In modern fluid management, a reliable and efficient mechanism is essential for the seamless movement of liquids. The design of these systems often includes a variety of intricate elements, each playing a crucial role in ensuring optimal flow and pressure control. Recognizing how these elements interact is key to maintaining smooth operations and extending the lifespan of the equipment.

Every element in such a setup serves a distinct purpose, from the connectors that secure pathways to the specialized devices that regulate flow rates. By understanding the functions and placement of each component, users can better maintain and troubleshoot the system, ensuring consistent performance in diverse conditions.

Detailed knowledge of these mechanisms allows for easier maintenance and adjustments. This understanding aids in recognizing when a component might need attention or replacement, helping to prevent potential issues before they disrupt the operation. Through a well-rounded understanding, users can ensure their fluid transfer systems operate efficiently and reliably over time.

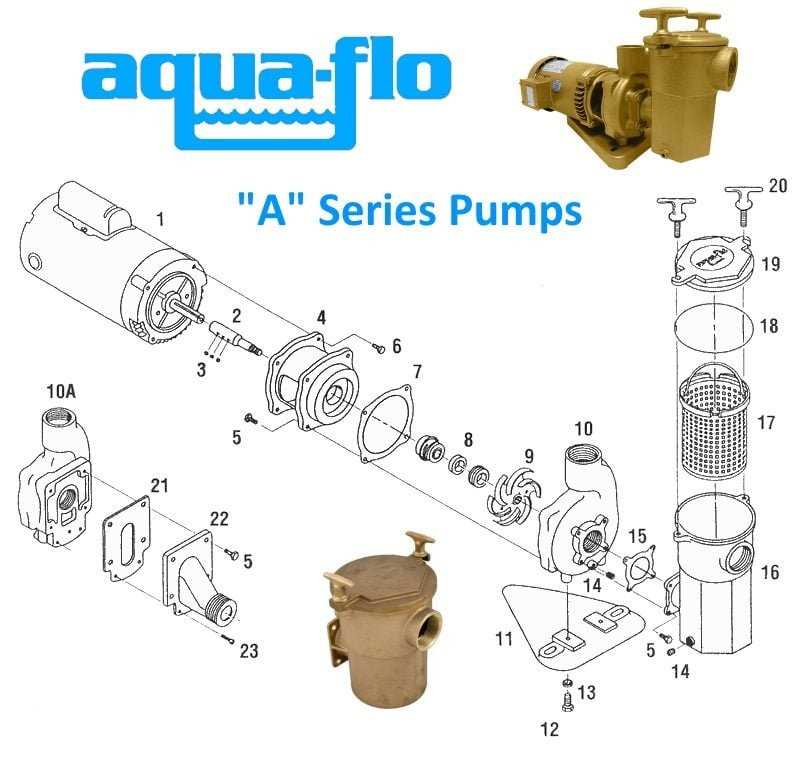

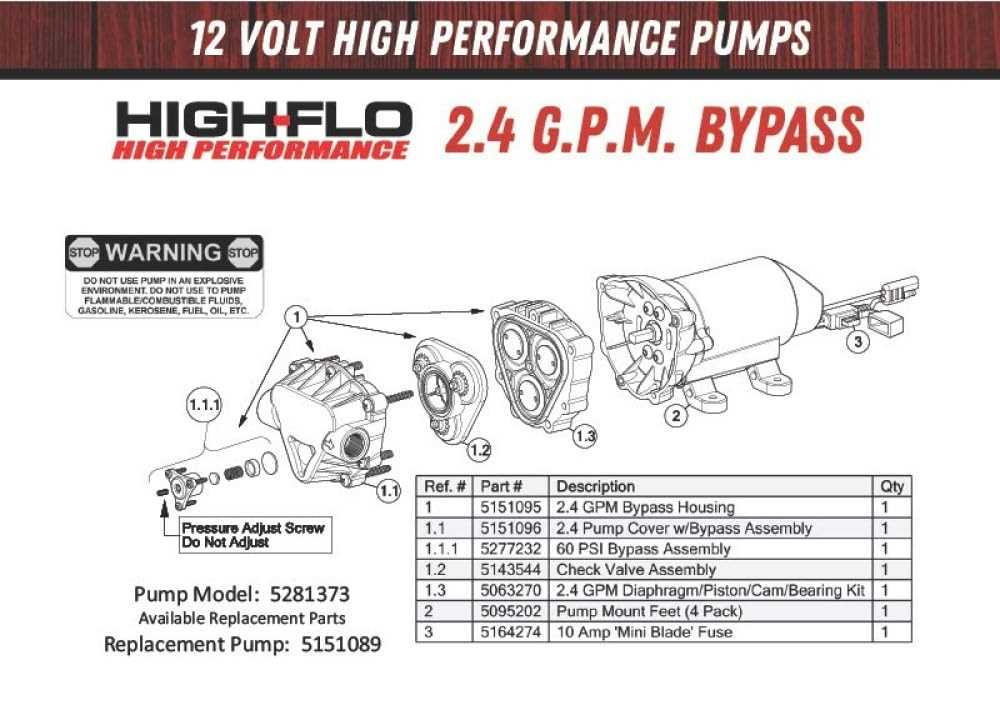

High-Flo Gold Series Pump Parts

Understanding the structure and components of this fluid transfer device is essential for proper maintenance and effective use. Each element plays a crucial role in ensuring smooth and efficient operation, contributing to the overall durability of the equipment.

Main Components Overview: The primary mechanisms are designed to facilitate seamless liquid movement, offering both stability and control. These core elements work together, allowing users to achieve the desired performance with minimal effort.

Additional Elements for Enhanced Functionality: Supplemental features are available to improve the versatility and efficiency of the device. These adjustments enable better adaptability to different situations, ensuring that the system can handle various demands with ease.

Proper upkeep and timely replacement of specific mechanisms can significantly extend the lifespan of the equipment. Regular inspection helps to identify potential issues early, ensuring consistent and reliable operation.

