When it comes to maintaining your aquatic vessel, having a clear grasp of its intricate assembly is essential. A comprehensive overview of the various elements that contribute to the smooth operation of your engine can greatly enhance your ability to diagnose issues and perform necessary repairs.

In this section, we delve into the layout of essential components, providing insight into how each piece interacts within the overall system. By familiarizing yourself with these individual parts, you’ll not only gain confidence in your technical skills but also ensure that your maritime experience remains enjoyable and hassle-free.

Visual representations of these elements serve as invaluable tools, guiding you through the complexities of your machinery. Understanding these visuals will empower you to identify parts quickly, facilitating effective maintenance and troubleshooting when needed. Explore the intricacies and keep your vessel in peak condition!

Understanding Quicksilver Commander 3000

This section delves into the intricacies of a specific marine control system, emphasizing its functionality and components. Designed for efficiency and reliability, this technology serves as a crucial interface between the operator and the vessel, enabling seamless navigation and operation.

Key Features

Among the standout attributes of this system are its user-friendly controls and robust build quality. Users can expect a responsive experience that enhances their overall boating adventure. The intuitive layout simplifies access to various functions, making it suitable for both seasoned mariners and novices alike.

Maintenance and Troubleshooting

Proper upkeep is essential for optimal performance. Regular checks and adjustments can prevent common issues, ensuring longevity and dependability. In case of malfunctions, a systematic approach to troubleshooting can help identify the root cause, allowing for swift resolutions and minimal downtime.

