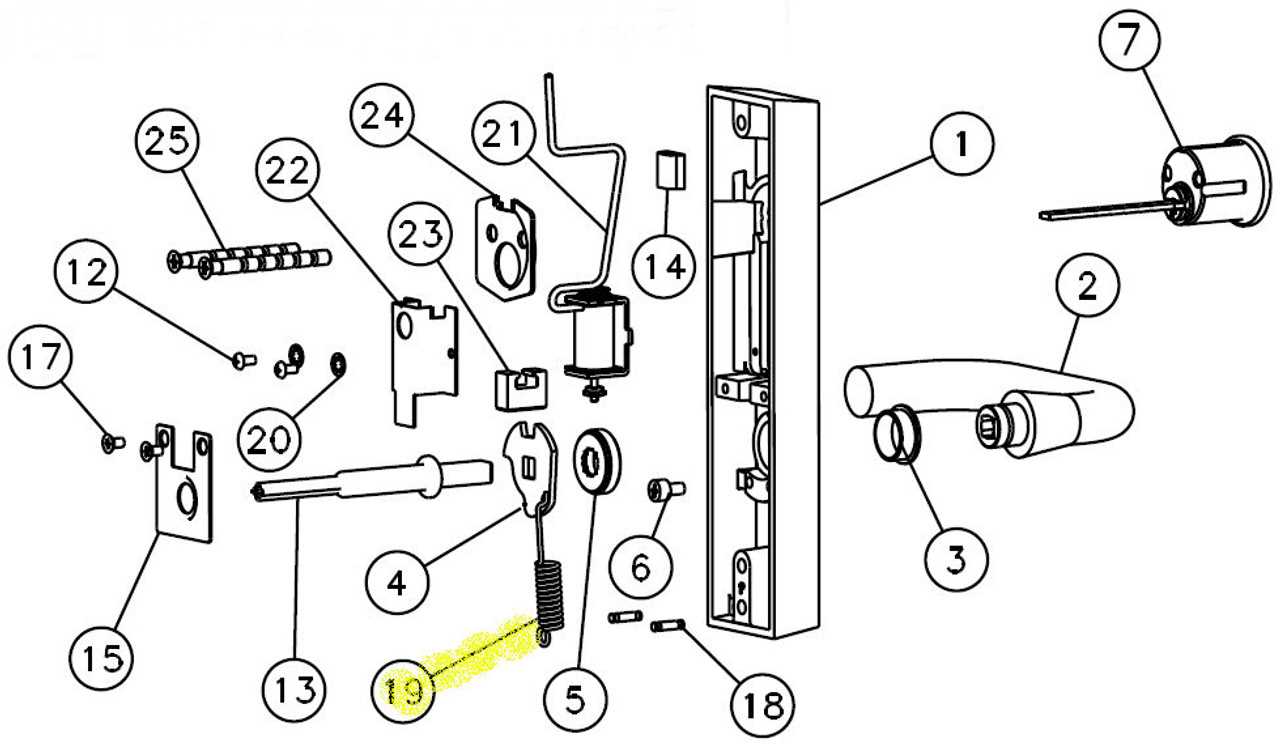

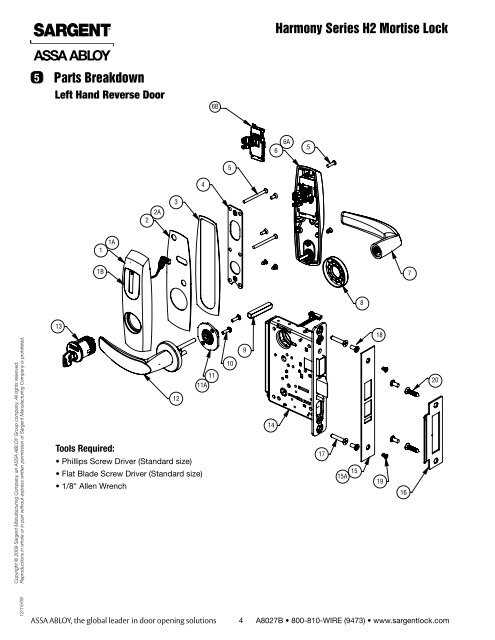

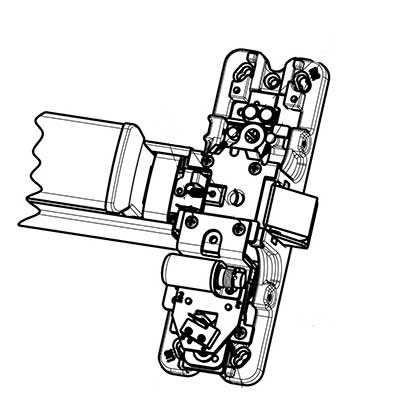

The intricate design of mechanical assemblies is crucial for understanding their functionality and ensuring efficient maintenance. This section delves into the visual representation of various elements within a specific model, showcasing how each component interacts with the others. By examining this layout, users can gain insights into the assembly’s structure and operational principles.