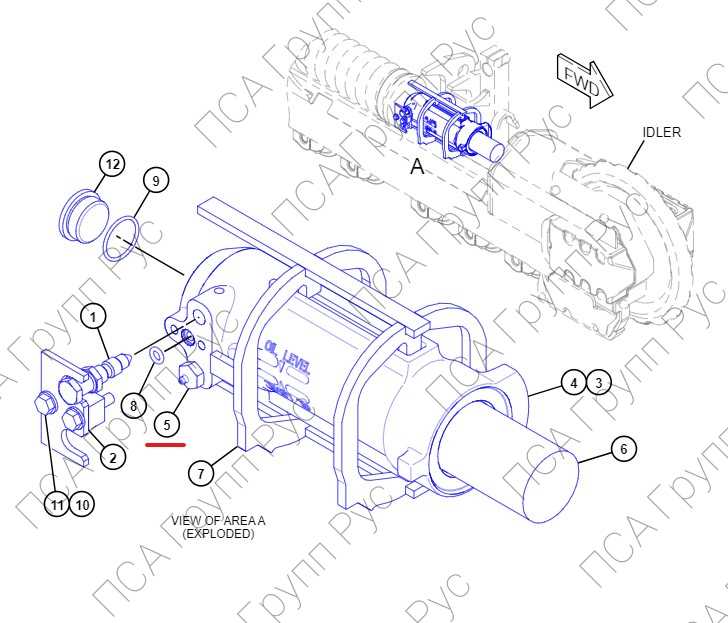

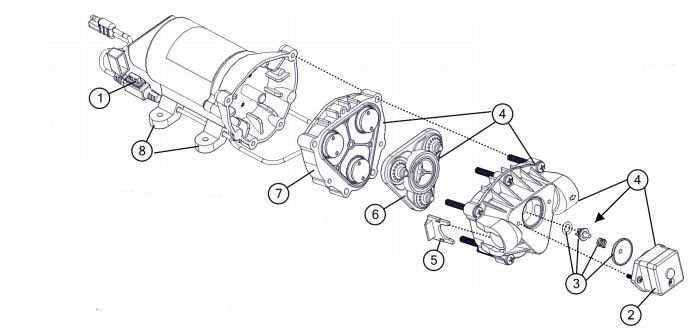

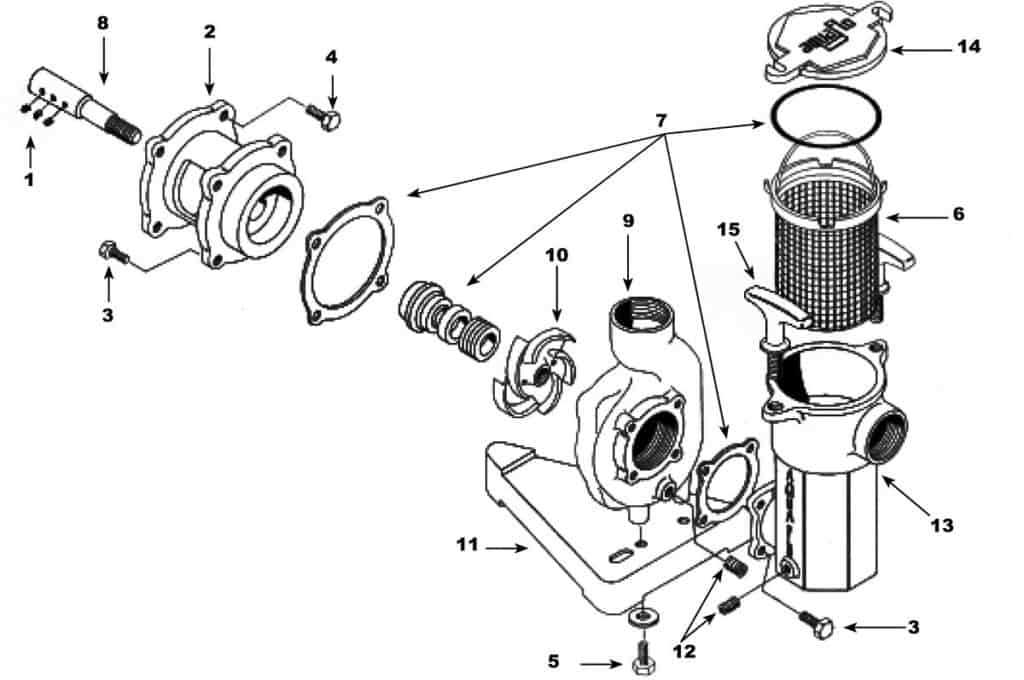

Overview of Pump Components

This section explores the key elements of a fluid transfer system, focusing on how each piece contributes to efficient movement and flow management. Understanding the different parts helps in ensuring smooth operation, maintaining pressure levels, and avoiding potential issues.

The core structure includes various elements responsible for guiding liquid movement, regulating flow speed, and ensuring a steady transfer. Each component has a specific role, from drawing in the liquid to pushing it through the system with consistent force. Proper alignment and compatibility between these elements are crucial for achieving optimal performance.