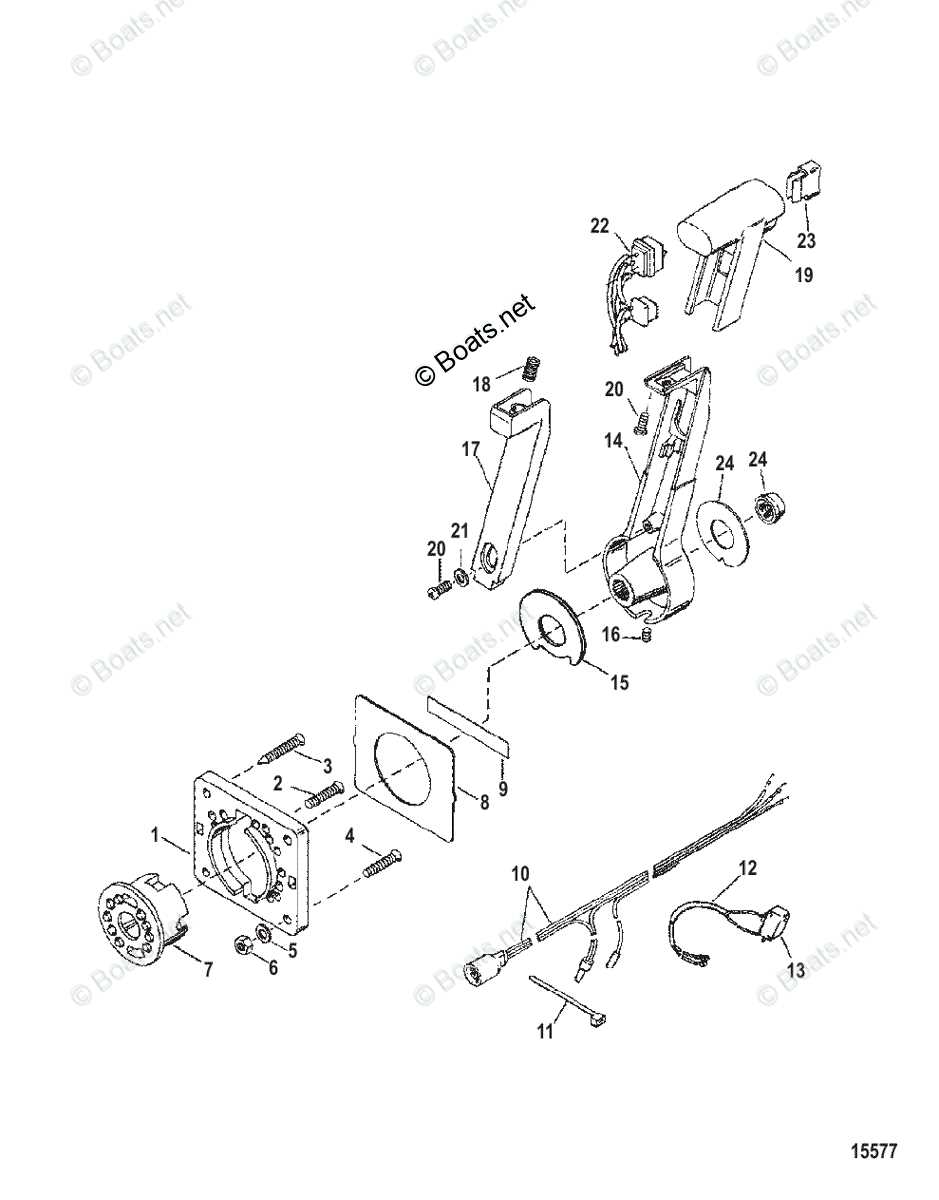

Components of the Commander 3000

This section delves into the essential elements that comprise the sophisticated control system, highlighting their roles and functionalities. Understanding these components is crucial for effective operation and maintenance.

Control Handle: The primary interface for the operator, this feature allows for precise maneuvering of the vessel. Its ergonomic design ensures comfort during extended use.

Shift Mechanism: This element facilitates the transition between gears, enabling smooth acceleration and deceleration. A well-functioning shift mechanism is vital for optimal performance.

Cabling System: A network of cables connects various components, transmitting signals and commands. Proper routing and maintenance of these cables are essential to avoid disruptions.

Throttle Assembly: Responsible for regulating engine power, this assembly ensures the vessel responds swiftly to the operator’s commands. Calibration of the throttle is key for efficient operation.

Indicator Lights: These visual cues provide important feedback regarding the system’s status. They alert the operator to potential issues, enhancing safety and functionality.

Mounting Bracket: This sturdy support structure secures the assembly in place, ensuring stability during operation. A reliable mounting bracket contributes to the overall integrity of the system.

Each of these components plays a vital role in the seamless operation of the control unit, and understanding their functions enhances both the user experience and maintenance efforts.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding the intricate assembly of machinery. Such illustrations not only aid in identifying individual elements but also streamline the maintenance and repair processes. By providing clarity, these visuals enhance efficiency and accuracy in handling equipment.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Facilitates a clearer grasp of how components fit and function together. |

| Improved Maintenance | Streamlines identification of parts needing attention or replacement. |

| Increased Efficiency | Reduces time spent on repairs and troubleshooting through clear guidance. |

| Accurate Repairs | Ensures the correct components are utilized, minimizing errors during replacements. |

How to Read the Diagram

Understanding the visual representation of components can significantly enhance your ability to manage and troubleshoot equipment. By familiarizing yourself with the symbols and layouts, you can streamline your maintenance tasks.

Follow these steps for effective interpretation:

- Identify the Sections: Break down the visual into distinct areas, focusing on each group of elements.

- Recognize Symbols: Familiarize yourself with common icons that represent specific parts or functions.

- Trace Connections: Look for lines that indicate how elements are linked; this reveals flow and interaction.

- Consult the Legend: If available, refer to the accompanying key for clarification on any unclear symbols.

By mastering these techniques, you can navigate the representation with confidence and enhance your understanding of the system’s operation.

Common Issues with Quicksilver Parts

When it comes to marine equipment, certain components can experience recurring problems that affect overall performance and reliability. Understanding these issues can help users maintain their systems effectively and avoid costly repairs.

One frequent concern is wear and tear over time. Various elements may degrade due to exposure to harsh marine environments, leading to decreased efficiency or complete failure. Regular inspections can help identify signs of deterioration early.

Another prevalent issue involves compatibility with other components. Incompatible parts can cause operational malfunctions, making it essential to ensure that all components are designed to work harmoniously together. Mismatched elements may lead to performance inconsistencies and additional stress on the system.

Corrosion is also a significant problem, particularly for metal components. Saltwater environments can accelerate the degradation of materials, necessitating protective measures such as regular cleaning and the use of corrosion-resistant finishes.

Lastly, improper installation can result in a range of complications, from minor inefficiencies to major breakdowns. Ensuring that all components are installed according to manufacturer guidelines is crucial for optimal operation and longevity.

Where to Find Replacement Parts

Finding the right components for your marine equipment can be crucial for optimal performance. A variety of resources are available to ensure you locate the necessary items effectively.

Online Retailers

- Specialized marine supply websites

- General online marketplaces

- Manufacturer’s official websites

Local Stores

- Marine supply shops

- Hardware stores with marine sections

- Boat dealerships

Exploring these options can significantly enhance your chances of acquiring the required components quickly and efficiently.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your marine equipment requires consistent care and attention. Regular maintenance not only enhances functionality but also extends the lifespan of your machinery.

