In the world of outdoor machinery, comprehending the intricate components that facilitate optimal performance is essential. This section offers an insightful exploration of key elements that contribute to the functionality of small engines, emphasizing their significance in maintenance and repair.

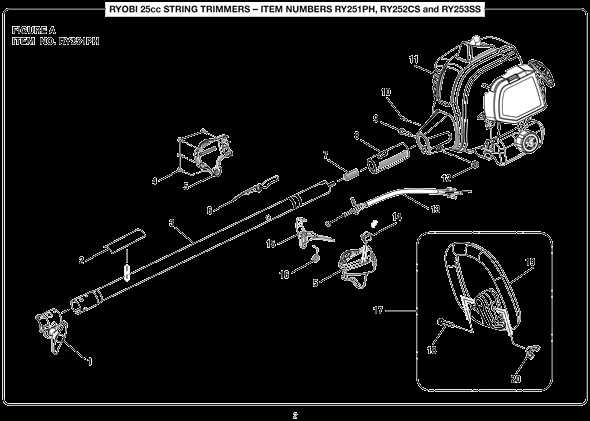

Visual aids can greatly enhance our understanding of these intricate systems. By breaking down the various sections and mechanisms, we can identify how each piece works in harmony to ensure efficient operation.

For enthusiasts and professionals alike, being able to delve into detailed schematics provides the ultimate advantage when troubleshooting issues or performing routine maintenance. Gaining clarity on these components empowers users to make informed decisions about repairs and upgrades.

Understanding Ryobi Carburetors

Gaining insight into the mechanisms that regulate fuel and air mixtures is essential for optimal engine performance. These devices play a crucial role in ensuring that the combustion process runs smoothly, which ultimately affects the efficiency and reliability of various outdoor equipment. Familiarizing oneself with the components and functions can lead to better maintenance and troubleshooting.

Key Components

Various elements work together to facilitate the proper operation of these fuel management systems. Understanding how each part contributes to the overall functionality can enhance one’s ability to perform repairs and adjustments. Below is a breakdown of essential components:

| Component | Function |

|---|---|

| Float | Regulates fuel level within the chamber |

| Jet | Controls the flow of fuel into the airflow |

| Throttle Valve | Adjusts the amount of air-fuel mixture entering the engine |

| Choke | Aids in starting the engine by enriching the fuel mixture |

Common Issues

Understanding typical problems can aid in quick diagnostics and effective solutions. From clogged passages to misadjusted components, recognizing these issues is the first step towards ensuring seamless operation. Regular inspection and maintenance are crucial for preventing performance deterioration.

Common Issues with Ryobi Carburetors

Understanding frequent problems that arise in fuel delivery systems can greatly enhance maintenance and performance. These issues often lead to poor engine function, increased emissions, and operational inefficiencies.

Clogged Jets: A common challenge is the accumulation of debris in the fuel delivery paths. This can restrict flow, causing the engine to run unevenly or stall. Regular cleaning can mitigate this issue.

Improper Mixture: Achieving the correct air-fuel mixture is crucial. An imbalance can result in hard starts, rough idling, or excessive smoke. Adjustments to the mixture settings may be necessary to restore optimal performance.

Worn Seals: Over time, gaskets and seals can degrade, leading to leaks. This not only affects performance but can also pose safety risks. Regular inspection and replacement of these components are recommended.

Fuel Quality: Using old or contaminated fuel can severely impact efficiency. It’s important to utilize fresh, clean fuel to prevent issues such as clogging and poor combustion.

Temperature Sensitivity: These systems can be sensitive to temperature variations. Cold starts may be problematic, and adjusting choke settings can help facilitate smoother operation during colder conditions.

