Maintaining a well-kept outdoor space often involves utilizing various tools designed for effective grass trimming. This section aims to provide a comprehensive overview of the intricate elements that contribute to the functionality of these machines. By examining these components, users can enhance their understanding and improve maintenance practices.

Familiarizing oneself with the different segments of these devices is crucial for optimal performance. From the engine assembly to the cutting mechanism, each part plays a vital role in ensuring efficiency and reliability. With the right knowledge, operators can address issues more effectively, ensuring their equipment runs smoothly and lasts longer.

This guide offers valuable insights into the layout and function of each segment, helping users to identify specific components quickly. Whether for troubleshooting or routine upkeep, understanding the structure of this type of machinery is essential for every operator.

The fundamental purpose of a grass-cutting machine is to maintain a neat and healthy outdoor space by efficiently trimming vegetation. Various mechanisms and components work in harmony to achieve optimal results, ensuring that the machine operates smoothly and effectively. Understanding these essential elements helps users appreciate how each part contributes to the overall performance.

Core Components and Their Functions

Key components play a vital role in the operation of a grass-cutting device. Each part has a specific function that contributes to the efficiency and effectiveness of the machine. Below is a table highlighting the main elements and their respective roles:

| Component | Function |

|---|---|

| Engine | Powers the device, providing the necessary energy for operation. |

| Blades | Cuts the grass evenly, ensuring a tidy appearance. |

| Deck | Houses the blades and protects other components, allowing for effective cutting. |

| Wheels | Facilitate movement across various terrains, enhancing maneuverability. |

| Fuel System | Stores and delivers fuel to the engine, ensuring proper combustion. |

Importance of Maintenance

Regular upkeep is essential for maintaining the functionality of a grass-trimming machine. Proper care extends the lifespan of the device and ensures it performs optimally. Routine checks and timely replacements of worn parts can prevent potential issues and enhance overall efficiency.

Key Components of the 625 Model

This section delves into the essential elements that make up a specific model of outdoor equipment designed for grass maintenance. Understanding these components is crucial for efficient operation and maintenance, ensuring longevity and optimal performance. Each part plays a vital role in the functionality and reliability of the equipment.

Main Functional Elements

Among the core features are the motor assembly, which provides the necessary power, and the cutting mechanism, responsible for achieving a clean and even trim. The chassis supports various components, ensuring stability and maneuverability. Additionally, the control system allows users to operate the device with ease and precision.

Supportive Accessories

Several auxiliary elements enhance the primary functions of this model. These include the fuel system, which ensures the engine receives the necessary energy source, and the filtration system, which maintains optimal air quality for combustion. Wheels and handles contribute to the overall user experience, making operation smooth and efficient.

| Component | Function |

|---|---|

| Motor Assembly | Provides power to the equipment |

| Cutting Mechanism | Ensures a clean and even cut |

| Chassis | Supports components and adds stability |

| Control System | Allows user operation and adjustment |

| Fuel System | Delivers energy to the engine |

| Filtration System | Maintains air quality for optimal combustion |

| Wheels | Facilitates easy movement |

| Handles | Enhances user control and comfort |

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires consistent care and attention. Implementing regular maintenance routines can significantly enhance the performance and lifespan of your machinery. By following a few simple guidelines, you can keep your tools in optimal condition and avoid unnecessary repairs.

Regular Inspections: Periodically check for any signs of wear or damage. This includes examining belts, blades, and other components for any irregularities. Early detection of issues can prevent further complications and costly repairs.

Keep it Clean: Debris and dirt accumulation can lead to mechanical problems. After each use, take the time to clean the exterior and undercarriage of your equipment. This not only improves performance but also helps to maintain its appearance.

Sharpen Blades: Keeping cutting edges sharp is crucial for efficiency. Dull blades can cause unnecessary strain on the engine and lead to uneven results. Regularly sharpening or replacing blades will ensure optimal cutting performance.

Fluid Levels: Regularly check and change engine oil and other fluids according to the manufacturer’s recommendations. Proper lubrication minimizes friction and wear, contributing to smoother operation.

Seasonal Maintenance: As seasons change, so should your maintenance routine. Prepare your equipment for seasonal use by checking batteries, fuel systems, and any other components that may require attention before heavy use.

By adopting these maintenance practices, you can extend the life of your outdoor equipment, ensuring reliable performance for years to come.

