When working with outdoor machines, it’s essential to have a clear overview of how different mechanisms come together. Knowing how various elements interact and where they are positioned helps in maintaining and repairing your device more efficiently. This section provides insights into the configuration of critical elements, ensuring that you can identify them with ease during any servicing or adjustments.

Whether you’re troubleshooting an issue or performing routine upkeep, having a reference for the internal and external components is key. With a detailed breakdown of each section, you’ll be better prepared to handle any challenges that may arise. By familiarizing yourself with these layouts, you can significantly extend the lifespan of your equipment and ensure it continues running smoothly.

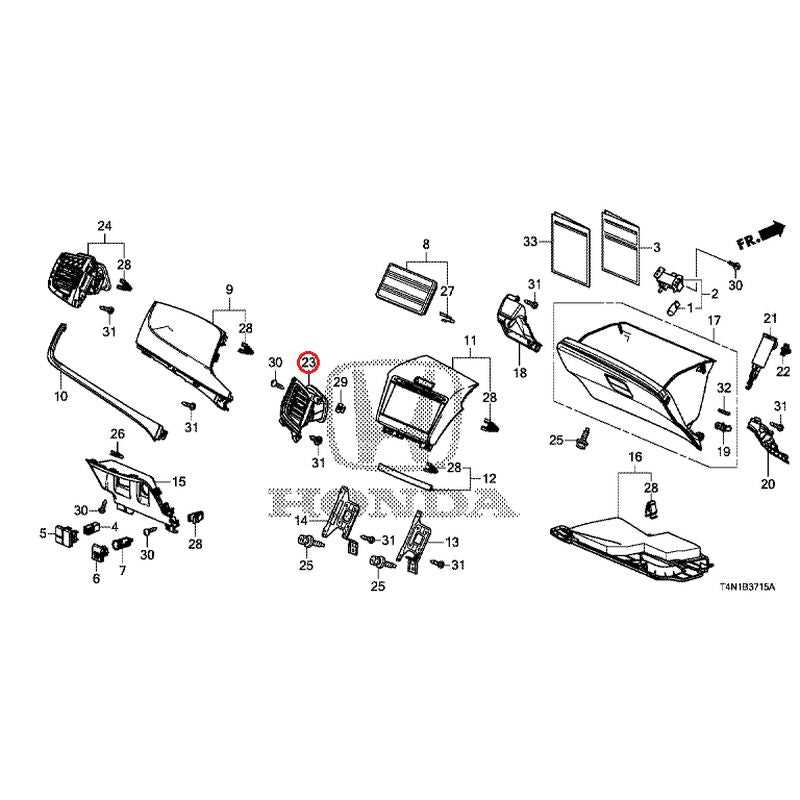

Comprehensive Guide to Honda Snowblower Components

Understanding how various elements of outdoor machinery work together is crucial for ensuring its smooth operation and long-term reliability. This section explores the key mechanical systems and their interconnected roles, helping users identify the most critical aspects of maintenance and performance.

Key Functional Areas

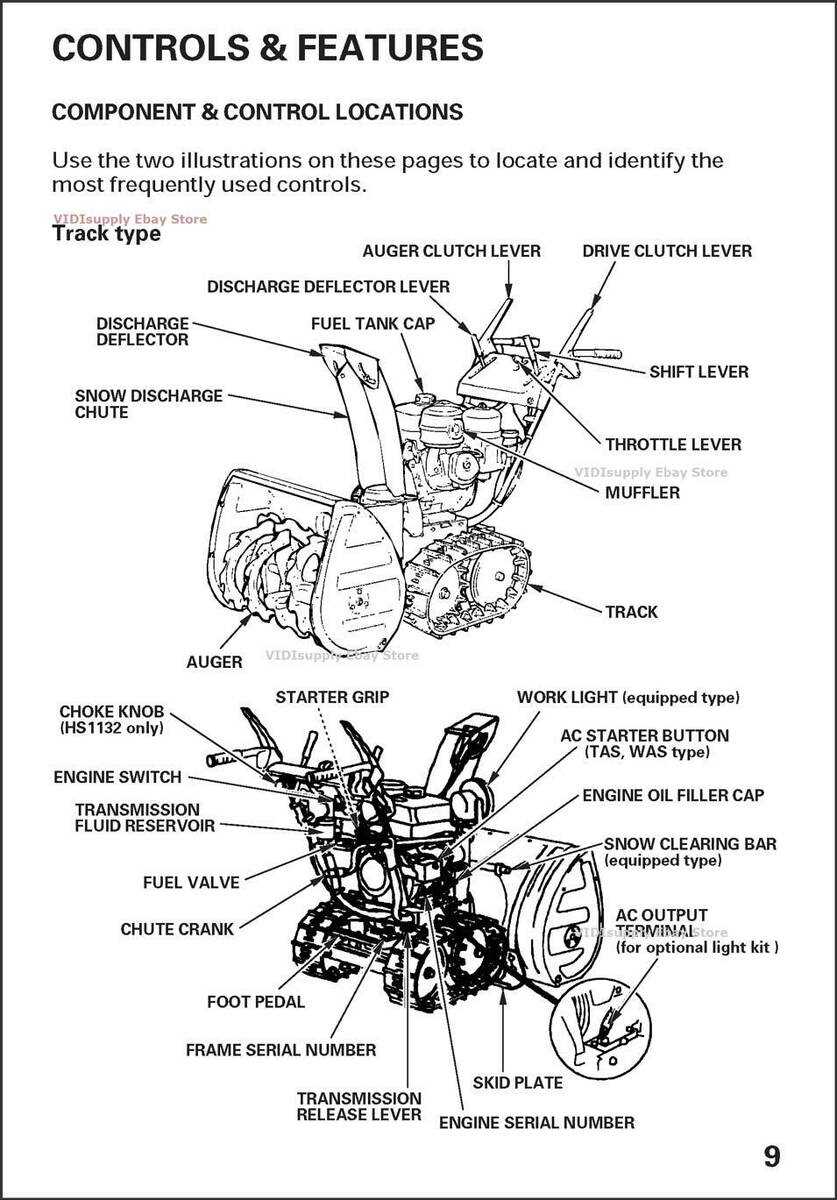

To ensure consistent and effective operation, several primary mechanisms work in harmony. These include systems responsible for propulsion, clearing operations, and control adjustments. Each serves a unique purpose in the overall functionality of the equipment.

