When maintaining small engines, grasping the intricacies of their structure is crucial for effective repairs and upgrades. Knowledge of how each element interacts not only aids in troubleshooting but also enhances overall performance and longevity. Having a clear visual representation of these components can significantly streamline the maintenance process.

Visual aids play a vital role in comprehending the configuration of various engine elements. By studying these schematics, enthusiasts and technicians alike can identify necessary replacements and modifications. This understanding empowers users to take charge of their equipment, ensuring it operates at its utmost efficiency.

Ultimately, familiarizing oneself with the layout of engine components fosters greater confidence in managing repairs. This detailed exploration provides insights into the functionality of each part, enabling a deeper appreciation for the machinery that powers our tools and devices.

Understanding Briggs and Stratton Engines

Engines play a crucial role in a variety of outdoor equipment, providing the power necessary for tasks ranging from lawn care to heavy-duty operations. Familiarity with these machines enhances maintenance and troubleshooting skills, ensuring optimal performance and longevity.

Key features of these engines include:

- Compact design, ideal for residential and commercial use

- Fuel efficiency, reducing operational costs

- Durability, built to withstand challenging conditions

Understanding the components is essential for effective upkeep. Here are the primary parts to consider:

- Cylinder: Houses the combustion process

- Piston: Converts pressure into mechanical energy

- Crankshaft: Transmits motion to the output

- Fuel System: Delivers the necessary fuel for combustion

- Ignition System: Initiates the combustion cycle

By gaining insight into these elements, users can troubleshoot issues more effectively, leading to enhanced performance and reduced downtime. Regular maintenance and an understanding of operational principles are vital for any engine owner.

Key Features of 550 Series

This segment highlights the essential attributes of a popular engine model, emphasizing its performance and reliability. Designed for various outdoor power equipment, it combines efficiency with durability, making it a preferred choice for many users.

Robust Power Output: The engine delivers a commendable amount of horsepower, ensuring that tasks are completed swiftly and effectively. This capability is ideal for homeowners and professionals alike.

Fuel Efficiency: With an emphasis on conservation, the model is engineered to maximize fuel usage, reducing operational costs while maintaining excellent performance standards.

Easy Maintenance: Accessibility to critical components is prioritized, allowing for straightforward servicing and repairs. This feature significantly enhances user experience and prolongs the engine’s lifespan.

Compact Design: The compact form factor makes it suitable for a variety of applications, enabling users to integrate it into different equipment without sacrificing space.

Quiet Operation: Designed with noise reduction in mind, this engine operates at lower sound levels, making it perfect for residential areas where noise can be a concern.

Durability: Built with high-quality materials, the engine is designed to withstand tough conditions, ensuring reliability in various environments and longevity in performance.