Common Issues and Solutions

When operating outdoor equipment, users often encounter various challenges that can impact performance and efficiency. Understanding these frequent complications and their remedies can enhance the longevity and functionality of your machine. This section will address some prevalent concerns along with practical solutions to restore optimal operation.

Engine Starting Problems

A common dilemma is the difficulty in initiating the engine. This issue can stem from several factors, including fuel-related problems or electrical malfunctions. Ensure that the fuel is fresh and the tank is filled appropriately. Additionally, inspect the battery connections and the ignition system for any loose wires or corrosion. Regular maintenance can prevent these complications from arising.

Uneven Cutting Performance

Another prevalent issue is inconsistent cutting, which can lead to unsatisfactory results. This problem may be due to dull blades or uneven tire pressure. It is crucial to sharpen the cutting blades regularly and check the tire inflation to ensure that they are at the recommended levels. Maintaining these aspects will help achieve a more uniform finish in your outdoor space.

Identifying Replacement Parts

Recognizing the necessary components for maintenance can significantly enhance the functionality and longevity of your equipment. Understanding the key elements and their roles is essential when seeking to replace specific items. This section provides insight into identifying the essential elements required for effective restoration.

Key Elements to Consider

- Compatibility: Ensure that the components you are considering are suitable for your specific model.

- Quality: Opt for high-quality items to guarantee optimal performance and durability.

- Manufacturer Specifications: Refer to the guidelines provided by the manufacturer to understand the appropriate components for replacement.

Common Components and Their Functions

- Engine Assembly: Responsible for powering the entire system and must be in good condition for effective operation.

- Cutting Blade: Essential for achieving a clean cut; should be sharp and free from damage.

- Fuel System: Comprises various parts that facilitate proper fuel flow, impacting performance.

- Transmission: Allows for smooth operation by transmitting power from the engine to the wheels.

By understanding these aspects, you can make informed decisions when searching for suitable replacements, ensuring your equipment runs smoothly and efficiently.

