In the realm of mechanical devices, comprehending the configuration and individual elements is crucial for effective maintenance and repair. A clear visual representation can significantly aid in recognizing the various components that come together to create a functional unit. This knowledge empowers users to troubleshoot issues and make informed decisions when seeking replacements or upgrades.

Whether you’re an enthusiast looking to enhance your understanding or a novice aiming to grasp the essentials, having access to an accurate representation of the internal structure can be invaluable. Such insights not only facilitate smoother repairs but also promote a deeper appreciation for the intricacies involved in the design and functionality of these machines.

Exploring the specific arrangements and roles of each segment allows for better diagnostics and enhances the overall user experience. By delving into the intricate details of these components, users can ensure their equipment operates efficiently and remains in optimal condition.

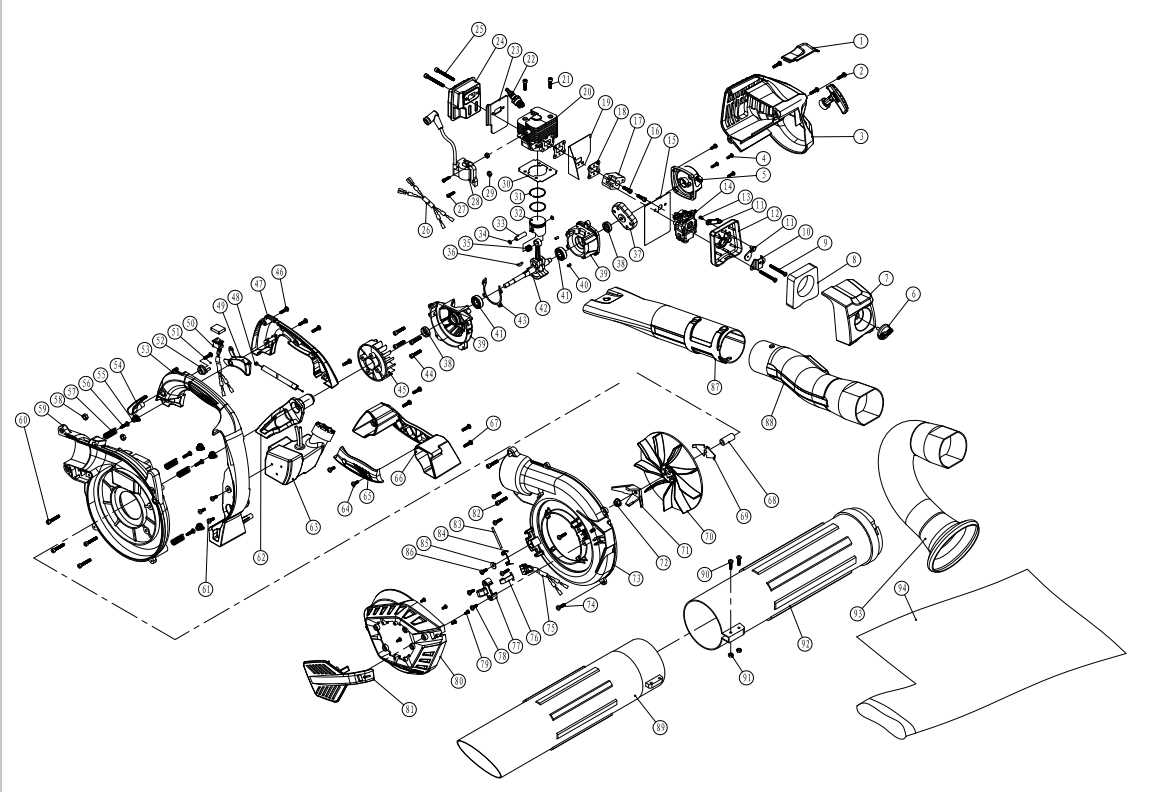

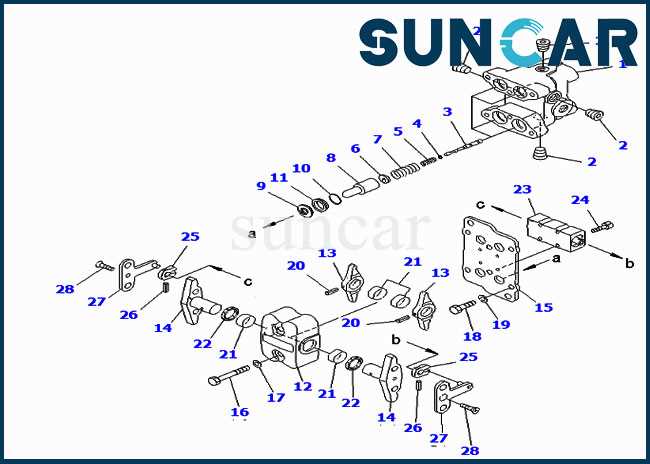

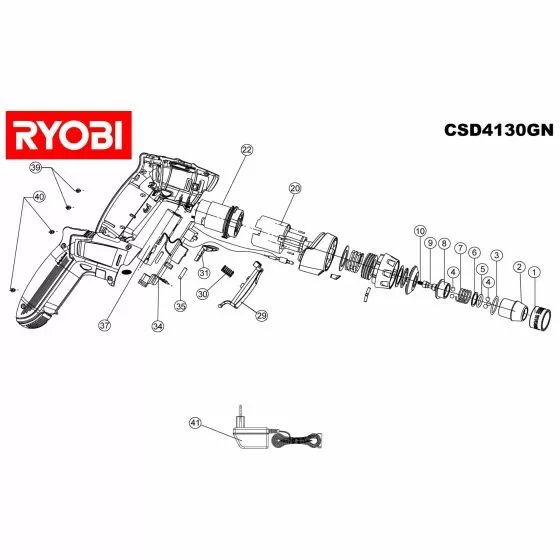

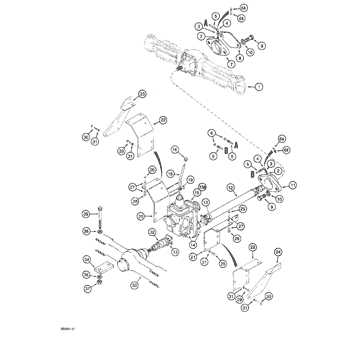

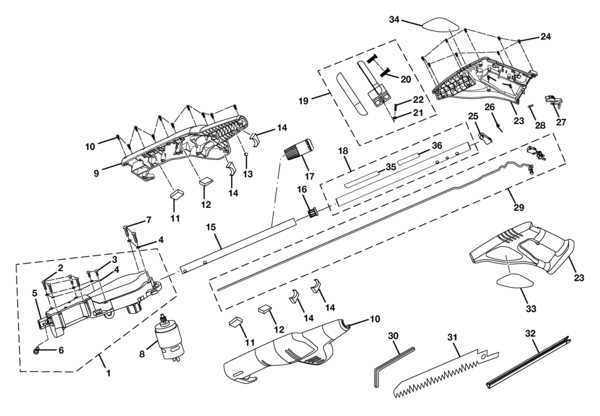

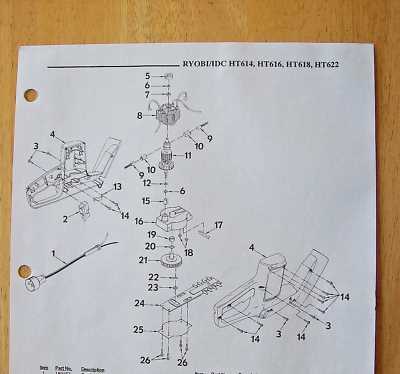

The visual representation of components is essential for anyone seeking to maintain or repair equipment. This illustration serves as a roadmap, guiding users through the intricate arrangement of elements and their respective functions. Grasping the layout allows for more efficient troubleshooting and replacement, ultimately enhancing the performance and longevity of the device.

Familiarity with this representation can provide significant benefits:

- Identifying Components: Quickly locate specific pieces and understand their role within the assembly.

- Simplifying Repairs: Streamline the repair process by knowing what to disassemble and how to replace worn-out items.