- Power Generation: Essential for initiating and sustaining movement, this component is at the heart of every mechanical system, transforming stored energy into active force.

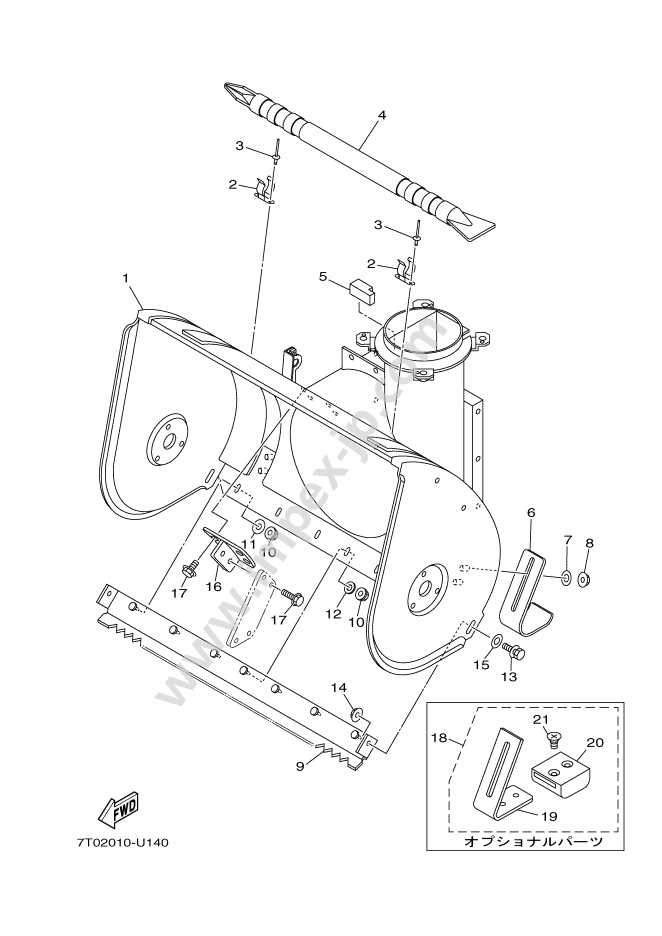

- Clearing Mechanism: Designed to handle tough outdoor conditions, this part ensures that debris or obstacles are effectively moved out of the way, allowing for a cleaner operational path.

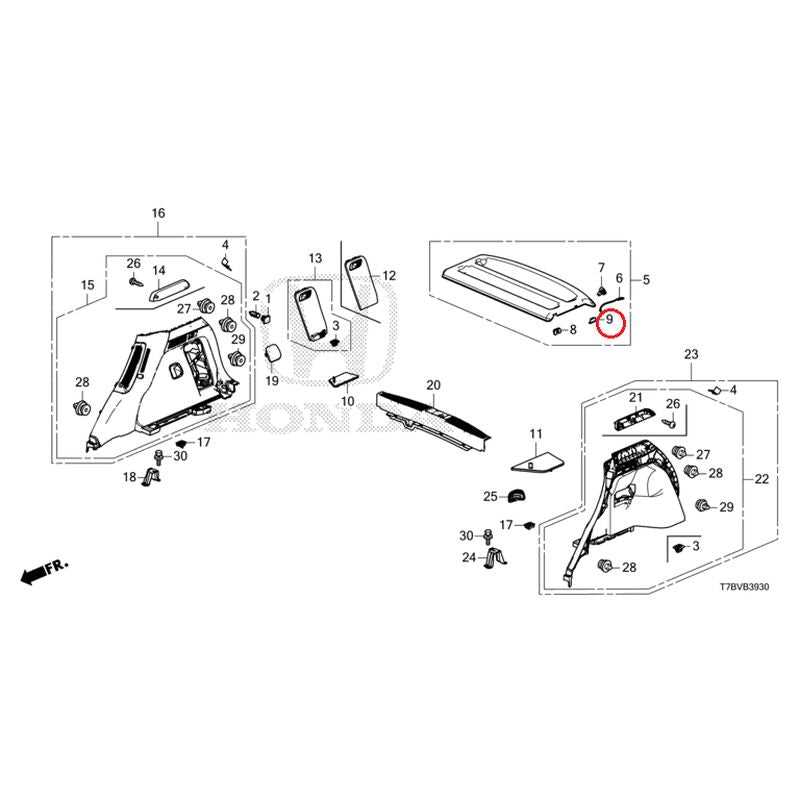

- Control System: This allows users to adjust settings such as direction and speed, ensuring that the machine responds appropriately to varied conditions.

Maintenance Tips

Regular upkeep of these mechanical systems ensures that performance remains optimal, extending the overall life of the machinery. Here are a few key areas to focus on:

- Check for wear and tear in moving parts regularly to prevent failure during use.