- Regular Inspections: Frequently check for signs of wear and tear. Look for leaks, corrosion, and loose connections.

- Clean Components: Keep all parts free of dirt and debris. Use appropriate cleaning agents to prevent buildup.

- Lubrication: Apply lubricants to moving parts regularly to reduce friction and wear.

- Monitor Fluid Levels: Regularly check and replace oils and fluids as needed to maintain efficiency.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations provided by the manufacturer.

By following these practices, you can ensure the ultimate performance and longevity of your equipment.

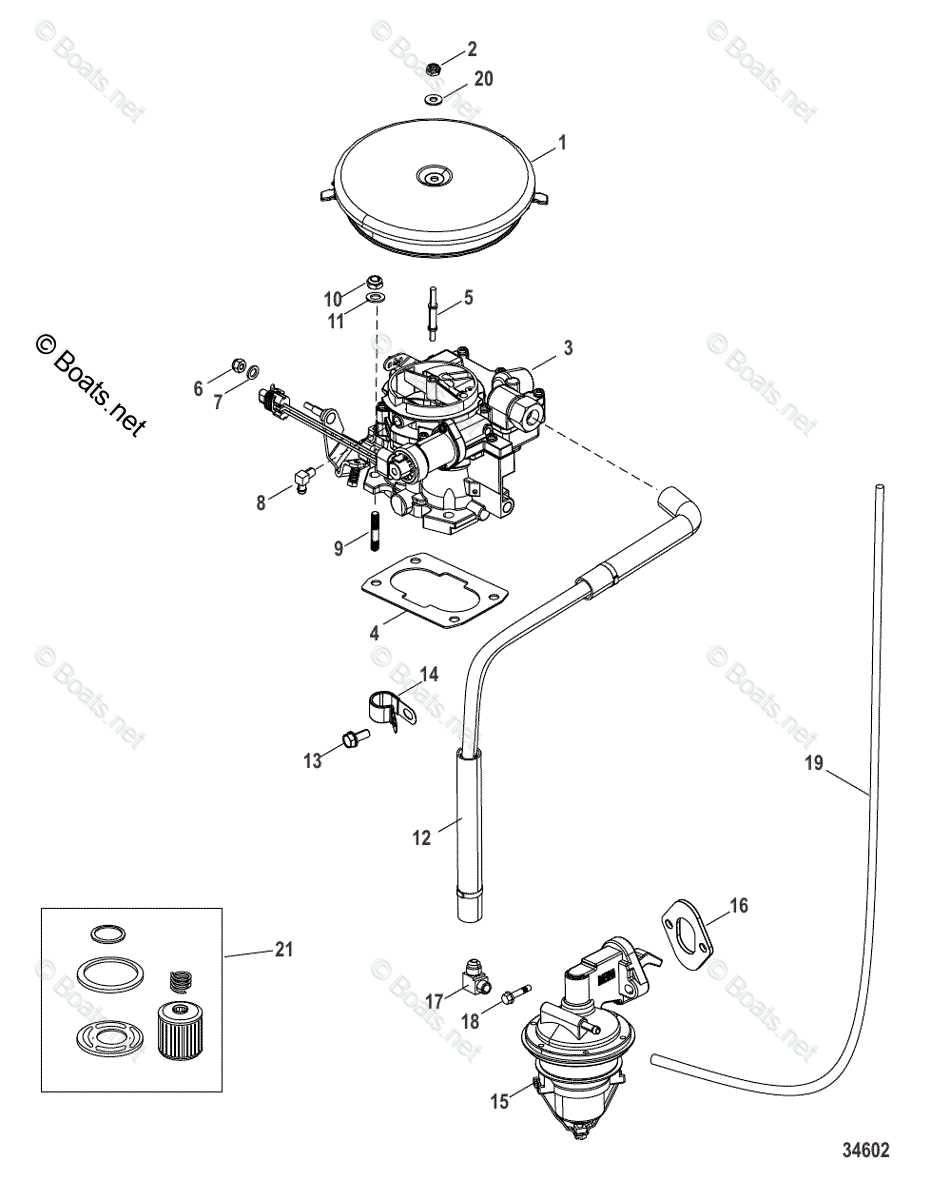

Installation Guide for Components

This section provides essential instructions for the effective installation of various elements within your system. Following these guidelines will ensure proper functionality and longevity of the components.

