Exploring the intricate arrangement of engine components is essential for effective maintenance and repair. This section delves into the various elements that constitute a specific engine model, offering a comprehensive overview of their functionality and interrelationships. By understanding how these components interact, users can enhance their repair skills and ensure optimal performance.

Visual representations serve as valuable tools for identifying individual elements and their respective roles within the engine assembly. This detailed exploration assists users in recognizing essential features and troubleshooting common issues that may arise. Moreover, it fosters a deeper appreciation for the engineering behind the machinery, promoting better care and longevity.

Ultimately, acquiring knowledge about the layout of these vital components empowers users to undertake repairs with confidence. Familiarity with the assembly aids in identifying compatible replacements, ensuring the machine continues to operate efficiently. Engaging with this information equips individuals with the skills necessary to maintain their engines effectively.

Overview of Briggs and Stratton 500E

This section provides a comprehensive look at a popular engine model known for its reliability and efficiency. Designed for various applications, this engine is favored by many users for its performance and durability. Understanding its components and functionality can greatly enhance user experience and maintenance practices.

Key Features

One of the standout qualities of this engine is its robust construction, which ensures longevity and minimal wear over time. Additionally, it incorporates advanced technology that enhances fuel efficiency while reducing emissions. Users can benefit from easy starting mechanisms, making it ideal for both novice and experienced operators.

Maintenance Tips

To ensure optimal performance, regular maintenance is essential. This includes routine checks on oil levels, air filters, and spark plugs. Keeping these components in good condition not only extends the life of the engine but also maintains its efficiency. Proper maintenance practices contribute to a smoother operation and prevent potential issues down the line.

