The effectiveness of a snow removal device relies heavily on the various elements that make up its construction. Each component plays a vital role in ensuring that the equipment operates smoothly and efficiently, allowing users to clear snow from their driveways and paths with ease. A thorough understanding of these elements is essential for maintenance and repair tasks, as it enables operators to identify issues and perform necessary fixes.

In this section, we will explore the different components of a specific model used for snow clearing. By examining the relationships between various parts, users can gain insights into how to keep their machines in optimal condition. Proper care and attention to detail can prolong the life of the equipment, ensuring reliable performance during the winter months.

Whether you are a seasoned operator or new to snow removal, familiarizing yourself with the structure and functionality of the components will enhance your ability to troubleshoot and resolve issues. Knowledge of the individual pieces will empower you to undertake repairs with confidence, leading to more effective snow management in challenging weather conditions.

This section provides an overview of the essential machinery designed to facilitate winter maintenance tasks. Understanding the key components of this equipment is vital for ensuring optimal performance and longevity. Users can benefit from familiarizing themselves with the various elements that make up this efficient tool.

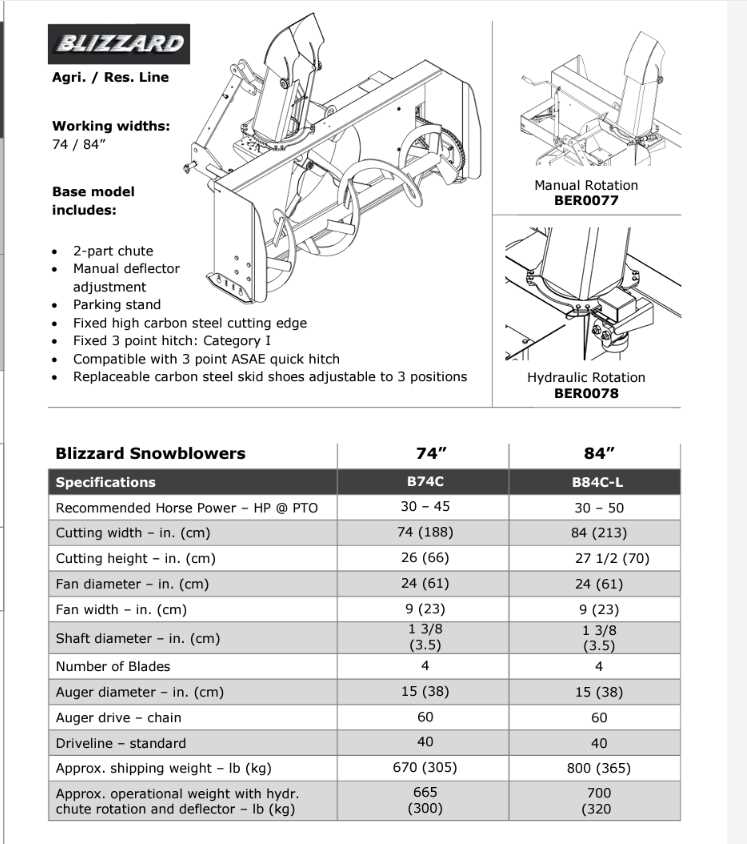

Key Features of the Equipment

Discussing the innovative attributes that enhance functionality, this segment highlights aspects such as durability, ease of use, and adaptability to various conditions.

Importance of Regular Maintenance

Maintaining the machinery is crucial for ensuring efficient operation. This part emphasizes the significance of routine checks and servicing to prevent unexpected failures and extend the lifespan of the equipment.

Understanding these aspects will provide users with a comprehensive knowledge base, enabling them to utilize the machinery effectively during the winter months.