- Facilitating Upgrades: Recognize which elements can be upgraded or modified for improved functionality.

When examining the visual layout, keep in mind the following steps to maximize understanding:

- Review the Legend: Start by checking the legend or key that denotes various parts and their corresponding labels.

- Trace Connections: Follow the lines or arrows that indicate how components interact with one another.

- Note Assembly Order: Observe the sequence in which elements are assembled, as this can aid in reassembly after repairs.

By mastering the interpretation of this visual guide, users can enhance their ability to perform maintenance tasks with confidence and efficiency.

Identifying Major Components

Understanding the essential elements of a mechanical device is crucial for effective maintenance and repair. By recognizing the primary components, users can enhance their familiarity with the overall structure, leading to better performance and longevity.

Here are some key parts that are commonly found:

- Engine: The heart of the machine, responsible for providing the necessary power for operation.

- Fuel System: Includes components that manage the storage and delivery of fuel, ensuring efficient performance.

- Ignition System: Responsible for starting the engine and ensuring it runs smoothly.

- Control Handle: The interface through which the operator manages various functions and settings.

- Cutting Mechanism: The part that interacts with the material being processed, determining effectiveness and efficiency.

- Housing: The outer shell that protects internal components from external elements and damage.

Familiarizing oneself with these elements allows for better troubleshooting and enhances the ability to perform routine inspections and repairs.

Common Issues with the Ryobi 410R

When operating a particular outdoor tool, users may encounter several recurring challenges that can affect performance and efficiency. Understanding these common problems is essential for maintaining functionality and ensuring longevity.