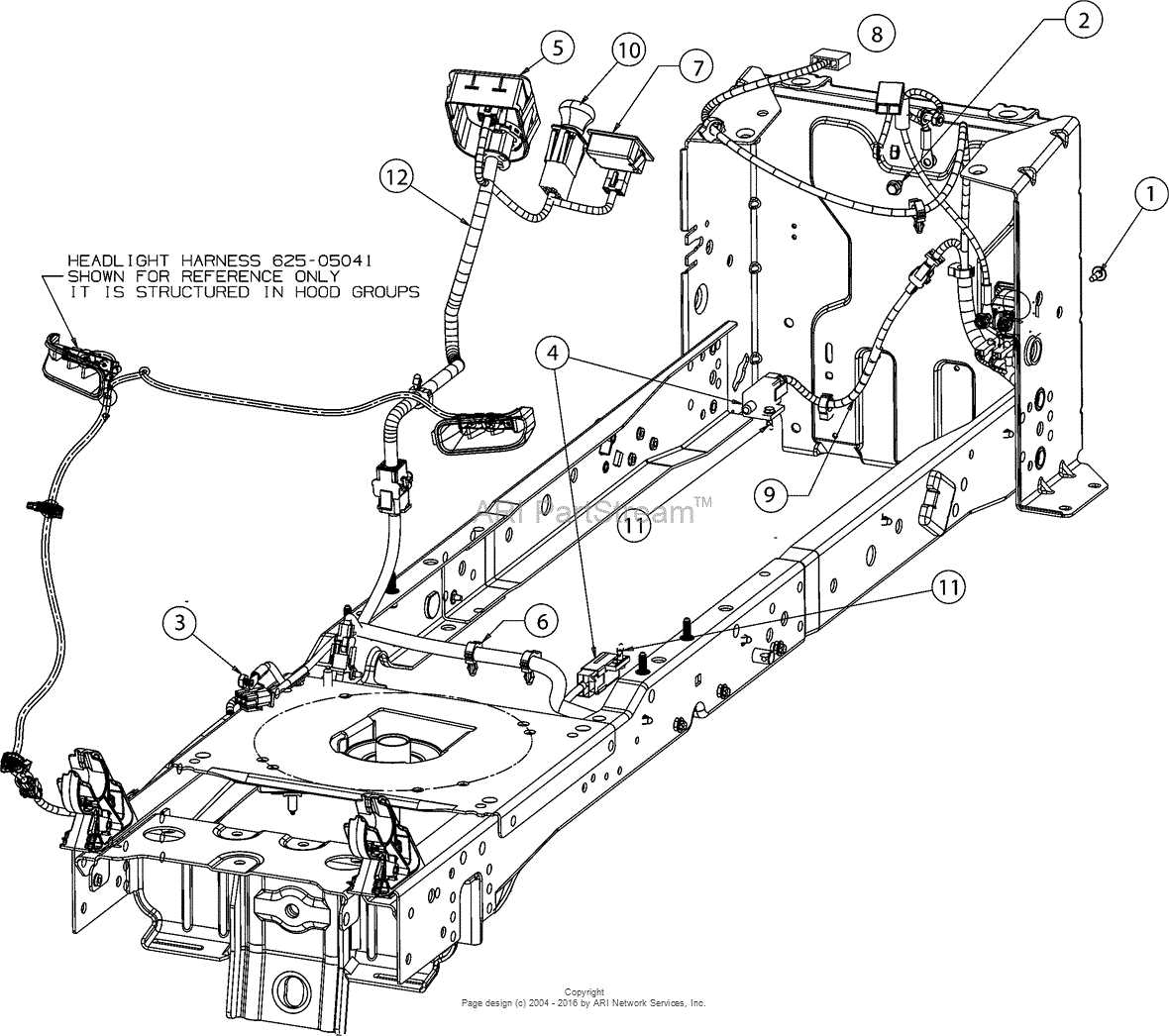

How to Access the Parts Diagram

Understanding the components of your equipment is crucial for effective maintenance and repairs. Accessing a visual representation of these elements can greatly simplify this process, enabling you to identify each part’s location and function.

Finding the Visual Representation

To locate the visual representation of the components, follow these steps:

- Visit the official website of the manufacturer or authorized service providers.

- Navigate to the support or resources section of the site.

- Use the search feature to enter the model information relevant to your equipment.

- Look for a downloadable or viewable version of the visual representation.

Utilizing User Manuals

User manuals are often a valuable resource for accessing visual representations. To utilize this option:

- Check if you have a physical copy of the user manual.

- If unavailable, search online for a PDF version by entering the model details.

- Review the manual for sections dedicated to the visual representation of components.

Understanding the Engine Specifications

Grasping the technical details of the power unit is essential for effective maintenance and optimal performance. Each engine variant features unique characteristics that contribute to the overall efficiency and functionality of the machine. By examining these attributes, users can enhance their understanding and ensure proper care.

Key specifications that should be noted include:

- Displacement: This refers to the engine’s total volume, typically measured in cubic centimeters (cc) or liters. A higher displacement often correlates with increased power output.

- Power Rating: Expressed in horsepower (HP) or kilowatts (kW), this figure indicates the engine’s capacity to perform work. It’s crucial for determining suitability for specific tasks.

- Fuel Type: The engine may operate on various fuel types, including gasoline, diesel, or alternative sources. Understanding the appropriate fuel is vital for efficiency and longevity.

- Compression Ratio: This ratio impacts engine efficiency and power. Higher compression typically results in improved fuel efficiency and performance.

- Cooling System: Engines may utilize air or liquid cooling methods. Each system has its advantages, influencing the engine’s operational stability and maintenance needs.

Being aware of these specifications not only aids in selecting the right engine for specific tasks but also informs users about maintenance routines and potential upgrades. Proper comprehension of these details ultimately leads to enhanced performance and durability.

Utilizing the User Manual Effectively

Accessing and interpreting the provided documentation is essential for optimizing the performance of your equipment. This guide serves as a comprehensive resource, offering detailed insights into operation, maintenance, and troubleshooting. By familiarizing yourself with its contents, you can enhance your understanding and ensure the longevity of your device.

Understanding the Structure is the first step to maximizing the manual’s benefits. Typically organized into sections, each segment covers different aspects such as assembly, maintenance schedules, and troubleshooting procedures. Familiarity with the table of contents will allow for quicker navigation, saving time when seeking specific information.

Following the Maintenance Guidelines outlined in the manual is crucial for preserving the functionality of your equipment. Regular checks and servicing as recommended can prevent common issues and extend the lifespan of your machine. Adhering to the specified intervals will help ensure that your device operates at peak efficiency.

