Home appliances play a crucial role in our daily routines, ensuring that tasks are completed efficiently and with minimal effort. Each device relies on a set of essential mechanisms working together to deliver optimal performance. In this section, we will delve into the primary elements that contribute to the functionality of a widely-used household machine, exploring how its intricate system of components operates seamlessly to maintain consistent output.

By examining the inner workings of these devices, users can gain a deeper understanding of how specific elements interact with each other to produce the desired results. Knowing the functions of various mechanisms not only enhances comprehension but also aids in troubleshooting when problems arise. This knowledge can be vital for maintenance, ensuring that the machine remains in excellent condition over time.

Essential Components of the Maytag Bravos Dryer

The functionality of modern laundry machines relies on a combination of key elements that ensure efficient operation. These components work together to dry clothes effectively, providing a balance of heat, airflow, and control. Understanding the crucial parts that form this system is important for maintaining optimal performance.

One vital element is the heating unit, which generates the warmth necessary to remove moisture from fabrics. Additionally, the blower fan circulates air, ensuring even distribution of heat throughout the interior. Another crucial feature is the drum, which rotates to tumble garments, aiding in the drying process by exposing all areas of the fabric to the airflow.

Equally important is the control panel, which allows the user to adjust settings, tailoring the drying cycle to different fabric types and moisture levels. Lastly, the machine is equipped with safety sensors that monitor temperature and moisture, ensuring that the appliance operates within safe limits and prevents overheating.

Common Issues with Maytag Bravos Dryers

When dealing with household appliances, users may occasionally face a range of technical problems that disrupt normal operation. These issues can arise unexpectedly, often due to prolonged use or component wear. Understanding the most typical malfunctions can help identify the source of the problem and guide you toward a timely solution.

One frequent challenge involves reduced heating performance, leading to longer drying times. Another common difficulty is an unresponsive control panel, which may result from electronic failures or connection problems. Additionally, unusual noises can indicate mechanical obstructions or worn-out components, affecting overall efficiency. Proper maintenance can often prevent these issues from escalating.

How to Identify Key Dryer Parts

Understanding the main components of a clothes-drying machine is essential for efficient maintenance and repairs. By recognizing the core elements, users can quickly pinpoint potential issues and ensure optimal performance. Whether you’re troubleshooting or simply learning more about the appliance, familiarizing yourself with the most critical features will save time and effort.

Among the most important sections to examine are the heating element, which generates warmth, and the blower wheel that ensures air circulation. Also, the control panel regulates various functions, while the belt and motor work together to rotate the drum, ensuring proper movement during operation. Keeping these components in good condition is key to ensuring smooth operation.

