient temperatures around the unit.

- Avoid overloading the system with excessive contents.

- Keep ventilation areas clear for efficient airflow.

Common Problems with Refrigerator Compressors

Understanding the typical issues that can arise with cooling units is essential for effective maintenance and troubleshooting. These problems often lead to reduced efficiency and may even result in complete failure if not addressed promptly. Below are some prevalent concerns that users may encounter.

| Problem | Description | Possible Causes |

|---|---|---|

| Inadequate Cooling | The unit fails to maintain the desired temperature. | Low refrigerant levels, dirty coils, or malfunctioning sensors. |

| Excessive Noise | Unusual sounds indicating possible malfunction. | Worn bearings, loose components, or debris in the fan. |

| Frequent Cycling | The system turns on and off too often. | Thermostat issues, dirty filters, or an obstructed airflow. |

| High Energy Consumption | Increased utility bills due to inefficiency. | Faulty components, poor insulation, or refrigerant leaks. |

| Unpleasant Odors | Strange smells emanating from the cooling unit. | Trapped food, mold, or electrical issues. |

Identifying these challenges early on can help ensure the longevity of the appliance and improve its performance. Regular maintenance and timely repairs are key to avoiding more serious problems down the line.

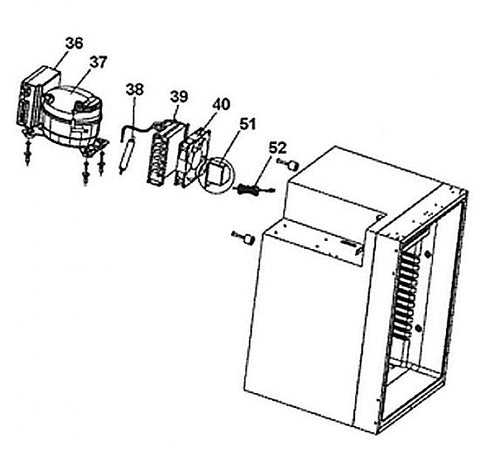

Replacing a Faulty Compressor

When your cooling unit stops functioning efficiently, it may be time to consider a replacement of the main unit responsible for the refrigeration process. Understanding the signs of failure and the steps involved in the replacement can save you time and ensure optimal performance in the long run.

Identifying the Need for Replacement

Common indicators of malfunction include unusual noises, inconsistent cooling, or complete failure to maintain low temperatures. If you notice any of these symptoms, it’s crucial to assess the situation promptly. Testing the unit can help determine whether a replacement is necessary or if repairs can be made instead.

Steps for Replacement

Before beginning the process, ensure that you have the necessary tools and a suitable replacement unit. Start by disconnecting the power supply and carefully removing the old unit. Follow manufacturer guidelines for installation, paying attention to proper alignment and secure connections. Once installed, restore power and monitor the performance to ensure everything operates smoothly.

Role of Refrigerant in Compressors

The functioning of cooling systems relies heavily on a specific fluid that plays a crucial role in heat transfer. This substance cycles through various stages, absorbing and releasing heat, thereby maintaining desired temperatures within a closed environment.

How It Works

During its journey, the fluid transitions between gaseous and liquid states, enabling it to extract heat from the surroundings and release it outside. This process is vital for achieving efficient temperature regulation.

Importance of Efficiency

Optimal performance of the cooling mechanism hinges on the properties of the fluid used. Factors such as boiling point and pressure greatly influence the system’s effectiveness and energy consumption.

| Property | Impact on Performance |

|---|---|

| Boiling Point | Determines heat absorption efficiency |

| Pressure | Affects flow rate and cooling capacity |

| Thermal Conductivity | Influences heat transfer rates |

Comparing Types of Compressors

This section explores various mechanisms used in cooling systems, highlighting their unique characteristics and applications. Understanding the distinctions between these systems can aid in selecting the most efficient option for specific needs.

Types of Mechanisms

- Piston Systems

- Scroll Mechanisms

- Rotary Options

- Centrifugal Variants

Key Differences

- Efficiency: Different systems operate at varying efficiency levels depending on design.

- Noise Levels: Some mechanisms are quieter, making them suitable for residential use.

- Maintenance: Certain types require more frequent upkeep than others.

- Cost: Initial investment and operational costs can vary widely.

Impact of Temperature on Performance

Temperature plays a crucial role in the efficiency and functionality of cooling systems. Variations can lead to significant changes in performance, affecting overall operation and longevity.

When examining the influence of temperature, consider the following factors:

- Operating Efficiency: Higher ambient temperatures can decrease the ability to maintain optimal conditions.

- Energy Consumption: Increased temperatures often lead to higher energy usage as systems work harder to achieve desired cooling levels.

- Component Lifespan: Elevated heat can accelerate wear and tear, leading to premature failure of essential elements.

Understanding these impacts is vital for effective maintenance and optimal functioning over time.

Future Technologies in Compressor Design

The evolution of cooling mechanisms is set to transform how we manage thermal processes. Innovations in efficiency, sustainability, and smart technologies are driving this transformation, ensuring that these systems become more adaptable and energy-efficient for modern applications.

Emerging advancements focus on several key areas:

| Technology | Description |

|---|---|

| Magnetocaloric Effect | A technique utilizing magnetic fields to induce temperature changes, offering an eco-friendly alternative. |

| Variable Speed Drives | Systems that adjust operational speed based on demand, enhancing energy efficiency and reducing wear. |

| Smart Sensors | Integration of IoT devices for real-time monitoring and predictive maintenance, optimizing performance. |

| Advanced Materials | Utilization of lightweight, high-performance materials to improve durability and thermal conductivity. |

These innovations are poised to create the ultimate balance between performance and environmental responsibility in thermal management technologies.