- Keep the power source

Understanding the Functionality of Key Parts

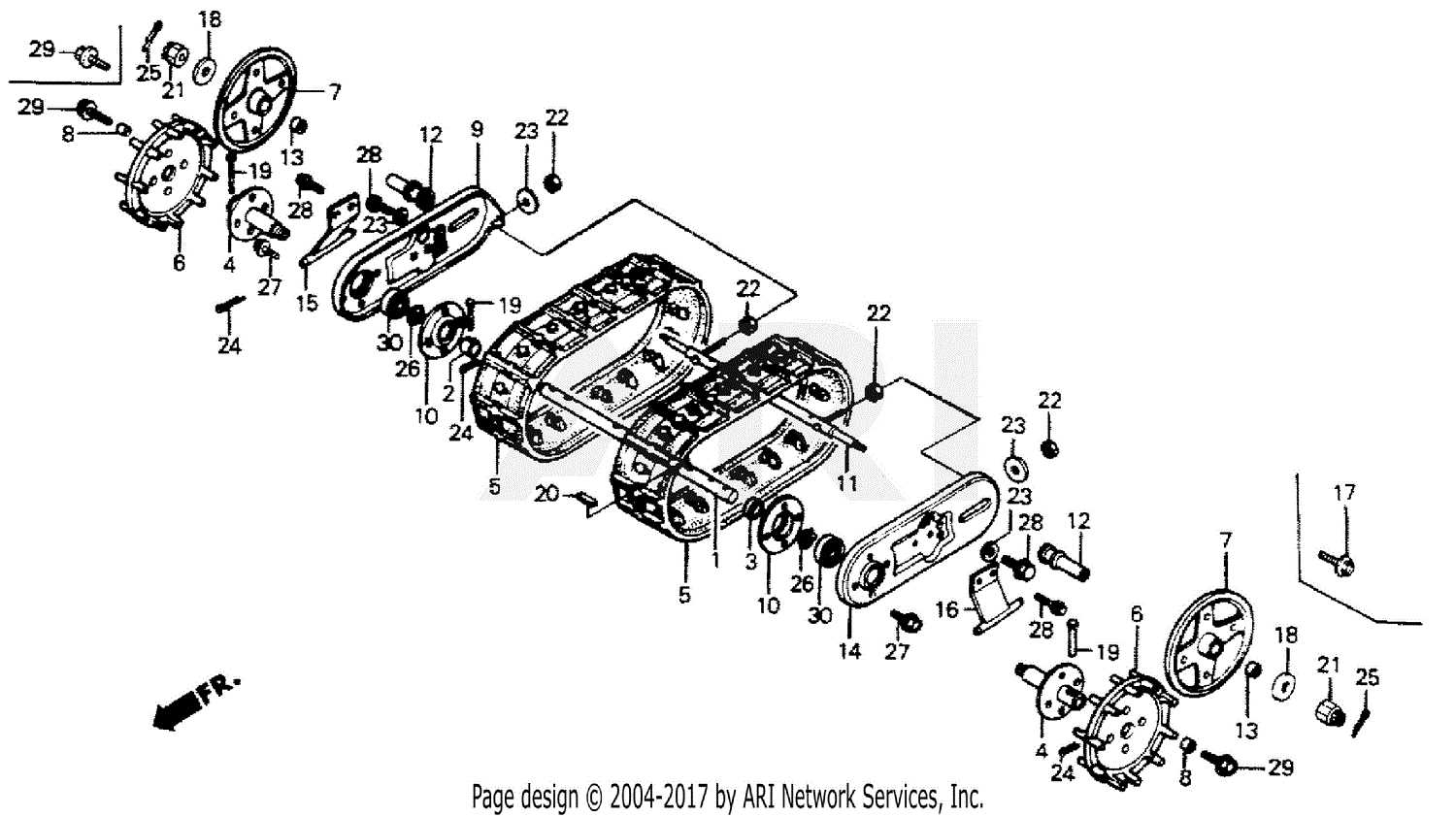

Each machine relies on several essential components working together to ensure smooth operation. By gaining a clear understanding of how these elements interact, users can better maintain their equipment and troubleshoot potential issues before they become significant problems.

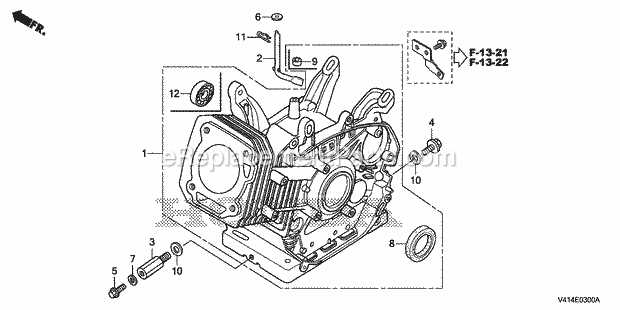

- Engine Mechanism: The driving force behind the entire system, responsible for powering all other operations.

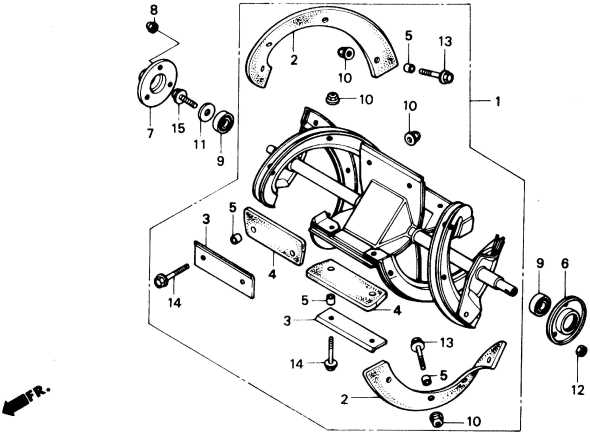

- Auger System: Plays a critical role in gathering and directing material efficiently to the intended location.

