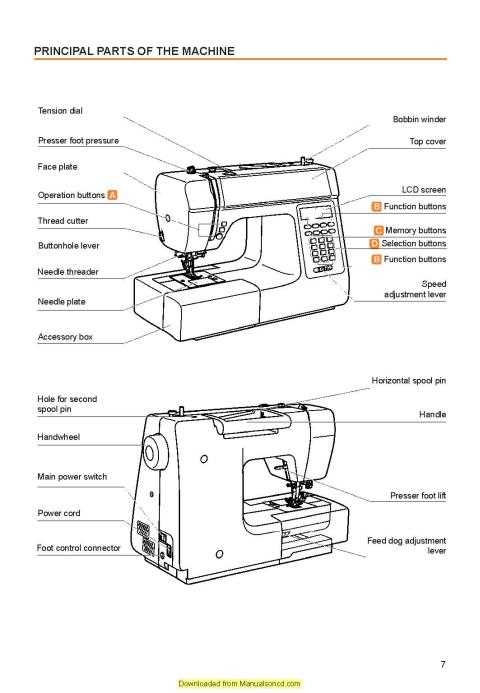

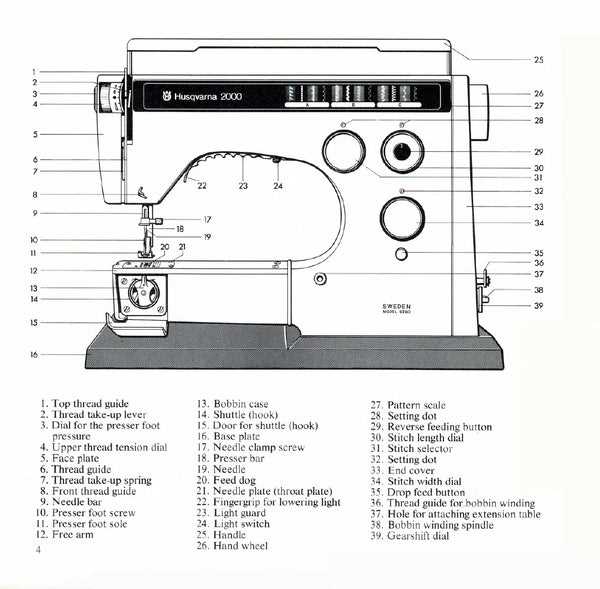

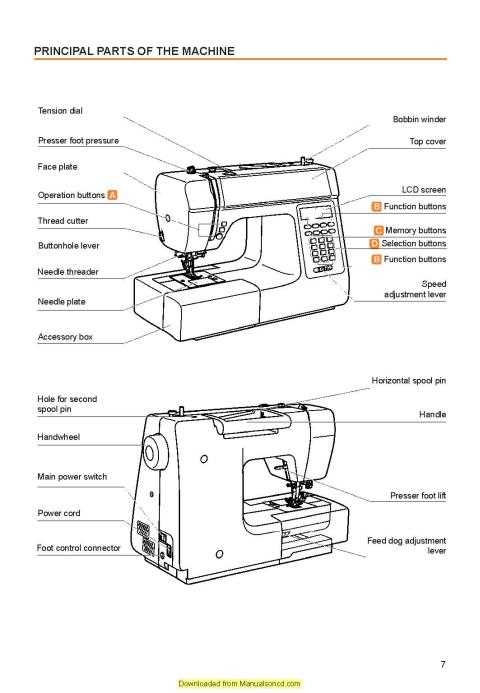

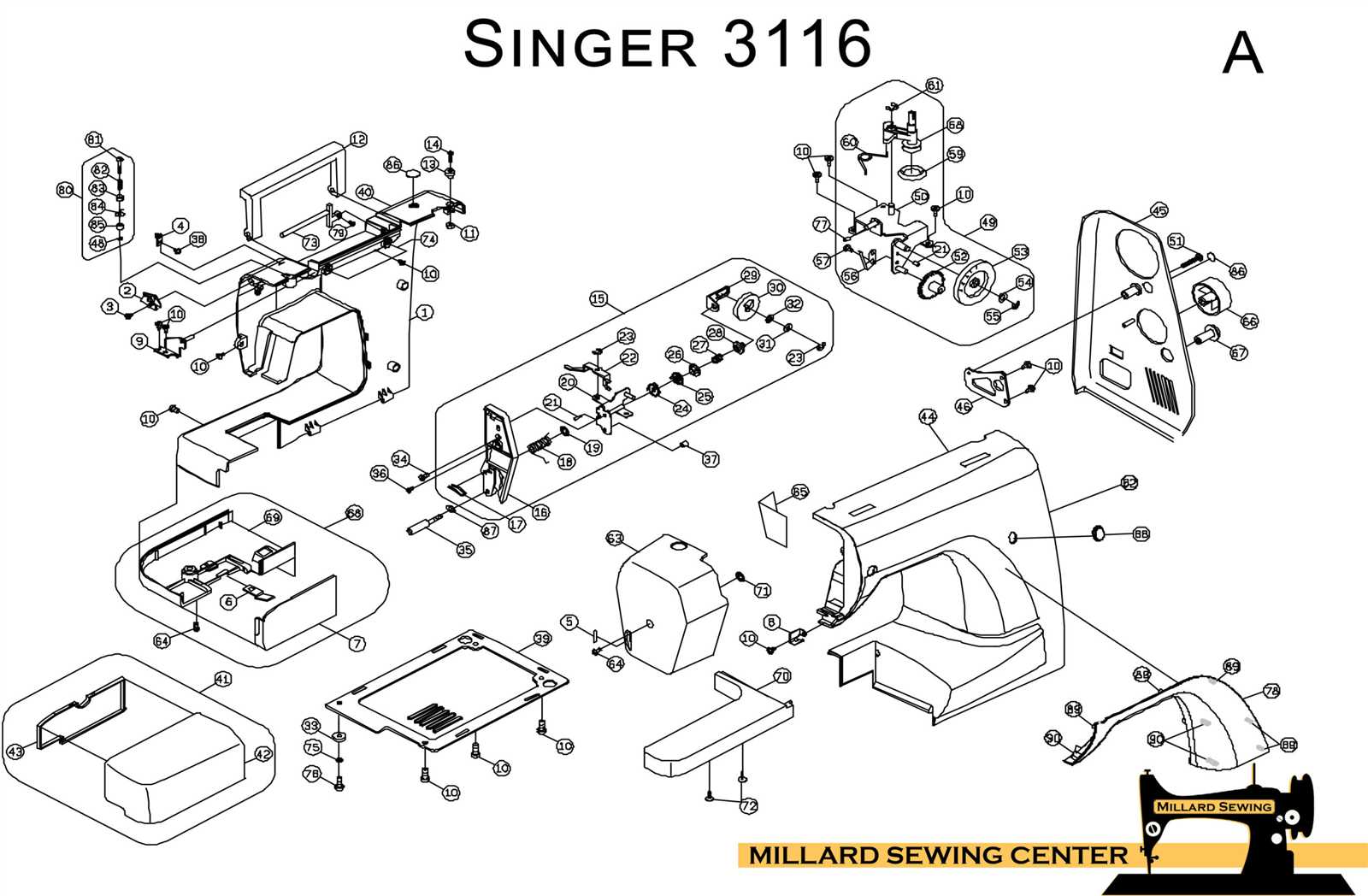

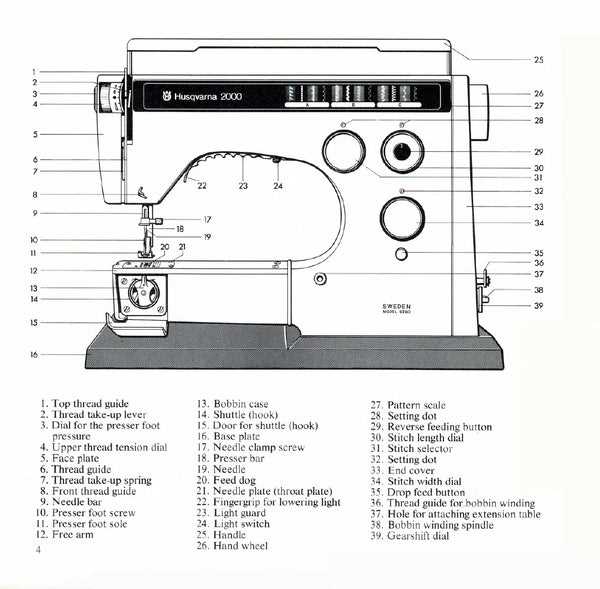

How to Identify Essential Parts

Understanding the core components of any complex mechanism is crucial for both maintenance and repair. Recognizing these elements allows users to troubleshoot issues effectively and ensure the longevity of their device. By familiarizing yourself with the individual components, you can gain a deeper appreciation for how the system operates as a whole.

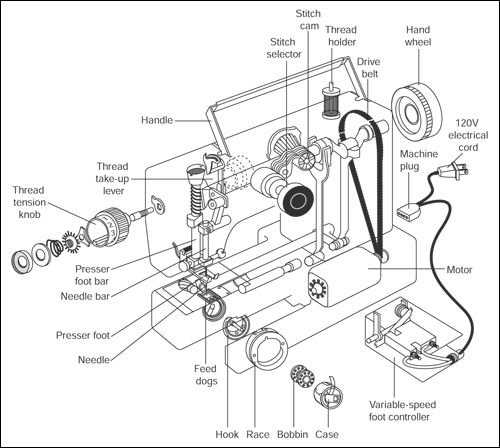

Key Structural Components

One of the main areas to focus on is the structural elements. These are typically the most visible and provide the framework necessary for smooth operation. Look for the base, framework, and key support structures that hold everything together. Identifying these elements will help you understand the physical integrity of the device and its ability to withstand wear and tear.

Functional Elements

The operational components are what make the entire system work efficiently. These include mechanisms responsible for movement, precision, and control. Pay attention to how different functional elements interact with each other. By locating and identifying these, you can diagnose any malfunctions or performance issues more easily.

Tip: Keep an eye on any components that seem

Guide to Maintenance and Replacement

Proper care and timely updates of essential components are key to ensuring long-term functionality. Consistent upkeep not only enhances performance but also prevents potential issues that can disrupt normal operation. In this section, we’ll explore some simple steps you can take to extend the life of your equipment.

Routine Care: To maintain optimal functionality, regular cleaning and lubrication are crucial. Dust and debris can accumulate over time, leading to friction and wear. Keeping the mechanism clean ensures smoother operation and reduces the likelihood of breakdowns.

Replacing Worn Components: Over time, certain elements may degrade due to continuous use. Identifying the signs of wear early, such as unusual noise or reduced performance, can help prevent more serious damage. When replacements are needed, it’s essential to choose high-quality parts that match the original specifications.

Preventive Measures: Regular inspection of key areas helps in identifying potential issues before they worsen. Checking for

