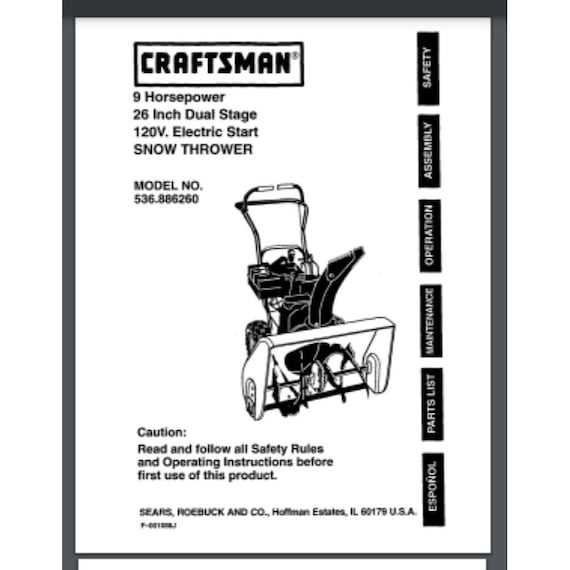

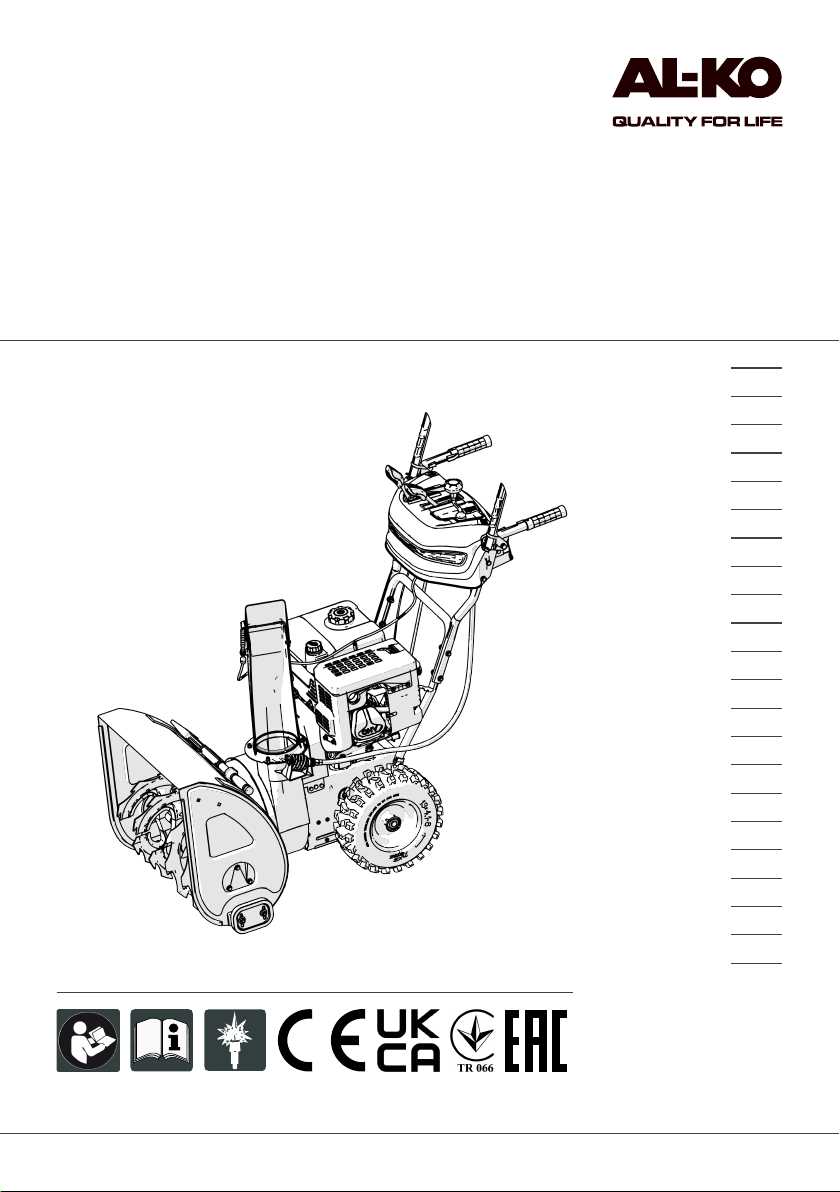

When it comes to maintaining outdoor machinery designed for winter weather, understanding the various elements involved is essential for optimal performance. This section aims to shed light on the intricate components that make up these powerful machines, ensuring that users can easily identify and comprehend each element’s role in the overall functionality.