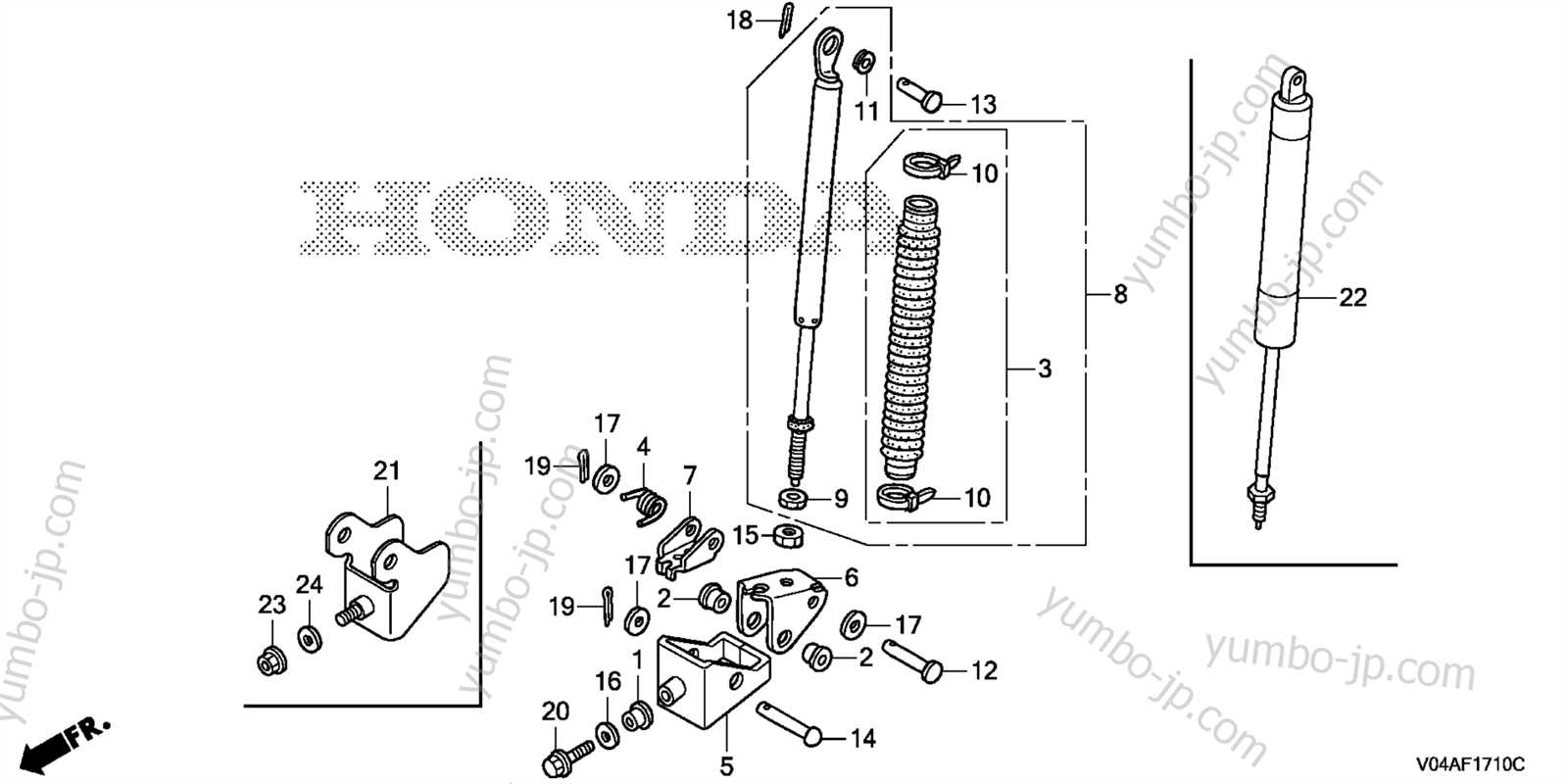

- Control Levers: Enable precise adjustments, providing the operator with control over movement and functionality.

- Chute Assembly: Ensures that collected material is properly directed for optimal results.