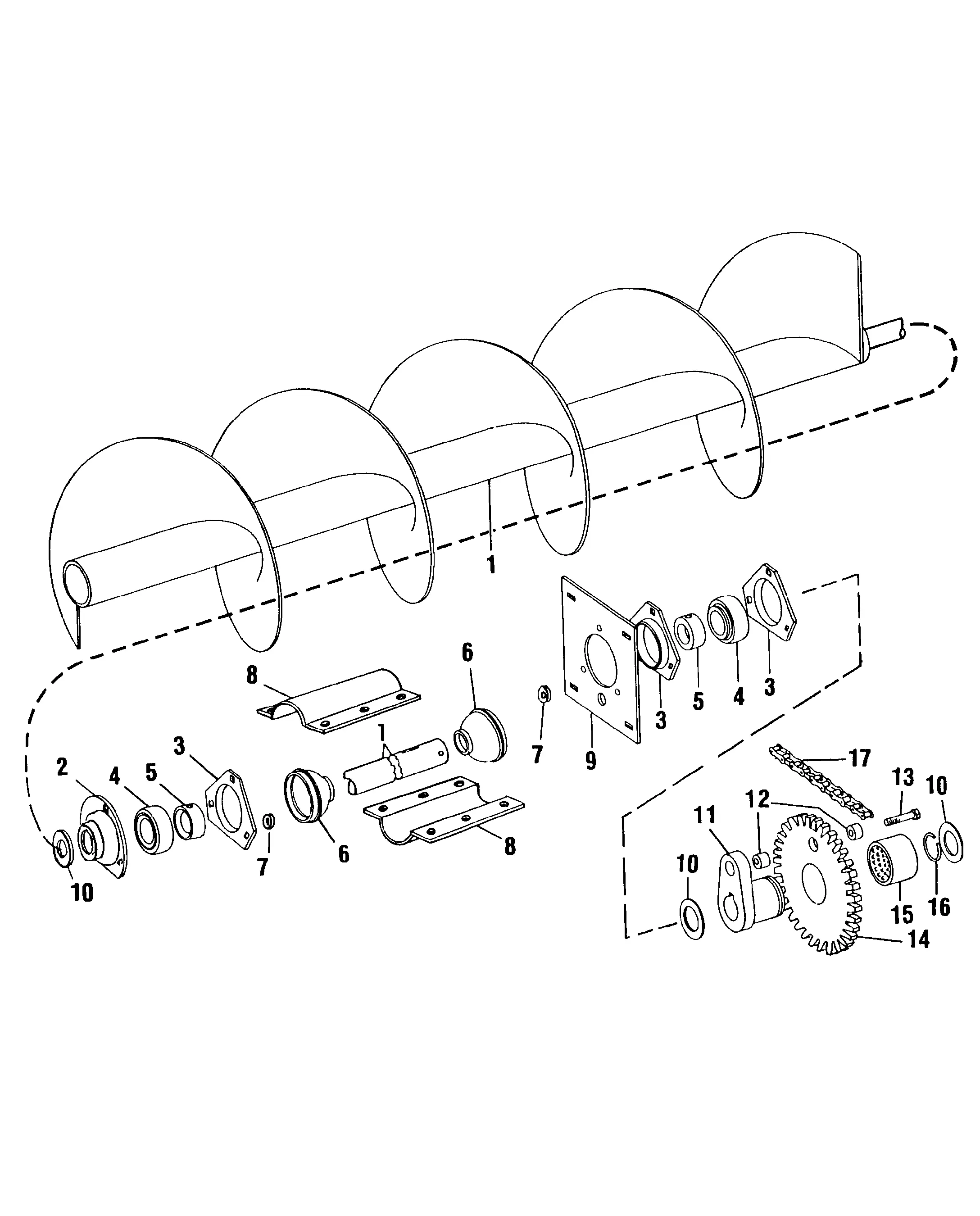

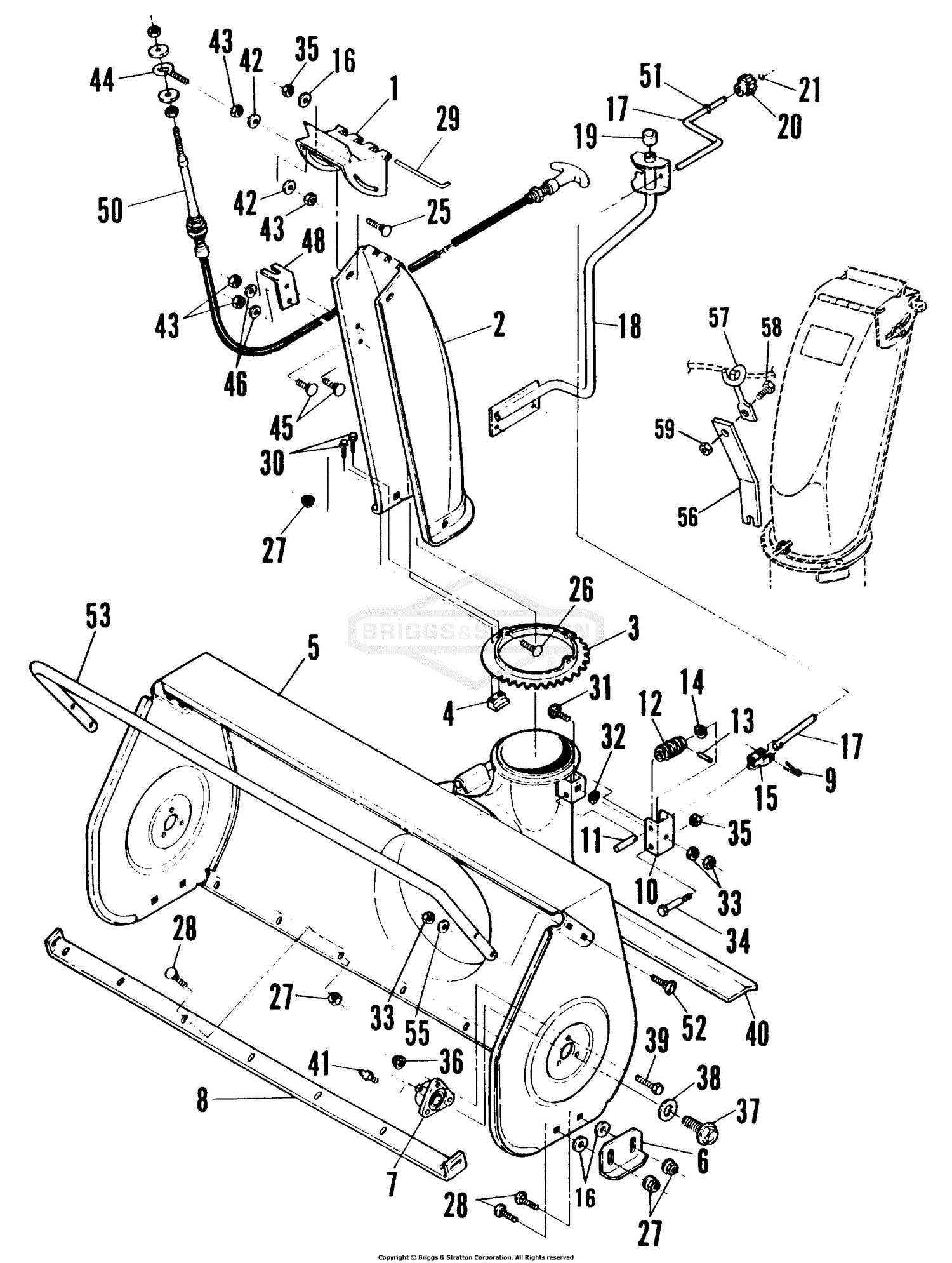

Key Components of the Snowblower

Understanding the essential elements of a snow clearing device is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, making it vital for users to familiarize themselves with these parts.

The primary elements include the intake housing, auger, impeller, and drive system. These components work in harmony to efficiently clear snow, providing a seamless experience for the operator.

| Component | Description |

|---|---|

| Intake Housing | This is the area where snow enters the machine, designed to handle various snow depths and conditions. |

| Auger | This rotating blade breaks up the snow and directs it towards the discharge chute for expulsion. |

| Impeller | Located behind the auger, the impeller helps propel the cleared snow out of the chute with force. |

| Drive System | This mechanism controls the movement of the device, allowing for forward and reverse operation on different terrains. |