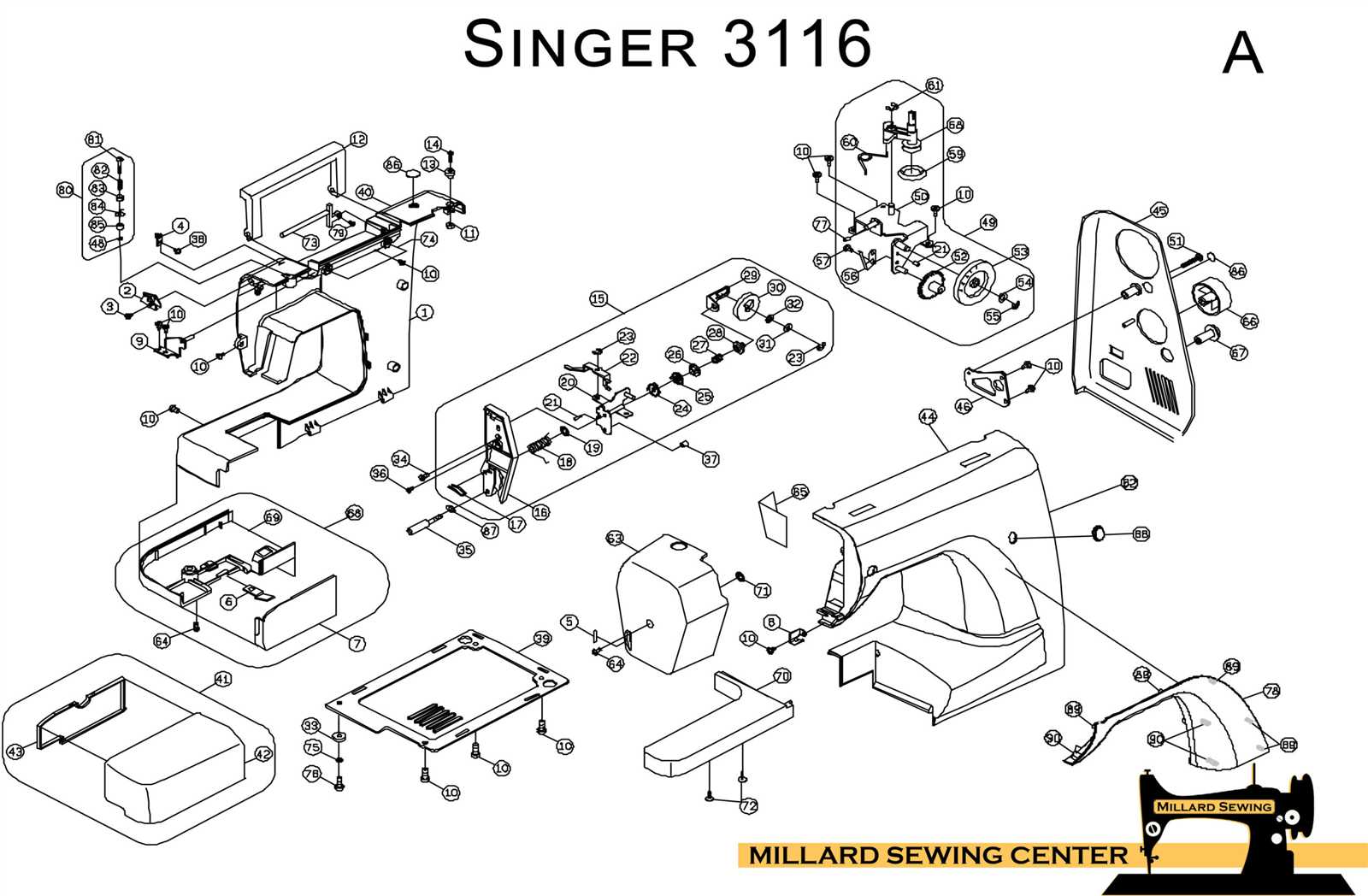

Exploring Mechanical and Electrical Parts

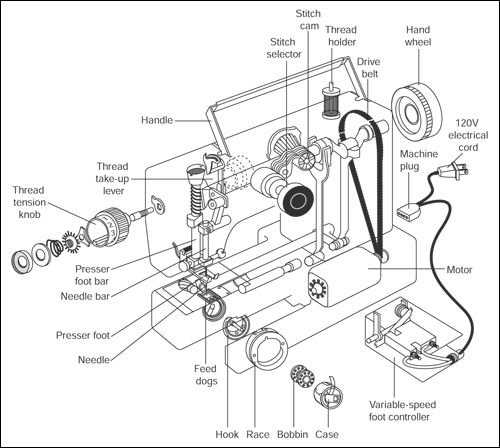

The internal structure of various devices relies on a combination of both physical mechanisms and electronic components. These elements work in harmony to perform essential tasks, ensuring functionality and precision. Understanding the relationship between moving elements and electrical circuits is crucial for maintaining and optimizing performance.

