Maintaining an effective tool requires a clear understanding of its internal structure and the role each element plays in its operation. A well-designed machine can significantly enhance productivity, provided that users are familiar with its various components and their functions. This knowledge not only aids in troubleshooting issues but also fosters better care and maintenance practices.

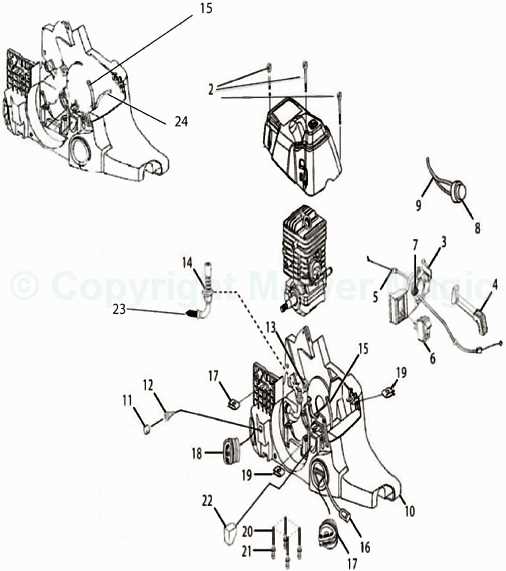

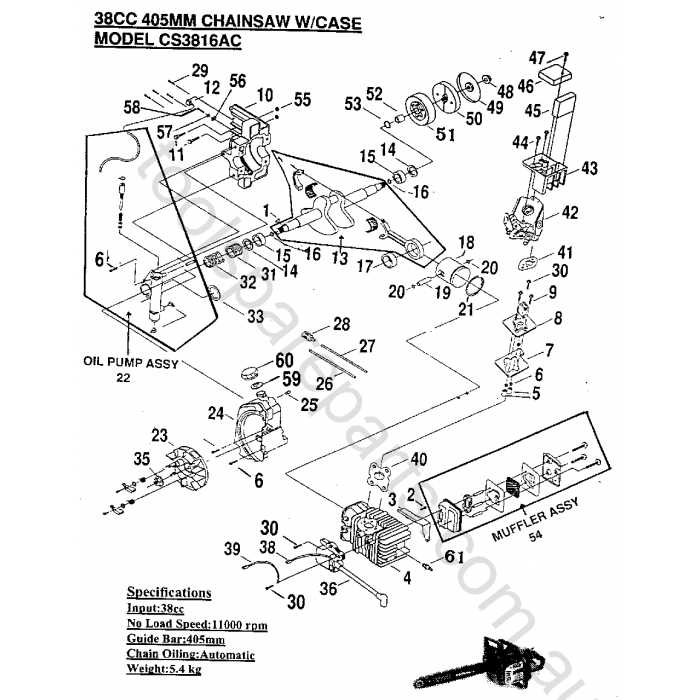

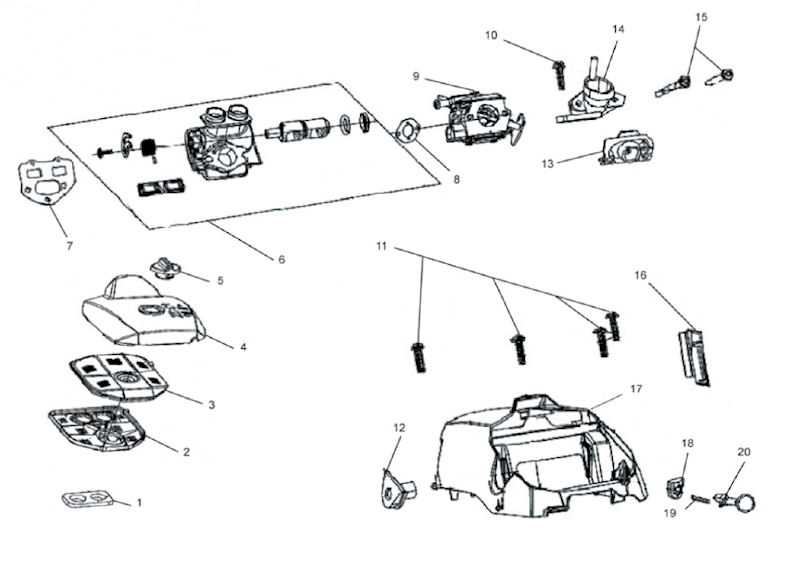

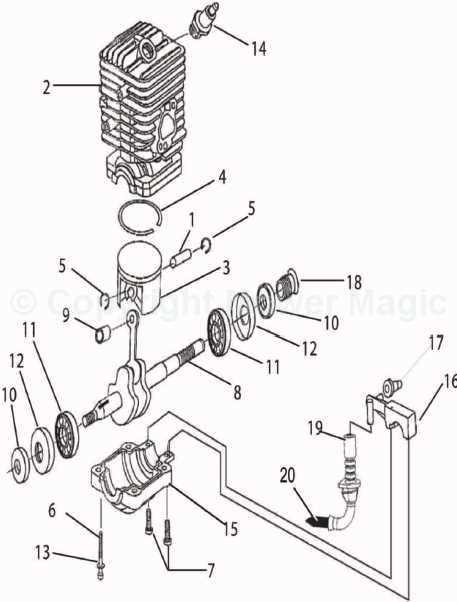

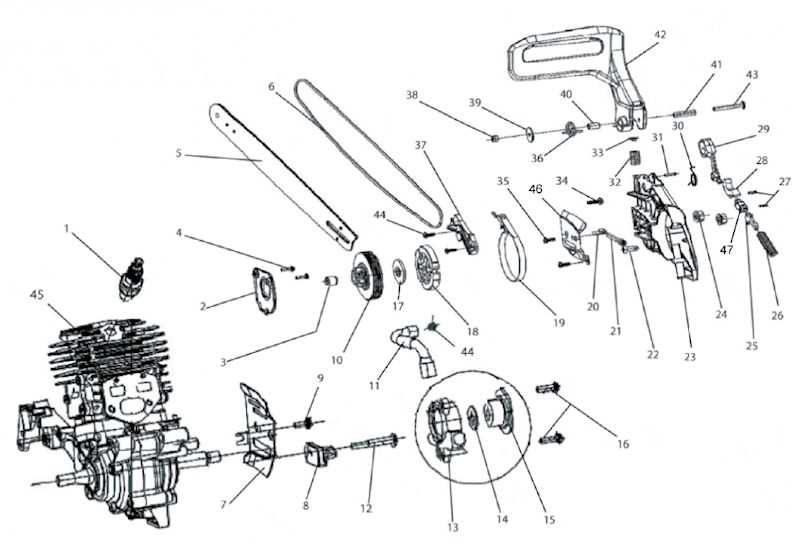

Visual representations of these components can be invaluable resources for users seeking to comprehend how their equipment works. Such illustrations serve as guides for identifying parts and understanding their arrangement within the tool. By examining these visual aids, individuals can gain insights into the assembly and potential points of failure, thereby empowering them to take informed actions.

In this section, we will explore the essential elements that contribute to the overall functionality of the device. By delving into the intricate details, users can enhance their proficiency and ensure longevity in the use of their equipment. Understanding these foundational aspects is a crucial step towards mastering the use of any power tool.

A cutting tool designed for various tasks features several essential components that work together to ensure efficient operation. Understanding these elements is crucial for effective maintenance and optimal performance.

Essential Components

- Power Source: This element provides the energy required for operation, whether it’s electric or fueled by a combustion engine.

- Guide Bar: A metal bar that supports the cutting chain, allowing it to rotate and perform its task.

- Cutting Chain: The loop of linked segments that includes sharp teeth designed for slicing through wood and other materials.

- Chain Tensioner: A mechanism that allows the user to adjust the tightness of the cutting chain for smooth operation.

- Handle: The grip that enables control over the tool, ensuring safety and maneuverability during use.

Additional Features

- Safety Mechanisms: Various features, such as chain brakes and throttle locks, are designed to enhance user safety.

- Lubrication System: This system ensures that the chain and guide bar receive adequate oil to minimize friction and wear.

- Air Filter: A component that cleans the air entering the engine, preventing debris from causing damage.

How to Identify Each Component

Understanding the various elements of your tool is crucial for effective maintenance and troubleshooting. Each part plays a specific role in the overall functionality, and recognizing them can enhance your familiarity and efficiency when operating the equipment.