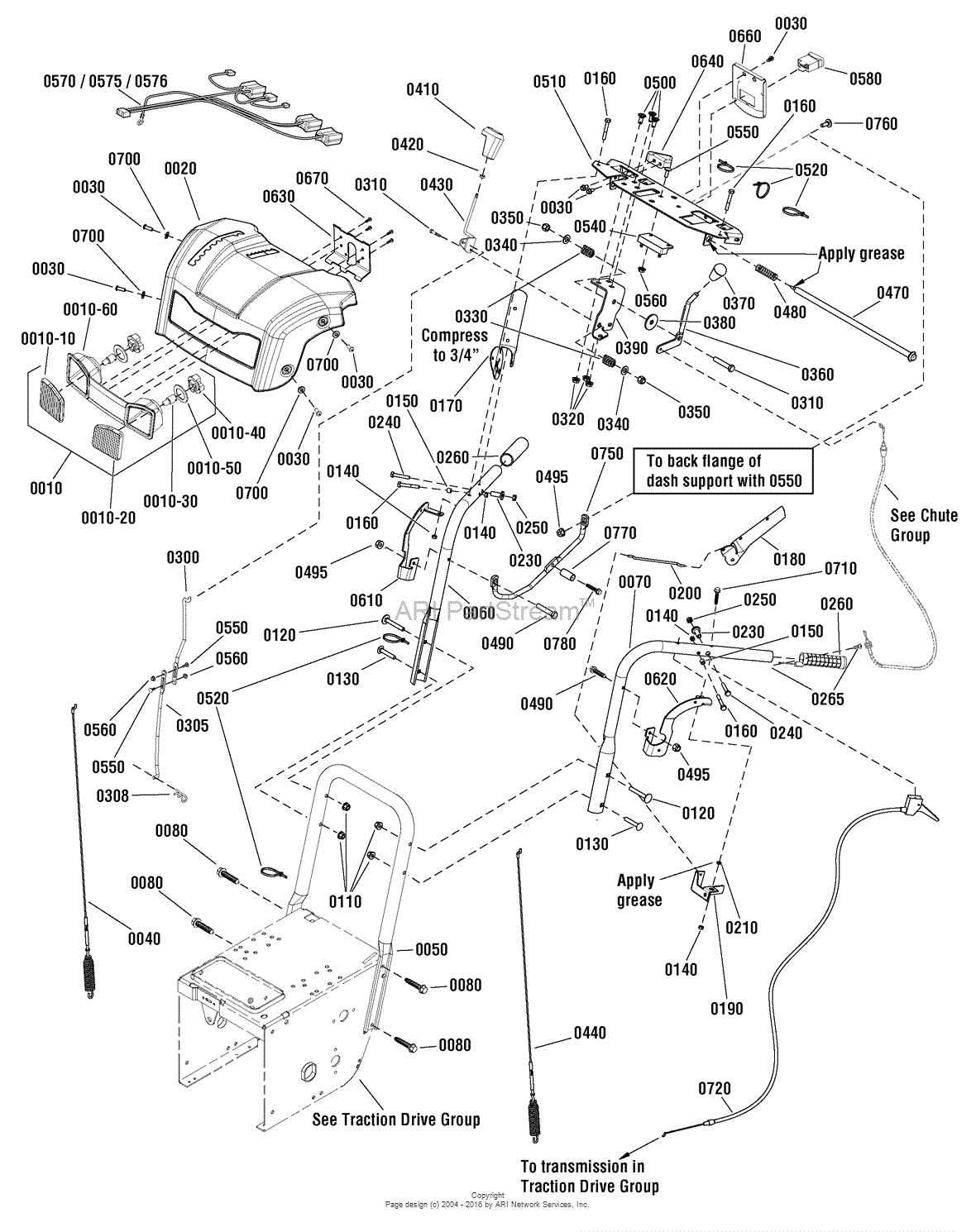

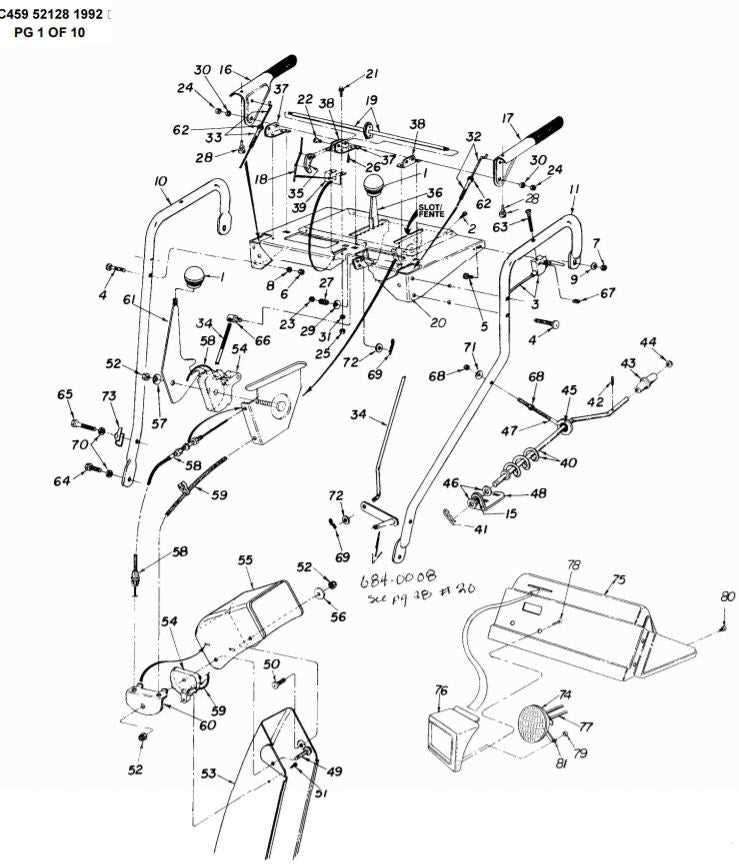

Importance of Parts Diagrams

The utilization of visual representations in machinery maintenance is crucial for ensuring efficient operation and troubleshooting. These illustrations serve as valuable resources for understanding the intricate components and their respective placements within a device.