Comprehending the arrangement of individual elements is essential for both seasoned technicians and those new to the field. An effective illustration serves as a roadmap, guiding users through the complexities of the assembly and highlighting the importance of each part in achieving optimal performance. Whether for repair or enhancement, a clear representation simplifies the process and fosters a deeper understanding.

As we navigate through the specifics of the components involved, the focus will be on identifying key features and their functions. This analysis not only aids in troubleshooting but also enhances the overall appreciation of the engineering behind the model. Engaging with these detailed representations empowers users to make informed decisions regarding maintenance and upgrades.

Understanding Sargent 80 Series Components

Exploring the intricacies of this particular range reveals the essential elements that contribute to its functionality and efficiency. Each component plays a critical role in the overall system, ensuring seamless operation and reliability. Gaining insights into these elements not only enhances maintenance practices but also promotes informed decision-making.

Identifying key features allows users to appreciate the engineering behind the design. From control mechanisms to support structures, every part is meticulously crafted for optimal performance. Recognizing the interaction between components can lead to better troubleshooting and upgrades, ensuring the system remains at its peak.

Importance of Parts Diagrams

Understanding the intricacies of mechanical assemblies is crucial for maintenance and repair. Visual representations of components provide clarity and facilitate efficient identification, ensuring that each element is accurately addressed during servicing. This enhances workflow and minimizes errors, ultimately leading to more effective operations.

| Benefits | Description |

|---|---|

| Clarity | Visual aids simplify complex structures, making them easier to understand. |

| Efficiency | Quick identification of components accelerates the repair process. |

| Error Reduction | Detailed visuals help prevent mistakes during assembly or disassembly. |

| Training Aid | New technicians can learn faster with clear, illustrated references. |

Common Issues with Sargent 80 Series

In the realm of electrical systems, certain complications frequently arise that can hinder performance and reliability. Understanding these common problems can aid users in effective troubleshooting and maintenance, ensuring that the overall functionality remains intact.

Electrical Failures

One prevalent issue is the occurrence of electrical failures. These can manifest as flickering lights or complete power outages, often resulting from loose connections or degraded wiring. Regular inspections can help identify potential weak points before they escalate into more significant malfunctions.

Component Wear and Tear

Another challenge involves the wear and tear of individual components. Over time, connectors, switches, and other critical elements may degrade due to constant use or exposure to environmental factors. Regular maintenance and timely replacements are essential to prevent unexpected breakdowns and ensure the system operates smoothly.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. These illustrations provide detailed insights into the arrangement and relationship of various elements, enabling users to identify necessary replacements and assemblies easily.

Identifying Components

Begin by familiarizing yourself with the labels and symbols used in the illustration. Each item typically has a unique identifier that corresponds to a list or key, making it easier to locate the required parts.

Understanding Relationships

Pay attention to how components are connected. Lines or arrows often indicate interactions or dependencies, which can guide you in the assembly or disassembly process.

| Component | Description |

|---|---|

| Item A | Main housing unit |

| Item B | Support bracket |

| Item C | Fastening screw |

Essential Tools for Maintenance

Proper upkeep of equipment requires a selection of vital instruments that facilitate efficient repair and servicing. These tools not only enhance the effectiveness of maintenance tasks but also ensure safety and accuracy during operations. Having the right implements at hand can make a significant difference in both the time spent and the quality of work achieved.

Wrenches are fundamental for tightening and loosening fasteners. A set of adjustable and fixed wrenches is indispensable for a variety of applications. Screwdrivers of different types, including flathead and Phillips, are crucial for working with screws in various sizes and shapes. Their versatility makes them a staple in any toolkit.

Pliers come in multiple forms, such as needle-nose and slip-joint, and are essential for gripping, twisting, and cutting. Socket sets provide a comprehensive solution for handling nuts and bolts, allowing for quick and efficient tightening or removal.