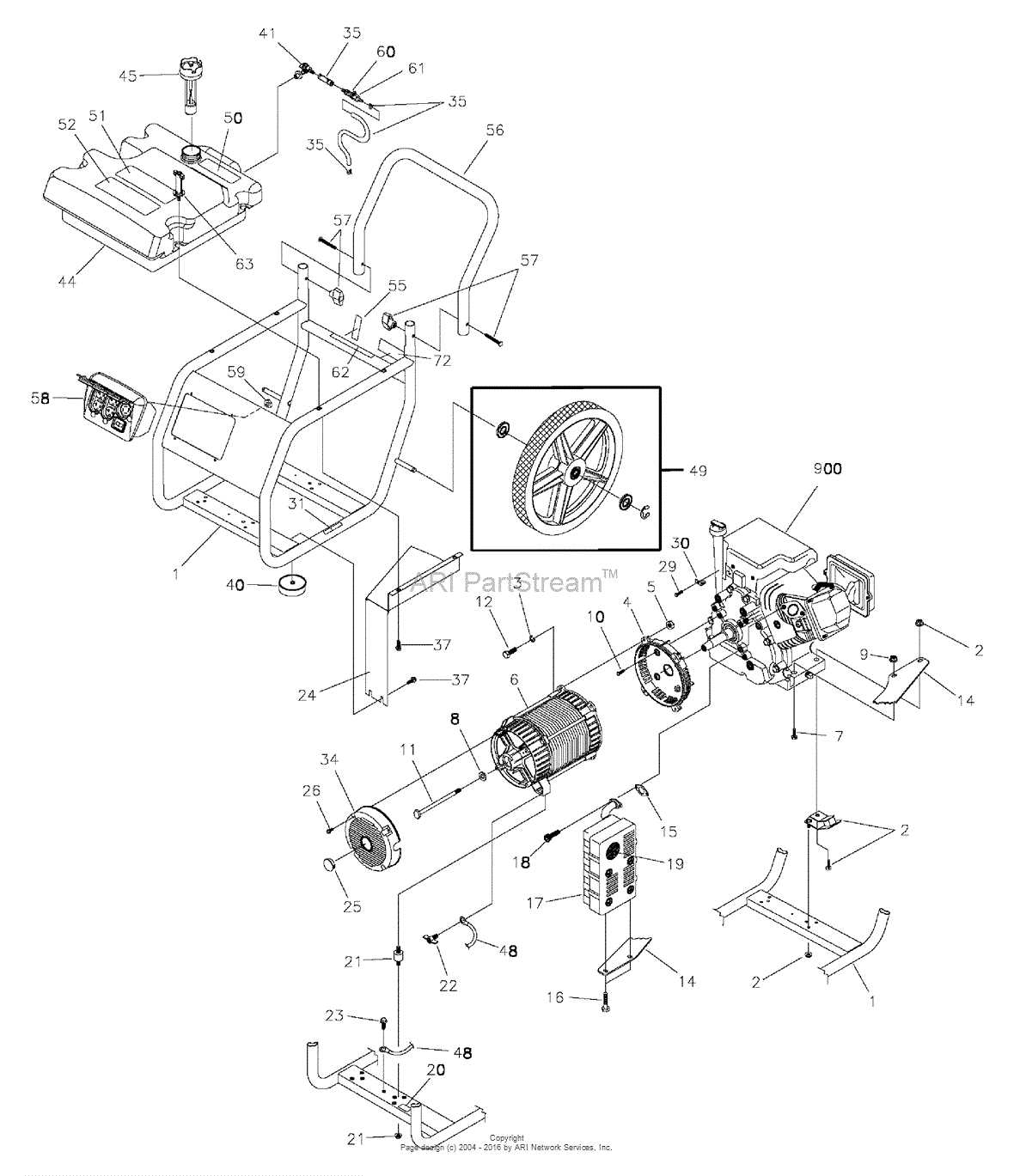

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. They provide clarity and insight, allowing users to understand the relationship between various elements and how they fit together. This understanding is essential for effective troubleshooting and ensuring optimal performance.

- Enhanced Understanding: Illustrations simplify complex structures, making it easier to identify each part’s function.

- Efficient Repairs: Quick reference guides allow for faster disassembly and reassembly.

- Accurate Ordering: Knowing exact components aids in ordering the right replacements, reducing downtime.

- Preventive Maintenance: Regularly consulting diagrams helps in spotting wear and tear before issues arise.

Overall, utilizing these visual aids leads to more informed decisions and better upkeep of equipment.

Common Issues with 550 Series

Understanding frequent problems that arise with small engine equipment can enhance maintenance and prolong lifespan. Users often encounter specific challenges that may hinder performance or lead to inefficient operation.

Fuel System Problems: One of the most prevalent issues involves the fuel system. Clogged filters or stale fuel can cause difficulties in starting or erratic performance.

Starting Difficulties: Many individuals report issues with ignition, which can stem from a faulty spark plug or electrical connections, leading to frustrating attempts at operation.

Overheating: Engines may overheat due to insufficient lubrication or cooling system malfunctions. Regular checks can prevent severe damage.

Air Filter Blockages: A dirty air filter can restrict airflow, resulting in poor combustion and reduced efficiency. Regular cleaning is essential for optimal function.

Maintenance Neglect: Skipping routine maintenance tasks can lead to a variety of issues, including decreased performance and increased wear. Adhering to a scheduled service can mitigate these problems.

Identifying Replacement Parts Easily

Finding the right components for your equipment can streamline maintenance and enhance performance. Knowing how to navigate the identification process is crucial for achieving optimal results.

- Refer to the owner’s manual for specific details on required components.

- Utilize online resources, including manufacturer websites, for accurate information.

- Examine existing components for model numbers or identifiers.

By employing these strategies, you can ensure you select the ultimate replacements for seamless operation.

- Start with a visual inspection to locate any model identifiers.

- Cross-reference these numbers with online databases.

- Consult with local dealers for expert guidance on suitable options.

This methodical approach will aid in pinpointing the exact replacements you need with confidence.

Tools Required for Maintenance

Proper upkeep of machinery necessitates a selection of essential implements. Utilizing the right equipment ensures efficiency and longevity, allowing for seamless operation. Without these tools, tasks may become cumbersome and prone to errors.

Key items include wrenches for tightening and loosening fasteners, screwdrivers for adjusting components, and pliers for gripping and manipulating various parts. Additionally, a clean cloth helps maintain surfaces, while a funnel can facilitate fluid changes without spills.

Having a sturdy workbench or surface is vital for organization and safety during maintenance tasks. Investing in high-quality tools not only enhances performance but also ensures a reliable experience every time maintenance is performed.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide crucial information about the different elements involved in a machine, making it easier to identify and replace any worn or broken pieces.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself with the Layout: Start by examining the overall structure. Most illustrations will categorize components logically, helping you navigate the different sections.

