In the realm of outdoor maintenance, high-performance cleaning devices play a crucial role in maintaining cleanliness and enhancing the appearance of various surfaces. These machines, designed for power and efficiency, utilize a variety of components that work in harmony to deliver exceptional results. A clear comprehension of these elements is essential for effective usage and maintenance.

By examining the individual elements of these cleaning devices, users can gain insight into their functionality and operation. This knowledge not only aids in troubleshooting but also empowers individuals to perform basic repairs and replacements, ultimately prolonging the life of the equipment. Understanding the intricate relationship between each component is vital for maximizing performance and ensuring optimal functionality.

Whether one is a seasoned professional or a DIY enthusiast, having access to detailed information about these essential features can make a significant difference in the overall experience. The right guidance enables users to navigate maintenance tasks with confidence, ensuring that their cleaning equipment remains in peak condition for years to come.

Understanding Ryobi Electric Pressure Washers

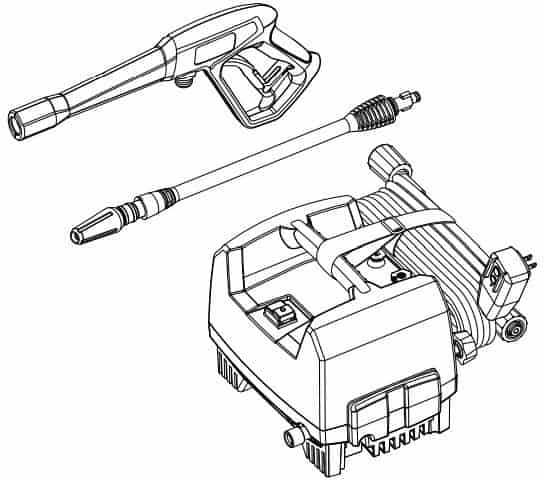

This section aims to provide an overview of a specific type of cleaning equipment designed for effective outdoor maintenance. These machines are widely appreciated for their efficiency in removing dirt, grime, and stains from various surfaces, making them essential tools for homeowners and professionals alike.

Key Features of Cleaning Equipment

Modern cleaning machines come with a variety of features that enhance their usability and performance. Users can often find options such as adjustable spray nozzles, ergonomic handles, and onboard detergent tanks. These elements contribute to a more convenient and effective cleaning process, allowing for tailored use depending on the task at hand.

Maintenance and Care

Proper maintenance is crucial for ensuring the longevity and efficiency of these cleaning devices. Regular inspections and routine upkeep, such as checking hoses for wear and cleaning filters, can significantly improve performance. Adhering to the manufacturer’s guidelines for care will help prevent issues and extend the life of the machine.

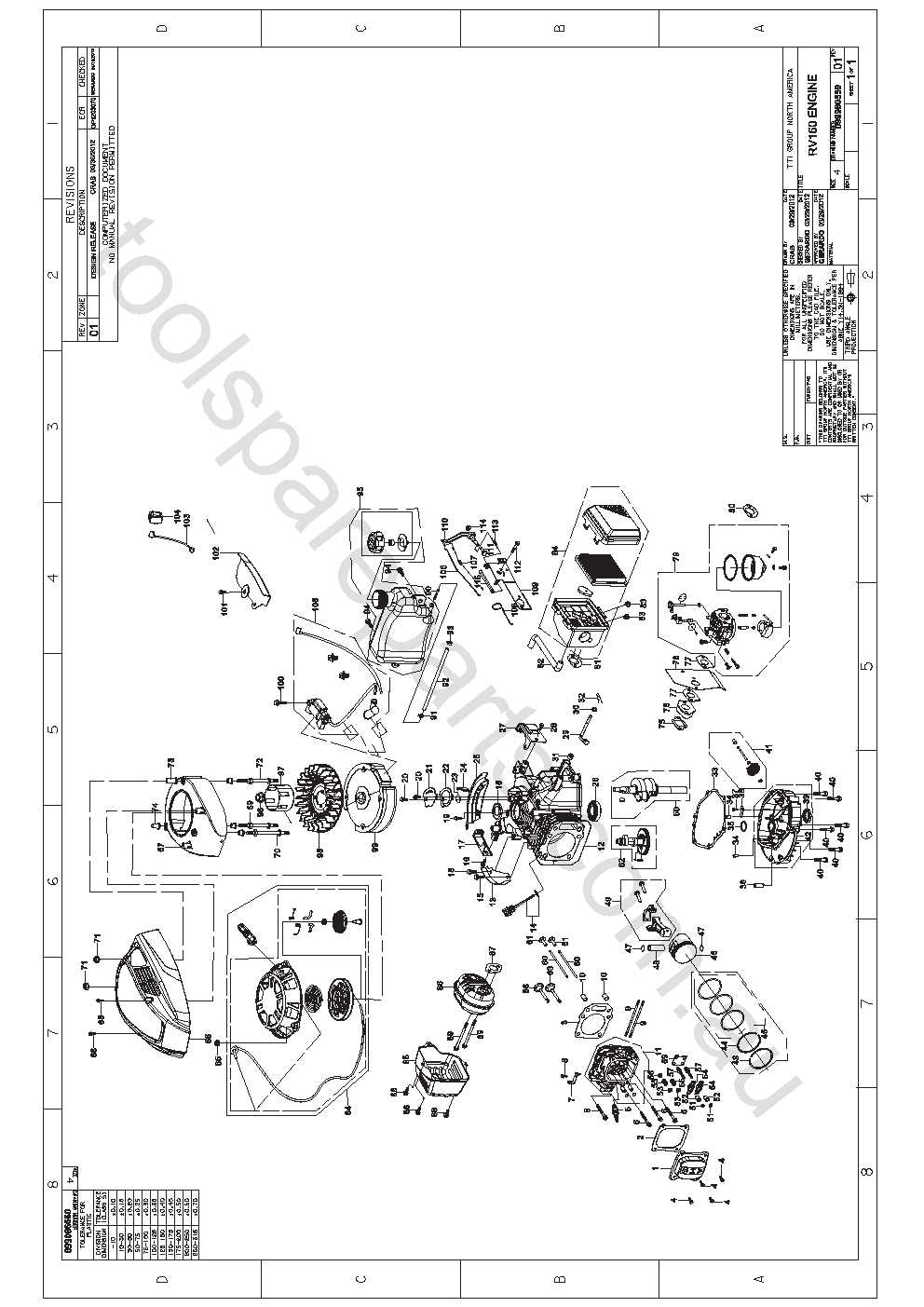

Key Components of Pressure Washers

Understanding the essential elements of high-powered cleaning devices is crucial for both effective usage and maintenance. These machines are designed to deliver exceptional cleaning results, and each component plays a significant role in their overall performance. Familiarity with these components can enhance the efficiency and longevity of the equipment.