Additionally, a torque wrench is vital for ensuring that fasteners are tightened to specific specifications, preventing damage from over-tightening. Safety gear, including gloves and goggles, is also paramount, protecting the user while performing maintenance tasks.

Investing in these essential tools not only streamlines the maintenance process but also contributes to the longevity and reliability of equipment. With the right instruments, maintaining optimal functionality becomes a manageable and efficient endeavor.

Where to Find Replacement Parts

Locating suitable components for your equipment can seem daunting, but various resources are available to simplify the process. Whether you’re searching for original or aftermarket alternatives, understanding where to look can save time and ensure the quality of your replacements.

Online Retailers

The internet is a treasure trove of options. Numerous e-commerce platforms specialize in supplying components, allowing you to browse an extensive selection and compare prices. Make sure to check customer reviews for reliability and authenticity.

Local Suppliers

Your nearby hardware or specialty shops can also be invaluable. Engaging with local vendors not only supports your community but often provides personalized assistance in finding the right items. Don’t hesitate to ask for recommendations or advice.

Tips for Troubleshooting Problems

Troubleshooting can often feel overwhelming, but a systematic approach can simplify the process. Identifying the root cause of an issue requires careful observation and methodical testing. By following a few essential steps, you can resolve problems efficiently and effectively.

Identify Symptoms

Begin by noting any irregular behaviors or signs of malfunction. Make a list of specific issues and circumstances in which they occur. This information will be invaluable for diagnosing the underlying problem and guiding your next steps.

Test Components

Once symptoms are identified, systematically test individual components related to the issue. This may involve checking connections, inspecting for damage, or verifying functionality. Document your findings, as this will help in isolating the problem and determining if a replacement or repair is necessary.

Upgrading Your Sargent System

Enhancing your electrical management system can significantly improve performance and efficiency. Upgrades may involve replacing outdated components, adding advanced features, or optimizing existing setups to meet modern demands.

Evaluating Current Setup

Before diving into enhancements, conduct a thorough assessment of your current configuration. Identify any limitations or areas where performance can be improved. This will help you prioritize which components require attention.

Choosing Compatible Components

When selecting new elements, ensure they are compatible with your existing framework. Research various options and consider factors such as functionality, durability, and user reviews to make informed decisions.

Installation Process

Follow the manufacturer’s guidelines for installation carefully. Proper setup is crucial to ensure that new components integrate seamlessly with the system. If you are unsure, consulting a professional can prevent potential issues.

Testing and Calibration

After installation, perform comprehensive testing to verify that everything operates as intended. Calibration may be necessary to achieve optimal performance, ensuring that all features work in harmony.

Regular Maintenance

To maximize the benefits of your upgrades, establish a routine maintenance schedule. Regular checks can help identify any issues early and prolong the lifespan of your system.

Frequently Asked Questions

This section addresses common inquiries regarding components and their functionality. It aims to provide clarity on various aspects related to maintenance and usage.

- What are the essential elements of the system?

The main elements include connectors, controllers, and support structures.

- How can I ensure optimal performance?

Regular inspections and timely replacements are crucial for maintaining efficiency.

- Where can I find replacement components?

Replacement items are typically available through authorized dealers or online retailers.

- What should I do if I encounter an issue?

Consult the troubleshooting guide or contact customer support for assistance.

If you have additional questions, feel free to reach out for more information!

Customer Reviews and Experiences

This section explores the insights and opinions shared by users regarding their interactions with the product. Their feedback highlights both the advantages and potential drawbacks, offering a comprehensive view for prospective buyers.

| Customer Name | Rating | Feedback |

|---|---|---|

| John D. | 5/5 | Exceptional quality and easy to install. Highly recommend! |

| Emily R. | 4/5 | Great performance, but the instructions could be clearer. |

| Michael T. | 3/5 | Decent product, but I experienced some issues with compatibility. |

