The world of vintage crafting tools offers a fascinating glimpse into the artistry and engineering of the past. These intricate devices, often seen as symbols of creativity, come with a variety of elements that work harmoniously to achieve their intended function.

To truly appreciate these remarkable instruments, one must explore their individual components. Each section plays a vital role, contributing to the ultimate performance and reliability of the whole unit. With a deeper understanding, enthusiasts can better maintain and restore these treasured collectibles.

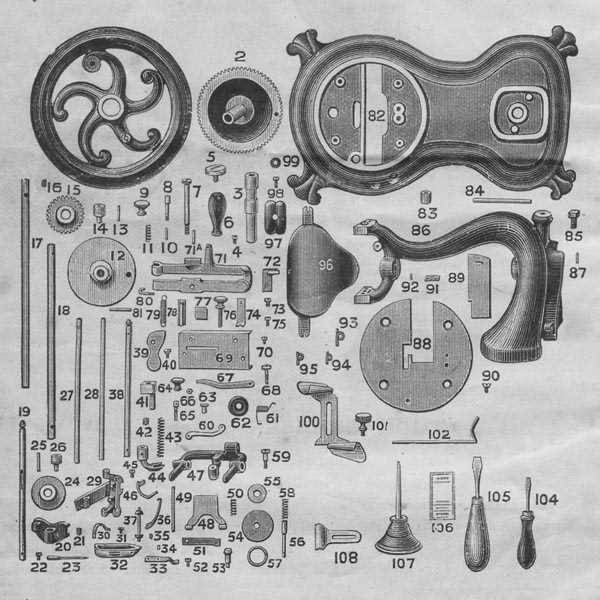

By examining a visual representation of these components, users can delve into the mechanics and design that define these historical treasures. This knowledge empowers collectors and hobbyists alike, ensuring that the legacy of these timeless tools continues to thrive.

Understanding Antique Singer Sewing Machines

Exploring the world of vintage textile tools reveals a fascinating blend of craftsmanship and innovation. These remarkable creations not only reflect the artistic designs of their era but also offer insight into the technological advancements that shaped their functionality. Recognizing the key elements that contribute to their operation can greatly enhance appreciation for these historic items.

Key Features

Each vintage textile device is characterized by unique attributes that distinguish it from contemporary alternatives. Some notable features include:

- Elegant craftsmanship, often showcasing intricate designs and high-quality materials.

- Mechanical ingenuity that highlights the evolution of fabric manipulation techniques.

- Durability, with many units still functioning after decades of use.

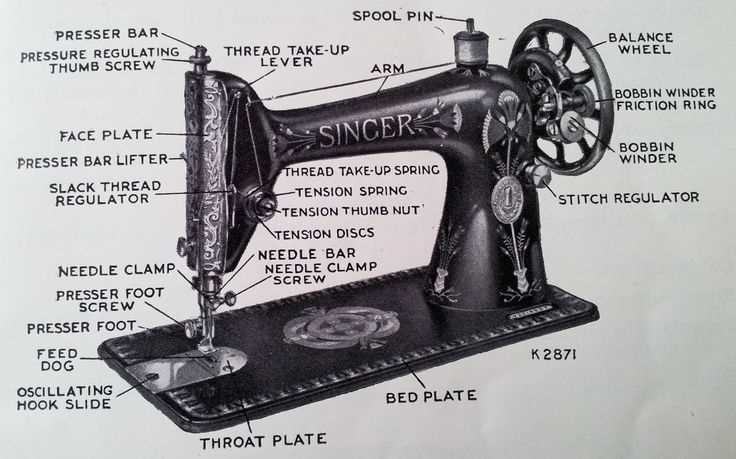

Understanding Components

A comprehensive knowledge of the various components helps in grasping how these tools operate. Key components include:

- Needle assembly, crucial for fabric penetration.

- Bobbin case, essential for thread storage and tension management.

- Feed mechanism, responsible for moving fabric during operation.

Delving into these elements not only aids in maintenance but also enriches the experience of utilizing these timeless devices.