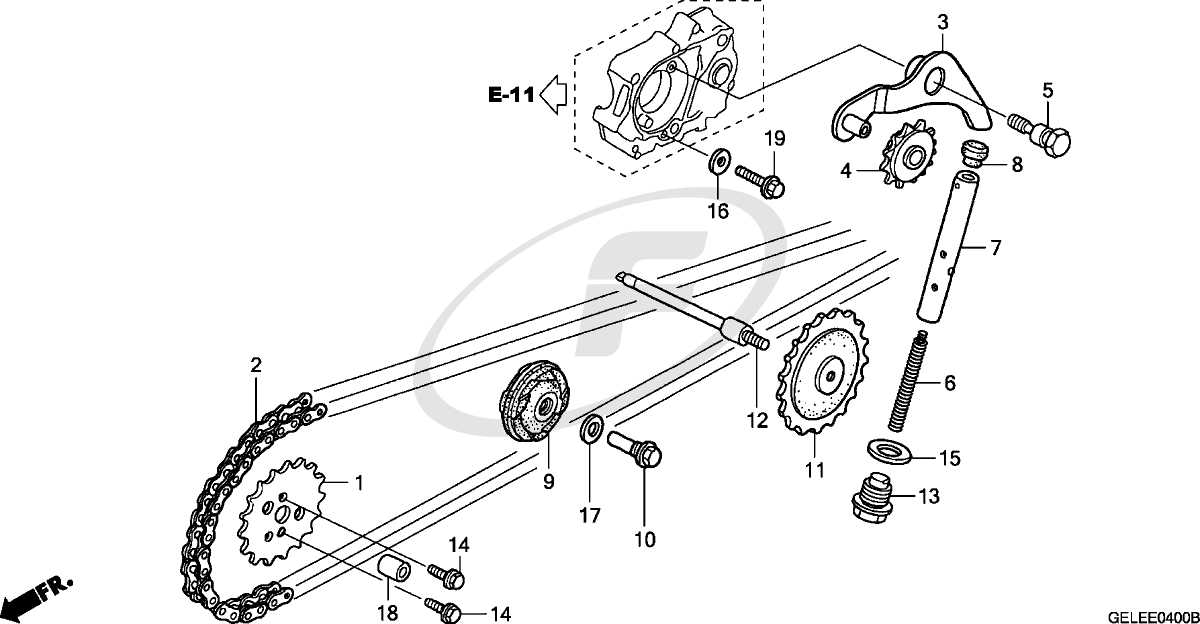

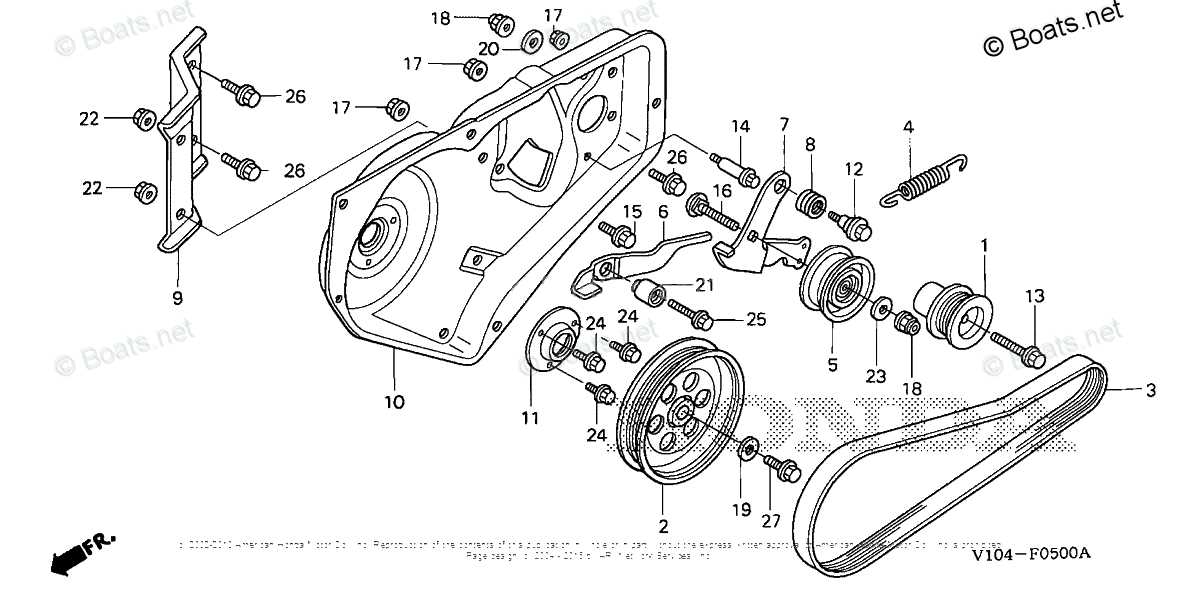

- Drive Mechanism: Facilitates movement and mobility, allowing the machine to navigate various terrains with ease.

By understanding the role of each core element, operators can maintain optimal performance and extend the longevity of their equipment through proper use and timely care.

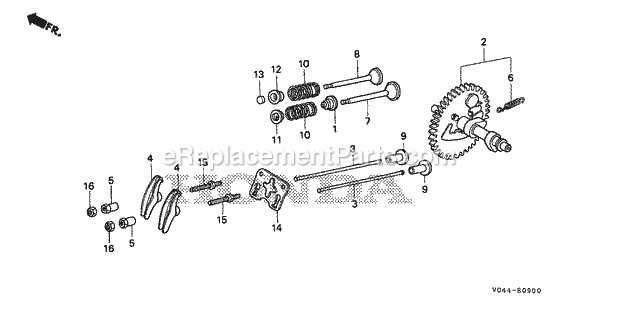

Exploring the Engine and Drive System

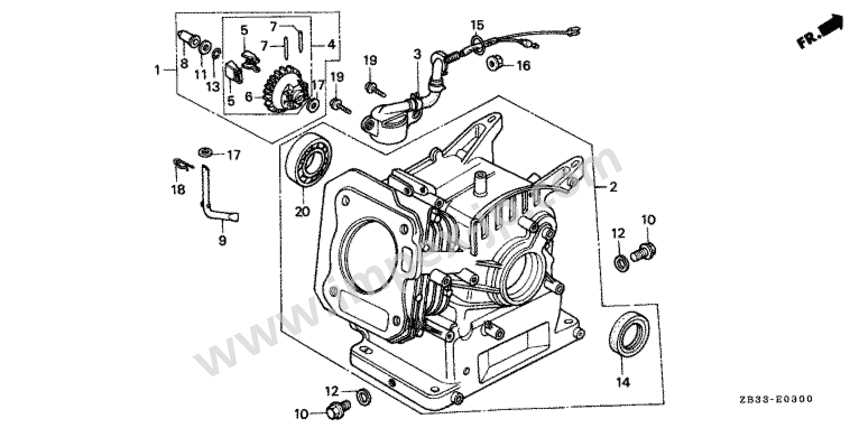

The heart of any machine relies heavily on the efficiency of its power unit and the components responsible for movement. Understanding how these key elements work together is crucial for ensuring optimal functionality and long-lasting performance. This section delves into the primary mechanisms that provide both energy and control, giving insight into how they contribute to smooth operation and reliability.

Power Unit Overview

The power unit is designed to convert fuel into motion, offering the necessary force to drive the entire system. It operates through a series of precise mechanical actions that ensure a steady output. Key aspects of this unit include its efficiency in fuel consumption and its ability to withstand different working conditions, providing reliable performance in a variety of scenarios.

Drive System Functionality

The drive system is responsible for translating the power generated into movement. It consists of various interrelated parts that ensure coordinated motion and control. Proper alignment and synchronization of these components are essential to avoid unnecessary wear and maintain smooth performance during operation. Regular maintenance of the drive system can help prevent disruptions and enhance the overall experience.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure the smooth operation of outdoor equipment, especially during demanding seasons. By following a consistent care routine, you can extend the life of your machinery and reduce the likelihood of unexpected breakdowns. Proper attention to critical areas will help maintain reliability and functionality over time.

Key Areas to Inspect

For continuous performance, it’s crucial to monitor the main components regularly. This includes ensuring that mechanical parts are well-lubricated and free from debris. Pay special attention to moving elements that may wear out faster due to frequent use. Replace worn-out elements as needed to prevent larger issues from developing.

Lubrication and Cleaning

Maintaining an adequate lubrication schedule can significantly enhance efficiency. Regularly check oil levels and apply grease where necessary to minimize friction between moving parts. Additionally, cleaning the equipment thoroughly after each use can prevent clogging and wear.