Replacing the Heating Element: A Guide

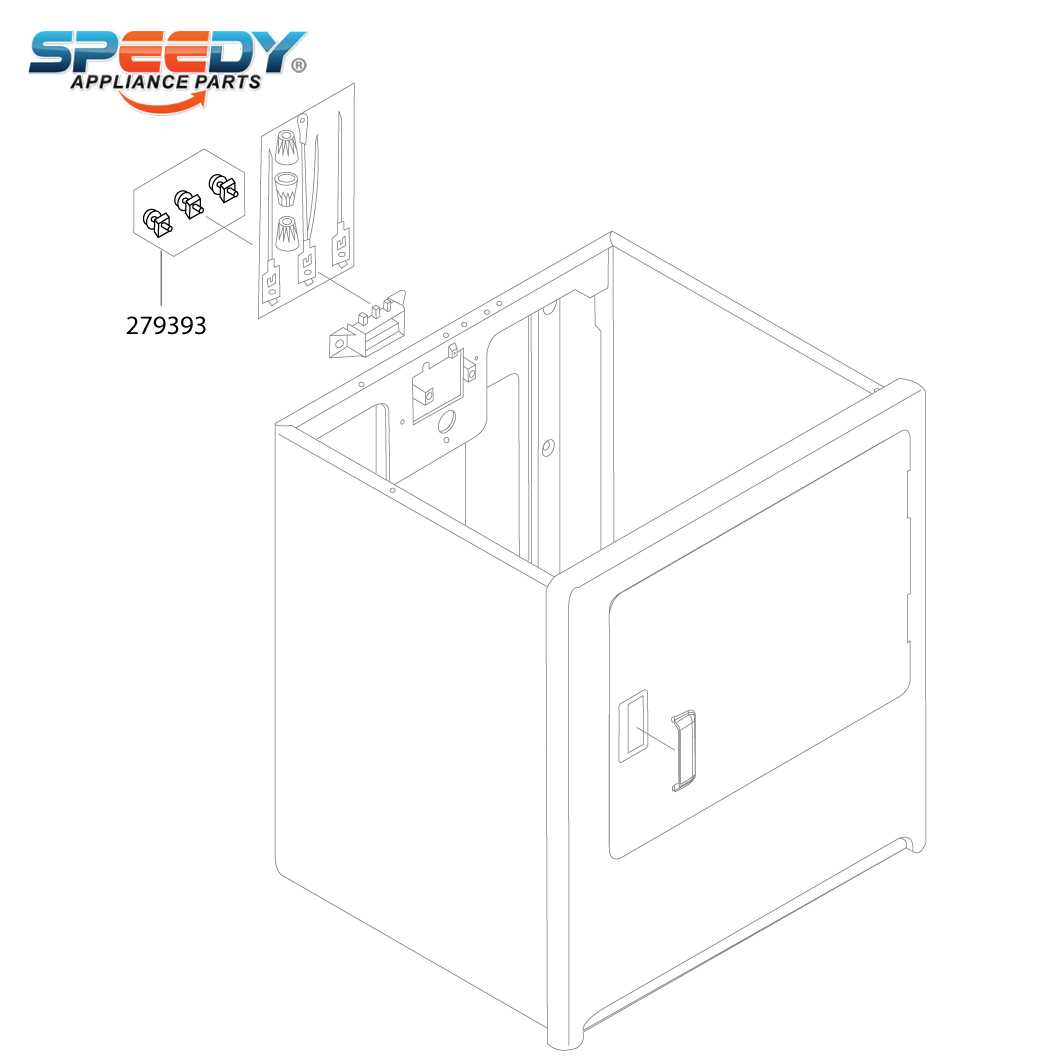

When the heating element in your appliance stops functioning properly, it’s essential to replace it to restore optimal performance. The process requires some basic tools and careful handling, but with the right approach, it can be completed efficiently. This guide will take you through the necessary steps to ensure the successful installation of a new heating component.

Preparation and Tools

Before beginning the replacement, make sure to disconnect the unit from any power source to avoid electrical hazards. You’ll need a screwdriver, multimeter, and a replacement heating element. Additionally, it’s useful to have a manual or diagram for your specific model, which helps locate the component accurately.

Step-by-Step Instructions

Start by removing the back panel of the machine to access the internal parts. The heating element is usually located near the back or base, connected by wiring. Carefully disconnect the wires and unscrew the element from its mount. Once removed, install the new component in its place, ensuring all connections are secure. Finally, reattach the panel and test the appliance to confirm it’s working correctly.

Understanding the Maytag Dryer Motor

The motor plays a crucial role in the overall functioning of a drying machine. Its primary function is to drive the drum and blower, ensuring that air circulates properly and clothes tumble effectively during the drying process. Without a well-operating motor, the device would struggle to achieve optimal performance, leading to longer drying times or even complete malfunction.

When exploring the inner workings of this component, it’s essential to understand its structure and how each part contributes to its efficiency. Below are key elements involved in its operation:

- Drive Mechanism: The motor powers the belt system, which in turn rotates the drum, ensuring that fabrics move consistently during each cycle.

- Blower Assembly: This part is responsible for pushing hot air through the drum, helping to remove moisture from the clothing.

- Electrical Connections: The motor is connected to various sensors and switches, allowing for smooth transitions between different drying settings.

Proper maintenance of the motor can prevent potential issues and extend the lifespan of the appliance. Regular inspections and timely replacements of worn-out parts are recommended to keep it running smoothly.

Troubleshooting Control Board Issues

The control board serves as the brain of your appliance, managing various functions and ensuring everything operates smoothly. When problems arise, it can lead to frustrating situations, impacting performance. Understanding how to identify and address these issues is essential for effective maintenance.

Common symptoms of control board malfunction may include failure to start, irregular cycles, or unresponsive settings. Here are steps to diagnose and resolve typical issues:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Appliance does not start | Power supply issue | Check power source and ensure the unit is plugged in securely. |

| Inconsistent operation | Faulty wiring | Inspect wiring connections for damage and ensure they are secure. |

| Settings do not respond | Defective control board | Test with a multimeter; if readings are inconsistent, consider replacing the board. |

| Error codes displayed | Malfunction indicator | Refer to the user manual for specific error code meanings and corrective actions. |

By following these troubleshooting steps, you can effectively diagnose and potentially resolve issues related to the control board. Regular maintenance and inspections will also help prolong the lifespan of your appliance and maintain its efficiency.

Proper Maintenance of Dryer Drum

Regular upkeep of the appliance’s drum is essential for optimal performance and longevity. This component plays a crucial role in the drying process, and maintaining it can help prevent common issues such as uneven drying or excessive noise. Implementing a few simple maintenance practices can enhance the efficiency of your unit and extend its lifespan.

To ensure effective maintenance, start by cleaning the drum regularly to remove lint, dirt, and any debris that may accumulate over time. A soft cloth or sponge with mild soap is effective for this purpose. Additionally, it’s important to check for any signs of wear or damage, such as cracks or rough edges, which could affect the performance of the appliance.

Furthermore, consider inspecting the drum’s belt and rollers periodically. These components should be free of obstructions and properly aligned. If you notice any unusual sounds or vibrations during operation, it may be an indication that these parts require attention. Addressing such issues promptly can prevent further damage and ensure smooth operation.