By gaining insight into the layout and arrangement of these key elements, operators can better manage their equipment and troubleshoot issues that may arise during operation. The relationship between each component is crucial, as it influences both efficiency and reliability, which are paramount when tackling challenging conditions.

Furthermore, having a clear understanding of how these elements interact allows users to make informed decisions regarding maintenance and repairs. Whether you’re a seasoned user or new to this type of machinery, familiarizing yourself with the essential aspects of your equipment will enhance your experience and ensure it serves you well throughout the winter months.

Regular upkeep of winter machinery is crucial for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also significantly reduces the risk of unexpected breakdowns during critical times. By implementing a consistent maintenance routine, users can enjoy reliable operation when it matters most.

Benefits of Regular Upkeep

- Increased Reliability: Consistent care minimizes the likelihood of malfunctions, providing peace of mind during harsh weather conditions.

- Enhanced Performance: Well-maintained equipment operates more effectively, making tasks easier and quicker to accomplish.

- Cost Savings: Preventive maintenance can help avoid costly repairs and extend the lifespan of machinery.

Key Maintenance Practices

- Check and change oil regularly to keep the engine running smoothly.

- Inspect belts and cables for wear and tear, replacing them as needed.

- Clean air filters to ensure optimal airflow and performance.

- Sharpen blades to enhance cutting efficiency.

- Store equipment properly during off-seasons to protect against environmental damage.

By prioritizing these maintenance tasks, users can ensure their winter machinery remains in peak condition, ready to tackle challenging conditions efficiently and effectively.

Common Issues with Snow Blowers

In regions that experience harsh winter conditions, these powerful machines are essential for clearing pathways and driveways. However, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems can help in effective troubleshooting and maintenance.

Frequent Problems

- Starting Difficulties: Many users find it challenging to start their machines, especially after prolonged periods of inactivity. This can be due to fuel issues, battery problems, or ignition system malfunctions.

- Clogging: A common issue is the buildup of snow and ice in the chute, leading to inefficient operation and possible damage. Regular cleaning is essential to prevent this.

- Uneven Clearing: Inconsistent performance may result in untrimmed areas, often caused by worn-out components or improper height settings.

Preventive Measures

- Perform regular maintenance checks to ensure all parts are in good condition.

- Store the unit in a dry place to prevent moisture buildup and rust.

- Use high-quality fuel and oil to enhance performance and longevity.