History of Singer Sewing Machines

The evolution of a renowned brand in the textile industry showcases significant advancements in craftsmanship and technology. Established in the 19th century, this company transformed domestic and industrial stitching practices, becoming synonymous with quality and innovation. Their journey reflects a blend of creativity and engineering that addressed the needs of consumers worldwide.

Early Innovations

The foundational years marked a series of groundbreaking developments. With a commitment to enhancing user experience, the introduction of unique features set this brand apart from its contemporaries. The integration of mechanical precision and aesthetic design captured the attention of both amateurs and professionals alike.

Global Influence

As the brand expanded its reach, it influenced various markets, adapting to regional preferences and demands. This adaptability ensured its place as a leader in the industry, fostering a community of dedicated users who celebrated the art of textile creation.

| Year | Milestone |

|---|---|

| 1851 | Founding of the company |

| 1870 | Introduction of the first mass-produced model |

| 1900 | Expansion into international markets |

| 1950 | Launch of electric-powered versions |

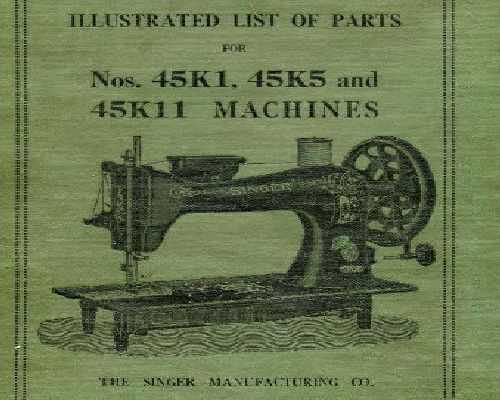

Common Parts of Antique Models

This section explores the various components found in vintage models, highlighting their functionality and importance. Understanding these elements is essential for enthusiasts and restorers alike, as they contribute to the overall operation and charm of these classic creations.

Main Components

Among the key elements, you will find mechanisms that drive the action, as well as those that assist in tension control and fabric handling. Each component plays a crucial role in ensuring a smooth and effective experience.

| Component | Description |

|---|---|

| Needle | Essential for piercing fabric and creating stitches. |

| Bobbin | Stores the lower thread, providing support for stitches. |

| Tension Regulator | Adjusts the tightness of the thread for balanced stitching. |