Lastly, ensure that the appliance is placed on a level surface to minimize unnecessary strain on the drum and other components. By following these maintenance tips, you can keep your appliance functioning efficiently and prolong its operational life.

Diagnosing Thermal Fuse Problems

When encountering issues with overheating or failure to heat, it is crucial to assess the thermal fuse’s condition. This component acts as a safety mechanism, interrupting the electrical flow when temperatures exceed safe levels. Identifying problems with this fuse can prevent further damage and ensure optimal functioning of the appliance.

Start by examining the device for any signs of malfunction, such as unusual noises or inconsistent heating. If these symptoms are present, the thermal fuse may be faulty. A multimeter can be used to test the fuse for continuity; a reading of zero indicates that it has blown and requires replacement. Additionally, ensure that vents and lint filters are clear, as blockages can lead to overheating and subsequent thermal fuse failure.

After identifying a defective fuse, it is important to determine the underlying cause of the issue. Frequent fuse failures may suggest a need for ventilation improvement or an examination of the heating element for any irregularities. By addressing these factors, you can enhance the appliance’s performance and extend its lifespan.

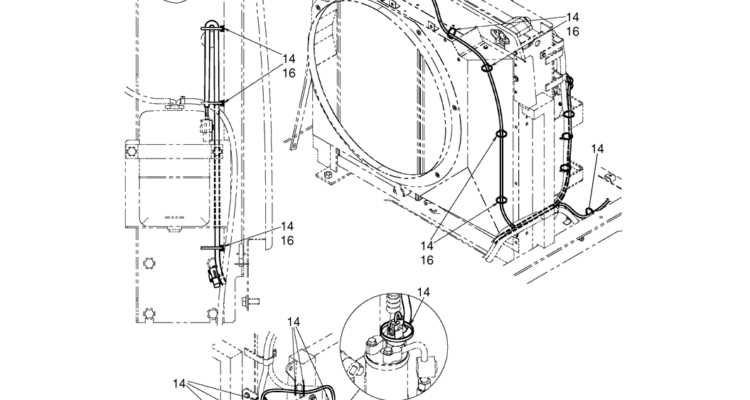

Tips for Maintaining Optimal Airflow

Ensuring efficient airflow is essential for the effective functioning of your appliance. Proper circulation not only enhances performance but also prolongs the lifespan of the equipment. Here are some valuable recommendations to maintain optimal airflow:

- Regular Cleaning: Frequently clean lint traps and filters to prevent blockages that hinder airflow.

- Inspect Ventilation Hoses: Check for kinks or obstructions in the ventilation ducts. Make sure they are clear to allow unrestricted air movement.

- Proper Installation: Ensure that the appliance is installed in a location that allows for adequate ventilation. Avoid placing it in confined spaces.

- Routine Maintenance: Schedule periodic inspections to identify any potential issues that may affect airflow, such as worn-out components.

- Adjust Settings Appropriately: Utilize the recommended settings for the load type to optimize airflow and efficiency.

By following these guidelines, you can help maintain the necessary airflow, resulting in improved efficiency and durability of your equipment.

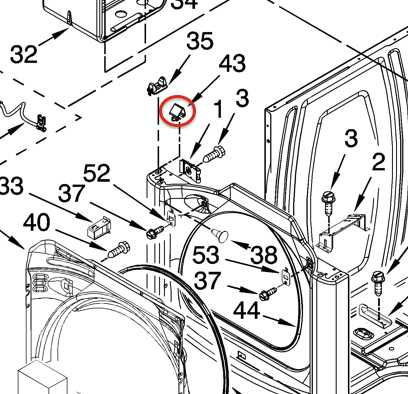

Repairing a Malfunctioning Door Latch

When a door latch fails to function properly, it can lead to operational issues and prevent the appliance from starting. Addressing this problem is crucial to ensure efficient performance and user safety. This section outlines the steps necessary for troubleshooting and fixing a faulty latch mechanism.

Identifying the Problem

The first step in repairing a faulty latch is to determine the specific issue. Common signs of a malfunctioning latch include:

- The door does not close securely.

- The appliance fails to start when the door is closed.

- Visible damage or wear on the latch mechanism.

Repair Steps

Once you have identified the issue, follow these steps to repair the latch:

- Unplug the appliance to ensure safety during the repair process.

- Remove the door from the appliance, if necessary, to access the latch mechanism.

- Inspect the latch for any visible damage, such as broken components or misalignment.

- Clean any debris or dirt that may be obstructing the latch’s function.

- If damage is found, replace the latch with a compatible replacement part.

- Reassemble the door and ensure it aligns properly with the latch mechanism.

- Plug the appliance back in and test the door latch to confirm it operates smoothly.

By following these steps, you can effectively address issues related to a malfunctioning latch, ensuring the appliance functions as intended.