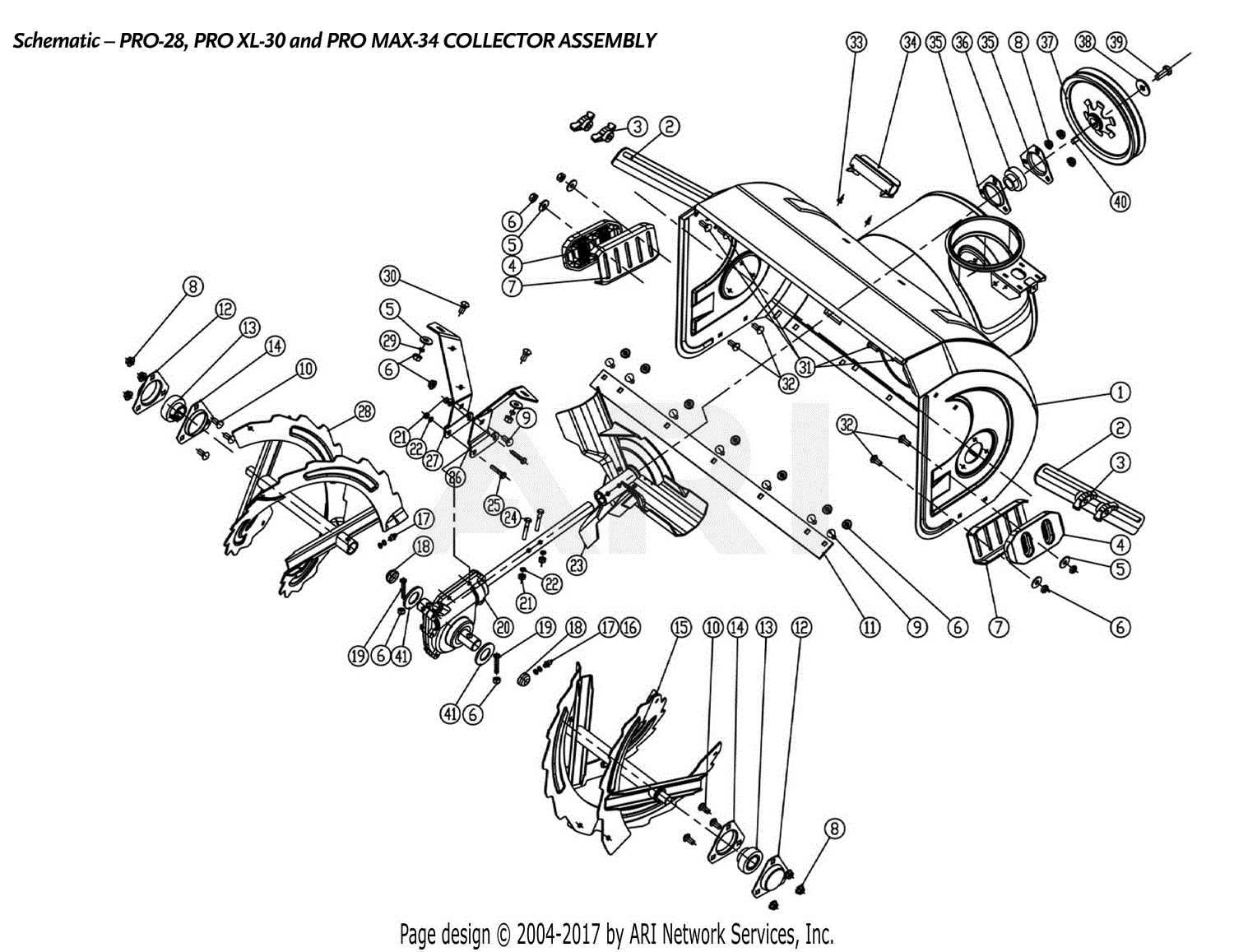

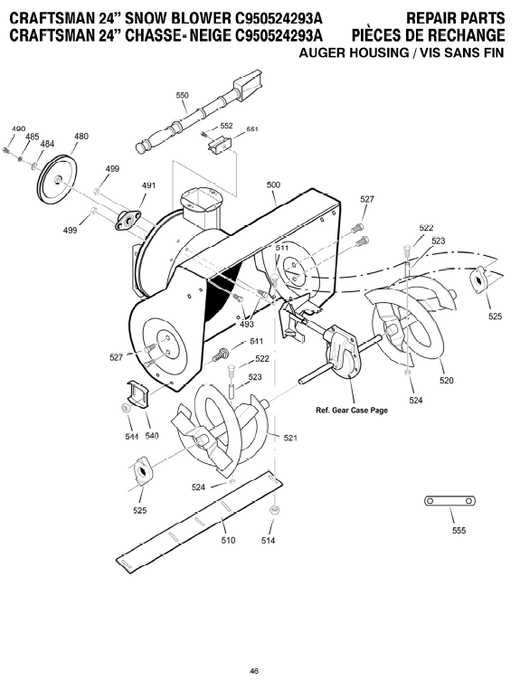

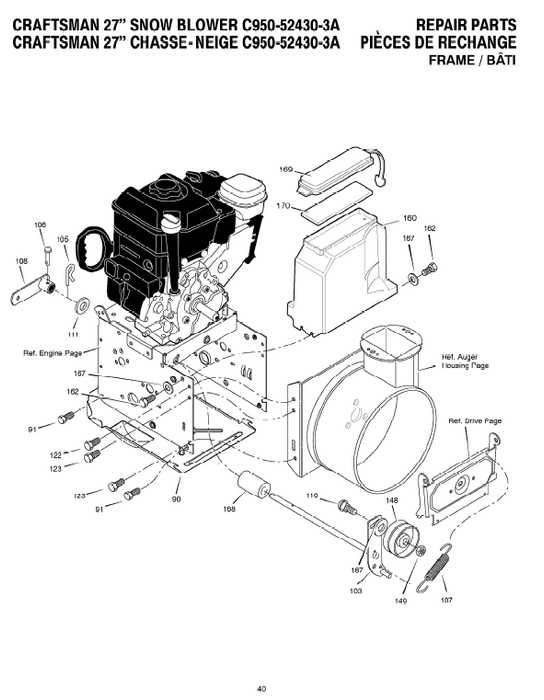

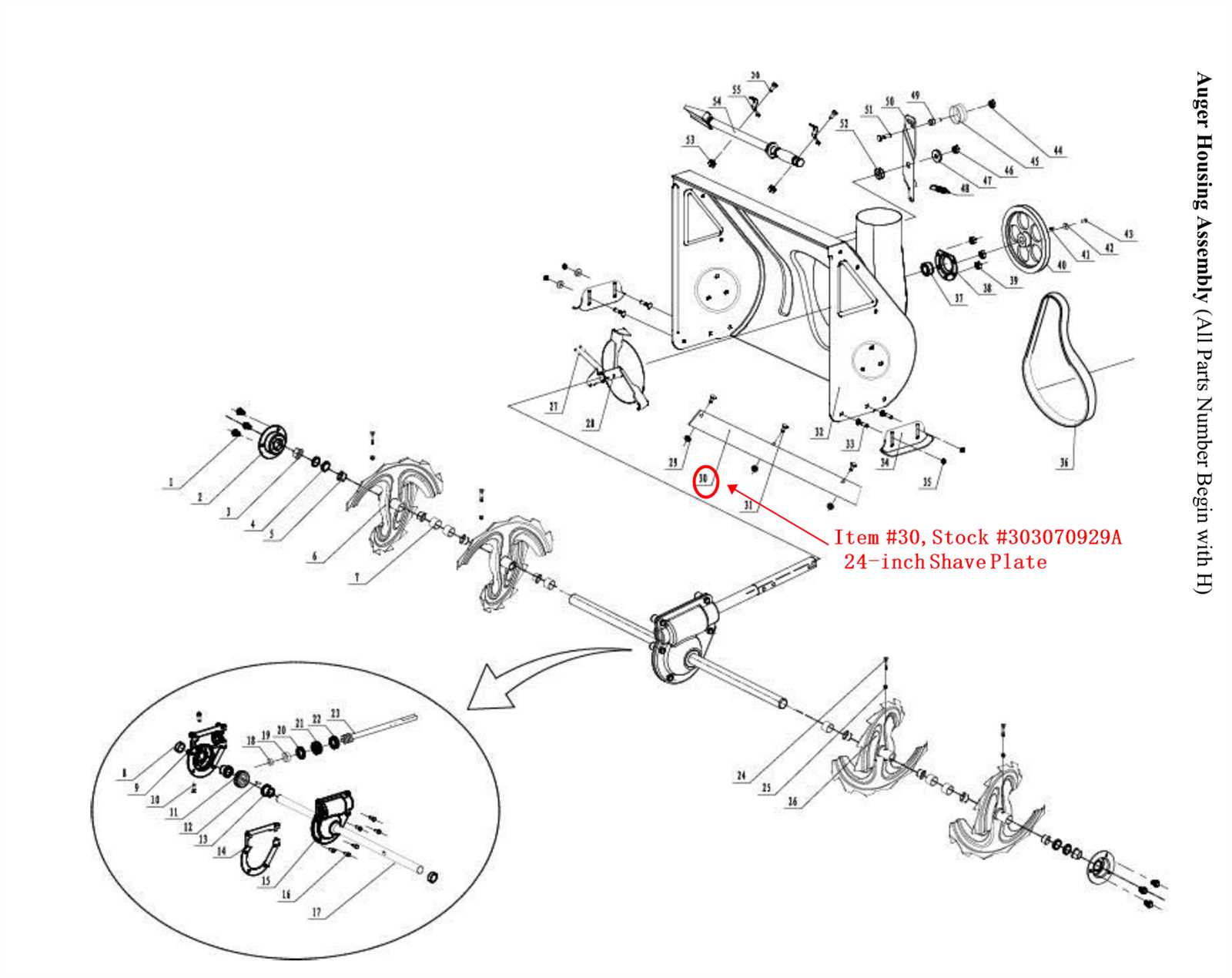

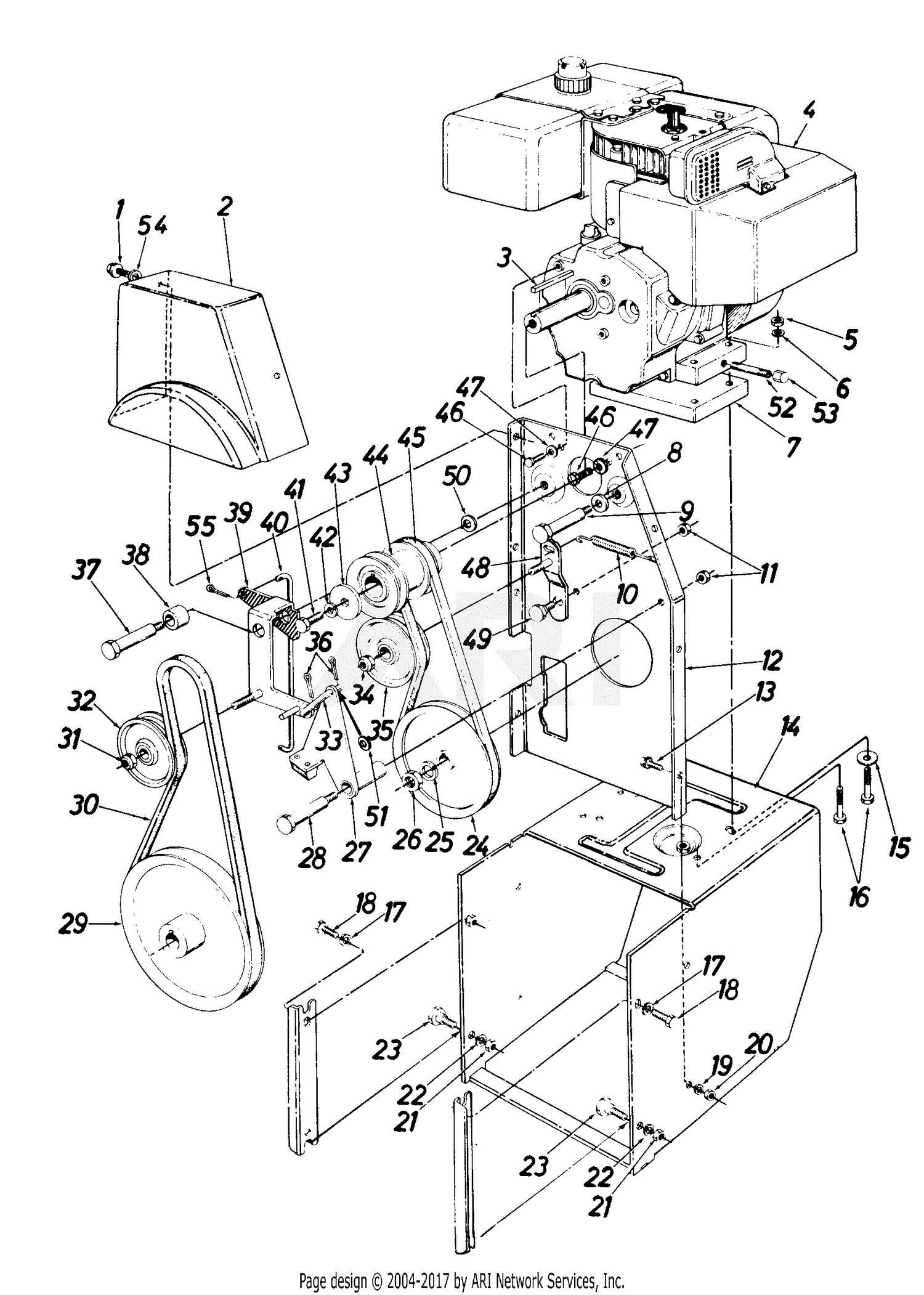