Mechanical elements typically involve gears, levers, and other physical structures that transfer motion and force. These elements are designed to withstand wear and ensure smooth operation over time. On the other hand, electronic components include wiring, switches, and control units that regulate energy flow and manage automated functions.

The interplay between these two systems allows for controlled movements, fine adjustments, and efficient energy use. Without properly functioning components, overall efficiency and accuracy can diminish, leading to potential malfunctions. Recognizing the role of both physical and electronic elements is essential for comprehensive understa

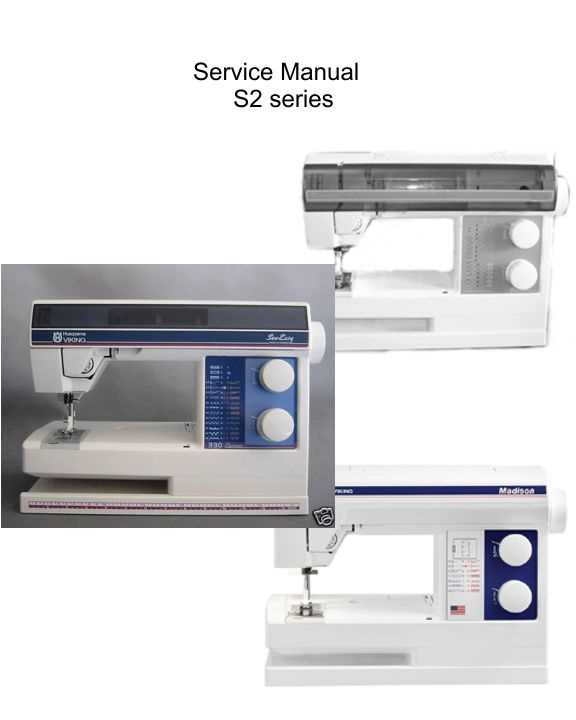

Common Issues with Viking Machines

In the realm of crafting tools, machines designed for fabric manipulation occasionally encounter recurring challenges that can frustrate users. These issues span from mechanical hitches that impede smooth operation to electrical malfunctions disrupting functionality. Understanding these common setbacks equips artisans with insights to swiftly troubleshoot and potentially resolve the intricacies of their crafting apparatus.

Operational Hurdles

Some users face difficulties related to the operational aspect of their crafting device, encountering challenges that hinder the intended flow of their creative process. These hurdles can manifest as irregularities in stitch formation or inconsistent fabric feeding mechanisms, impacting the quality and precision of the final output.

Maintenance and Longevity

Maintenance is crucial for preserving the longevity of any crafting tool. Over time, components may wear down, necessitating careful upkeep to sustain optimal performance. Neglecting routine maintenance can lead to issues such as motor strain or alignment discrepancies, potentially compromising the overall functionality of the machine.

Upgrading Your Viking Sewing Machine

When it comes to enhancing the performance of your device, selecting the right enhancements can bring significant improvements. Whether you’re looking to increase its efficiency, extend its lifespan, or add new features, investing in the right components and accessories ensures that your tool will continue to meet your needs for years to come.

Hardware improvements are an essential step toward maximizing your tool’s potential. By upgrading key mechanisms, you can reduce wear and tear, increase precision, and achieve smoother operation.

Additionally, digital upgrades allow for modern conveniences and advanced functionality. This can include anything from updated control systems to more intuitive user interfaces, making your work easier and more productive.

The Role of Gears and Motors

The components that facilitate movement within a fabric manipulation device are essential for its overall functionality. These elements work in harmony to ensure precise operations, enabling the user to achieve desired results efficiently. Understanding the importance of these mechanisms can enhance one’s appreciation of how they contribute to the effectiveness of the equipment.