Motor: The driving force behind the entire operation, the motor is responsible for generating power. It converts electrical energy into mechanical energy, enabling the device to perform its cleaning tasks efficiently.

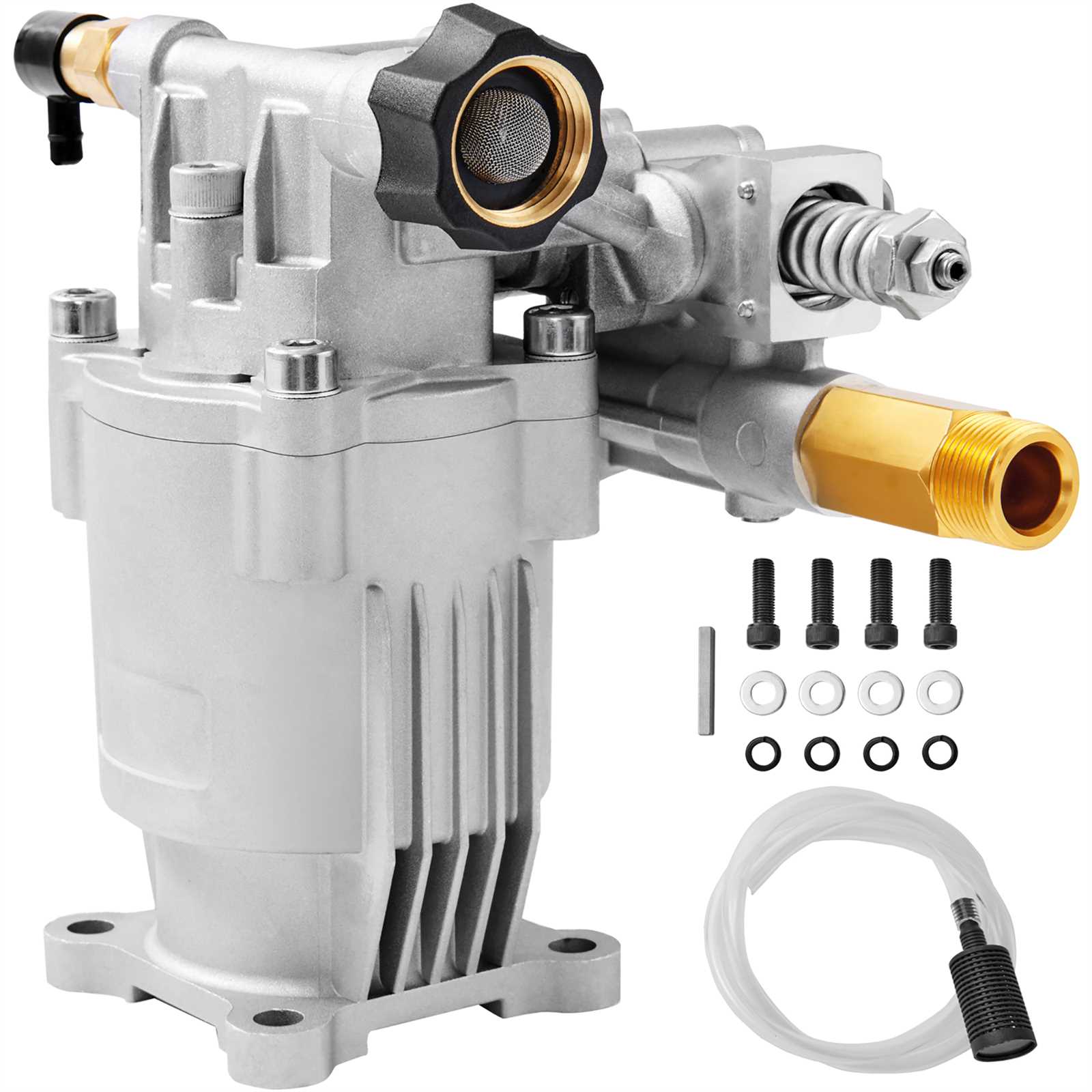

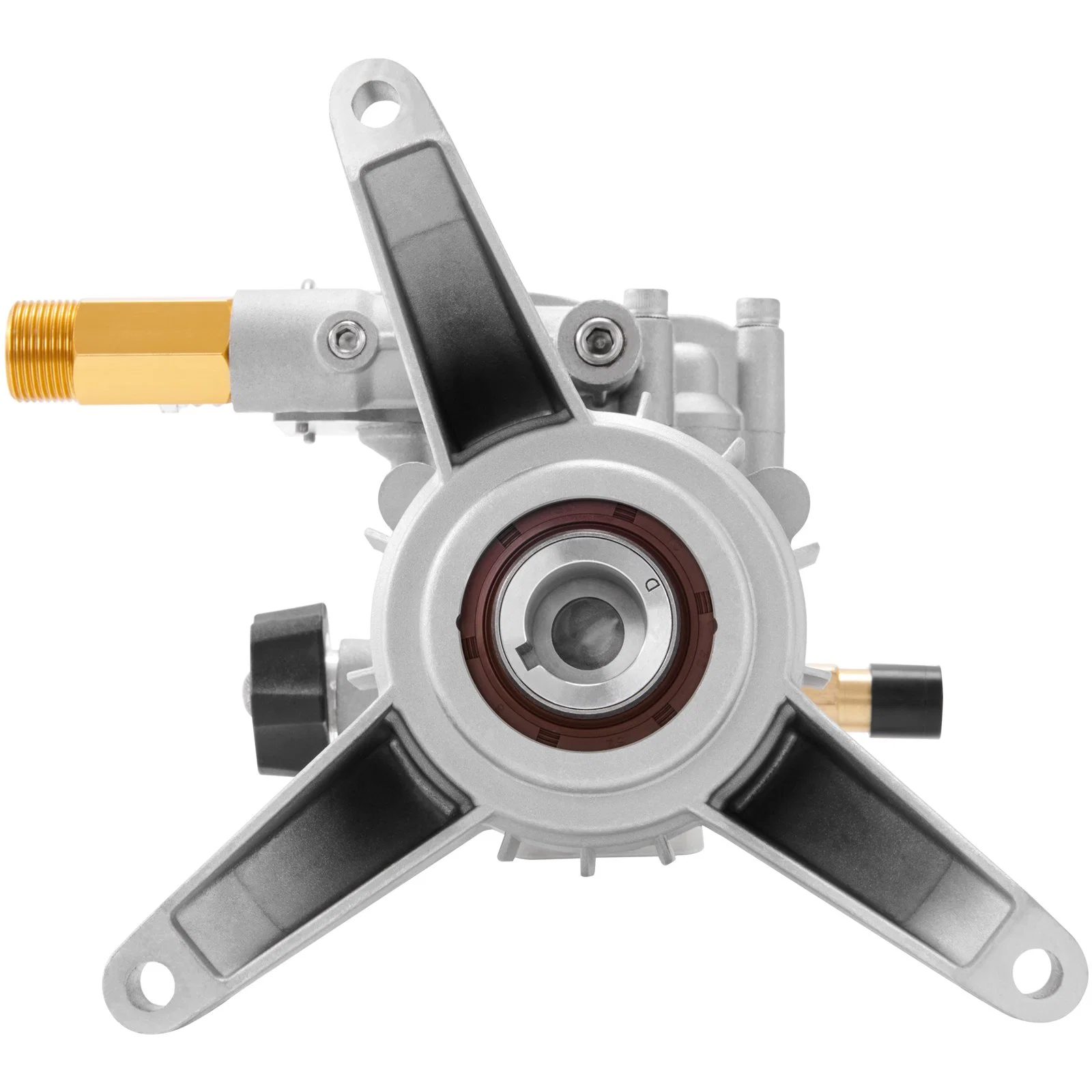

Pump: Acting as the heart of the system, the pump draws in water and increases its pressure. This elevated pressure is essential for effectively removing dirt and grime from various surfaces.

Nozzle: The nozzle is a critical element that controls the flow and direction of the water stream. Different nozzle types allow for adjustments in pressure and coverage, making it versatile for various cleaning tasks.

Hose: The flexible tube connects the nozzle to the pump, facilitating the movement of water. A durable hose is essential for withstanding high pressure and ensuring a consistent flow of water during operation.

Frame: The frame provides structural integrity and support for the components. A robust frame enhances stability and ensures that the device can withstand frequent use in various environments.

Water Inlet: This component allows for the connection of a water source, ensuring a steady supply during operation. A secure inlet is vital to prevent leaks and maintain efficiency.

By familiarizing oneself with these key components, users can better understand their functionality and the importance of regular maintenance, ultimately ensuring optimal performance and longevity of the cleaning device.