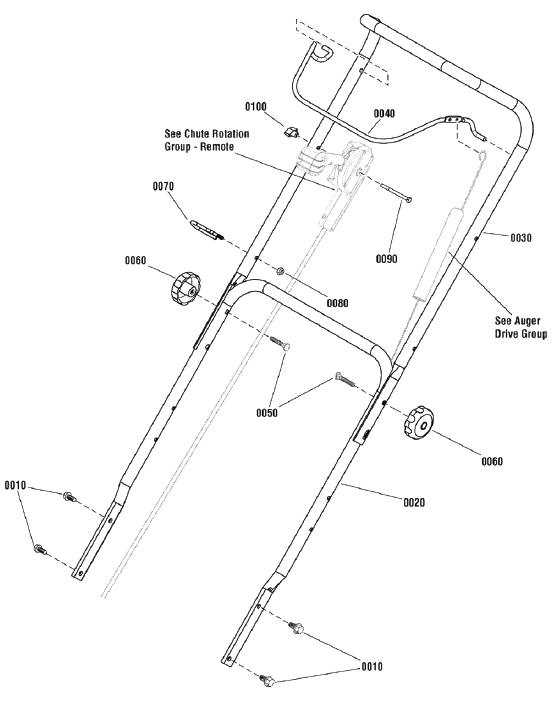

Identifying Essential Parts of Snow King

Understanding the critical components of a winter maintenance machine is vital for ensuring optimal performance and longevity. Each element plays a significant role in the overall functionality, making it essential to recognize their specific functions and how they interact with one another.

