Every household relies on essential devices that simplify daily chores. When one of these devices starts to show signs of wear, it becomes necessary to identify and replace certain elements to ensure smooth operation. For many, understanding the internal setup of such machines can seem daunting, but breaking down the key components helps demystify the process.

By exploring the inner workings of these appliances, you gain valuable knowledge that empowers you to maintain and repair them efficiently. This overview highlights the essential elements that contribute to the functionality of a common laundry machine, guiding you through each part and its role in the overall system.

Knowing how each piece functions not only aids in troubleshooting but also prolongs the lifespan of your

Understanding Key Components of Kenmore 500 Washer

Recognizing the essential elements of a laundry appliance can greatly enhance its performance and longevity. By familiarizing yourself with the major components, you can troubleshoot issues more effectively and ensure smooth operation for years to come.

- Control Panel: This section houses the various settings and buttons that allow you to customize each cycle. It provides options for water temperature, cycle type, and spin speed.

- Drum: The inner drum is where clothes are placed. It spins during the cleaning process to agitate the garments and ensure a thorough wash.

- Water Inlet

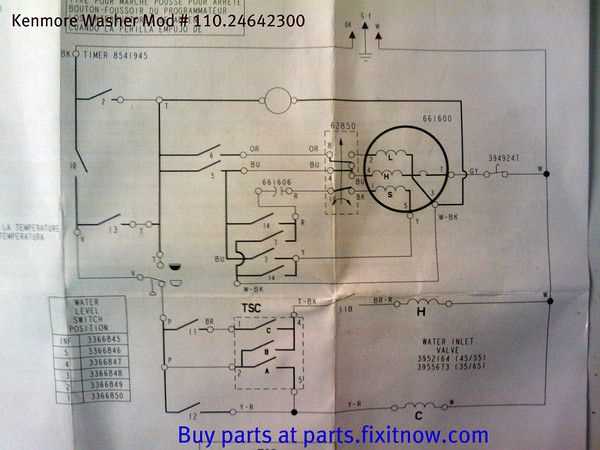

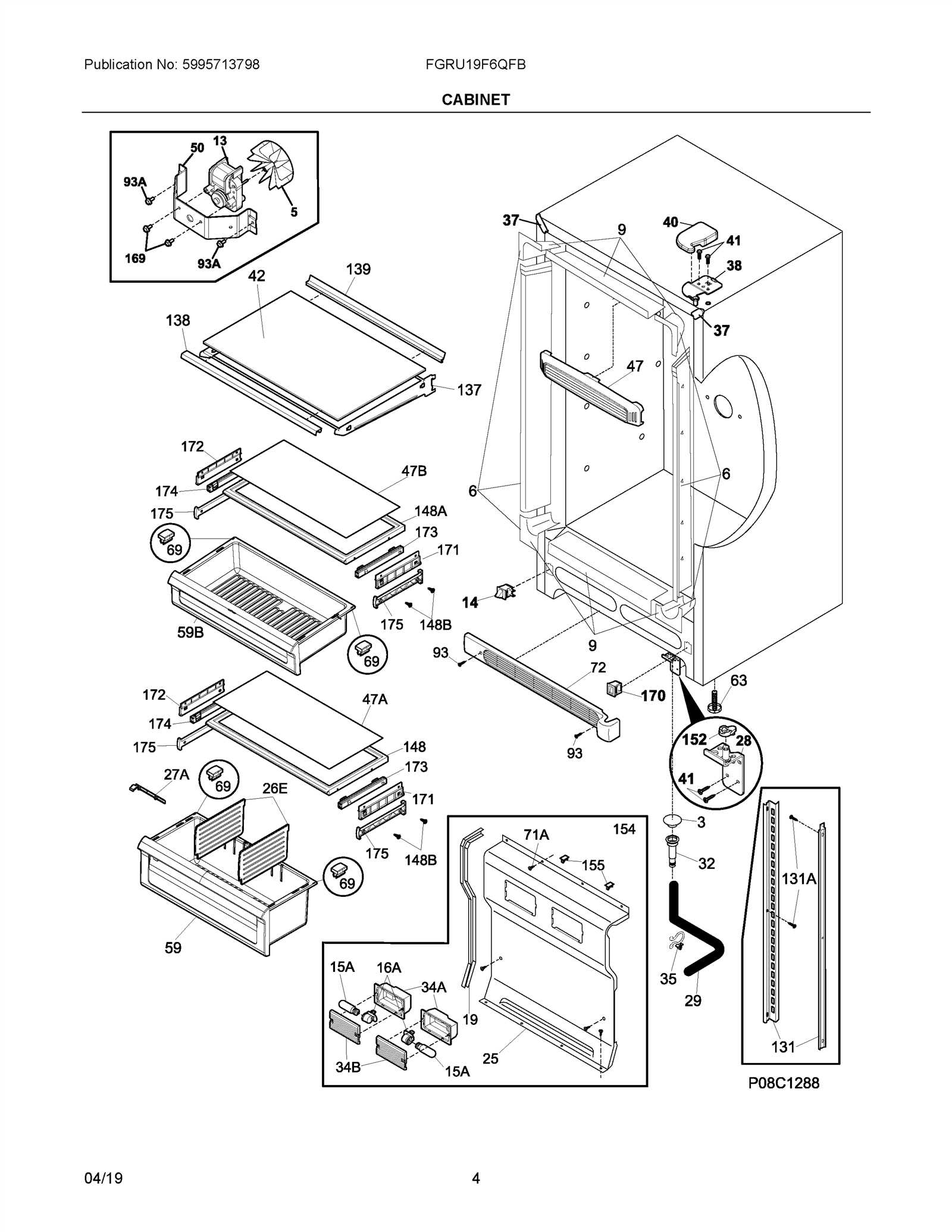

Diagram Overview of Essential Washer Parts

Understanding the key components of a laundry machine is crucial for both maintenance and repair. A well-detailed visual guide helps users identify each element clearly, facilitating troubleshooting and part replacement. This section will cover the core elements that ensure efficient operation, breaking down their functions and locations within the appliance.

Internal Structure

At the heart of every machine, there are several essential internal mechanisms responsible for smooth performance. The motor powers the entire system, while the drum facilitates the rotation necessary for cleaning. Additionally, the transmission system helps regulate speed and movement during different cycles.

External Features

The exterior is equipped with various controls and access points, including the control panel for setting cycles and the lid for accessing the drum. Other notable elements include water inlets, which manage the flow of water into the machine, and drainage components that remove water post-cycle.

Main Control Panel Functions and Features

The central control interface offers an intuitive way to manage various settings and options for optimizing performance. This panel provides users with multiple functions designed to ensure efficiency and customization for different needs. Understanding how to navigate and utilize these features can significantly improve operation.