- Identify Numbering Systems: Pay attention to any reference numbers or labels. These will often correlate with a list of items, allowing you to find specific parts quickly.

- Understand Symbols: Different symbols may represent various types of components, such as fasteners, connectors, or mechanical parts. Learning these can simplify the reading process.

- Refer to the Legend: Many visuals include a legend or key. This section explains the symbols and markings used, providing clarity on how to interpret the illustration.

- Cross-Reference with Manuals: Using the illustration in conjunction with a service manual or parts catalog can enhance understanding and ensure you’re sourcing the correct items.

By following these guidelines, you can gain confidence in navigating through illustrations of components, making your repair and maintenance tasks much more efficient.

Best Practices for Engine Care

Caring for your motor is essential for optimal performance and longevity. Regular maintenance helps to prevent issues and ensures smooth operation. By following a few simple guidelines, you can significantly enhance the reliability and efficiency of your engine.

Regular Oil Changes: Keeping the lubricant fresh is crucial. Change the oil according to the manufacturer’s recommendations to minimize wear and tear.

Clean Air Filters: Ensure that air intake systems are unobstructed. Regularly inspect and replace filters to maintain airflow and prevent debris from entering the combustion chamber.

Inspect Spark Plugs: Check spark plugs periodically for wear. Replacing them at the right intervals can improve ignition efficiency and overall performance.

Check Fuel Quality: Use clean, high-quality fuel to avoid contamination. Stale or contaminated fuel can lead to starting issues and poor engine function.

Keep It Clean: Regularly clean the exterior of the engine. Removing dirt and debris helps to prevent overheating and makes it easier to spot potential problems.

Store Properly: If not in use for an extended period, store the engine in a dry, cool place. This helps to prevent rust and other damage.

By implementing these practices, you can ensure your motor remains in peak condition, ultimately prolonging its lifespan and enhancing its performance.

Where to Find Quality Parts

When seeking reliable components for your outdoor equipment, it’s essential to explore a variety of sources to ensure you receive durable and efficient items. Quality parts not only enhance the performance of your machinery but also extend its lifespan. Understanding where to shop can make a significant difference in your overall experience and satisfaction.

Authorized Dealers

One of the most dependable places to locate high-quality components is through authorized dealers. These outlets often carry original equipment manufacturer (OEM) items, ensuring compatibility and longevity. Additionally, purchasing from authorized retailers often comes with warranties and customer support, providing extra peace of mind.

Online Marketplaces

The internet offers a vast array of online marketplaces where you can find both new and used components. Reputable websites provide detailed descriptions, customer reviews, and ratings that can guide your purchasing decisions. Always check the seller’s credibility and return policy to safeguard your investment.

Step-by-Step Repair Guide

This guide provides a systematic approach to troubleshooting and fixing common issues with small engines. By following these steps, you can ensure your equipment operates efficiently and reliably.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and a multimeter.

- Obtain a detailed schematic for reference.

- Ensure safety equipment is on hand, including gloves and goggles.

Troubleshooting Process

- Identify the problem: Start with symptoms such as unusual noises or starting issues.

- Inspect components: Check for wear and tear, loose connections, or blockages.

- Test electrical systems: Use a multimeter to check for voltage and continuity.

- Replace damaged parts: Order suitable replacements based on your findings.

- Reassemble and test: Ensure everything is securely reattached before starting the engine.

Comparing 550 Series to Other Models

This section explores the distinctions between a specific engine model and its counterparts. Each engine has unique characteristics that cater to varying performance requirements, maintenance needs, and user preferences. Understanding these differences can help in making informed choices for specific applications.

The highlighted model typically boasts a robust design suited for light to medium tasks, while other variants may offer enhanced power or efficiency. When analyzing different options, factors such as displacement, torque output, and fuel consumption are critical. Users may find that certain models excel in durability, while others shine in versatility.

Additionally, features like ease of maintenance and part availability can influence the decision-making process. As enthusiasts delve into the specifics, they may uncover the ultimate fit for their needs, whether it’s for lawn care, outdoor power equipment, or other uses.

Expert Tips for Long-Term Performance

Ensuring the longevity of your equipment requires careful attention and regular maintenance. By implementing effective strategies, you can significantly enhance efficiency and reliability over time. This section explores key practices that contribute to sustained functionality.

Regular Maintenance Schedule

Establishing a consistent maintenance routine is crucial. Regularly inspect components for wear and tear, clean air filters, and replace oils as needed. These steps not only optimize performance but also prevent costly repairs.

Proper Storage Techniques

When not in use, ensure your equipment is stored in a dry, protected environment. Covering your tools can shield them from dust and moisture, prolonging their lifespan and maintaining peak performance.