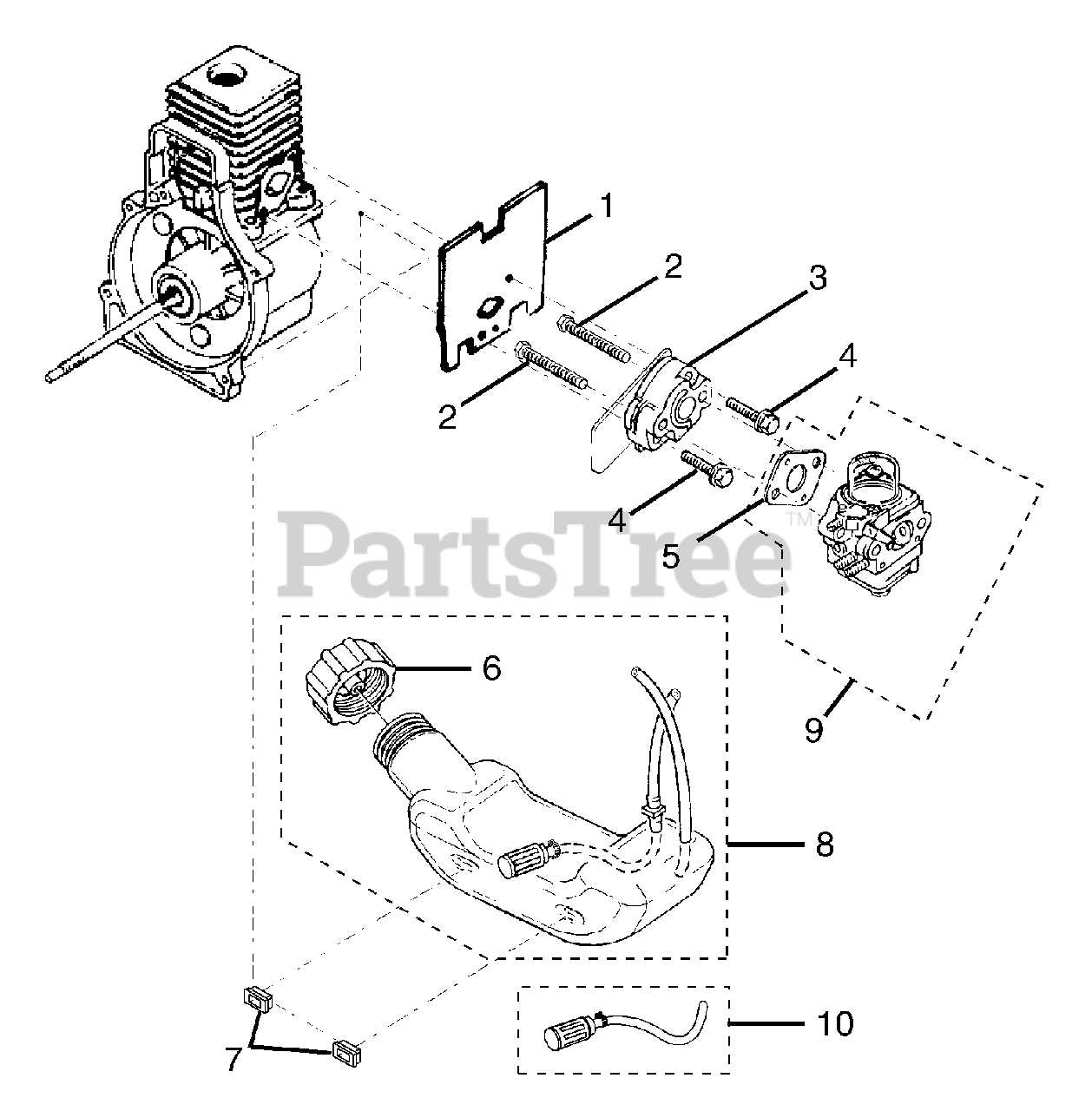

Key Components of Carburetors

The effective functioning of a fuel delivery system relies on several essential elements that work in unison to ensure optimal performance. Understanding these critical components is vital for maintenance and troubleshooting, as they play significant roles in the mixture of air and fuel, influencing the overall efficiency of the engine.

Essential Elements

Among the primary components, the throttle valve is pivotal in regulating the airflow into the combustion chamber. By adjusting the position of this valve, the amount of air entering the system can be controlled, thus impacting the engine’s power output.

Mixing Mechanism

The float chamber serves as a reservoir for fuel, maintaining a consistent supply. This component is crucial for stabilizing the fuel level, ensuring that the mixture remains balanced. Additionally, the emulsion tube plays a significant role in mixing air with fuel, optimizing combustion efficiency. Understanding these components can aid in effective diagnostics and repairs, enhancing overall engine performance.