Function Description Cycle Selection Allows users to choose from various cycles tailored for different fabric types and soil levels, ensuring the best results. Temperature Control Enables adjustment of water temperature to match the specific requirements of each load, ensuring safe and effective cleaning. Spin Speed Offers the ability to modify the spin intensity to suit delicate or more robust fabrics, balancing performance and care. Inside the Agitator Mechanism Explained

The core function of the central stirring component in modern laundry equipment lies in its ability to move and rotate, ensuring that fabrics are thoroughly cleaned. This essential feature involves a set of internal parts working together to create a consistent and effective cleaning motion. Understanding how these elements interact can provide a clearer picture of how the machine operates and why this process is critical for fabric care.

Main Components of the Agitator

The key elements within the stirring mechanism are specifically designed to drive movement and aid in distributing water and detergent through the laundry. The combination of fins, gears, and shafts ensures balanced rotation and movement, which is crucial for the cleaning process.

Component Function Fins Create agitation and move water through clothes Gears Control rotation speed and direction Role of the Water Inlet Valve in Washing

The water inlet valve plays a vital part in ensuring the proper operation of a washing device by controlling the flow of water into the drum. It regulates the amount of water needed for various stages of the cleaning process. This mechanism operates by opening and closing at precise moments, allowing the correct balance of hot and cold water to enter the appliance.

Additionally, the valve helps manage water pressure, ensuring that clothes are washed efficiently without the risk of overfilling. Its function is essential to both energy efficiency and the overall performance of the cleaning cycle, making it a crucial element in modern laundering systems.

Drive Belt: Importance and Maintenance Tips

The drive belt is a crucial component in many household appliances, facilitating the transfer of power from the motor to the drum. Its role is essential for ensuring smooth and efficient operation, making it vital for optimal performance.

Significance of the Drive Belt

This component plays a pivotal role in the functionality of the appliance. Here are some key points regarding its importance:

- Transmits power effectively to enable movement.

- Maintains the correct speed for different cycles.

- Ensures the longevity of the motor by reducing strain.

Maintenance Tips for Longevity

Proper care can extend the life of the drive belt. Consider the following maintenance strategies:

- Regularly inspect for wear and tear.

- Keep the appliance clean to prevent debris accumulation.

- Check the alignment to ensure proper tension.

- Replace the belt at the first sign of damage to avoid further complications.