Maintenance Task Frequency Lubrication of moving parts Every 10 hours of use Checking belt tension Monthly Inspecting wear components Every 20 hours of use Identifying Commonly Replaced Components

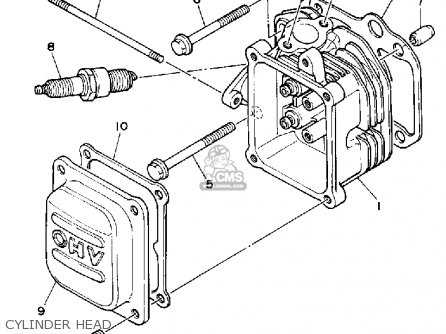

Over time, various components in outdoor equipment may wear out or fail due to regular use or environmental conditions. Recognizing these frequently changed elements helps in maintaining the machine’s efficiency and longevity. It is essential to understand which parts tend to need replacement more often to prevent unexpected breakdowns.

Among the most commonly swapped components are belts, which are crucial for smooth operation. Blades also experience significant wear and often require attention. Additionally, spark plugs are known to deteriorate, impacting overall performance. Addressing these issues early ensures that the equipment continues to run reliably.

Troubleshooting Issues with Moving Parts

When dealing with machinery, it’s common to encounter challenges related to the mechanisms that facilitate movement. Recognizing and addressing these issues promptly can enhance efficiency and prolong the lifespan of your equipment. This section will guide you through some typical problems and provide solutions to ensure smooth operation.

Identifying Common Problems

Various factors can lead to malfunctioning components, such as wear and tear, misalignment, or lack of lubrication. Observing unusual sounds or erratic movement can indicate underlying issues. Conducting regular inspections can help in early detection, allowing for timely maintenance.

Solutions and Maintenance Tips

To rectify movement-related issues, start by ensuring all connections are secure and properly aligned. Regularly lubricating moving components can significantly reduce friction and prevent overheating. If a specific part appears worn, replacing it with a new component may be necessary to restore optimal functionality. Always consult the equipment manual for specific guidelines on maintenance and troubleshooting.

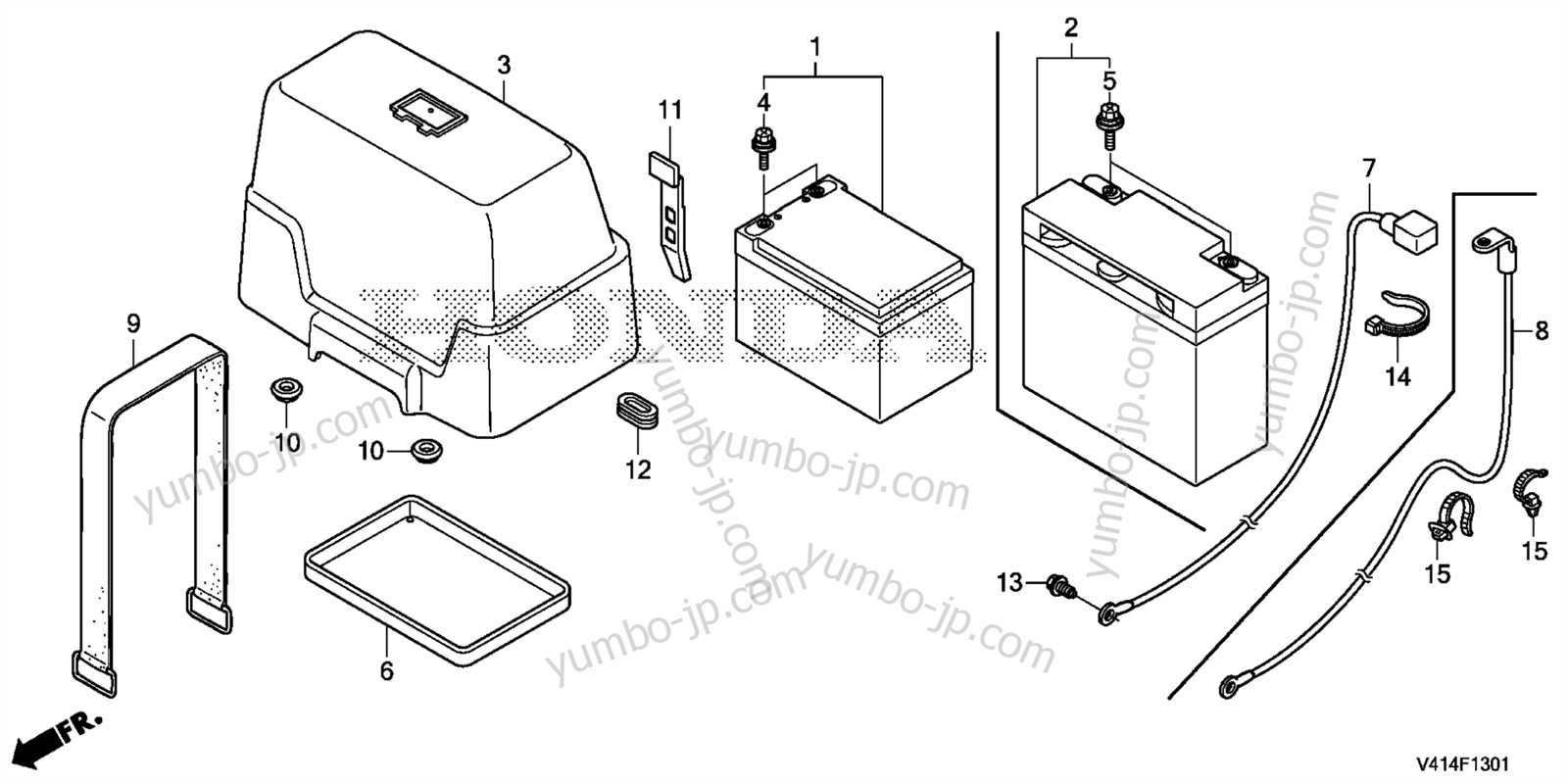

Overview of Electrical System Elements

The electrical components play a vital role in the overall functionality of machinery, ensuring smooth operation and effective performance. Understanding these elements is crucial for maintenance and troubleshooting. This section highlights the essential components that make up the electrical system, their functions, and their importance in machinery operations.