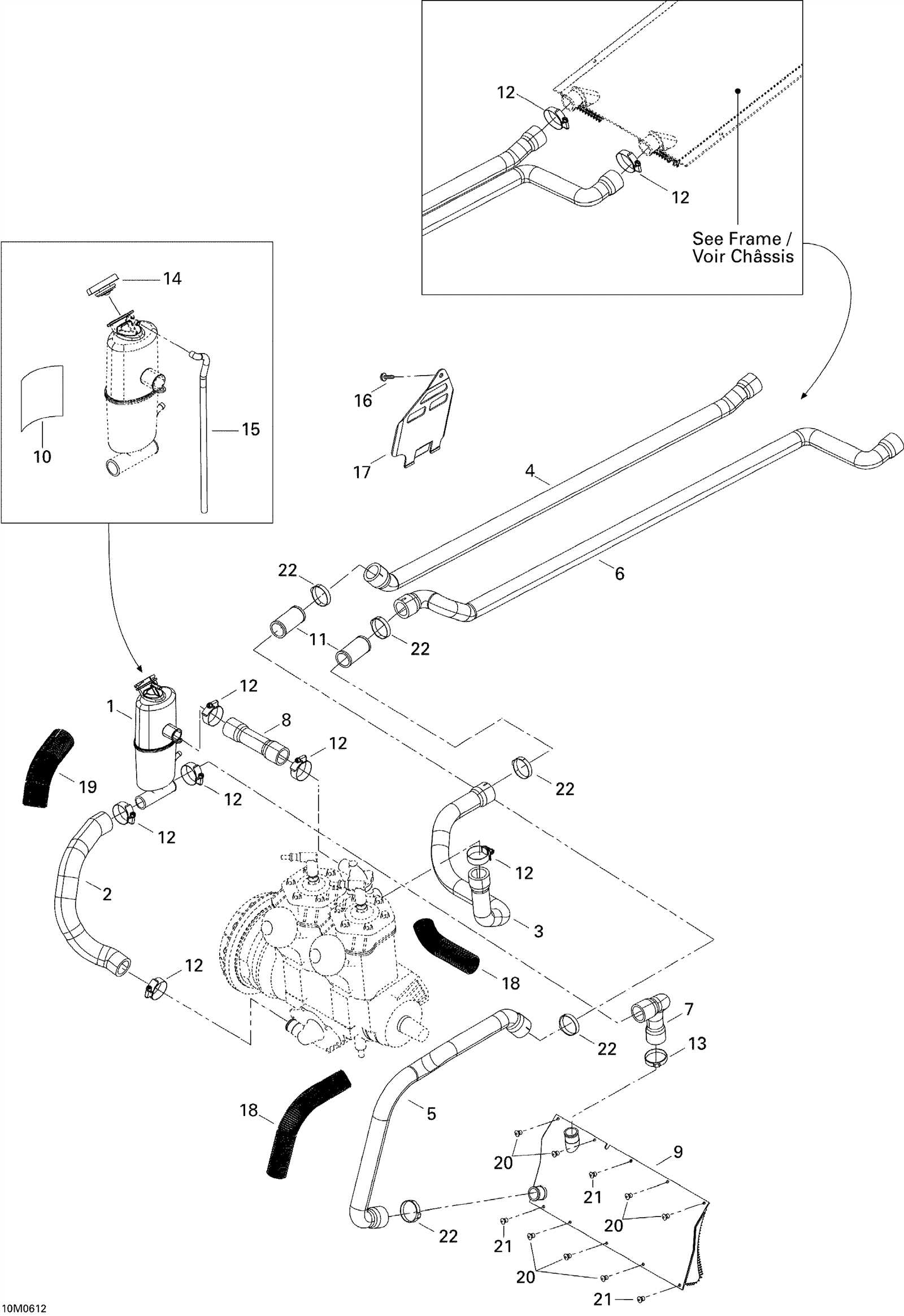

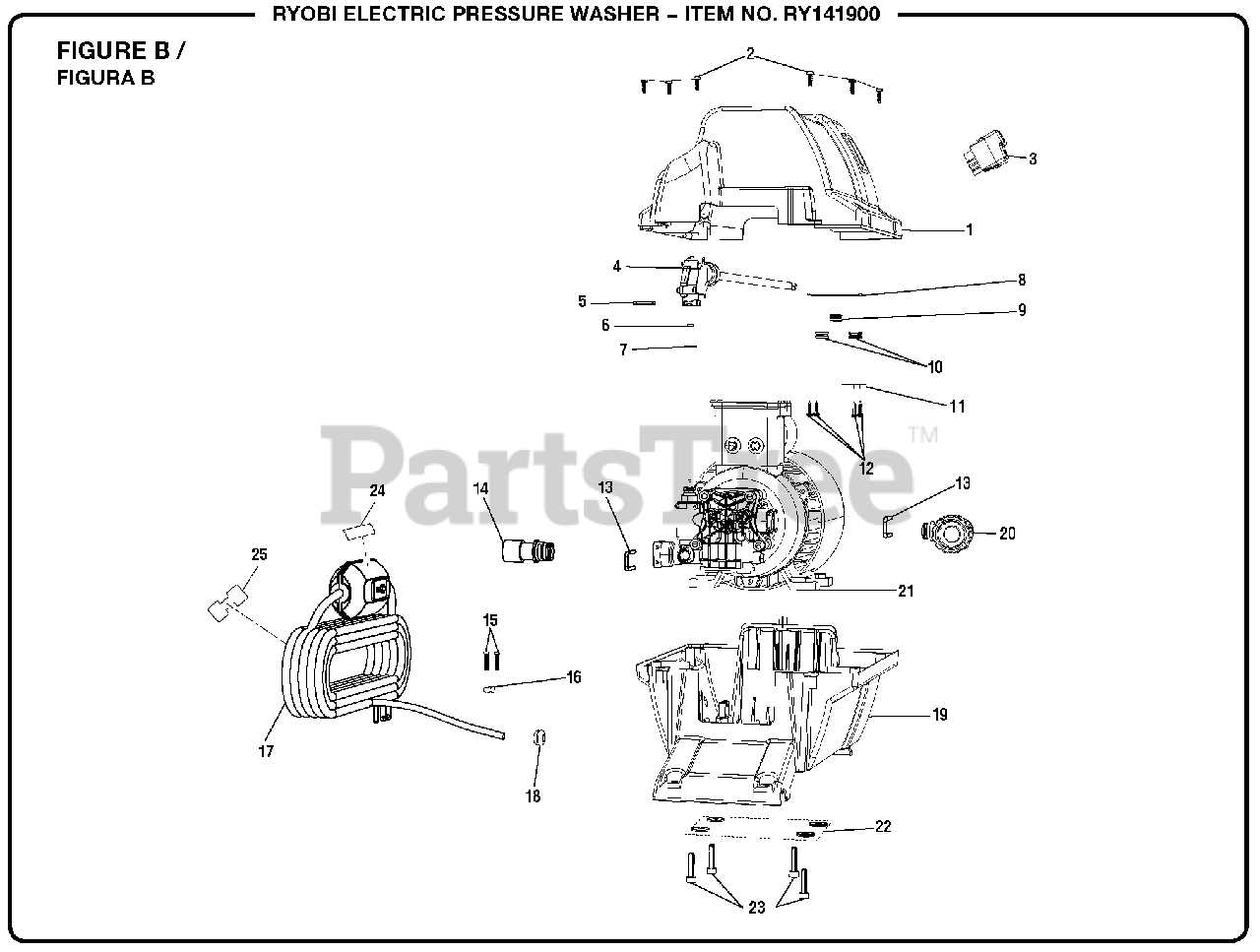

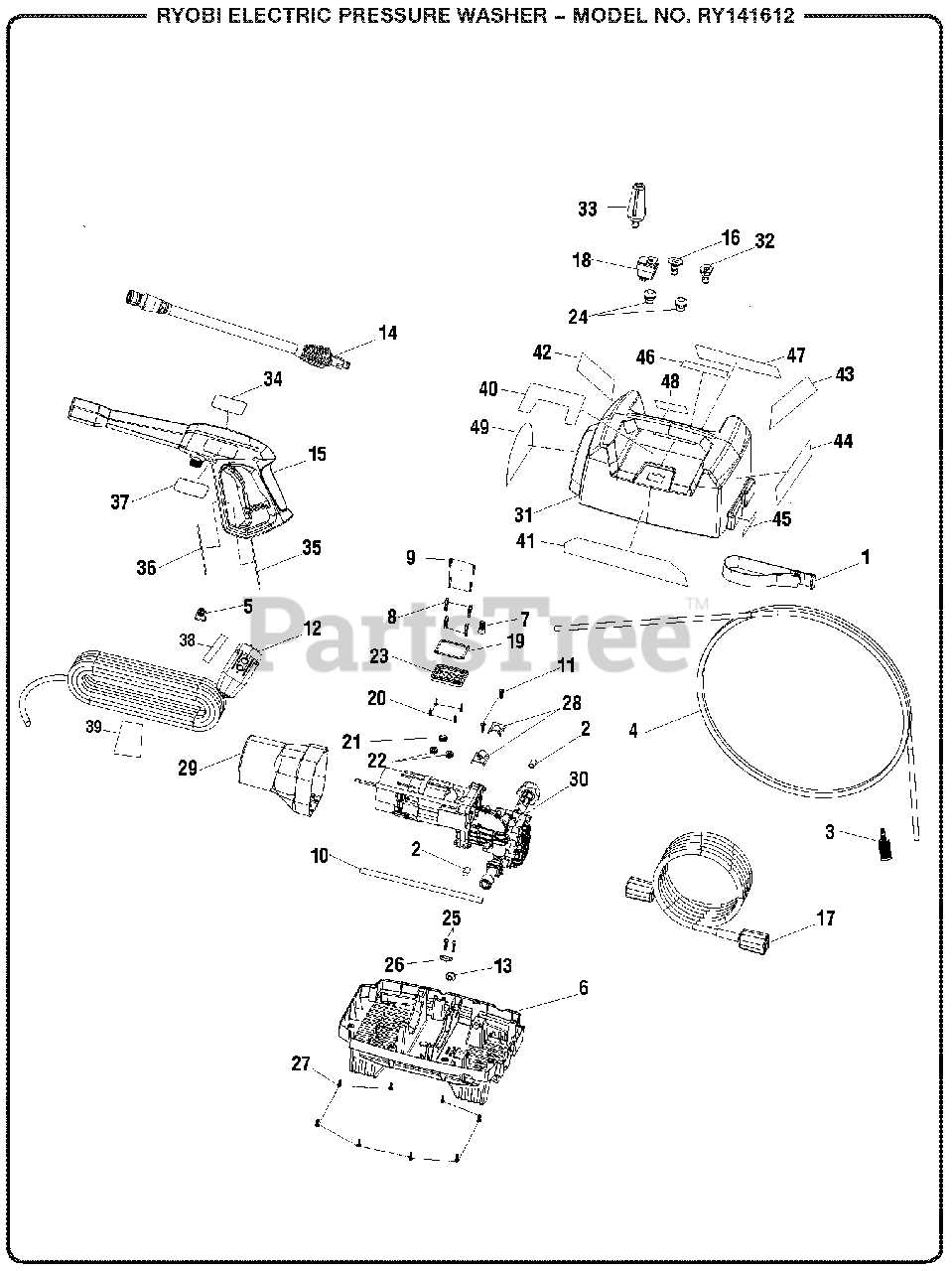

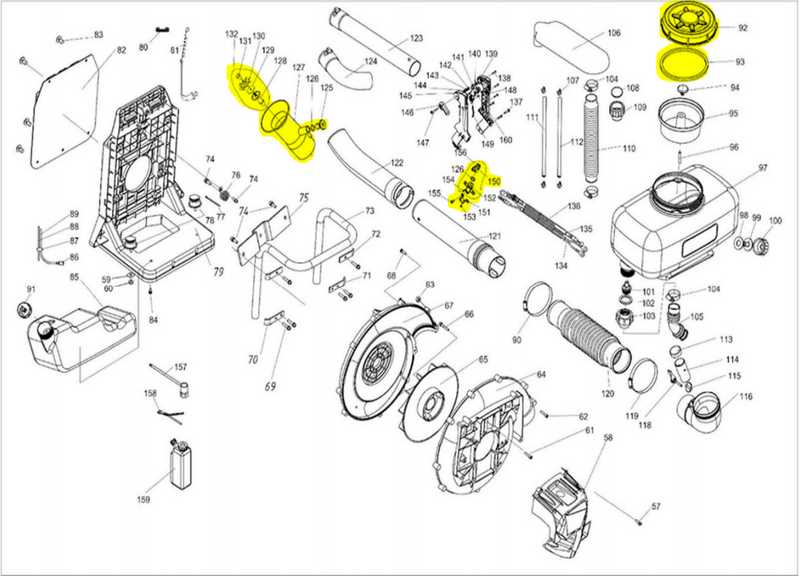

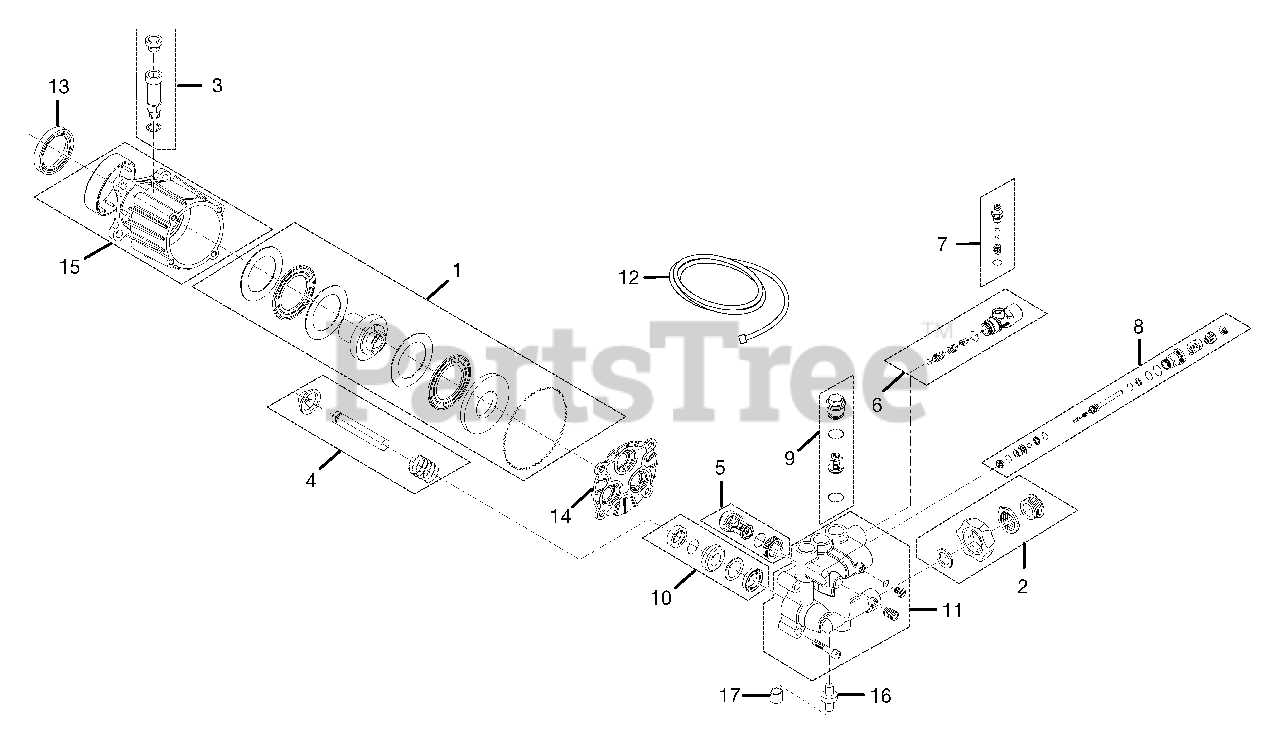

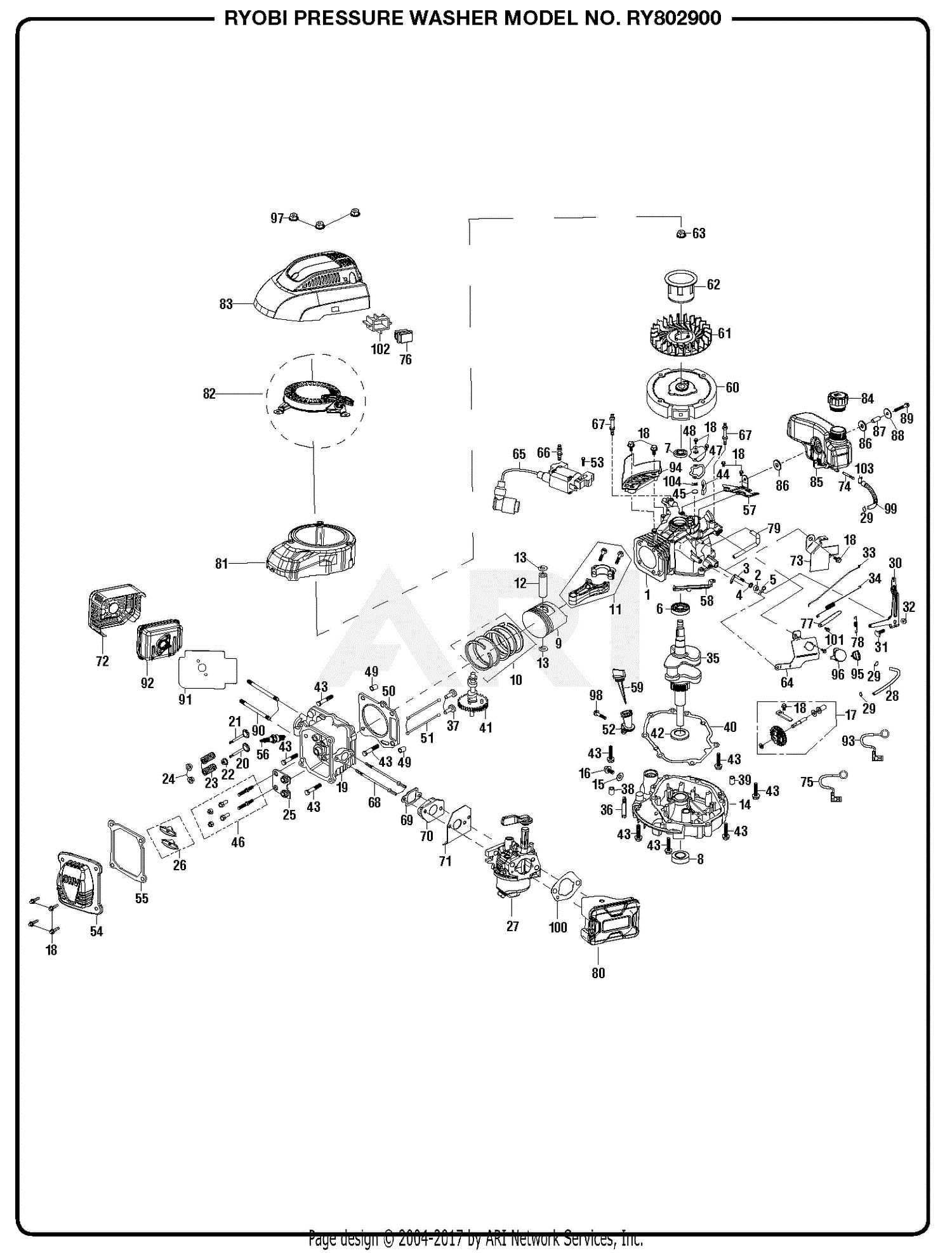

Exploring the Parts Diagram

This section delves into the components of a high-pressure cleaning machine, providing a comprehensive overview of its structure and functionality. Understanding these elements is essential for effective maintenance and troubleshooting.

Key Components Overview

- Motor Assembly: Powers the device and drives the pump.

- Pump Unit: Responsible for generating high pressure, allowing for efficient cleaning.

- Nozzle Types: Various options for different cleaning tasks, including fan and pinpoint spray.

- Hose System: Connects the unit to the water source and delivers the pressurized fluid.

- Trigger Gun: Allows the operator to control water flow and pressure easily.

- Wheels and Frame: Provides mobility and stability during operation.

Benefits of Understanding the Components

- Enhanced Maintenance: Familiarity with each component aids in regular upkeep.

- Efficient Troubleshooting: Identifying issues becomes easier when one understands the function of each part.