Maintenance of these elements requires knowledge of their functions and common challenges. Recognizing the symptoms of wear and the need for adjustments can help extend the lifespan of the system and prevent interruptions. Regular inspections are essential to identify any signs of degradation or imbalances that might affect overall functionality.

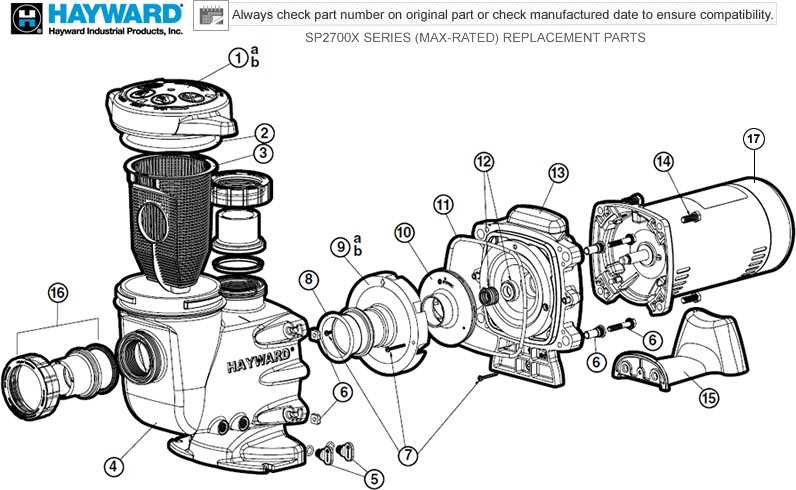

Assembly Guide for Efficient Operation

Properly aligning and connecting the various elements ensures smooth performance and long-lasting functionality. Understanding how each component fits together is essential for maintaining reliable and consistent operation. By following the detailed steps below, users can achieve a seamless integration of the individual parts.