Key Components

- Battery: Supplies the necessary power for starting the engine and powering electrical accessories.

- Starter Motor: Engages the engine to initiate the combustion process.

- Ignition System: Responsible for igniting the fuel-air mixture in the engine cylinders.

- Wiring Harness: Connects various electrical components, allowing for the transfer of power and signals.

- Fuses and Relays: Protect electrical circuits from overloads and control the flow of electricity to different parts.

Functionality and Maintenance

Each of these components works together to ensure the efficient operation of the machinery. Regular inspection and maintenance of the electrical system can prevent potential failures and enhance longevity. Key maintenance practices include:

- Checking battery connections and ensuring proper charge levels.

- Inspecting wiring for signs of wear or damage.

- Testing the ignition system to confirm reliable performance.

- Replacing blown fuses and faulty relays as needed.

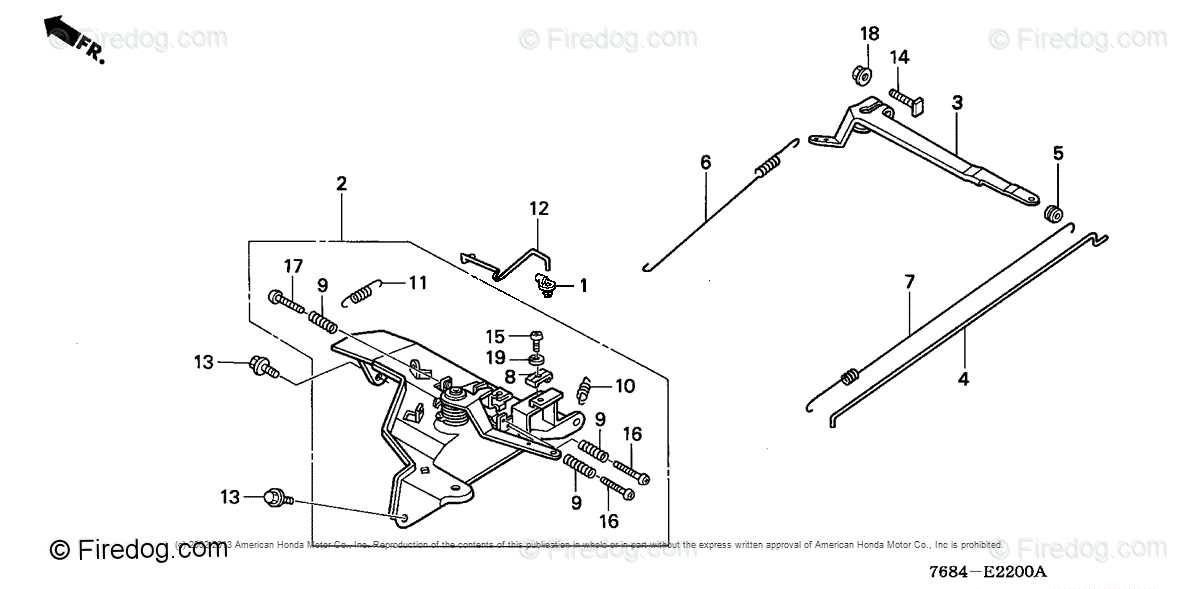

Adjusting and Replacing Control Cables

Proper management of the control lines is essential for optimal functionality and performance. Ensuring these cables are in good condition and correctly adjusted allows for smooth operation and responsiveness of the equipment. Regular inspection and timely replacement of worn or frayed cables can prevent operational issues and enhance safety.

To adjust the control cables, start by locating the adjustment points on the device. Typically, these will be situated near the control handle or the mechanism itself. Loosen the adjustment nut, then pull or push the cable to achieve the desired tension. Once adjusted, tighten the nut securely to maintain the new position.

When it comes to replacing the cables, first disconnect the existing ones from their attachment points. Carefully remove any clips or fasteners holding the cables in place. Once removed, install the new cables by following the original routing. Ensure that they are properly secured and free from obstructions. After installation, adjust the new cables as needed to ensure smooth operation.

Regular maintenance of control lines is crucial for maintaining the efficiency and safety of the equipment. By being proactive in adjustments and replacements, users can significantly prolong the lifespan of their machinery and enhance overall performance.

Protecting Your Snowblower from Wear

Maintaining your equipment in optimal condition is crucial for ensuring longevity and efficient performance. Regular care can prevent premature deterioration and extend the life of your machine. Implementing protective measures is essential to safeguard against the harsh conditions faced during winter use.

Regular Maintenance Checks

Conducting consistent inspections helps identify potential issues before they escalate. Focus on the following areas:

- Check for signs of wear on belts and cables.

- Inspect the housing for any cracks or damages.

- Ensure all moving parts are properly lubricated.

Storage Practices

How you store your equipment can significantly impact its longevity. Consider these storage tips:

- Store in a dry location to prevent rust and corrosion.

- Cover the unit to protect it from dust and debris.

- Empty the fuel tank to avoid potential damage from stale gasoline.

Safety Features and Their Importance

Ensuring the security of operators and bystanders is crucial when utilizing outdoor machinery. Manufacturers incorporate various safety mechanisms designed to prevent accidents and minimize risks during operation. Understanding these elements can significantly enhance user awareness and promote safe handling practices.

Key Safety Mechanisms

Modern equipment often includes features such as automatic shut-off systems, emergency stop buttons, and safety guards. Automatic shut-off helps to instantly halt operation in the event of a malfunction, while emergency stop buttons provide a quick means to stop the machine when immediate action is necessary. Additionally, protective barriers can shield users from moving parts, reducing the likelihood of injury.

Promoting Safe Operation

Understanding and utilizing these safety features is essential for effective operation. Regular maintenance checks and adhering to operational guidelines further enhance safety. By prioritizing these elements, users can enjoy a more secure and efficient experience, ultimately leading to a reduction in accidents and injuries.