1. Engine Starting Difficulties: One prevalent issue is the difficulty in starting the engine. This can be attributed to factors such as fuel quality, air filter blockages, or spark plug malfunctions. Regular maintenance and checks can help prevent these obstacles.

2. Poor Cutting Performance: Users often report subpar cutting capabilities. This may arise from dull blades, improper height adjustments, or an unbalanced cutting mechanism. Regular sharpening and adjustment are vital for optimal operation.

3. Overheating Problems: Overheating can occur during prolonged use, leading to decreased efficiency and potential damage. This is frequently caused by a lack of lubrication or airflow restrictions. Ensuring proper maintenance can mitigate this risk.

4. Vibration Issues: Excessive vibrations can be uncomfortable and indicate underlying mechanical problems. These vibrations may stem from loose components or unbalanced parts. Regular inspections and secure fittings are necessary to address this concern.

5. Fuel Leaks: Fuel leaks are another critical issue that can pose safety risks and reduce efficiency. These leaks often result from damaged fuel lines or loose fittings. Prompt attention to any signs of leakage is essential for safe operation.

Maintenance Tips for Longevity

To ensure the extended life and optimal performance of your equipment, regular upkeep is essential. By following a few simple guidelines, you can keep your device running smoothly and efficiently, preventing unnecessary wear and tear.

Regular Cleaning

- Remove debris and dirt after each use to prevent buildup.

- Use a soft brush or cloth to clean sensitive areas.

- Check and clean air filters regularly to maintain airflow.

Periodic Inspections

- Inspect all components for signs of damage or wear.

- Ensure all fasteners are tight and secure.

- Look for any unusual noises during operation, which may indicate underlying issues.

By incorporating these maintenance practices into your routine, you can significantly enhance the durability and reliability of your equipment, ensuring it serves you well for years to come.

Where to Find Replacement Parts

When searching for components to restore or enhance your equipment, it’s essential to explore various sources. Whether you are looking for specific items or general accessories, several avenues can provide the necessary resources.

Online Retailers: Numerous websites specialize in selling various components for different models. These platforms often feature a vast selection, enabling you to easily compare prices and specifications. Ensure to check customer reviews to gauge reliability.

Local Hardware Stores: Many local shops carry a range of essential supplies. Visiting these stores can also provide the advantage of immediate availability. Staff members can often offer advice and recommendations based on their experience.

Manufacturer Websites: The official website of the manufacturer typically has a dedicated section for consumers to explore available components. This option often guarantees that you are getting high-quality replacements designed specifically for your equipment.

Online Marketplaces: Platforms like eBay or Amazon can be excellent sources for both new and used components. It’s crucial to verify the credibility of the seller and the condition of the items before making a purchase.

Specialty Shops: Certain stores focus specifically on equipment maintenance and may have a more extensive selection of specific items. These businesses can provide expertise and help you find rare or hard-to-find components.

Comparing Genuine and Aftermarket Options

When it comes to selecting components for your equipment, the choice between authentic and alternative solutions is crucial. Each option has its unique attributes that cater to varying preferences and budgets. Understanding the differences can help you make an informed decision for your needs.

Benefits of Authentic Components

- Quality Assurance: Genuine items typically undergo rigorous testing and meet specific manufacturing standards, ensuring reliability.

- Warranty Support: Purchasing original components often comes with a warranty, providing peace of mind in case of defects.

- Perfect Fit: Authentic parts are designed to match your device precisely, minimizing the risk of compatibility issues.

Advantages of Alternative Solutions

- Cost-Effective: Aftermarket options are often more affordable, making them an attractive choice for budget-conscious consumers.

- Variety of Choices: There is a wide range of aftermarket products available, giving you flexibility in selection based on your requirements.

- Innovative Features: Some alternative components may offer unique features or enhancements not found in the original versions.

Ultimately, the decision between genuine and aftermarket components will depend on your individual needs, budget, and expectations regarding performance and longevity.