| Sara K. | 5/5 | Absolutely satisfied! It exceeded my expectations. |

| David L. | 2/5 | Not as durable as I hoped; had to replace it quickly. |

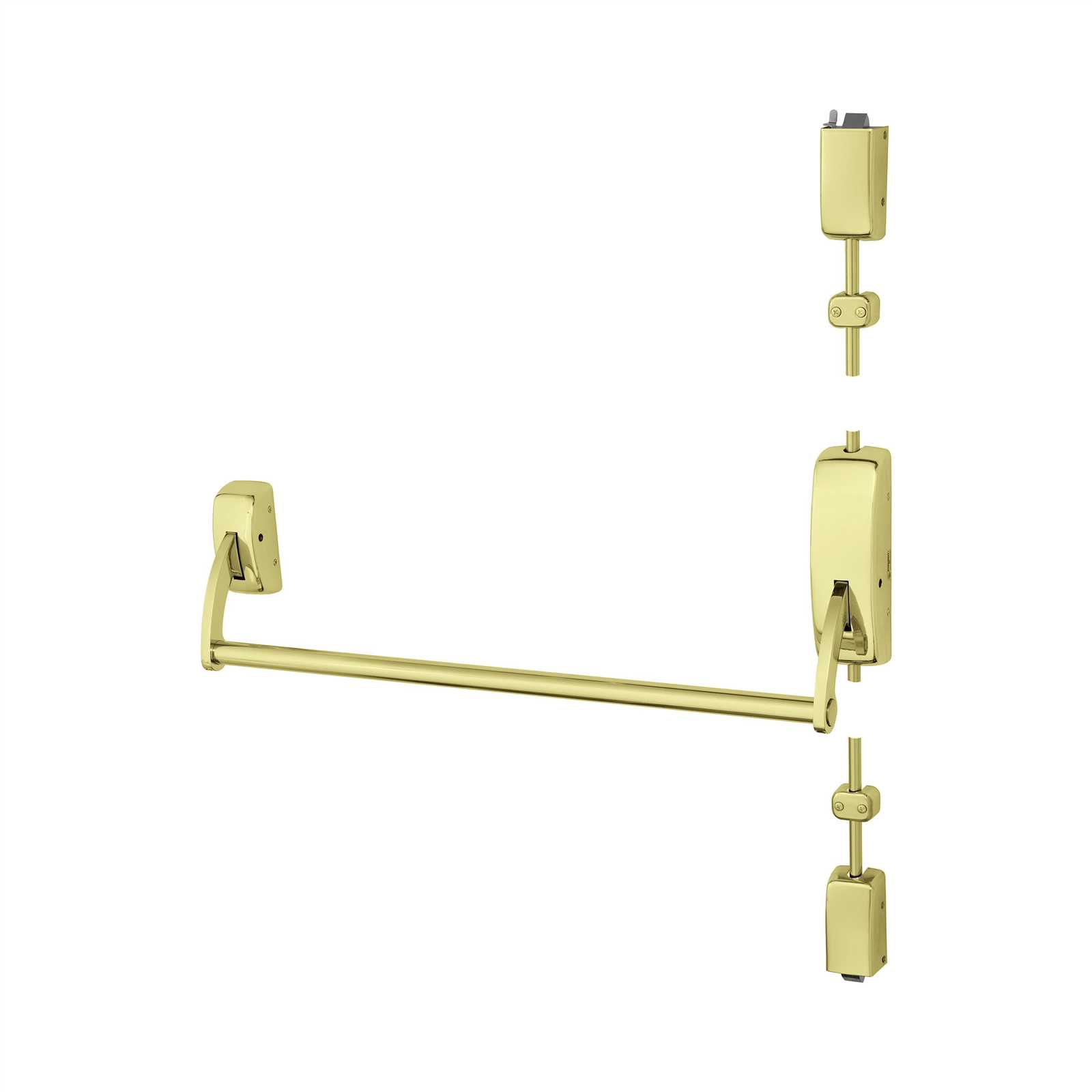

Comparing Sargent Models and Features

This section explores the various offerings in the range of products, highlighting key characteristics and differences among them. Understanding these distinctions can help users make informed choices based on their specific needs and preferences.

- Design Variations:

- Some models feature compact designs, suitable for limited spaces.

- Others prioritize larger capacities, catering to extensive requirements.

- Functionality:

- Different options provide various functionalities, from basic to advanced features.

- Models may include unique functionalities aimed at enhancing user experience.

- Durability:

- Some variants are constructed for extreme conditions, ensuring longevity.

- Others may offer lightweight materials for easy transport.

- Price Range:

- Entry-level options provide affordability without compromising essential features.

- Premium models deliver advanced capabilities at a higher investment.

By evaluating these factors, users can delve into the ultimate choice that aligns with their requirements and expectations.