Maintaining optimal performance during the cold months is essential for any machinery designed to clear snow and ice. Familiarity with the individual elements that comprise such equipment can significantly enhance its efficiency and longevity. By grasping the relationships between these components, operators can troubleshoot issues more effectively and ensure seamless operation.

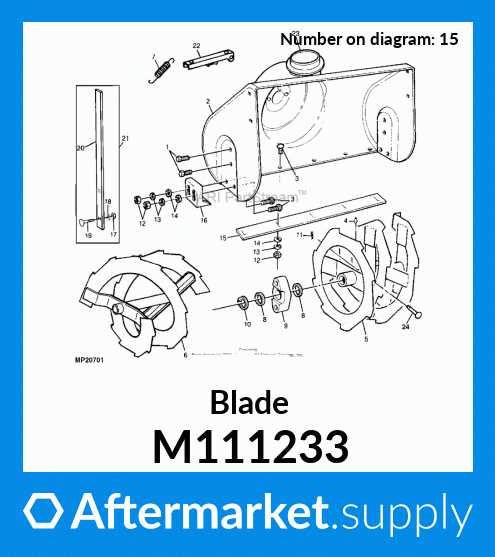

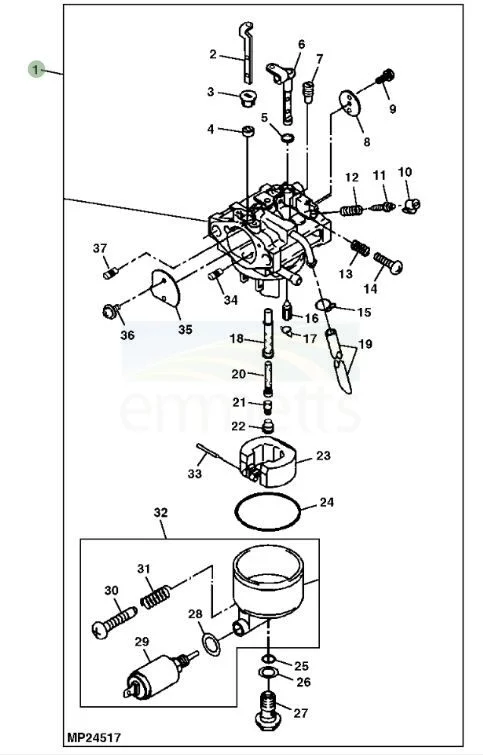

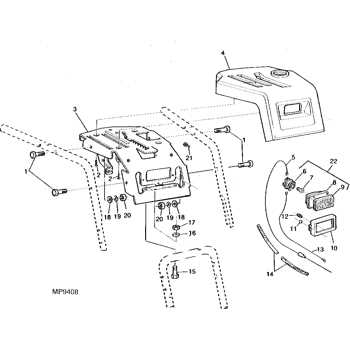

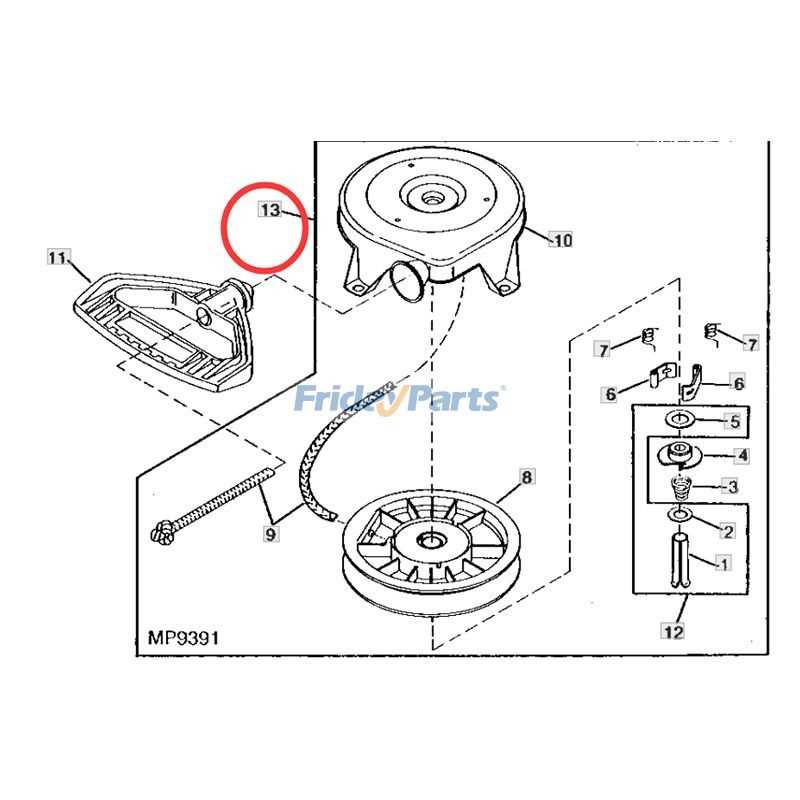

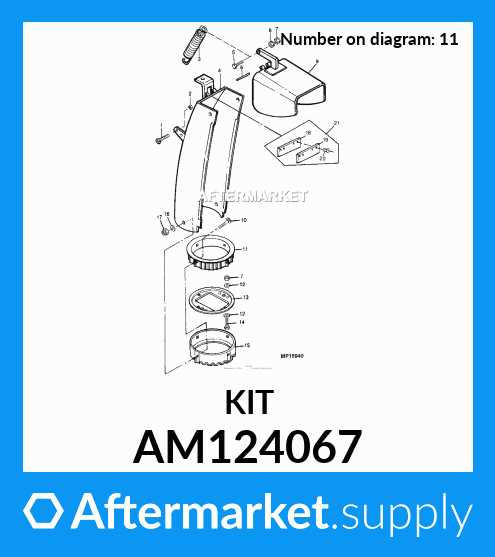

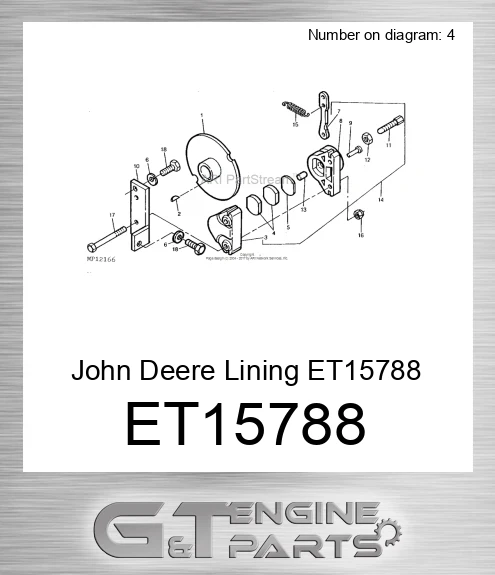

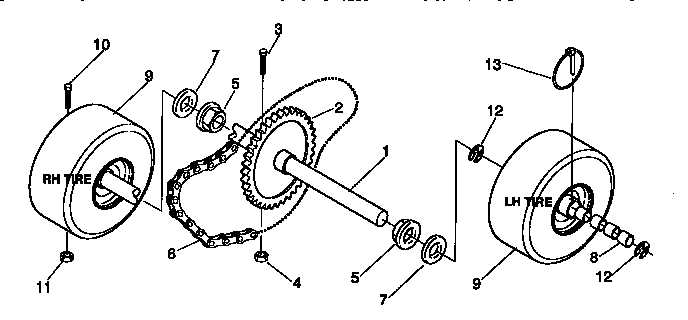

For enthusiasts and professionals alike, visual aids that illustrate the various sections and mechanisms are invaluable. These resources provide clear guidance on assembly, disassembly, and potential repairs. Understanding how each piece interacts with others not only aids in maintenance but also fosters a deeper appreciation for the engineering involved.

Whether you’re a seasoned user or new to winter clearing tools, having access to a comprehensive visual reference can demystify the complexities of your machinery. With this knowledge, users can confidently address problems and enhance their equipment’s performance during the harshest weather conditions.