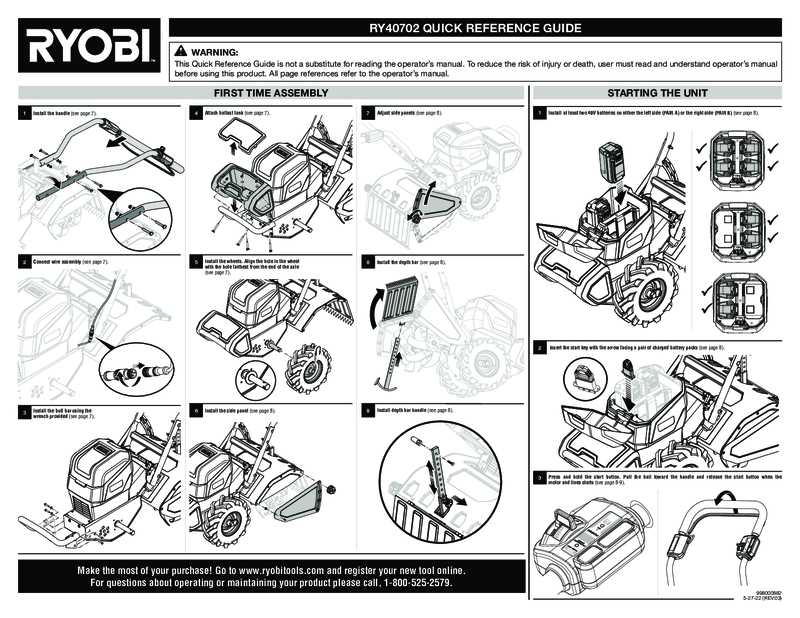

Step-by-Step Assembly Guide

Assembling your equipment can be a rewarding experience, allowing you to understand its components and functionality better. This guide will walk you through the process of putting together the various elements systematically, ensuring a smooth and efficient assembly. Follow each step carefully to achieve the best results.

Step 1: Begin by laying out all the components on a flat surface. This will help you familiarize yourself with each part and its respective role in the overall structure. Organizing everything before you start will save time and reduce frustration during the assembly process.

Step 2: Refer to the assembly instructions to identify the sequence in which the pieces need to be joined. Start with the base or foundation, which will provide stability for the entire structure. Secure it in place with the appropriate fasteners, making sure everything is aligned correctly.

Step 3: Gradually add the subsequent components according to the guidelines. Take care to connect each part firmly, ensuring they fit snugly together. If necessary, use a tool to tighten the connections, but be cautious not to overtighten and risk damaging any components.

Step 4: Once the main structure is assembled, inspect all joints and connections for stability. Make any adjustments as needed to ensure everything is secure. This step is crucial for the longevity and safety of your assembly.

Step 5: Finally, review the assembly instructions one last time to confirm that no steps were overlooked. Testing the completed assembly before putting it into use will help you identify any potential issues early on.

By following this structured approach, you can confidently assemble your equipment, maximizing its efficiency and performance.

Tools Needed for Repairs

Having the right equipment is essential for effectively addressing maintenance tasks. Whether you’re performing minor adjustments or more significant fixes, specific tools will make the process smoother and more efficient.

Here are the essential items you should have on hand:

- Screwdrivers: A set of various sizes, including Phillips and flathead, is necessary for loosening and tightening screws.

- Wrenches: Both adjustable and fixed wrenches are crucial for gripping and turning nuts and bolts.

- Socket Set: A collection of sockets will allow for easier access to fasteners in tight spaces.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small components.

- Utility Knife: This tool is handy for cutting materials and removing old parts or packaging.

- Measuring Tape: Accurate measurements ensure that replacements fit perfectly.

- Cleaning Supplies: Rags and brushes will help keep the work area tidy and maintain the equipment.

By ensuring you have these essential tools, you’ll be well-prepared to tackle any maintenance project efficiently.

User Reviews and Feedback

This section presents a collection of insights and evaluations from users who have engaged with the product. The experiences shared by customers provide valuable information regarding the performance, durability, and usability of the item, aiding potential buyers in making informed decisions.

Customer Experiences

Users have expressed a variety of opinions based on their interactions. Many appreciate the reliability and efficiency of the device, while others highlight areas for improvement. Below is a summary of common themes found in user feedback.

| Feedback Aspect | Positive Comments | Negative Comments |

|---|---|---|

| Performance | Consistently effective in various tasks. | Occasional issues with power output. |

| Durability | Sturdy build quality that withstands heavy use. | Some components may wear out faster than expected. |

| User-Friendliness | Intuitive controls and easy setup. | Initial learning curve for new users. |

Overall Satisfaction

In conclusion, the overall feedback from users indicates a generally positive reception, with many recommending the product to others. While there are some drawbacks mentioned, the advantages often outweigh the negatives, making it a worthwhile consideration for potential customers.

Additional Resources for Owners

For those who possess this particular device, accessing supplementary materials can greatly enhance the overall experience and performance. Whether you seek maintenance tips, troubleshooting advice, or upgrades, various avenues are available to assist in optimizing your ownership journey.

Online Communities and Forums

Engaging with fellow enthusiasts through online platforms can be invaluable. Many dedicated forums provide a space for users to share experiences, seek advice, and discuss modifications. By participating in these communities, you can gain insights and solutions from individuals who have navigated similar challenges.

Manufacturer Resources

Exploring the official resources offered by the manufacturer is another excellent approach. Many manufacturers provide comprehensive guides, instructional videos, and FAQs designed to support owners. Utilizing these materials can help you better understand the intricacies of your device and ensure proper upkeep.