| Presser Foot | Holds the fabric in place while the needle works. |

| Feed Dogs | Move the fabric forward during stitching. |

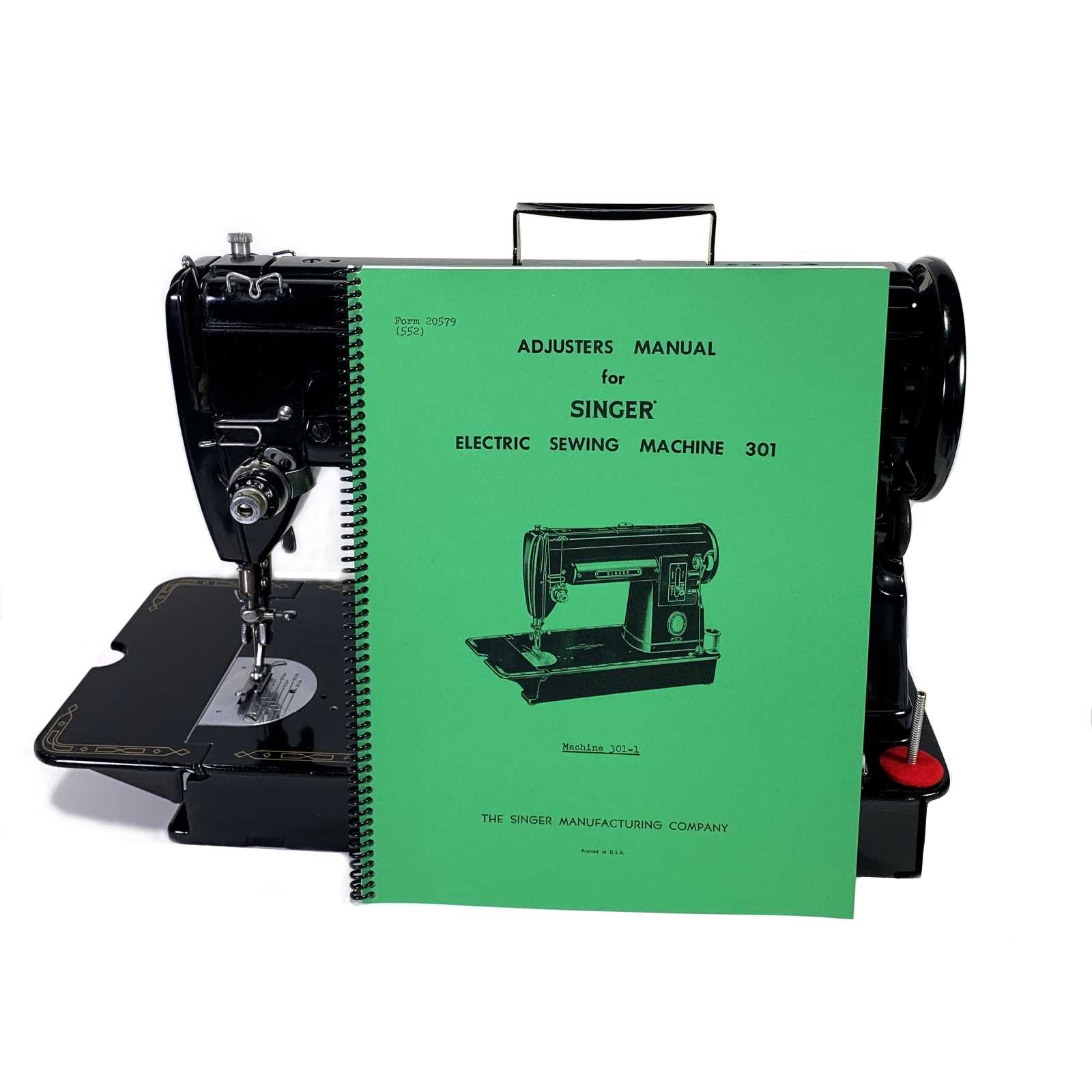

Identifying Your Specific Model

Understanding the unique characteristics of your vintage creation is essential for proper restoration and maintenance. Each unit possesses distinctive features that can aid in identifying its exact version, ensuring you find the correct resources and accessories.

Key Features to Examine

- Model Number: Look for any numerical identifiers located on the frame or base.

- Design Elements: Observe the color, shape, and embellishments that differentiate your item.

- Serial Number: Often engraved, this number can provide information about the production year.

Resources for Identification

- Online Forums: Join communities dedicated to enthusiasts for insights and assistance.

- Manufacturer Websites: Some offer historical archives that can clarify details about different versions.

- Books and Catalogs: Reference materials can provide visual guides to help distinguish between models.

Importance of Diagrams in Repairs

Visual representations play a crucial role in the maintenance and restoration of intricate mechanisms. They serve as guides that enhance understanding and facilitate the repair process. By offering a clear layout, these illustrations help users identify components, troubleshoot issues, and execute necessary adjustments effectively.

Here are some key reasons why these visuals are essential:

- Clarity: Diagrams break down complex assemblies into manageable parts, making it easier to comprehend how each element interacts.

- Precision: Detailed visuals help ensure that repairs are carried out accurately, reducing the likelihood of errors.

- Efficiency: With a clear guide, repair processes can be expedited, saving both time and effort.

- Documentation: These illustrations serve as a valuable reference for future repairs or restorations, providing insight into the original setup.

- Accessibility: Diagrams make information more accessible, enabling even novice users to undertake repairs with confidence.

In summary, visual aids are indispensable tools in the repair process, fostering a deeper understanding and promoting successful restoration efforts.

How to Read Sewing Machine Diagrams

Understanding technical illustrations can significantly enhance your ability to work with various crafting tools. These visuals provide essential insights into the structure and function of equipment, guiding you in troubleshooting and repairs. Familiarity with these representations will empower you to navigate complexities with ease.

Key Elements to Identify

- Labels: Often indicate specific components and their functions.