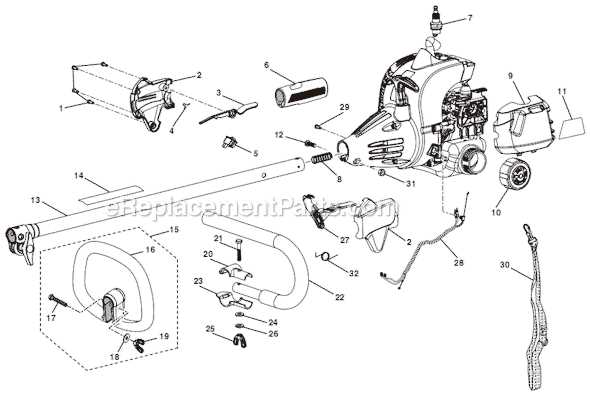

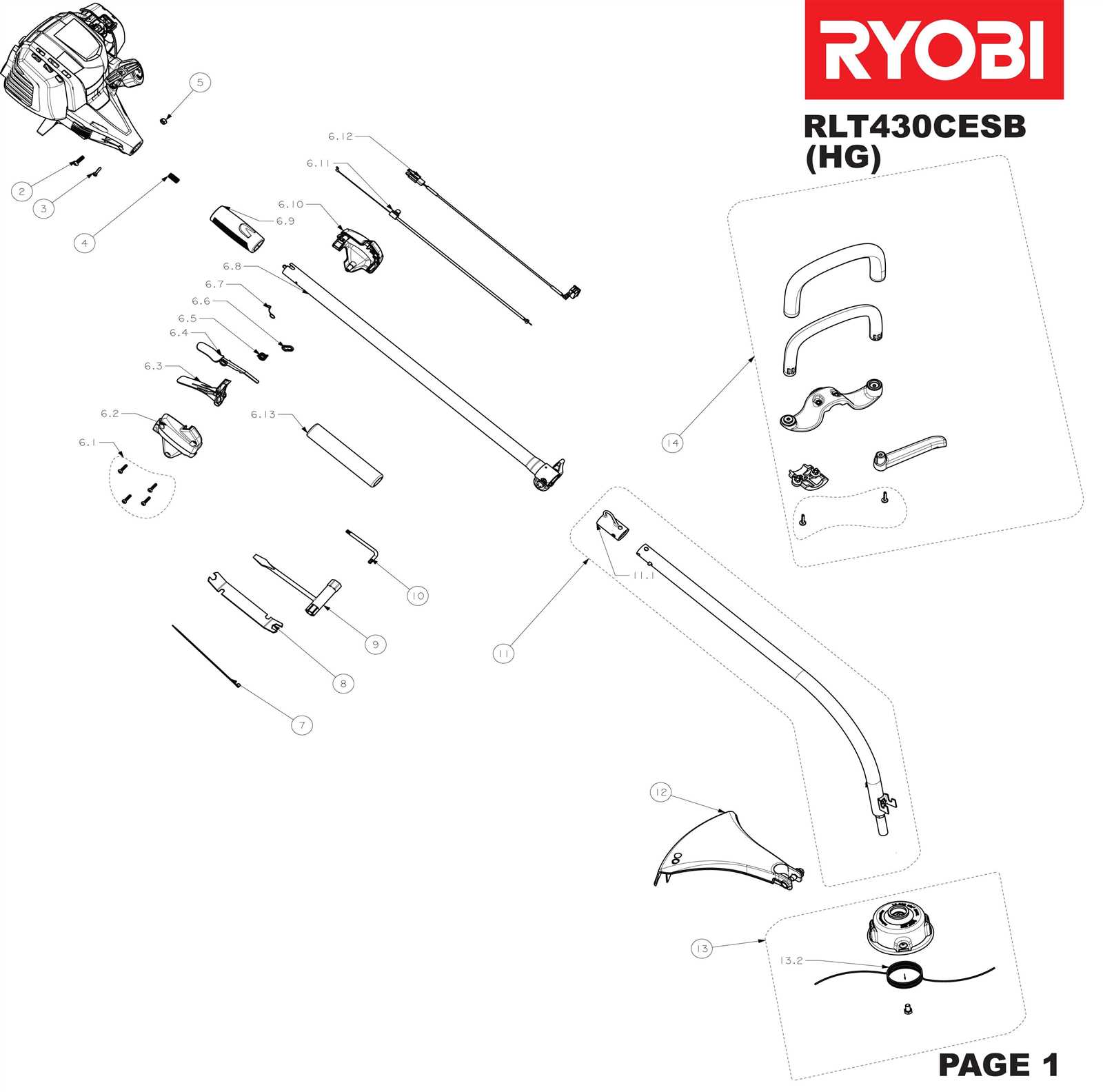

How to Read a Parts Diagram

Understanding a schematic can greatly enhance your ability to troubleshoot and maintain equipment. By grasping the relationships and functions of various components, you can ensure optimal performance and longevity.