Understanding the Parts Diagram

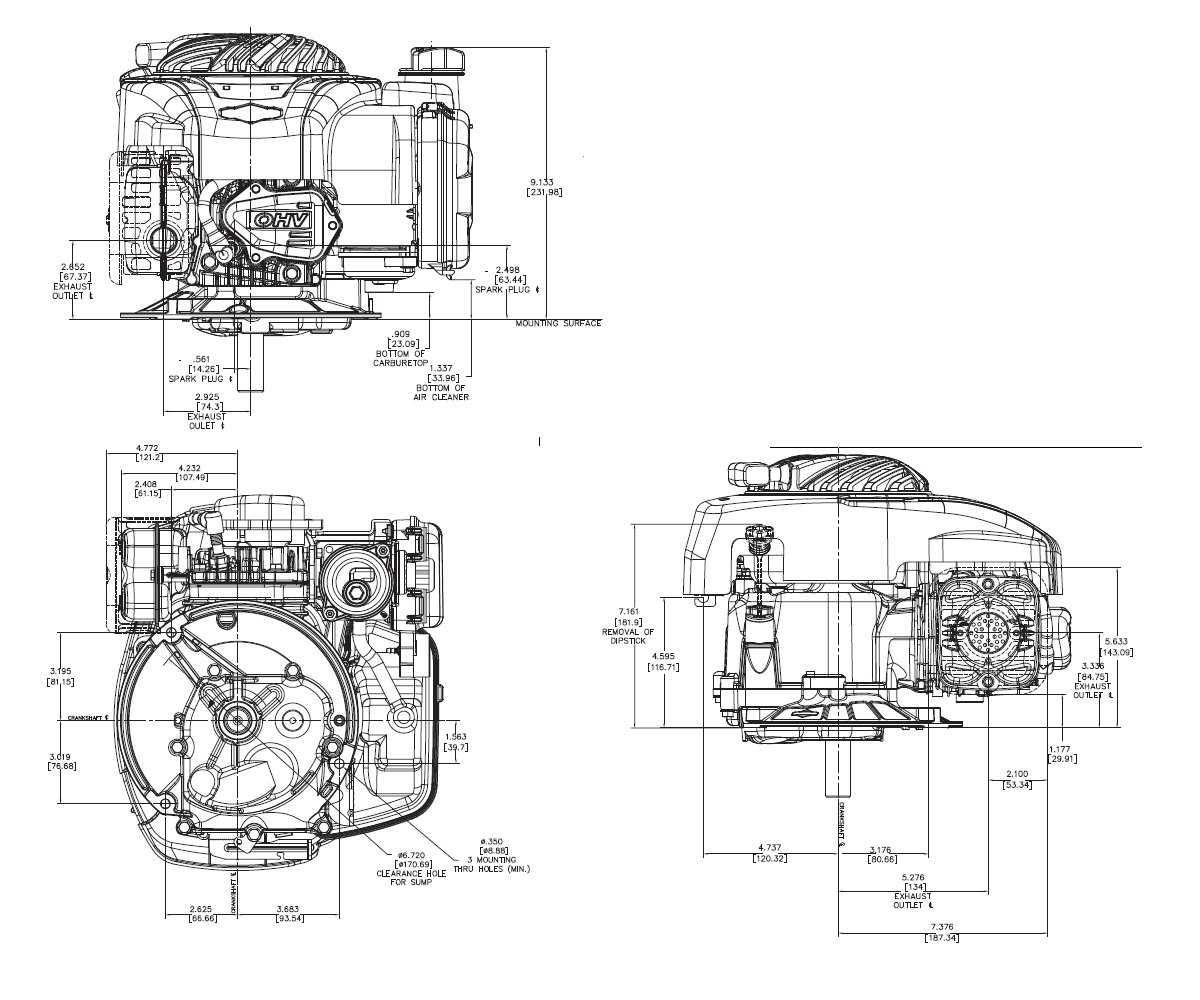

A comprehensive visual representation of components is essential for anyone involved in maintenance or repair tasks. Such illustrations provide clarity on how various elements fit together, facilitating easier identification and troubleshooting. Recognizing these illustrations can significantly enhance one’s ability to perform repairs effectively.

Key Components Explained

Familiarizing oneself with specific elements in the illustration can lead to more efficient maintenance practices. Below are some essential parts commonly found in these representations:

- Engine Block: The core of the machine, housing crucial components that enable functionality.

- Fuel System: Responsible for delivering the necessary fuel for operation.

- Ignition System: Ensures the engine starts and runs smoothly by generating the spark needed for combustion.

- Cooling Mechanism: Prevents overheating, maintaining optimal operating temperatures.

Benefits of Utilizing Visual References

Employing these visual guides can significantly streamline the repair process. Consider the following advantages:

- Improved accuracy in identifying components.

- Enhanced understanding of assembly and disassembly procedures.

- Reduction of errors during maintenance tasks.

- Increased efficiency in repairs, saving both time and effort.

Key Components of 500E Series

This section provides an overview of essential elements found in the 500E model. Understanding these components is vital for efficient maintenance and troubleshooting. Each part plays a significant role in the overall functionality, contributing to the device’s performance and reliability.

| Component Name | Description |

|---|---|

| Air Filter | Helps maintain optimal airflow to the engine while preventing dirt and debris from entering. |

| Fuel Tank | Stores the fuel required for operation, ensuring a steady supply to the engine. |

| Spark Plug | Ignites the air-fuel mixture, initiating the combustion process within the engine. |

| Carburetor | Mixes the fuel with air to create the combustible mixture necessary for engine operation. |

| Exhaust Muffler | Reduces engine noise and directs exhaust gases away from the working area. |

Common Issues and Repairs

Many users encounter a variety of challenges when operating small engine equipment. Understanding these common problems can lead to effective solutions and maintain optimal performance. This section outlines frequent issues, their causes, and potential repair strategies to keep your machinery running smoothly.

Engine Won’t Start

A prevalent issue is when the engine fails to ignite. This can stem from various factors, such as a drained battery, clogged fuel lines, or faulty spark plugs. Regular maintenance, including checking the fuel system and replacing worn components, can often resolve this problem. Ensure that the battery is charged and connections are clean to improve the chances of starting.

Overheating Concerns

Another common challenge is overheating, which can occur due to inadequate airflow or coolant levels. If the engine becomes too hot, it may shut down to prevent damage. Regularly inspecting the cooling system and cleaning air filters can mitigate this issue. If overheating persists, it might be necessary to examine the engine for internal damage or replace faulty parts.

Identifying Replacement Parts

Understanding the components of your equipment is essential for maintaining its functionality and efficiency. Recognizing the right elements needed for replacements ensures seamless operation and longevity. This section will guide you through the process of identifying the necessary components for effective upkeep.

Key Considerations for Component Recognition

When seeking to replace any element, it’s important to consider several factors. First, familiarize yourself with the specific model of your device, as variations can significantly affect compatibility. Second, consult the user manual, which often contains vital information regarding the components and their specifications. Lastly, cross-reference any available online resources, such as forums and parts retailers, to verify that you are selecting the correct items.

Using Visual Aids for Identification

Visual aids, such as detailed illustrations or charts, can be immensely helpful in pinpointing the necessary components. Many manufacturers provide resources that depict various elements, making it easier to match what you need with the actual components in your equipment. These resources can assist in simplifying the identification process, leading to more informed purchasing decisions.

Maintenance Tips for Optimal Performance

Ensuring that your equipment operates efficiently requires regular upkeep and attention to detail. Implementing a consistent maintenance routine not only enhances functionality but also extends the lifespan of the machinery. Here are several essential tips to keep your device in prime condition.

Regular Inspection

Conducting frequent checks on various components is vital. Look for signs of wear and tear, leaks, or any unusual noises during operation. Identifying potential issues early can prevent costly repairs down the line.

Cleanliness Matters

Keeping the machine clean is crucial for optimal performance. Remove debris, dirt, and grime from both the exterior and interior parts. A clean environment helps in maintaining airflow and cooling, contributing to efficient operation.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace oil to ensure smooth engine function and longevity. |

| Air Filter Cleaning | Every 25 hours | Remove and clean the filter to prevent dirt from entering the engine. |

| Spark Plug Replacement | Every season | Replace the spark plug to maintain reliable ignition. |

How to Read the Diagram

Understanding the layout of components can greatly enhance your ability to troubleshoot and maintain equipment effectively. A clear visual representation provides valuable insights into how different elements are interconnected, allowing for easier identification of necessary replacements or adjustments.