Visual Inspection

Start by visually examining the device. Look for distinct shapes and sizes of components, as well as their arrangement. Familiarize yourself with the following:

- Handle – Often the most prominent feature, providing grip and control.

- Motor Housing – Usually a robust enclosure that protects internal mechanisms.

- Guide Bar – A long, flat piece that guides the cutting tool.

- Chain – A moving element designed for cutting through materials.

- Safety Features – Elements designed to prevent accidents, often found near the handle.

Using Reference Materials

Consult user manuals or online resources to find labeled illustrations of the tool. This can provide clarity on the purpose of each element. Key areas to focus on include:

- Maintenance Sections – Often detail how to care for and identify each component.

- Troubleshooting Guides – Can help in recognizing parts related to common issues.

By combining visual inspections with reference materials, you can effectively identify and understand the various components of your device, ensuring better performance and safety.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding the assembly and functionality of any mechanical device. By providing a clear overview of each element, it facilitates effective maintenance, repairs, and upgrades. Such illustrations help users quickly identify parts, leading to efficient troubleshooting and enhanced performance.

Enhanced Understanding

Having a visual reference allows individuals to grasp the relationships between different components more easily. This insight is invaluable when performing repairs or replacements, as it aids in ensuring that each piece is correctly fitted and functions as intended.

Efficiency in Repairs

When faced with a malfunction, referring to a visual guide can significantly reduce the time spent diagnosing issues. By pinpointing the specific elements involved, users can focus their efforts on the areas that require attention, minimizing frustration and downtime.

| Benefit | Description |

|---|---|

| Clear Identification | Facilitates easy recognition of components for maintenance tasks. |

| Time-Saving | Reduces the duration of troubleshooting and repairs. |

| Improved Accuracy | Enhances the likelihood of correct assembly and disassembly. |

Common Replacement Parts Available

When maintaining outdoor power equipment, it’s essential to have access to various components that may require replacement over time. Regular wear and tear can affect performance, and having the right replacements on hand ensures your device operates smoothly. This section highlights some of the frequently needed components to keep your machinery in top condition.

Essential Components

Among the critical items for maintaining performance are items like blades, batteries, and drive mechanisms. These elements play significant roles in ensuring efficiency and reliability during operation.

| Component Type | Description | Function |

|---|---|---|

| Blades | Cutting edges that handle various materials. | Facilitate precise cutting actions. |

| Batteries | Power sources for operation. | Provide necessary energy for the device to function. |

| Drive Belts | Connect power to the cutting mechanism. | Transmit power effectively for operation. |

Additional Accessories

In addition to essential components, various accessories can enhance functionality and convenience. Having extra chains and guides can significantly improve versatility for different tasks.

| Accessory Type | Description | Benefit |

|---|---|---|

| Chains | Interchangeable cutting chains for different applications. | Allow for adaptability to various cutting needs. |

| Guide Bars | Support the cutting chain. | Ensure accurate cuts and extend the life of the chain. |

| Maintenance Kits | Sets that include lubricants and tools. | Facilitate proper upkeep and enhance performance longevity. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficient performance of your outdoor power tool. Regular attention to maintenance not only extends the lifespan of the equipment but also enhances its reliability during operation. Adopting a proactive approach can prevent potential issues and keep the tool functioning optimally.

Regular Cleaning

Cleaning the tool after each use is crucial. Debris, dirt, and residue can accumulate, affecting performance and safety. Focus on removing sawdust and any residue from the cutting mechanism, as well as ensuring ventilation areas remain clear.

Inspect and Replace Worn Parts

Frequent inspections help identify any components that may be wearing down. Replacing damaged or worn-out parts promptly can prevent further complications and maintain efficiency. Always consult the user manual for guidelines on which components may require regular replacement.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean Cutting Mechanism | After Each Use | Remove all debris and residue. |

| Inspect Components | Monthly | Check for signs of wear or damage. |

| Replace Worn Parts | As Needed | Refer to user manual for specific parts. |

Troubleshooting Common Issues

This section addresses frequent problems encountered with outdoor power tools and provides effective solutions to ensure optimal performance. Understanding common issues can help users diagnose and resolve difficulties, enhancing the longevity and efficiency of their equipment.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Tool not starting | Faulty battery, loose connections, or worn-out components | Check battery charge, inspect connections, and replace worn parts if necessary |

| Poor cutting performance | Dull blade, incorrect chain tension, or debris blockage | Sharpen the blade, adjust chain tension, and clear any obstructions |

| Excessive vibration | Loose components or imbalanced attachments | Tighten all screws and bolts, and ensure attachments are balanced |

| Overheating | Extended use without rest, low lubrication, or blocked vents | Allow the tool to cool down, check lubrication levels, and clean vents |