Start by organizing all the necessary pieces, ensuring they are clean and free of obstructions. Begin with the main housing and attach the primary mechanism, ensuring that it sits securely in place. Use the provided fasteners to tighten, but avoid overtightening to prevent damage.

Next, align the rotational element with the central axis, making sure it moves freely without resistance. Secure it with the recommended locking mechanisms. Proceed to attach the supporting structure, which stabilizes the main assembly and minimizes vibration during operation.

Finally, connect the flow regulation system to the main framework, checking that all seals and gaskets are correctly positioned to prevent leaks. Test the assembly by running a preliminary check to ensure all components are functioning as expected, making adjustments as necessary for optimal performance.

Key Features of the Pump System

This section explores the essential aspects that make the fluid transfer device efficient and reliable for various applications. It is designed to handle a range of tasks with precision and stability, ensuring consistent operation under different conditions.

Durability and Resilience: The system is built to withstand continuous use, providing long-lasting performance. Its robust materials help it operate effectively even in demanding environments, reducing the need for frequent maintenance.

Optimized Flow Control: Precision in regulating liquid movement is a critical advantage of this setup. It ensures a steady, controlled transfer process, making it suitable for delicate and heavy-duty operations alike.

Ease of Adjustment: Flexibility in modifying operational parameters allows for fine-tuning based on specific requirements. This adaptability enhances overall usability, catering to different needs and preferences.

Energy Efficiency: Designed to minimize energy consumption, this system is crafted to deliver optimal results with lower power usage. This not only conserves resources but also helps in reducing operational costs.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. A well-maintained device not only functions smoothly but also extends its operational life. By adopting some simple upkeep practices, you can prevent wear and ensure optimal performance over time.

Regular Cleaning: Keeping the exterior and interior components free from dust and debris helps maintain consistent performance. Use a soft brush or cloth to wipe off accumulated particles, paying special attention to hard-to-reach areas.

Lubrication: Applying appropriate lubricants to moving parts reduces friction and prevents overheating. Ensure that only the recommended type is used, as this can significantly enhance the smoothness of operation.

Periodic Inspections: Regularly check for signs of wear or damage, such as loose connections or unusual noises during operation. Identifying and addressing minor issues early can prevent major malfunctions and costly repairs.

Maintaining your device with these simple methods will ensure steady performance and reduce the chances of unexpected breakdowns. Proper care not only enhances reliability but also contributes to a longer service life.

Troubleshooting Common Issues

Identifying and resolving frequent complications is essential for maintaining optimal performance in any fluid transfer system. Various factors can contribute to malfunctions, and recognizing these issues early can prevent further damage and ensure efficient operation.

One common problem is a lack of flow, which may result from blockages or obstructions in the system. Inspecting the inlet and outlet for debris or restrictions is a crucial first step. Additionally, worn seals or gaskets can lead to leaks, compromising pressure and functionality. Regular checks and replacements can mitigate these concerns.

Another frequent issue involves unusual noises during operation. Such sounds often indicate mechanical problems or misalignments. It is advisable to examine the motor and components for wear or misalignment and address any discrepancies promptly.

Finally, fluctuations in performance can signal underlying issues with power supply or component efficiency. Ensuring that electrical connections are secure and that all parts are functioning within their specified limits will help maintain consistent operation. Routine maintenance and vigilant monitoring are key to preventing and resolving these challenges.

Installation Process for New Users

Setting up a new unit can be an exciting yet challenging endeavor for those unfamiliar with the equipment. This section aims to provide clear and concise guidance for individuals embarking on this task, ensuring a seamless experience from start to finish.