Key Components to Identify

- Labels: Familiarize yourself with the terminology used for each item.

- Symbols: Recognize standard representations for different types of elements.

- Connections: Pay attention to how parts are linked, indicating their interaction.

Steps to Follow

- Begin by reviewing the overall layout to get a sense of organization.

- Identify each component based on its label or symbol.

- Note the connections, which will help you understand the workflow.

- Cross-reference with a list of components for clarification.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By following a few essential maintenance practices, you can extend the lifespan of your machinery and prevent potential issues. This guide outlines key steps that will help keep your devices running smoothly and effectively.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect and clean air filters | Every 10 hours of use | Improves airflow and engine efficiency |

| Check fuel system for leaks | Every use | Prevents fuel wastage and hazards |

| Replace worn-out components | As needed | Ensures optimal performance and safety |

| Lubricate moving parts | Every 20 hours of use | Reduces friction and wear |

| Store in a dry place | Always | Prevents rust and damage |

By adhering to these guidelines, you can effectively maintain your equipment, ensuring it remains reliable and functional for years to come. Regular maintenance not only enhances performance but also saves you time and money in the long run.

Signs Your Carburetor Needs Replacement

Recognizing when a crucial component of your engine requires a change can save you time and frustration. Several indicators suggest that this essential element may no longer be functioning optimally, impacting overall performance.

Frequent Stalling: If your machine frequently stalls or struggles to maintain a steady operation, it may signal an issue with fuel delivery.

Inconsistent Acceleration: Noticeable hesitation or irregular acceleration when pressing the throttle can indicate malfunctioning mechanisms.

Poor Fuel Efficiency: A significant drop in miles per gallon suggests that the unit is not properly mixing air and fuel, which may necessitate a replacement.

Visible Damage: Inspect for cracks, leaks, or other visible damage that can impede functionality and warrant a new component.

Difficulty Starting: If the engine requires multiple attempts to start or does not start at all, it may indicate deeper issues within the system.

Pay attention to these signs to ensure your equipment remains in peak condition and operates smoothly.

Tools Required for Repair

Successfully completing a maintenance task relies heavily on having the right instruments at hand. The following tools will ensure efficiency and accuracy during the repair process.

- Socket Wrench Set

- Flathead and Phillips Screwdrivers

- Needle-Nose Pliers

- Torque Wrench

- Cleaning Brushes

Additionally, consider having the following items available:

- Replacement seals and gaskets

- Fuel line clippers

- Safety goggles

- Work gloves

- Shop towels

With these essential tools, you will be well-equipped to tackle any task and delve deeper into the repair process, ultimately achieving optimal results.

Step-by-Step Carburetor Disassembly

Disassembling the fuel delivery mechanism requires precision and careful attention to detail. This process allows for a thorough cleaning and assessment of each component, ensuring optimal performance. Follow these steps to effectively take apart the assembly.

Preparation and Tools

Gather the necessary tools, including screwdrivers, pliers, and a clean workspace. Ensure that you have a container for small components to prevent loss. Read the manufacturer’s instructions for specific guidance tailored to your model.

Disassembly Steps

Begin by removing the outer casing, taking care to note the location of screws and clips. Gently detach the internal components, keeping track of their arrangement. Inspect each piece for wear and damage as you proceed. This meticulous approach will pave the way for effective reassembly and maintenance.

How to Clean Carburetor Parts

Maintaining the efficiency of small engines involves ensuring their internal components are free from buildup and grime. A thorough cleaning routine can enhance performance and prolong the lifespan of these essential mechanisms.

Step 1: Begin by disassembling the unit carefully, ensuring you keep track of each element. Use a clean workspace to avoid losing any components.

Step 2: Utilize a suitable solvent to soak the individual elements. This helps dissolve stubborn deposits, making it easier to scrub them away.

Step 3: After soaking, employ a soft brush to meticulously clean each section. Pay special attention to crevices where dirt tends to accumulate.