Assembly Instructions for Parts

This section provides guidance on the assembly process of essential components in a power tool. Properly assembling these elements is crucial for optimal performance and longevity.

Required Tools

- Screwdriver

- Wrench

- Hex key

- Pliers

Assembly Steps

- Begin by gathering all necessary components and tools in a clean workspace.

- Refer to the provided schematic for a visual reference of each component’s placement.

- Start with the main body; ensure all connectors are aligned properly.

- Secure the main assembly using the designated screws and fasteners.

- Attach additional components, following the sequence indicated in the schematic.

- Once all pieces are in place, double-check each connection for stability.

- Finally, conduct a visual inspection to confirm that everything is assembled correctly.

Safety Precautions When Using

Ensuring safety during operation is crucial when handling power tools designed for cutting. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. It is essential to understand the equipment’s capabilities and limitations to use it responsibly.

Personal Protective Equipment

Wearing appropriate protective gear is vital. This includes a sturdy helmet to shield the head, eye protection to prevent debris from causing injury, and hearing protection to mitigate noise exposure. Additionally, gloves should be worn to ensure a firm grip, while steel-toed boots provide necessary foot protection.

Safe Operating Practices

Before commencing work, it is advisable to inspect the tool for any damage or wear. Ensure that the area is clear of obstacles and that bystanders are at a safe distance. When cutting, maintain a stable stance and always be aware of your surroundings. Following the manufacturer’s guidelines for operation will enhance safety and efficiency.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for ensuring efficiency and effectiveness. Proper tools not only facilitate repairs but also enhance safety during the process. Below is a guide to essential equipment that can make your repair efforts more successful.

Basic Hand Tools

Standard hand tools are fundamental for any repair job. Items such as screwdrivers, wrenches, and pliers are indispensable. These tools allow for the disassembly and reassembly of components, making it easier to access and address specific issues.

Specialized Equipment

In addition to basic tools, having specialized equipment can significantly improve the repair process. Socket sets, torque wrenches, and blade sharpeners are examples of items that enhance precision and ensure proper functioning after repairs. Investing in quality equipment can lead to better outcomes and longer-lasting results.

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its longevity and performance. Various sources offer the necessary replacements, ensuring you maintain optimal functionality without compromising quality.

Authorized Dealers

One of the most reliable ways to obtain replacements is through authorized dealers. These establishments provide original components that match the specifications of your equipment. Visiting a dealer can also give you access to knowledgeable staff who can assist you in identifying the correct items.

Online Retailers

The internet has made it easier than ever to locate specific items. Numerous online retailers specialize in various equipment components, offering a vast selection at competitive prices. Before making a purchase, ensure that the seller is reputable and offers return policies in case the items do not meet your expectations.

Important: Always verify the compatibility of the components with your specific model to avoid any issues during installation.

Exploring Upgrade Options for Performance

Improving the efficiency and functionality of your power equipment can significantly enhance your experience and productivity. Various enhancements can be considered to achieve superior performance, allowing users to tackle tasks more effectively.

When evaluating upgrade possibilities, several factors should be taken into account:

- Power Source: Consider transitioning to a more robust battery system that offers greater energy capacity, leading to longer operating times.

- Bar Length: Opting for a longer bar can increase cutting capacity, enabling the handling of larger materials.

- Chain Quality: Upgrading to a high-performance chain can improve cutting efficiency and reduce wear and tear.

- Guide System: A well-designed guide can provide better stability and control during operation, enhancing overall safety.

- Ergonomic Features: Investing in improved grip and balance can reduce user fatigue and improve handling.

By exploring these upgrade options, users can enhance their equipment’s performance, making it more suitable for various tasks while ensuring optimal efficiency.