Before beginning the installation, gather all necessary components and tools. It is crucial to follow each step meticulously to ensure proper functioning and longevity of the equipment.

| Step | Description |

|---|---|

| 1 | Review the user manual thoroughly to understand the specifications and requirements for installation. |

| 2 | Prepare the installation site by ensuring it is clean and free from obstructions. |

| 3 | Assemble the necessary tools such as wrenches, screwdrivers, and safety gear before proceeding. |

| 4 | Connect the various components according to the guidelines provided, ensuring secure and tight fittings. |

| 5 | Conduct a thorough inspection of the setup to identify any potential issues before powering up the unit. |

| 6 | Power on the system and monitor its operation for any irregularities, making adjustments as necessary. |

Following these steps will help new users establish their equipment correctly and effectively, paving the way for optimal performance.

Performance Optimization Techniques

Enhancing efficiency in machinery involves several strategies that focus on maximizing output while minimizing input. By adopting these methods, users can achieve superior operational effectiveness, ultimately leading to cost savings and improved functionality.

Key techniques for optimization include:

- Regular Maintenance: Implementing a consistent maintenance schedule ensures that components are in optimal condition, reducing wear and tear.

- Monitoring Performance: Utilizing diagnostic tools can help identify inefficiencies, enabling timely interventions to rectify issues.

- Adjusting Operating Parameters: Fine-tuning settings based on operational demands can lead to significant improvements in efficiency.

- Quality Components: Investing in high-quality materials enhances durability and performance, leading to less frequent replacements.

- System Upgrades: Incorporating modern technology can enhance capabilities, allowing for better performance metrics.

By integrating these techniques, users can significantly enhance the overall performance of their systems, ensuring longevity and reliability.

Safety Precautions During Use

Ensuring safety during operation is crucial to prevent accidents and maintain equipment longevity. Adhering to recommended guidelines minimizes risks associated with handling and functionality.

Always wear appropriate personal protective equipment, including gloves and goggles, to shield against potential hazards. This is essential when dealing with any operational device.

Before commencing any task, inspect the equipment thoroughly for signs of wear or damage. Regular maintenance checks can identify issues early and reduce the likelihood of malfunctions.

Ensure that the area is clear of obstacles and that all users are aware of the operational process. Proper communication helps to maintain a safe working environment and prevent mishaps.

Follow the manufacturer’s instructions for operation closely. Familiarizing oneself with the guidelines ensures that the equipment is used correctly and efficiently, enhancing safety during its use.

In case of any irregular sounds or malfunctions, cease operation immediately and conduct a detailed assessment. Ignoring unusual indicators can lead to further complications and pose safety risks.

Choosing the Right Replacement Parts

When it comes to maintaining equipment, selecting the appropriate components is crucial for optimal performance and longevity. Understanding the various options available can help ensure that the machinery operates efficiently and meets the necessary standards.

Firstly, it is important to consider the compatibility of the new elements with the existing system. Each mechanism has specific requirements, and choosing items that match these specifications can prevent future malfunctions. Additionally, paying attention to the quality of the replacements is essential, as inferior products may lead to further complications down the line.

Furthermore, researching the reputation of manufacturers can provide insights into their reliability and the durability of their offerings. Opting for well-known brands often translates to better performance and support. Finally, consulting with experts or referencing detailed resources can guide users in making informed decisions, ensuring that all components function harmoniously together.

Cleaning and Storage Guidelines

Maintaining optimal performance and longevity of your equipment requires proper cleaning and storage practices. Regular upkeep not only enhances efficiency but also prevents potential issues that may arise from neglect. Implementing effective strategies can significantly contribute to the overall functionality of your device.

Before storing your equipment, ensure that all components are thoroughly cleaned to remove any residues or contaminants. Utilize suitable cleaning agents and tools that are safe for the materials involved. After cleaning, allow all parts to dry completely to prevent moisture buildup, which could lead to corrosion or mold.

When it comes to storage, choose a cool, dry location that is free from extreme temperatures and humidity. It is advisable to keep components in their original packaging or in protective containers to avoid damage from dust or physical impact. Additionally, regularly check the stored items for any signs of wear or degradation, ensuring they remain in good condition for future use.