- Improved Performance: Knowledge of the machine’s structure can help optimize usage and efficiency.

- Cost-Effective Repairs: Being aware of the components allows for informed decisions regarding repairs and replacements.

Importance of Each Component

Every element within a cleaning apparatus plays a vital role in its overall functionality and efficiency. Understanding the significance of each individual component helps users appreciate the intricate design and engineering that ensures effective performance.

The motor serves as the powerhouse of the system, converting electrical energy into mechanical energy to drive the pump. Its performance directly affects the device’s operational capabilities and pressure generation.

The pump is crucial for propelling water at high speeds. This component determines the flow rate and pressure, making it essential for effective dirt removal and surface cleaning.

The nozzle alters the water stream’s pattern, allowing for adjustments based on the cleaning task. Different nozzle types provide versatility, enabling users to tackle various surfaces and stains effectively.

The hose ensures a steady supply of water from the source to the unit. Its durability and flexibility are important for maneuverability during use, making it a key factor in overall ease of operation.

The trigger gun acts as the control mechanism, allowing users to start and stop the flow of water. Its ergonomic design enhances user comfort while providing safety features to prevent accidental discharge.

In summary, recognizing the importance of each component fosters a deeper understanding of the machinery’s functionality, ultimately leading to better maintenance practices and more efficient usage.

Common Replacement Parts Overview

When maintaining a high-performance cleaning device, understanding the key components that may require replacement is essential. Regular use can lead to wear and tear, making it crucial to identify which elements need attention to ensure optimal functionality.

Hoses are vital for connecting the equipment to the water source and can often become damaged due to friction or exposure. Replacing a worn or cracked hose can significantly improve efficiency and prevent leaks.

Nozzles play an essential role in directing the flow of water. Different types are available, each designed for specific cleaning tasks. Ensuring you have the right nozzle for the job can enhance cleaning effectiveness.

Filters are crucial for keeping debris out of the system. Over time, these components can become clogged, leading to reduced performance. Regular replacement can help maintain the machine’s power and longevity.

Seals and O-rings are necessary for preventing leaks in various areas of the unit. These small yet significant components often degrade over time, necessitating periodic checks and replacements to ensure a tight seal.

By staying informed about these common components, users can proactively address maintenance needs, ensuring the equipment remains in excellent working condition for all cleaning tasks.

Troubleshooting Issues with Components

Identifying and resolving challenges with various elements of cleaning equipment is essential for maintaining optimal performance. Users may encounter several common issues that can affect functionality, leading to inefficiency and frustration. This section outlines steps to diagnose and rectify these problems, ensuring a seamless experience during use.

Common Problems and Solutions

- Insufficient Water Flow

- Check for clogs in the inlet filter or hose.

- Ensure the water supply is turned on and providing adequate pressure.

- Inspect the nozzle for blockages that may restrict flow.

- Device Not Starting

- Verify the power source is functioning properly.

- Examine the power cord for damage or wear.

- Ensure the safety lock is disengaged, allowing operation.

- Inconsistent Performance

- Assess the condition of the spray wand for leaks or malfunctions.

- Check if the motor is overheating, which may cause automatic shutdown.

- Review the settings to confirm they are appropriate for the task.

Maintenance Tips

- Regularly clean filters and nozzles to prevent build-up.

- Store the equipment in a dry area to avoid moisture-related issues.

- Conduct periodic inspections of hoses and connectors for wear and tear.

Maintenance Tips for Longevity

Proper upkeep is essential to extend the lifespan of any equipment. Regular attention to detail not only enhances performance but also prevents premature wear and tear. By implementing a few straightforward practices, users can ensure their devices remain efficient and reliable for many years.

Regular Cleaning

Cleaning components after each use is crucial. Dirt and grime can accumulate, leading to blockages and inefficiencies. Wipe down surfaces, remove debris, and ensure all openings are clear. This simple task can significantly improve the functionality and longevity of the equipment.

Periodic Inspections

Conducting routine checks allows users to identify potential issues before they escalate. Look for signs of wear, loose connections, or unusual noises. Addressing minor problems promptly can prevent costly repairs and downtime in the future.

How to Identify Compatible Parts

Finding the right components for your cleaning device is crucial for optimal performance and longevity. Ensuring compatibility involves understanding specific details about the device’s requirements and specifications. By following a systematic approach, you can easily identify suitable replacements and accessories.

Begin by consulting the user manual or product specifications sheet that came with your device. These documents typically provide detailed information regarding component types, sizes, and any model-specific features. If these resources are unavailable, check the manufacturer’s website for digital copies or additional guidance.

Another effective method is to examine the existing components closely. Look for model numbers, part identifiers, and any logos that can lead you to the correct replacements. When you remove a worn or damaged piece, note its dimensions and material to find an equivalent.

Using a reliable online retailer or a physical store, you can cross-reference your findings. Many vendors offer search tools that allow you to input the specifications or model information to find compatible options quickly.

| Component | What to Look For | Where to Check |

|---|---|---|

| Hoses | Diameter, length, and connection type | User manual, existing hose |

| Nozzles | Type of spray pattern, threading | Online parts catalog, manufacturer’s site |

| Filters | Size, shape, and filtration capability | User manual, product specifications |