Step 4: Rinse with clean water or compressed air to eliminate any residual cleaner and debris. Ensure everything is thoroughly dried before reassembly.

Step 5: Reassemble the components carefully, following the reverse order of disassembly, and check for proper alignment to guarantee optimal functionality.

Regular maintenance and cleaning of these internal elements can lead to enhanced performance and reliability, making it a vital task for any owner.

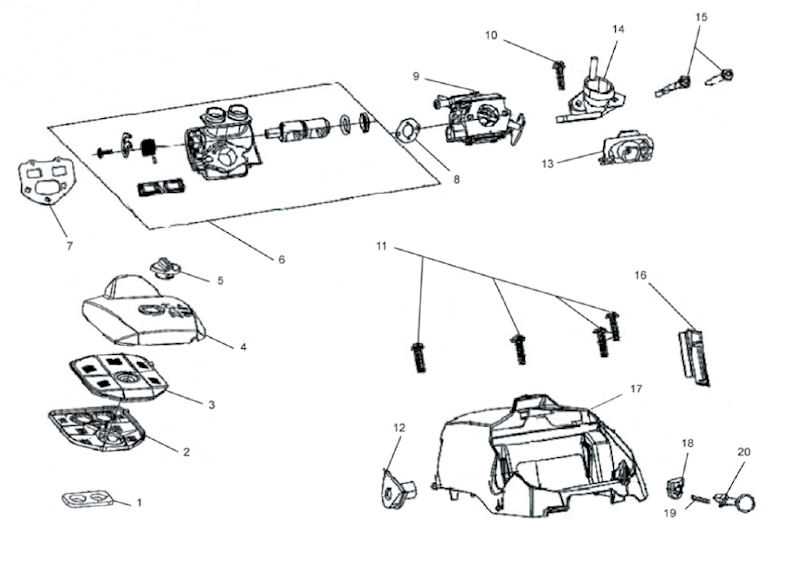

Identifying Different Carburetor Models

Understanding various models of fuel delivery systems is essential for effective maintenance and repair. Each model may have unique features and configurations that set it apart from others. Recognizing these differences can significantly aid in troubleshooting and optimizing performance.

Firstly, examine the design elements such as the shape and size of the housing. Different versions often have distinct outlines that can help in identification. Additionally, the location of specific components, like adjustment screws and fuel inlets, varies between models, providing further clues.

Secondly, check for model numbers or serial codes typically located on the body. These identifiers are invaluable for pinpointing the exact version you are working with. Consulting manufacturer resources can also offer insights into the variations and specific characteristics of each model.

Lastly, studying the operational mechanisms, such as diaphragm types and throttle responses, can give a deeper understanding. This knowledge not only assists in identifying the right model but also enhances overall performance and longevity.

Ordering Replacement Parts Online

Acquiring new components for your equipment can be a straightforward process if approached correctly. With the rise of online shopping, many individuals find it convenient to search for and purchase essential items from the comfort of their homes. This section will guide you through the steps to ensure a smooth ordering experience.

Finding the Right Components

Before making a purchase, it’s crucial to identify the specific items needed. Here are some tips to help you locate the correct components:

- Check the equipment’s model number to ensure compatibility.

- Consult the manufacturer’s website for recommended items.

- Read reviews to gauge the quality of the options available.

Placing Your Order

Once you have identified the required components, follow these steps to complete your order:

- Visit a reputable online retailer.

- Search for the items using the model number or description.

- Add the desired components to your shopping cart.

- Proceed to checkout and enter your shipping information.

- Choose a payment method and confirm your order.

By following these guidelines, you can efficiently obtain the components you need without unnecessary hassle.

Expert Recommendations for Ryobi Users

When it comes to maintaining outdoor equipment, having reliable guidance is essential for optimal performance. Users are encouraged to familiarize themselves with key components to ensure longevity and efficiency. Proper maintenance can make a significant difference in operation and overall satisfaction.

Routine Maintenance Tips

- Regularly inspect fuel systems to prevent clogs.

- Clean air filters frequently to enhance airflow.

- Use high-quality fuel to improve engine performance.

- Check spark plugs for wear and replace as needed.

Common Issues and Solutions

- If the engine won’t start, check the ignition system.

- For stalling, inspect the fuel supply for blockages.

- When facing poor acceleration, clean the airflow components.

- Monitor for unusual noises that could indicate mechanical issues.