Clarity is one of the primary advantages offered by these visuals. They simplify complex assemblies, allowing users to quickly identify and locate individual elements. This enhanced understanding can significantly reduce the time spent on repairs and adjustments.

Moreover, efficiency is heightened when mechanics can refer to these visual aids during their work. Instead of relying solely on textual descriptions, which may be ambiguous, a graphical overview provides a clear roadmap for assembly and disassembly procedures.

Additionally, accuracy in repairs is improved through the use of these illustrations. By having a precise reference, users can ensure they are working with the correct components, minimizing the risk of errors that could lead to further complications.

In summary, these visual guides are indispensable tools for anyone involved in equipment maintenance. They enhance understanding, efficiency, and accuracy, ultimately contributing to better performance and longevity of the machinery.

Common Issues with Snow Clearing Equipment Components

When it comes to clearing snow, various challenges can arise with the equipment’s components. Understanding these common problems can help in maintaining optimal performance and ensuring the longevity of the machinery. Often, users encounter issues that stem from wear and tear, improper maintenance, or even seasonal changes. Identifying and addressing these concerns promptly can lead to more effective snow removal and a smoother operation overall.

Frequent Problems Encountered

Several issues may manifest in different components of snow clearing equipment, impacting functionality. Here are some typical challenges:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Clogs | Reduced efficiency, stalling | Regularly clean the intake area and chute. |

| Worn Belts | Slipping, unusual noises | Inspect and replace if necessary. |

| Faulty Controls | Non-responsive buttons or levers | Check wiring and connections; repair or replace as needed. |

| Fuel Issues | Hard starting, engine stalling | Use fresh fuel and check for blockages in the lines. |

Maintenance Tips

To minimize the risk of encountering these issues, regular maintenance is essential. Simple practices such as cleaning after use, checking for wear, and storing the equipment properly during off-seasons can significantly enhance performance and reliability. Implementing a routine inspection schedule can also help in catching potential problems early, ensuring smooth operation when snow needs to be cleared.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of outdoor equipment requires regular upkeep and attention. Implementing a consistent maintenance routine can significantly extend the lifespan of machinery and improve its performance. Here are some essential tips to maintain your equipment effectively.

- Regular Cleaning:

Remove debris and dirt after each use to prevent buildup that can affect functionality. Pay special attention to the undercarriage and moving parts.

- Lubrication:

Apply appropriate lubricants to moving components to reduce friction and wear. Check the manufacturer’s guidelines for recommended products.

- Inspect Belts and Cables:

Regularly check for signs of wear or damage. Replace any frayed or cracked belts and cables promptly to avoid operational issues.

- Check Fluid Levels:

Monitor oil and fuel levels regularly. Changing the oil according to the recommended schedule ensures smooth operation and prevents engine damage.

- Store Properly:

When not in use, store equipment in a dry, sheltered area. Use protective covers to shield it from dust and moisture.

- Follow Manufacturer’s Guidelines:

Always adhere to the maintenance schedule provided in the user manual. This includes recommended service intervals and procedures.

By following these maintenance practices, you can enhance the reliability and lifespan of your machinery, ensuring it remains a valuable tool for years to come.