Understanding John Deere TRS27 Features

When it comes to efficient winter equipment, several features stand out, enhancing usability and performance. These characteristics not only contribute to effective operation but also ensure a seamless experience during harsh weather conditions.

Key Characteristics

- Powerful Engine: Provides robust performance for clearing snow quickly.

- Adjustable Chute: Allows precise control of snow direction and distance.

- Ergonomic Design: Ensures user comfort during prolonged use.

- Durable Build: Made from high-quality materials to withstand tough conditions.

Performance Enhancements

- Multiple Speed Settings: Offers versatility for different snow conditions.

- Headlight: Improves visibility during early mornings or late evenings.

- Easy Maneuverability: Designed for smooth navigation, even in tight spaces.

- Self-Propelled Function: Reduces user effort and increases efficiency.

Importance of Snowblower Maintenance

Proper upkeep of your winter clearing equipment is essential for optimal performance and longevity. Regular attention ensures that the machine operates efficiently, preventing breakdowns during critical times.

Benefits of Regular Maintenance

- Enhances efficiency, reducing fuel consumption.

- Minimizes the risk of unexpected failures.

- Extends the lifespan of components.

- Ensures safety while in use.

Key Maintenance Practices

- Regularly check and change the oil.

- Inspect and replace the spark plug as needed.

- Clear any debris from the chute and housing.

- Examine belts and cables for wear.

Identifying Common TRS27 Issues

Recognizing prevalent challenges with outdoor power equipment can significantly enhance performance and extend longevity. By understanding typical symptoms and their causes, users can take proactive measures to maintain functionality.

- Starting Problems:

Difficulty in initiating the engine can stem from various sources, including:

- Clogged fuel lines

- Weak battery

- Faulty spark plugs

- Inadequate Power:

Insufficient output may be caused by:

- Blocked air filters

- Worn-out belts

- Improper fuel mixture

- Unusual Noises:

Strange sounds can indicate:

- Loose components

- Worn bearings

- Improperly adjusted settings

Regular inspections can help detect these issues early, ensuring optimal operation and safety during use.

Parts Replacement Tips and Tricks

Maintaining your equipment effectively involves knowing how to replace essential components efficiently. This section provides valuable insights to streamline the replacement process, ensuring optimal performance and longevity.

1. Identify the Right Components: Before starting, confirm that you have the correct components for your machine. Refer to your owner’s manual or trusted online resources to avoid any compatibility issues.

2. Gather the Necessary Tools: Ensure you have all required tools at hand, such as wrenches, screwdrivers, and pliers. Having everything ready minimizes downtime during the replacement process.

3. Follow Step-by-Step Guides: Utilize detailed guides or videos to follow along. These resources can help you navigate through the replacement, making it easier to understand each step.

4. Take Notes: If disassembling multiple parts, take notes or photos to keep track of the original setup. This practice will assist in reassembly, ensuring nothing is overlooked.

5. Safety First: Always prioritize safety by disconnecting power sources and wearing appropriate gear. A cautious approach prevents accidents and promotes a safer working environment.

6. Test Thoroughly: After replacing components, perform a thorough test to confirm proper function. This step is crucial to ensure that everything operates smoothly before returning to regular use.

Locating Official John Deere Diagrams

Finding authentic illustrations and schematics for machinery can significantly enhance maintenance and repair efforts. Official resources provide detailed visuals that assist users in identifying components and understanding assembly processes. Accessing these materials ensures accuracy and reliability, which are crucial for effective troubleshooting and service.

To obtain these essential references, users can visit the manufacturer’s official website, where a dedicated section for technical resources is typically available. This section often includes a search function, allowing for easy navigation based on model numbers or machine types. Additionally, authorized dealers may provide printed manuals and online access to digital resources, making it convenient to retrieve necessary information.

Furthermore, online forums and community groups focused on equipment maintenance can be valuable. Members often share links to official materials and may even post their own compilations. Engaging with these communities can lead to discovering helpful resources that may not be immediately obvious through official channels.

Essential Tools for Repairs

Having the right instruments is crucial for efficient maintenance and restoration tasks. These tools not only facilitate the repair process but also ensure safety and precision.

- Wrenches: Ideal for loosening and tightening bolts.