In addition, the Troubleshooting Section can be an invaluable asset when encountering operational challenges. This part typically provides a list of common problems along with potential solutions. By consulting this section, you can often resolve issues independently, avoiding unnecessary delays and repair costs.

Finally, keeping the manual accessible during use is advisable. Having it nearby allows for quick reference to critical information, ensuring that you can address any concerns promptly. This proactive approach will help maintain optimal performance and enhance your overall experience.

Comparing with Other Mower Models

This section delves into the differences and similarities between various cutting machines available in the market. By examining key features, functionality, and user experiences, we can better understand how these devices stack up against one another. Analyzing these aspects allows potential buyers to make informed decisions based on their specific needs and preferences.

When evaluating different models, it is essential to consider factors such as engine performance, cutting efficiency, and ease of maintenance. The following table highlights some critical attributes of popular alternatives, providing a clear overview for comparison:

| Model | Engine Power (HP) | Cutting Width (inches) | Weight (lbs) | Price ($) |

|---|---|---|---|---|

| Model A | 5.5 | 20 | 50 | 299 |

| Model B | 6.0 | 22 | 55 | 349 |

| Model C | 4.5 | 18 | 45 | 259 |

| Model D | 5.0 | 21 | 52 | 299 |

By comparing these machines, users can identify which model best fits their requirements. Each design offers unique advantages, catering to various types of users, whether they seek power, efficiency, or affordability.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential to ensure optimal performance and longevity. Whether you’re a seasoned user or a newcomer, knowing where to source high-quality replacements can save time and enhance your experience. Here are some reliable options to consider when looking for genuine items.

- Authorized Retailers: Many certified sellers offer original items directly from manufacturers. These outlets typically provide a wide range of selections and ensure the authenticity of their products.

- Official Websites: Visiting the official websites of manufacturers allows you to browse their catalogs and order directly. This method guarantees you receive genuine components and often provides detailed specifications.

- Local Dealers: Local dealerships frequently stock authentic replacements and can assist with installation or maintenance inquiries. Building a relationship with your local dealer can lead to personalized service and expert advice.

- Online Marketplaces: Reputable online platforms also sell genuine items. Look for listings that specifically mention authenticity and read customer reviews to verify the seller’s credibility.

In summary, sourcing authentic components is crucial for maintaining equipment efficiency. By exploring the options listed above, you can ensure you obtain the quality needed for reliable operation.

Assembly and Disassembly Instructions

This section provides essential guidance for the correct assembly and disassembly of your equipment. Following these steps ensures safety and optimal performance while maintaining the device’s integrity.

Before starting, gather all necessary tools and components. It’s crucial to work in a well-lit area and have a clean workspace to avoid losing any small pieces. Here are the steps to follow:

- Preparation:

- Ensure the device is turned off and disconnected from any power source.

- Wear appropriate safety gear, including gloves and goggles.

- Disassembly:

- Begin by removing any protective covers and guards.

- Carefully detach components by unscrewing or unclipping as required.

- Place removed parts in an organized manner to facilitate reassembly.

- Inspection:

- Examine each component for wear or damage.

- Replace any faulty parts before proceeding.

- Reassembly:

- Refer to the manual for proper placement and orientation of each piece.

- Securely fasten components, ensuring no loose parts remain.

- Final Check:

- Ensure everything is properly assembled and secured.

- Reconnect the power source and conduct a test run.

By adhering to these instructions, you can effectively manage the assembly and disassembly of your equipment, ensuring longevity and reliable performance.

Safety Precautions for Repairs

When undertaking maintenance on any machinery, adhering to safety protocols is essential to prevent accidents and ensure a secure working environment. Awareness of potential hazards and the implementation of proper procedures can significantly reduce risks associated with repairs.

Essential Safety Guidelines

- Always disconnect the power source before beginning any work to avoid unintended starts.

- Utilize appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure your workspace is clean and free of clutter to prevent trips and falls.

- Read the owner’s manual thoroughly to understand specific safety instructions related to the equipment.

- Never attempt repairs on damaged components without proper guidance or knowledge.

Proper Tool Usage

- Use tools designed for the specific task to avoid damage or injury.

- Inspect tools before use to ensure they are in good condition and safe to operate.

- Store tools properly after use to prevent accidents in the workspace.

- Follow manufacturer recommendations for tool operation and maintenance.