Winterizing Tips for Long-Term Durability

Preparing your outdoor equipment for the colder months is crucial to ensure its longevity and reliable performance. Proper maintenance can prevent costly repairs and enhance the lifespan of your machinery. Follow these essential tips to effectively protect your equipment during the winter season.

- Clean Thoroughly: Remove any debris, dirt, and residues from your equipment. Pay special attention to the undercarriage and any accessible parts to prevent rust and corrosion.

- Drain Fluids: Empty fuel and oil tanks to avoid deterioration or contamination over the winter. Stale fuel can cause starting issues when the season changes.

- Inspect for Damage: Check for any wear and tear on components. Replace any damaged or worn parts to avoid malfunctions when you start using your equipment again.

- Lubricate Moving Parts: Apply appropriate lubricants to all moving parts to ensure smooth operation and prevent rusting.

- Store Properly: Keep your machinery in a dry, sheltered place away from extreme temperatures. Consider using a cover to protect it from dust and moisture.

By following these guidelines, you can ensure that your equipment remains in top condition and ready for action when the snow begins to fall. Taking the time to winterize properly will save you time and money in the long run.

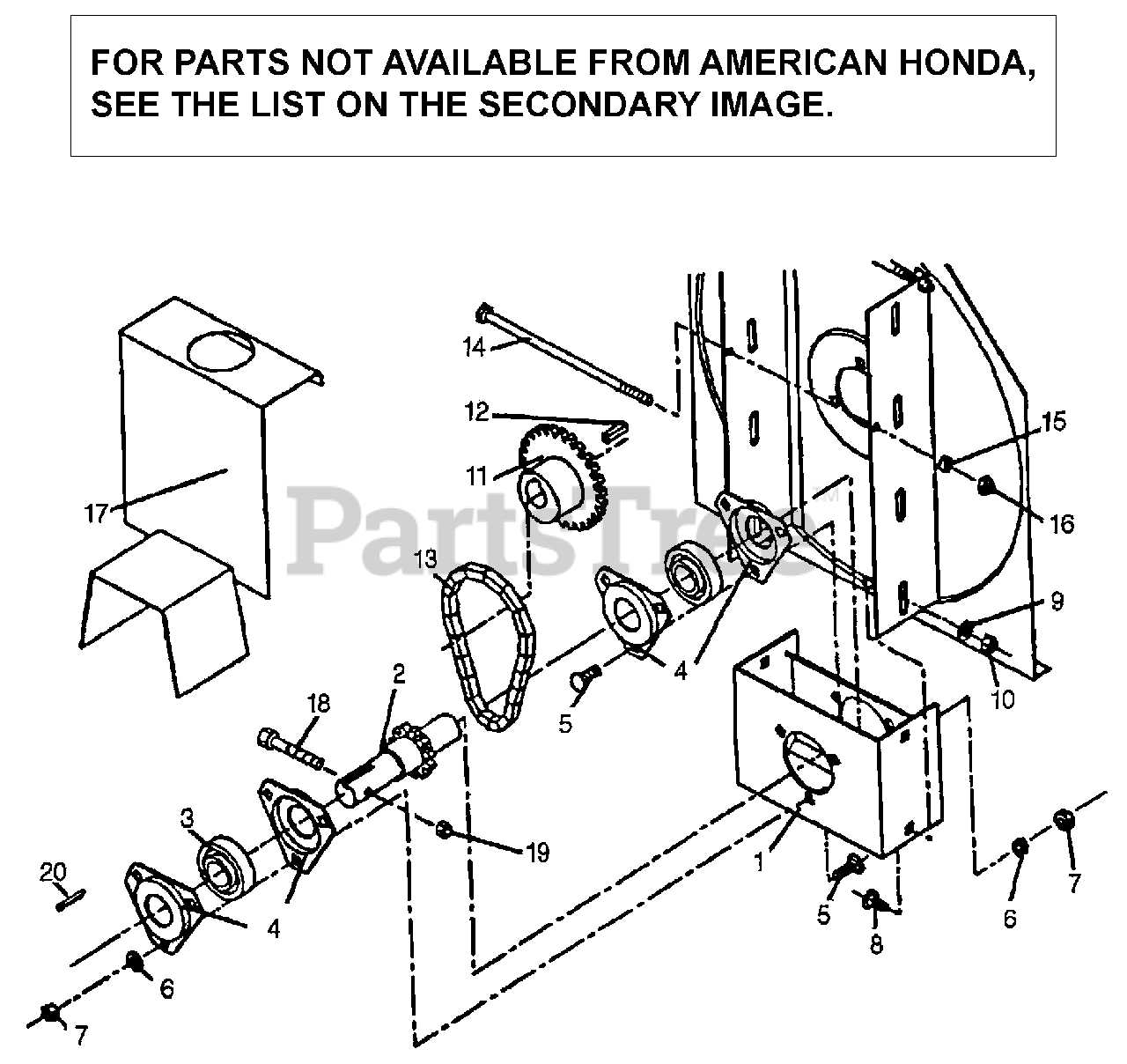

How to Find the Right Replacement Parts

Ensuring the optimal functioning of your equipment often requires sourcing the appropriate components. This process can seem daunting, but with the right approach, you can easily locate what you need. Understanding the specifications and compatibility is crucial for making informed decisions and prolonging the lifespan of your machinery.

Understanding Specifications

Familiarize yourself with the specifications of the components required for your machine. This includes knowing the model number, dimensions, and any unique features that the item may possess. Gathering this information helps in identifying suitable substitutes and eliminates confusion when searching for replacements.

Utilizing Online Resources

The internet offers a wealth of information and resources for identifying and acquiring the necessary items. Manufacturer websites, forums, and online retailers can provide comprehensive listings and diagrams, making it easier to visualize the components you are looking for. Additionally, reading reviews can help gauge the quality of the items available.

Criteria Description Model Number The specific identification number assigned to your equipment. Dimensions Measurements of the components to ensure proper fit. Compatibility How well a component works with other parts of the machinery. Quality Overall standard and durability of the components available.