Importance of Gears

Gears play a critical role in the transmission of power within the apparatus. They convert the rotational force generated by the motor into controlled movements. This allows for the adjustment of speed and torque, which is crucial for executing various tasks. The intricate arrangement of gears ensures that the motion is both smooth and consistent, significantly impacting the quality of the final output.

Functionality of Motors

Motors are the driving force behind the entire system, providing the energy necessary for operation. They convert electrical energy into mechanical energy, initiating the movement of gears and other components. The efficiency and reliability of the motors are paramount, as they determine how well the device performs under different conditions. A well-functioning motor ensures that the apparatus can handle diverse materials and techniques with ease.

Understanding the Tension Mechanism

The tension mechanism plays a crucial role in the functionality of textile crafting devices, ensuring that threads are appropriately managed during the stitching process. This component regulates the degree of pull applied to the thread, directly influencing the quality of the final product. A balanced tension system allows for consistent and precise results, preventing issues such as puckering or thread breakage.

To grasp the significance of this mechanism, it is essential to consider its various aspects:

- Components: The tension assembly typically includes a tension dial, discs, and springs, which work together to maintain appropriate thread tautness.

- Adjustment: Proper calibration of the tension system is vital. Users can modify settings based on fabric type and thickness, ensuring optimal performance.

- Impact on Stitch Quality: Inconsistent tension can lead to various complications, including skipped stitches and uneven seams.

Understanding how to effectively manage this mechanism is key for anyone looking to enhance their crafting skills. Regular maintenance and adjustment can significantly improve the overall experience and outcomes.

In summary, the tension system is a fundamental aspect of any textile crafting endeavor. Mastery over this component allows crafters to achieve professional-quality results with ease.

Accessories and Their Compatibility

In this section, we explore the range of additional components and their suitability with various models, ensuring seamless integration and enhanced functionality. Understanding the versatility of these add-ons allows for optimized performance without the constraints of model specifics. Each item enhances the sewing experience, emphasizing adaptability and user convenience. Compatibility considerations ensure that accessories not only fit mechanically but also enhance operational ease, catering to diverse sewing needs and preferences. This exploration empowers users to personalize their equipment setup effectively, enhancing both efficiency and creativity in crafting endeavors.

Choosing the Right Foot Attachments

Selecting the appropriate accessories for your fabric crafting tool is essential for achieving the best results in your projects. These attachments can significantly enhance your capabilities, allowing for more intricate designs and finishes. Understanding the different types available will enable you to make informed choices that suit your specific needs.

Types of Foot Accessories

- Zipper Foot: Ideal for inserting zippers with precision.

- Walking Foot: Useful for working with multiple layers of fabric, ensuring even feeding.

- Designed to create professional buttonholes effortlessly.

- Perfect for achieving invisible hems on garments.

Factors to Consider

- Project Type: Consider what kind of items you will be crafting, as different projects may require specific attachments.

- Fabric Weight: Heavier materials may benefit from specialized feet that provide additional support.

- Skill Level: Some accessories are more complex to use; choose ones that match your proficiency.

Exploring the Bobbin System in Viking Models

The bobbin mechanism is a vital component in various stitching devices, playing a crucial role in the overall functionality and performance. Understanding its design and operation can enhance the user experience and ensure optimal results during fabric manipulation.

This section delves into the fundamental aspects of the bobbin assembly:

- Types of Bobbins: Different models may use various styles of bobbins, each designed for specific purposes.

- Loading Techniques: Proper loading is essential to prevent jams and ensure smooth operation.

- Thread Tension: Maintaining appropriate tension is key for achieving consistent stitch quality.

- Maintenance: Regular cleaning and inspection can prolong the life of the bobbin system.

By familiarizing oneself with these elements, users can achieve a deeper understanding of their devices and enhance their crafting endeavors.