Pump and Drainage System Breakdown

The effective operation of a laundry appliance heavily relies on its drainage and pumping mechanisms. These components work in harmony to ensure that excess water is efficiently removed during the washing and rinsing cycles. Understanding how these systems function can aid in troubleshooting and maintenance, leading to optimal performance.

Key Components

- Drain Pump: This motor-driven unit is responsible for expelling water from the drum at the end of each wash cycle.

- Drain Hose: A flexible tube that transports water from the drain pump to the household drainage system.

- Filter: A mesh component that captures lint and debris, preventing clogs in the pump and drainage system.

- Drain Valve: Controls the flow of water, ensuring it only exits the system at appropriate times.

Common Issues

- Clogs: Blockages in the drain hose or filter can lead to water accumulation, causing inefficient drainage.

- Pump Failure: A malfunctioning pump may fail to remove water effectively, resulting in longer cycles and potential flooding.

- Leaking Hoses: Deteriorated or damaged hoses can lead to leaks, affecting overall performance.

Understanding the Role of the Timer Assembly

The timer assembly is a crucial component in the operation of a domestic cleaning machine. It orchestrates the various cycles and functions, ensuring that the appliance runs smoothly and efficiently. By regulating the timing of different tasks, this assembly allows for optimal performance and reliability.

This mechanism not only controls the duration of each cycle but also coordinates with other elements to guarantee that the entire process adheres to specified settings. When functioning properly, the timer contributes significantly to the machine’s efficiency and effectiveness.

Function Description Cycle Regulation Determines the duration of washing, rinsing, and spinning cycles. Component Coordination Works with other parts to ensure synchronized operation. User Settings Allows users to select different cycles based on their needs. In conclusion, the timer assembly plays a vital role in the functionality of a domestic cleaning device, impacting both its performance and user experience.

Common Motor Issues and Solutions

Electric appliances often encounter motor-related problems that can hinder their performance. Understanding these common issues can assist in diagnosing faults and implementing effective solutions. This section outlines typical motor concerns and offers practical remedies to restore functionality.

Symptoms of Motor Malfunctions

Several signs may indicate a malfunctioning motor, including unusual noises, failure to start, or intermittent operation. Observing these symptoms early can prevent further damage and costly repairs.

Troubleshooting Steps

When addressing motor issues, follow these troubleshooting steps:

Issue Possible Cause Solution Does not start Faulty power supply Check electrical connections and ensure power source is functional. Unusual noises Worn bearings Lubricate or replace bearings to reduce friction. Overheating Blocked ventilation Clean air vents and ensure proper airflow around the motor. Intermittent operation Loose wiring Inspect wiring connections and tighten any loose connections. By following these guidelines, users can effectively address motor issues and maintain the longevity of their appliances.

Identifying and Replacing the Lid Switch

The lid switch is a crucial component in a washing device, serving as a safety feature that prevents operation when the lid is open. Understanding how to identify and replace this part can enhance the functionality of your appliance and ensure safe usage.

To determine if the lid switch is malfunctioning, look for the following signs:

- The machine does not start when the lid is closed.

- Water does not fill in the drum despite being set to start.

- The cycle does not advance when the lid is closed.

Once you suspect that the lid switch needs replacement, follow these steps for a proper installation:

- Unplug the appliance from the power source to ensure safety.

- Remove the screws securing the control panel to access the lid switch.

- Disconnect the old switch by gently pulling off the wiring connectors.

- Install the new switch by connecting the wiring and securing it in place.

- Reassemble the control panel and plug the device back into the outlet.

After replacing the lid switch, test the appliance to confirm that it operates correctly with the lid closed. Regular maintenance and timely replacement of faulty parts will keep your appliance functioning smoothly.

Top Tips for Maintaining Kenmore 500 Series Washer

Keeping your laundry appliance in optimal condition is essential for ensuring its longevity and efficiency. Regular maintenance not only enhances performance but also prevents unexpected breakdowns and costly repairs. Here are some practical suggestions to help you care for your appliance effectively.

First, routinely clean the drum and detergent dispensers to remove any residue that can accumulate over time. A simple mixture of vinegar and water can help eliminate odors and maintain freshness.

Next, check the hoses for signs of wear or leaks. Ensuring they are securely attached and in good condition can prevent water damage and enhance the appliance’s performance.

Additionally, balance the load appropriately during operation. Overloading can lead to excessive strain on the machine, causing premature wear on components.

Finally, schedule periodic professional inspections to address any potential issues before they escalate. This proactive approach can save you time and money in the long run.