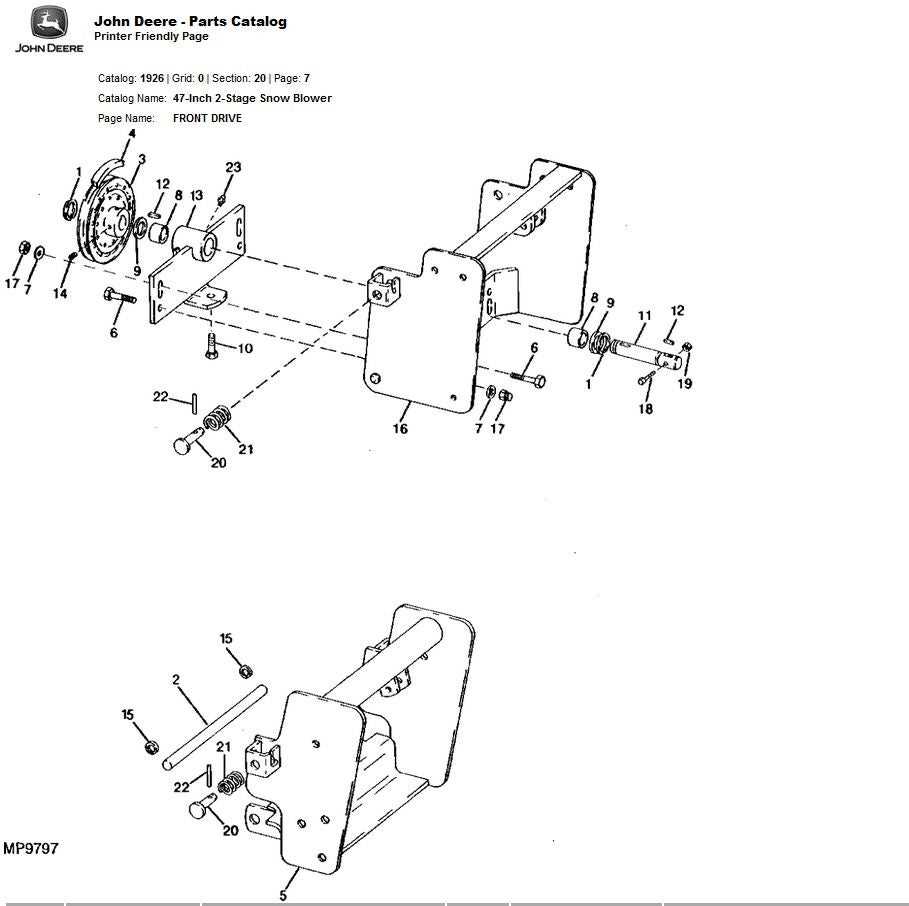

How to Identify Parts by Diagram

Understanding the components of a machine can significantly enhance maintenance and repair efforts. Visual representations of equipment help users locate and identify individual elements quickly, facilitating effective troubleshooting and replacement processes. This section outlines the method for recognizing parts through illustrations, allowing for a more systematic approach to equipment care.

Recognizing Component Functions

Before delving into the visual guides, it is essential to familiarize yourself with the basic functionalities of various components. Each element has a specific role, contributing to the overall operation of the device. This knowledge aids in pinpointing issues and determining which sections require attention.

Using Visual Aids Effectively

When consulting an illustration, follow these steps to ensure accurate identification:

- Examine the legend or key if provided; it usually contains essential details regarding the elements depicted.

- Compare the physical component to the visual representation, noting any similarities in shape, size, and position.

- Take note of any markings or numbers on the component that may correlate with the visual guide.

| Component | Common Issues | Replacement Tips |

|---|---|---|

| Impeller | Clogs, wear | Ensure correct fit and alignment during installation. |

| Drive Belt | Fraying, slipping | Check tension and replace if necessary. |

| Housing | Dents, cracks | Inspect for integrity; repair or replace if damaged. |

Replacing Worn-Out Components

Maintaining optimal functionality in your equipment requires timely replacement of degraded elements. Over time, various components may wear down, leading to decreased performance and potential malfunctions. Addressing these issues promptly can help ensure the longevity and efficiency of your machinery.

Identifying worn-out parts is crucial for effective maintenance. Look for signs such as:

- Visible damage or cracking

- Increased noise during operation

- Reduced efficiency or performance

- Unusual vibrations

Once you have pinpointed the components needing replacement, follow these steps:

- Gather necessary tools: Ensure you have all required tools at hand, including wrenches, screwdrivers, and replacement components.

- Turn off the machine: For safety, disconnect the power source before beginning any repairs.

- Remove the damaged components: Carefully detach the worn parts, noting how they are connected for reassembly.

- Install new components: Position the new parts in place and secure them according to the manufacturer’s specifications.

- Test the equipment: After reassembly, power on the machine to ensure everything functions correctly.

Regularly replacing outdated elements not only enhances performance but also minimizes the risk of future complications. Establish a maintenance schedule to routinely check and address wear in your machinery.