- Symbols: Commonly used to represent actions or parts.

- Lines: Illustrate connections and movements within the system.

Steps to Interpret Illustrations

- Start by familiarizing yourself with the legend, if available.

- Identify the main components and their placements.

- Follow the lines to understand the relationships between different elements.

- Use context clues to deduce the purpose of each part.

Finding Replacement Parts Online

Locating specific components for vintage equipment can be a rewarding yet challenging endeavor. With the vast resources available on the internet, enthusiasts and collectors alike can discover a range of options to source the necessary elements to restore functionality. Understanding how to navigate these online platforms can significantly enhance the search experience.

Utilizing Specialized Marketplaces

There are numerous online marketplaces that cater specifically to vintage enthusiasts. Websites dedicated to restoration and collectible items often provide a wide array of components. Searching through these platforms, using keywords related to the item’s model or year, can yield fruitful results. Look for sellers with positive reviews and detailed descriptions to ensure the quality of the items.

Exploring Community Forums

Engaging with online communities can be invaluable. Many forums and social media groups consist of passionate individuals who share tips, resources, and even direct leads to vendors. By participating in discussions, one can often find recommendations for trustworthy suppliers or even fellow collectors willing to sell or trade their own surplus.

In summary, leveraging online resources effectively requires a strategic approach. By focusing on niche marketplaces and engaging with like-minded individuals, one can increase the chances of successfully finding the components needed for restoration projects.

Restoration Tips for Vintage Machines

Reviving classic equipment requires careful consideration and dedication. A thoughtful approach not only enhances functionality but also preserves historical significance. Here are essential guidelines to help you in the restoration journey.

| Step | Description |

|---|---|

| Assessment | Begin by evaluating the condition of the item. Identify any areas that need repair or replacement, focusing on both mechanical and aesthetic aspects. |

| Cleaning | Gently clean all surfaces using appropriate materials. Avoid harsh chemicals that may damage original finishes. |

| Repairs | Address any mechanical issues. Tighten loose components and replace damaged parts with high-quality substitutes when necessary. |

| Lubrication | Apply suitable lubricants to moving parts. Ensure that all mechanisms operate smoothly without excessive friction. |

| Finishing Touches | Consider reconditioning the exterior. This may involve polishing or refinishing to enhance the overall appearance while maintaining authenticity. |

| Testing | Once restoration is complete, thoroughly test functionality. Ensure everything operates as intended, making adjustments if necessary. |

By following these steps, you can successfully breathe new life into cherished equipment, preserving its charm for future generations.

Maintenance Practices for Longevity

Proper care and regular upkeep are essential for ensuring the enduring functionality of your cherished device. By adopting effective strategies, you can significantly extend its lifespan and maintain optimal performance. This section highlights key practices that will help preserve the integrity of your treasured item over time.

Regular Cleaning: Keeping your equipment clean is crucial. Accumulated dust and debris can lead to wear and tear. Use a soft cloth and gentle cleaning solution to wipe down surfaces, paying particular attention to intricate areas where dirt tends to accumulate.

Lubrication: Adequate lubrication is vital for smooth operation. Apply suitable oil to moving components as recommended in the user manual. This minimizes friction and prevents potential damage, ensuring a seamless experience every time you use it.

Environment Control: Storing your device in a controlled environment is paramount. Avoid exposing it to extreme temperatures, humidity, or direct sunlight, as these factors can compromise its functionality. A stable environment helps maintain the materials and finishes.

Periodic Inspections: Conduct regular inspections to identify any signs of wear or malfunction. Addressing issues promptly can prevent more significant problems down the line. Keep an eye out for loose screws, fraying threads, or unusual noises during operation.

Usage Practices: Utilize your item as intended, following any guidelines for operation. Avoid overextending its capabilities, as this can lead to premature wear. Gentle handling will contribute to its longevity and reliable performance.

By implementing these essential maintenance practices, you can enjoy the benefits of your beloved item for years to come, ensuring it remains a cherished part of your life.