Preparation Steps

Before you begin, gather all necessary tools and components. Ensure that the workspace is clean and organized. Reviewing the accompanying documentation will help you understand each part’s role and installation procedure.

Installation Process

Start by securely attaching the main unit to a stable surface. Next, proceed to connect the auxiliary components, making sure to follow the recommended sequence. Double-check all connections for tightness, and test the setup to confirm everything is functioning as intended before finalizing the installation.

Frequently Asked Questions

This section aims to address common inquiries related to the specific system and its components. Here, users can find clarity on various topics to enhance their understanding and facilitate troubleshooting.

- What is the purpose of this system?

The primary function is to manage engine operations efficiently, ensuring optimal performance.

- How do I identify the components?

Refer to the labeled illustrations or consult the user manual for detailed information.

- What are common issues users face?

- Inconsistent performance

- Difficulty in starting

- Unusual noises during operation

- Where can I find replacement components?

Check authorized retailers or online marketplaces that specialize in marine equipment.

- How can I perform basic maintenance?

Regularly inspect connections, clean filters, and ensure proper lubrication of moving parts.

Comparison with Other Systems

When evaluating different control systems, it is essential to consider their functionality, ease of use, and reliability. Each system offers unique features that cater to various user needs, making it crucial to analyze how they stack up against one another. This comparison will provide insights into performance, compatibility, and user experience.

In terms of functionality, many alternatives provide similar capabilities, but differences in design and interface can significantly impact user interaction. Some systems prioritize intuitive controls, allowing for quicker adaptation, while others may require a steeper learning curve due to their complexity. This aspect is particularly important for those who frequently operate in high-pressure environments where quick decision-making is vital.

Reliability is another critical factor. Various models have established reputations based on durability and performance under diverse conditions. Users often report their experiences, highlighting which systems withstand wear and tear better and which ones may encounter issues over time. Such insights can be invaluable when making a choice that will affect long-term operations.

Compatibility with existing equipment also plays a significant role. Some systems boast extensive integration options, enabling seamless communication with other devices, while others may have limitations that necessitate additional investments or adjustments. Understanding these compatibilities can save users time and resources in the long run.

Ultimately, the decision to choose one control system over another hinges on personal or organizational preferences and specific operational requirements. By closely examining these elements, users can make informed choices that enhance their overall efficiency and effectiveness.

Upgrades and Modifications Available

Enhancing performance and aesthetics through various upgrades and modifications can significantly elevate your experience. From improved functionality to personalized styling, a range of options exists to cater to diverse preferences and needs.

Performance Enhancements

Optimizing your vessel’s performance is achievable with upgrades such as high-efficiency propellers and advanced fuel systems. These enhancements can provide greater speed and fuel economy, allowing for a more exhilarating journey on the water.

Customization Options

Personalizing your setup is equally important. Options like custom paint jobs and interior upgrades can transform the appearance and comfort of your craft, making it uniquely yours.

Expert Insights on Performance

Understanding the intricacies of marine engine systems can significantly enhance operational efficiency and reliability. By focusing on critical components and their interactions, enthusiasts and professionals alike can unlock the full potential of their vessels. This section delves into key considerations for optimizing performance in various marine applications.

Key Factors Influencing Efficiency

Several elements play a crucial role in determining the overall effectiveness of a marine engine. Maintenance practices are essential; regular checks and timely replacements of consumables can prevent unexpected breakdowns and ensure smooth operation. Additionally, fuel quality cannot be overlooked, as it directly impacts combustion efficiency and engine longevity.

Upgrades and Modifications

For those looking to boost performance, strategic upgrades can yield substantial benefits. Enhancing air intake systems or integrating advanced exhaust solutions can improve airflow, thereby increasing horsepower and torque. Furthermore, electronic tuning options allow for precise adjustments that cater to specific operational demands, making it easier to adapt to varying conditions.

Customer Experiences and Reviews

This section aims to highlight the feedback and insights shared by users regarding their interactions with the product. Understanding real-life experiences can provide valuable perspectives on functionality, reliability, and overall satisfaction.

Many users have expressed their appreciation for the intuitive design, noting how it simplifies operation and enhances performance. Several reviews highlight the durability and efficiency, making it a preferred choice among enthusiasts.

However, some customers reported challenges during installation, emphasizing the need for clearer instructions. Overall feedback indicates that while there are minor hurdles, the benefits greatly outweigh the drawbacks, leading to a positive consensus.