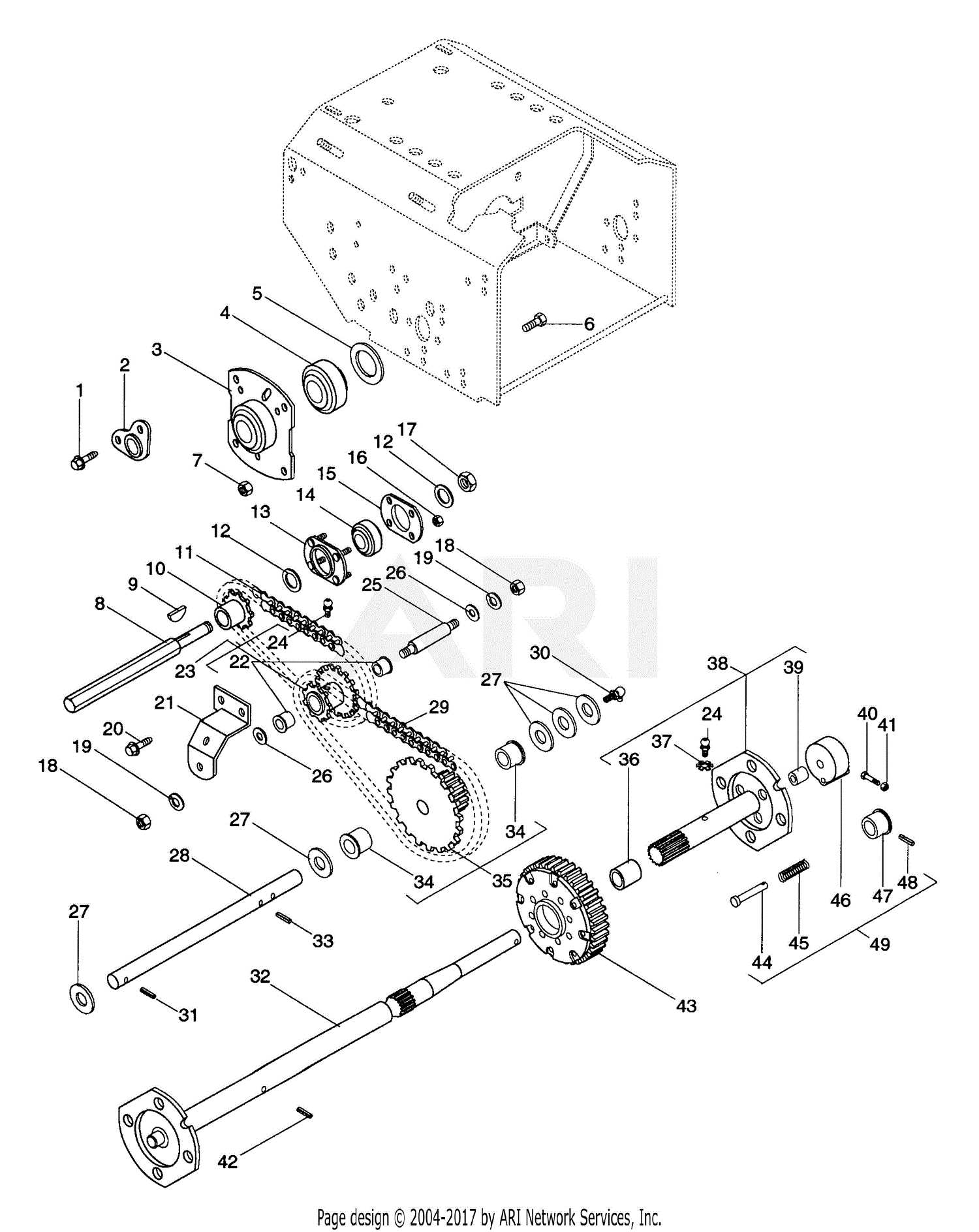

Understanding the Snowblower’s Mechanics

The operation of a snow-clearing machine relies on a variety of intricate mechanisms working in harmony. Comprehending how these elements interact is crucial for effective maintenance and troubleshooting.

At the heart of this equipment lies a powerful engine that drives the entire system. Here are some key components involved in its operation:

- Engine: Provides the necessary power to propel the unit and drive the throwing mechanism.

- Auger: The rotating blade that collects snow and feeds it into the discharge chute.

- Impeller: Moves the gathered snow from the auger and expels it through the chute.

- Chassis: The frame that houses and supports all components, ensuring stability during operation.

Understanding the relationships between these components can enhance performance and extend the lifespan of the machinery. Regular inspection and maintenance of these parts will ensure optimal functionality and prevent potential issues.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that fit perfectly and function as intended.