- Screwdrivers: Necessary for handling various types of screws.

- Pliers: Useful for gripping and bending materials.

- Socket Set: Provides a range of sizes for effective fastening.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Oil Can: Important for lubrication during assembly.

Equipping your workspace with these essential items will enhance your ability to delve into any repair task confidently.

Step-by-Step Assembly Instructions

Assembling your equipment can be a straightforward process when approached methodically. Each component plays a crucial role, and understanding their arrangement ensures optimal functionality. Follow these sequential steps to effectively construct your machine.

Step 1: Begin by gathering all necessary components and tools. Verify that you have everything required for assembly to avoid interruptions.

Step 2: Start with the base unit. Secure the lower frame using the provided fasteners, ensuring stability before moving to the next section.

Step 3: Attach the drive mechanism, aligning it with the designated slots. Make certain that all connections are tight and properly fitted.

Step 4: Proceed to connect the control panel. Ensure that the wiring is managed neatly, preventing any interference with moving parts.

Step 5: Finally, install the exterior casing. Double-check all screws and bolts for tightness, confirming that everything is securely in place.

Once completed, conduct a thorough inspection to ensure that the assembly meets all operational standards. With everything in order, you are ready to use your equipment effectively.

Upgrading Your Snowblower Performance

Enhancing the efficiency of your winter equipment can significantly improve its functionality and reliability. By focusing on key components and implementing specific upgrades, you can ensure that your machine operates at its highest capacity during harsh weather conditions. This guide will explore various methods to boost performance and durability.

Improving Power and Efficiency

One of the most effective ways to enhance performance is by upgrading the engine. Opting for a higher horsepower model or tuning the existing engine can lead to better snow-clearing capabilities. Additionally, regularly maintaining the fuel system can improve combustion efficiency, resulting in a more powerful operation.

Enhancing Maneuverability and Control

To maximize handling, consider upgrading the tires or tracks. High-traction options provide better grip on icy surfaces, allowing for smoother navigation. Furthermore, installing ergonomic controls can significantly improve user experience, making operation easier and more intuitive.

Where to Buy Genuine Parts

Acquiring authentic components is essential for maintaining the longevity and efficiency of your machinery. Utilizing original replacements ensures optimal performance and durability, reducing the risk of malfunction or damage over time.

Authorized Dealers

One of the most reliable sources for acquiring genuine components is through authorized dealerships. These vendors are equipped with comprehensive inventories and provide assurance that you are receiving authentic items that meet the manufacturer’s specifications.

Online Retailers

Another convenient option is to explore various online platforms. Numerous e-commerce sites specialize in authentic equipment, offering a wide range of products. Always verify the seller’s reputation and ensure they provide a guarantee for the items sold to avoid counterfeit alternatives.

Remember that using original components not only enhances performance but also helps maintain the warranty of your equipment. Investing in quality is always a wise decision.

Safety Precautions During Operation

Ensuring safety while operating equipment is crucial for preventing accidents and injuries. By following proper guidelines, users can minimize risks associated with handling machinery. Awareness of potential hazards and adherence to recommended practices are essential for a secure operating environment.

Essential Guidelines

Before starting any task, it is important to review and implement the following safety measures:

| Precaution | Description |

|---|---|

| Read the Manual | Familiarize yourself with the operation manual to understand the machine’s features and safety instructions. |

| Wear Protective Gear | Always use appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. |

| Check for Obstacles | Inspect the area for debris or obstacles before starting, ensuring a clear path for operation. |

| Avoid Loose Clothing | Wear fitted clothing to prevent any parts from getting caught in moving components. |

| Stay Alert | Maintain focus while operating; avoid distractions that could lead to mishaps. |

Emergency Procedures

In case of an emergency, being prepared can significantly reduce risks:

| Action | Details |

|---|---|

| Know the Shutdown Process | Be aware of how to quickly turn off the machine in case of malfunction. |

| Keep First Aid Kit Accessible | Ensure that a first aid kit is nearby and easily reachable in case of an injury. |

| Report Hazards | Immediately inform others about any potential dangers or mechanical issues. |