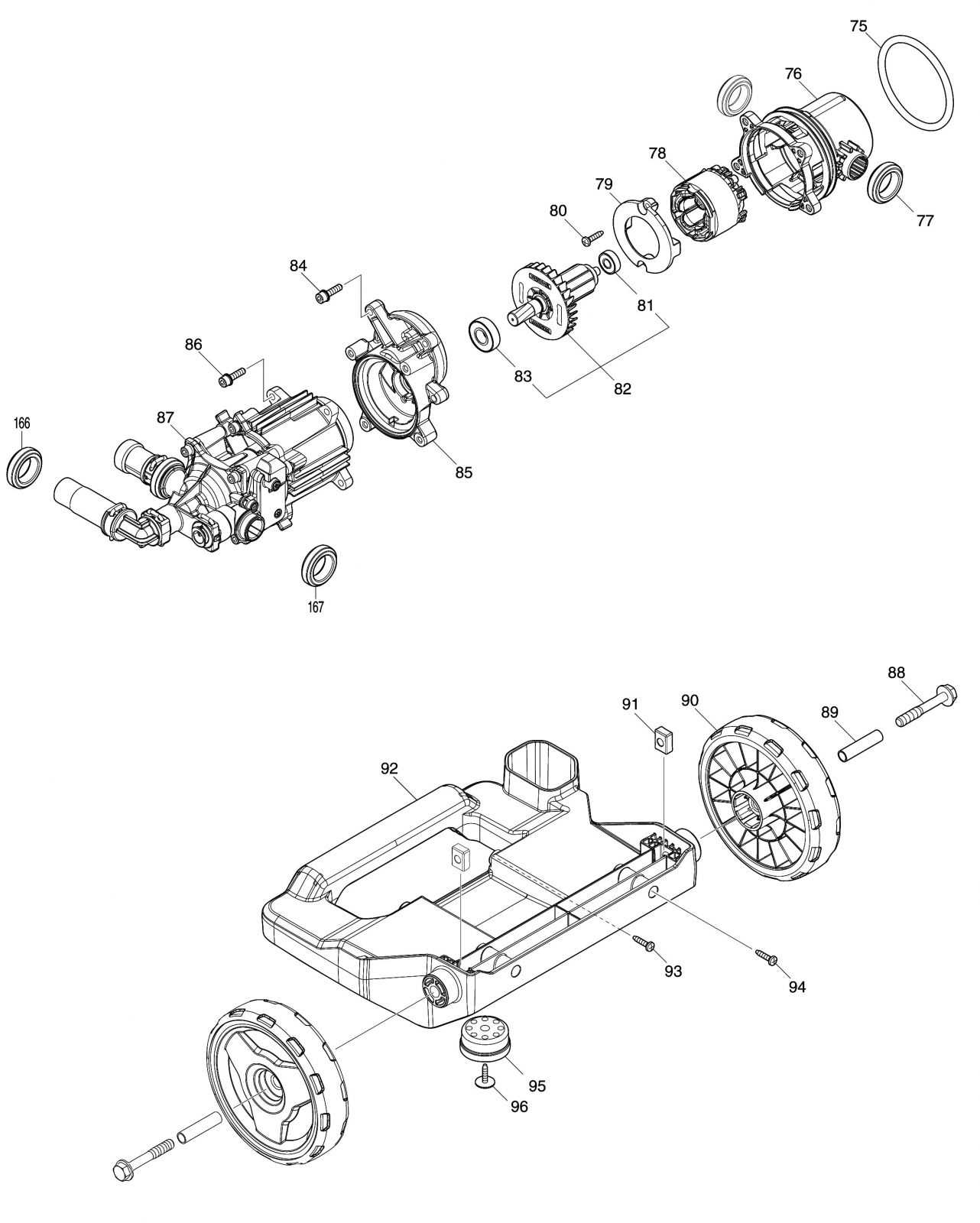

Assembly and Disassembly Guidelines

Understanding the process of putting together and taking apart your equipment is essential for maintaining its functionality and longevity. This section provides comprehensive instructions that will help you navigate the assembly and disassembly procedures effectively, ensuring that you can manage your device with confidence.

Preparation is key before starting any assembly or disassembly task. Gather all necessary tools and components in a clean workspace to facilitate a smooth process. Ensure that you have the appropriate manual or reference material at hand to guide you through the steps.

During disassembly, it is advisable to work systematically. Begin by disconnecting any power source to avoid accidents. Remove components in the reverse order of their assembly, carefully noting how each part fits together. This approach not only simplifies reassembly but also minimizes the risk of losing or damaging any parts.

When reassembling, follow the reverse steps of disassembly. Ensure that each component is securely fastened and correctly oriented. Pay attention to any seals or gaskets that may need replacement during this process. Taking the time to double-check your work can save you from potential issues in the future.

Finally, always conduct a functionality check after reassembly to confirm that everything operates as intended. This practice is crucial for identifying any errors that may have occurred during the process, ensuring optimal performance of your device.

Upgrading Parts for Better Performance

Enhancing the components of your cleaning device can significantly boost its efficiency and effectiveness. By selecting superior materials and advanced designs, you can ensure that your machine operates at optimal levels, leading to improved results in various tasks.

One of the key areas to consider for upgrades is the nozzle. Switching to a more versatile or specialized nozzle can enhance the spray pattern and pressure, making it easier to tackle stubborn stains and dirt. Additionally, using high-quality hoses can improve water flow and reduce the chances of leaks, ensuring a consistent performance throughout use.

Moreover, examining the internal mechanisms is crucial. Upgrading the pump or motor can result in a noticeable increase in power and durability. Enhanced components not only provide better pressure but also contribute to the longevity of the equipment, allowing for prolonged periods of use without compromising performance.

Finally, consider accessories that complement your device. Specialized brushes and surface cleaners can enhance versatility and efficiency, making it possible to tackle a wider range of surfaces and materials. By investing in these upgrades, you create a more powerful and reliable cleaning tool that meets your specific needs.

Where to Find Replacement Parts

Finding suitable components for your cleaning equipment is essential for maintaining its performance and longevity. There are several reliable sources where you can locate the necessary items to ensure your device operates smoothly.

One of the best places to start is the manufacturer’s official website, which often provides a dedicated section for accessories and components. Here, you can browse through various listings and order directly from the source, ensuring you receive genuine items.

Additionally, numerous online retailers specialize in home maintenance equipment, offering a wide range of alternatives. Websites like e-commerce giants typically feature user reviews, which can help you gauge the quality and compatibility of the components you need.

Local hardware and home improvement stores may also carry essential items, allowing you to inspect them in person before making a purchase. Don’t forget to check with authorized dealers, as they may offer specialized assistance and product recommendations based on your specific model.

Finally, online marketplaces and community forums can be valuable resources for finding second-hand or refurbished components. Engaging with fellow users can lead to discovering rare items or cost-effective solutions to restore your equipment to its optimal condition.