One of the best places to start your search is through the official dealer network. Authorized retailers provide a wide range of original components and often have knowledgeable staff who can assist you in identifying the correct items for your machine.

Another option is to explore specialized online retailers. Numerous websites are dedicated to supplying genuine components, allowing you to browse extensive catalogs from the comfort of your home. When choosing an online source, ensure it has a good reputation and positive customer reviews.

Additionally, local repair shops often carry a selection of original components or can order them for you. Establishing a relationship with a trustworthy technician can provide you with valuable insights and recommendations on where to find the necessary items.

Lastly, consider checking manufacturer websites. Many provide online resources and tools that help you identify and order the right components directly.

DIY Repair vs. Professional Service

When it comes to maintaining and fixing outdoor equipment, individuals often face the choice between tackling repairs themselves or seeking the help of professionals. Each approach has its own set of advantages and challenges that can influence the outcome of the repair process.

Opting for a do-it-yourself approach can be a rewarding experience, allowing owners to save on labor costs while gaining hands-on experience with their equipment. However, this method requires a certain level of skill, knowledge, and access to the necessary tools. Mistakes made during self-repairs can lead to further complications, potentially resulting in higher costs down the line.

On the other hand, hiring a professional service provides the benefit of expertise and efficiency. Trained technicians possess the experience and tools to diagnose and resolve issues quickly. This can alleviate stress for owners who may feel uncertain about their ability to perform repairs correctly. However, the associated costs can be a drawback for some, especially if the repair is minor.

Ultimately, the decision between DIY repairs and professional assistance depends on the individual’s comfort level with technical tasks, the complexity of the repair, and budget considerations. Evaluating these factors can help ensure the best outcome for maintaining outdoor machinery.

Helpful Tools for Snowblower Repairs

Having the right tools is essential for maintaining and fixing your winter equipment effectively. Proper instruments not only simplify the process but also enhance safety and efficiency. Here are some essential tools that can help with various maintenance tasks.

Essential Hand Tools

- Wrenches: Adjustable and socket wrenches are necessary for loosening and tightening bolts.

- Screwdrivers: A set of flathead and Phillips screwdrivers is crucial for removing and securing screws.

- Pliers: These are useful for gripping and bending components that need adjustment.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

Power Tools for Efficiency

- Drill: A cordless drill can make the process of removing and installing screws faster and easier.

- Impact Wrench: Perfect for quickly removing stubborn bolts.

- Angle Grinder: Useful for cutting and shaping metal parts if modifications are needed.

- Heat Gun: Can help in loosening rusted components and speeding up adhesive removal.

Seasonal Preparations for Snow Removal

As winter approaches, it is essential to prepare your equipment and surroundings for effective snow management. Proper readiness not only ensures efficiency but also enhances safety during harsh weather conditions. Taking the time to assess and maintain your machinery can make a significant difference when the snow starts to accumulate.

Begin by inspecting all tools and machinery that will be utilized for clearing pathways and driveways. This involves checking for wear and tear, ensuring that all components function correctly, and replacing any damaged parts. Additionally, it’s wise to have a stock of essential supplies on hand, such as fuel and lubricants, to avoid any interruptions during operation.

| Task | Description | Frequency |

|---|---|---|

| Equipment Inspection | Check for functionality and signs of damage | Before the season |

| Lubrication | Apply oil to moving parts to ensure smooth operation | Before use |

| Supply Check | Inventory fuel and other necessary materials | Monthly |

| Snow Removal Practice | Familiarize yourself with equipment operation | Seasonally |

Finally, familiarize yourself with your neighborhood’s snow removal policies and local regulations. Understanding these guidelines will help ensure that your efforts contribute positively to the community and comply with any legal requirements.

Customer Reviews of John Deere Models

This section explores user feedback regarding various models of outdoor equipment, focusing on performance, durability, and overall satisfaction. Customers often share their experiences, highlighting the strengths and weaknesses of different machinery.

Many users appreciate the efficiency and reliability of their equipment, noting how well it handles various tasks. The robust design and ease of use are frequently mentioned, making it a preferred choice for both residential and commercial applications.

However, some reviews point out areas for improvement, such as the need for better customer service support and availability of replacement components. Users have expressed that while the machinery performs well, accessing service or parts can sometimes be challenging.

Overall, feedback from customers reflects a blend of admiration for the equipment’s capabilities and constructive criticism aimed at enhancing user experience and service options.