Challenges in Sourcing Components

Finding specific mechanical components for older equipment can be a daunting task due to various factors. Many of these items are no longer in production, making them rare and difficult to locate. The search often requires combing through multiple sources, from specialized retailers to collectors and second-hand marketplaces. However, even when parts are found, they may not always meet quality expectations, which can pose additional challenges.

- Rarity: As time passes, many original components become scarce due to discontinuation, making them harder to find in suitable condition.

- Condition Issues: Parts that are available may show significant wear, leading to functional concerns or requiring further restoration.

- Price Fluctuations: Due to scarcity, prices can vary greatly, often making it expensive to acquire necessary elements.

- Authenticity: Sourcing original items can be complicated by counterfeit or modified parts that may not perform as expected.

Each of these obstacles adds complexity to the process, often requiring patience, research, and sometimes compromise in terms of quality or cost.

Community Resources for Enthusiasts

For those passionate about restoring and preserving vintage tools, there are many online and local communities where knowledge is shared and connections are made. These platforms provide opportunities to exchange ideas, find helpful tips, and seek assistance from fellow hobbyists. Whether you’re searching for guidance or simply looking to connect with like-minded individuals, these resources can be invaluable.

- Online forums where members discuss restoration techniques and share project updates.

- Local clubs and groups that organize meetups and offer hands-on workshops.

- Social media groups where enthusiasts post photos, ask for advice, and celebrate finished projects.

- Dedicated websites with catalogs, manuals, and how-to guides for various types of equipment.

Exploring these resources can open up a world of knowledge and support, ensuring that your restoration journey is both successful and enjoyable.

Comparing Antique and Modern Machines

The evolution of mechanical devices used for crafting textiles offers a fascinating contrast between older designs and more recent technological advancements. While both types serve the same purpose, they differ significantly in terms of functionality, ease of use, and features. Older models often required more manual effort and maintenance, while newer ones prioritize automation and user convenience.

- Durability: Early versions were built to last with heavy materials, whereas modern options often use lighter, more portable components.

- Complexity: Older devices typically had fewer functions but demanded more skill, while today’s options come equipped with numerous features for a variety of tasks.

- Maintenance: Older devices may require frequent manual adjustments, whereas newer models often include self-maintenance features or digital troubleshooting.

The differences reflect changes in user expectations, production methods, and technological capabilities over time.

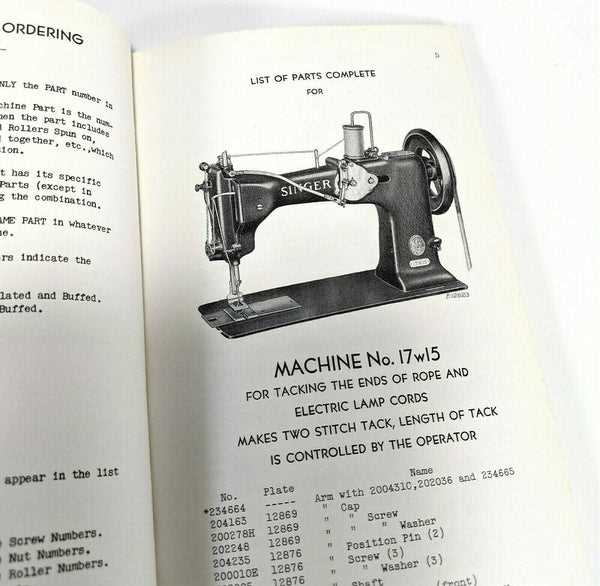

Showcasing Unique Singer Models

Throughout the years, certain models have stood out for their distinctive features and remarkable craftsmanship. These devices, known for their durability and design, reflect the ingenuity of their time, offering a range of functionalities that set them apart from other tools. Their unique construction and versatility made them popular among various groups of users.

Design Excellence has always been a hallmark of these models, with sleek shapes and innovative mechanisms that were ahead of their time. The intricate details and functionality were paired with ease of use, making these models both reliable and visually appealing.

Innovation in Mechanics was another key aspect. Many models introduced new technologies that enhanced performance, allowing users to achieve better results with less effort. These improvements in engineering contributed to their lasting legacy and enduring popularity.