Identify Key Elements

Begin by familiarizing yourself with the essential symbols and notations used in the illustration. Each symbol represents a specific component, and recognizing these symbols is crucial for accurate interpretation. Pay attention to the labels associated with each part, which often include numbers or letters that correlate with additional information in accompanying manuals or guides.

Follow the Connections

Next, examine how the various components relate to one another. Trace the lines that indicate connections between elements; these lines often represent mechanical linkages or electrical pathways. Understanding these relationships will help you see how the system operates as a whole and pinpoint areas that may require attention.

By following these steps, you’ll gain confidence in navigating visual representations of your equipment, making it easier to maintain and repair as needed.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for ensuring optimal performance and longevity. Numerous options are available for those seeking reliable sources to obtain quality items. Identifying trustworthy suppliers can make all the difference in maintaining your machinery’s efficiency.

Local Dealers: Many individuals prefer visiting nearby retailers that specialize in outdoor equipment. These locations often carry a variety of authentic components and accessories, allowing for direct consultation with knowledgeable staff. This face-to-face interaction can provide valuable insights into compatibility and installation.

Online Retailers: The internet offers a wealth of resources for purchasing genuine items. Several reputable websites provide detailed catalogs, enabling you to search for specific components from the comfort of your home. Look for sites that offer customer reviews and secure payment options to ensure a safe shopping experience.

Manufacturer’s Website: Purchasing directly from the manufacturer’s official site guarantees authenticity. Often, manufacturers provide comprehensive product information and support, making it easier to find the exact components you need. Additionally, many offer warranties and return policies that provide peace of mind.

Specialty Shops: There are also specialty shops focused solely on outdoor power equipment. These businesses frequently carry a vast selection of authentic components and can assist you in finding hard-to-locate items. Their expertise in the field ensures you receive the correct products for your specific needs.

In summary, whether you prefer local visits or online shopping, numerous avenues are available for acquiring genuine components. Ensuring you choose reputable sources will ultimately enhance your equipment’s performance and durability.

Exploring Aftermarket Options

When it comes to enhancing the performance and longevity of your outdoor equipment, considering alternative components can be a smart choice. Aftermarket offerings often provide a variety of enhancements that cater to specific needs, allowing users to customize their machines according to their preferences. This section delves into the benefits and considerations of selecting non-original items, which may offer cost savings and improved functionality.

Benefits of Alternative Components

One of the primary advantages of exploring alternative components is the potential for reduced costs. Many manufacturers produce high-quality items that rival original options but at a fraction of the price. Furthermore, aftermarket parts can sometimes offer improved durability or performance, enabling users to maximize the efficiency of their machines. Additionally, the wide availability of these components allows for easier sourcing and quicker repairs, ensuring minimal downtime.

Considerations When Choosing Alternatives

While there are numerous benefits to selecting aftermarket options, it is essential to evaluate the quality and compatibility of these components. Not all alternatives are created equal; therefore, researching reputable manufacturers and reading customer reviews can help ensure that you choose reliable products. It’s also crucial to verify that the selected components are compatible with your specific equipment to avoid any performance issues or damage.

Tools Required for Assembly

When undertaking the assembly of small engines, having the right tools is essential for ensuring a smooth and efficient process. The correct equipment not only simplifies tasks but also enhances the overall quality of the assembly, reducing the risk of errors.

Here is a list of essential tools that you will need:

- Socket Wrench Set: A variety of sizes is necessary for different bolts and nuts.

- Torque Wrench: To ensure proper tightening of components, preventing damage from over-torquing.

- Screwdrivers: A set including both flathead and Phillips types for various fasteners.

- Pliers: Useful for gripping and twisting wires or small components.

- Cutting Tools: For trimming any excess materials or components as needed.

- Measuring Tools: Such as calipers or tape measures for precise measurements during assembly.

Having these tools readily available will facilitate the assembly process and help achieve optimal results.

Safety Precautions During Maintenance

Ensuring a safe environment during maintenance tasks is crucial for preventing accidents and injuries. Adopting proper safety measures not only protects the individual performing the work but also safeguards the equipment involved. Awareness of potential hazards and preparedness can significantly reduce risks associated with maintenance activities.

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. This gear is essential to shield against sharp objects, chemical exposure, and potential falls. Furthermore, it is important to work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Before starting any maintenance, disconnect the power source to eliminate the risk of accidental startups. Additionally, ensure that all tools are in good condition and suitable for the tasks at hand. Regularly inspect equipment for any signs of wear or damage to prevent unexpected failures during operation.

Maintain a clean workspace to reduce the chance of slips and trips. Organizing tools and materials can help keep distractions to a minimum and enhance efficiency. Finally, familiarize yourself with the equipment’s manual and follow all recommended safety protocols for maintenance procedures.