Engine: The heart of the unit, this component generates the power needed to operate effectively. Regular maintenance of the engine is crucial for reliable performance during harsh weather conditions.

Auger: This rotating element is responsible for breaking up and collecting the frozen precipitation. Its design and material significantly influence how well it can handle various types of accumulated snow.

Chute: The discharge chute directs the cleared material away from the machine. Adjusting the chute’s angle allows for better control of where the debris is expelled, enhancing maneuverability.

Gear System: The mechanism that enables the machine to move forward or backward, providing essential mobility. Proper maintenance of this system ensures smooth transitions between different speed settings.

Handlebars: These provide the operator with control over the device. Ergonomically designed handlebars can reduce strain during operation and improve overall user experience.

Fuel System: This system ensures the engine receives the necessary fuel for operation. Keeping it clean and functional is vital for optimal performance and efficiency.

By familiarizing oneself with these essential components, users can better understand maintenance requirements and troubleshoot potential issues, leading to a more efficient and effective winter maintenance experience.

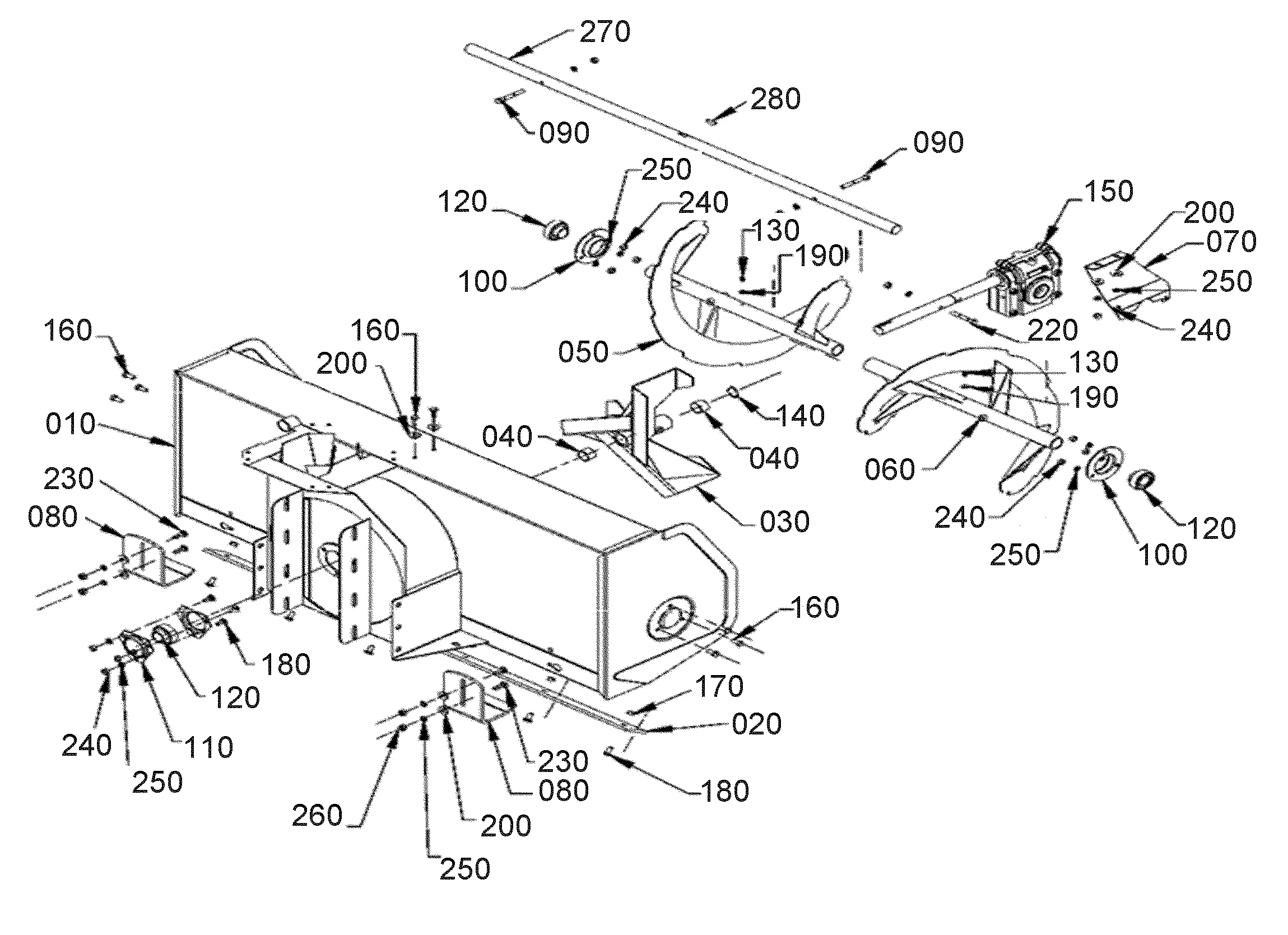

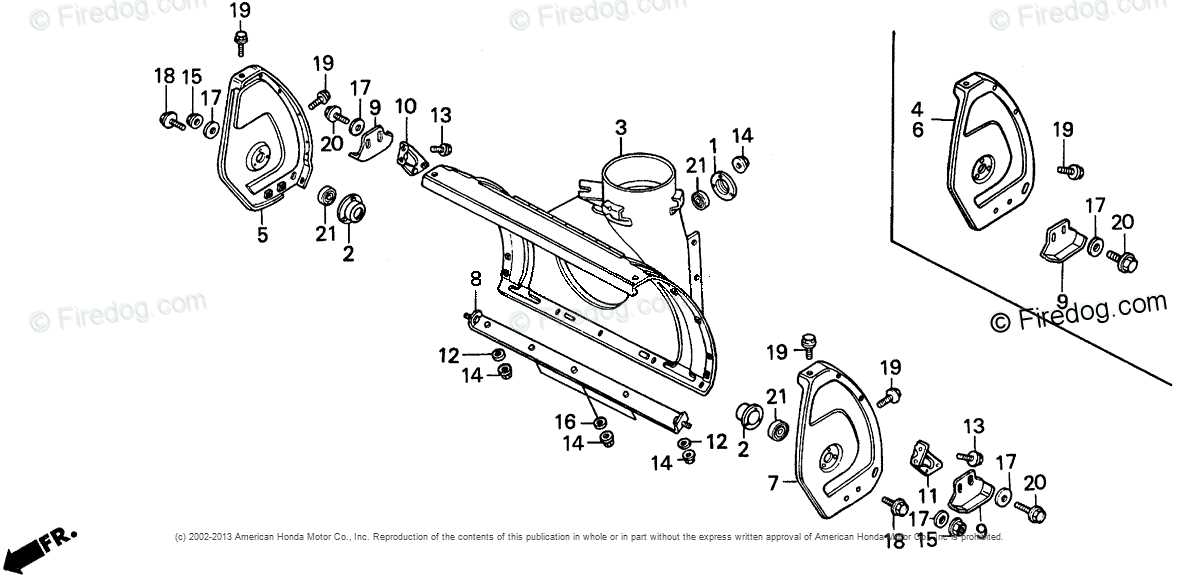

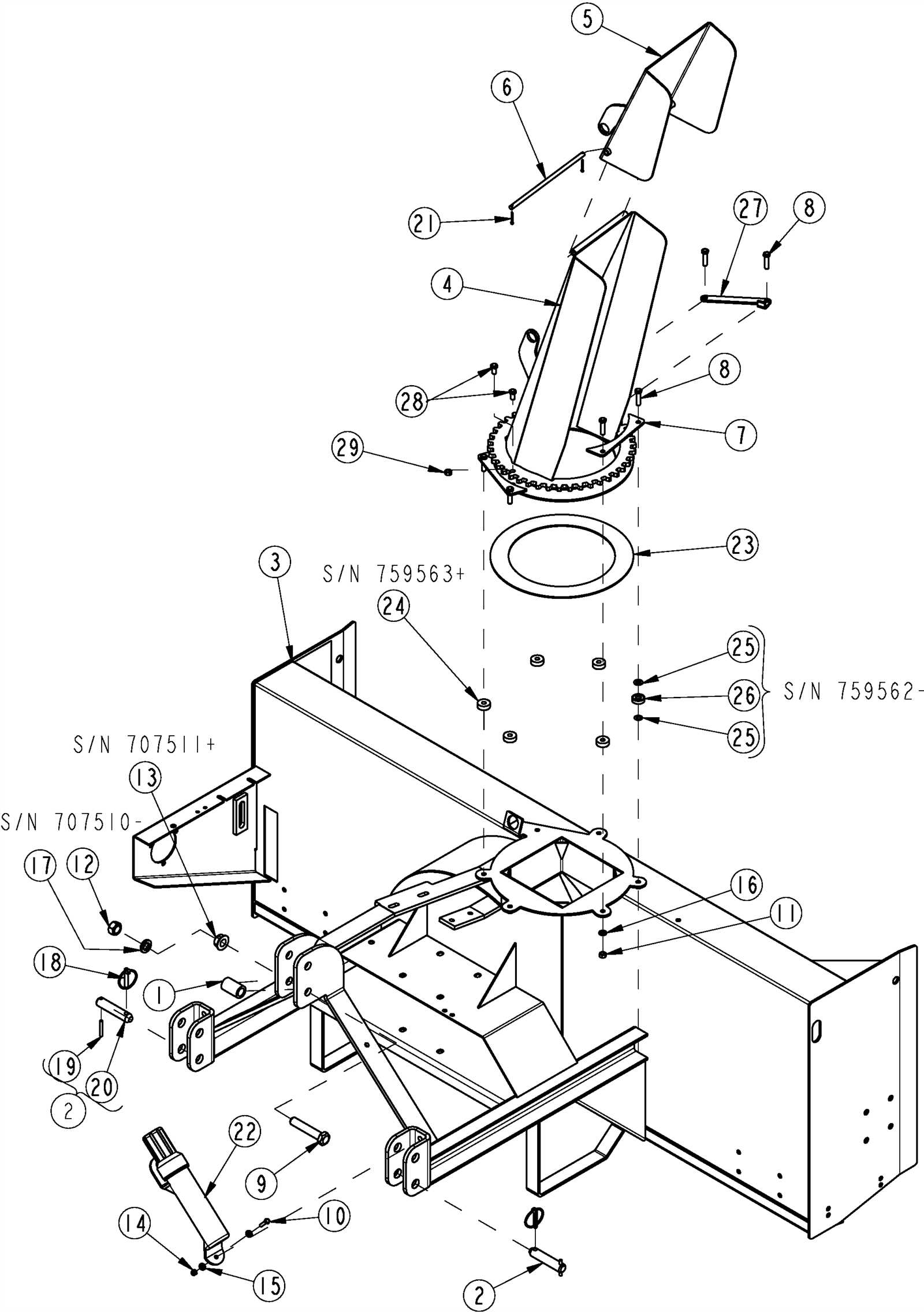

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effectively maintaining and repairing equipment. These visual representations provide a clear overview of components and their relationships, making it easier to identify the necessary elements for repairs or replacements.

To effectively interpret these illustrations, follow these guidelines:

- Familiarize Yourself with Symbols: Each illustration often uses specific icons or symbols to represent different components. Knowing these symbols helps in quickly locating parts.

- Identify the Sections: Most illustrations are divided into sections based on function or location. Take note of these divisions to better understand how components interact.

- Refer to the Legend: Many diagrams include a legend that explains the symbols and numbering used. Always check this section for clarification.

- Follow the Numbering: Components are usually numbered for easy reference. Use these numbers when ordering or discussing specific parts with suppliers or service centers.

- Observe Connections: Pay attention to how parts connect with one another. Understanding these relationships is crucial for reassembly and troubleshooting.

By mastering these skills, you’ll enhance your ability to manage equipment effectively and ensure its longevity.

Replacing Worn Components Safely

Maintaining the efficiency of your outdoor equipment is essential for optimal performance. Over time, certain elements may wear down, necessitating replacement to ensure smooth operation. This section focuses on the importance of safely replacing these aged components to enhance durability and functionality.

Before starting the replacement process, consider the following precautions:

- Ensure the equipment is powered off and disconnected from any electrical source.

- Use appropriate personal protective equipment, including gloves and safety goggles.

- Consult the user manual for specific instructions regarding the components you are replacing.

When replacing the old components, follow these guidelines:

- Identify the worn components by visually inspecting the unit for any signs of damage or wear.

- Carefully remove the damaged parts, taking note of how they are installed.

- Install the new components, ensuring they are securely fastened and aligned correctly.

- Double-check all connections and fittings to confirm they are tight and secure.

After completing the replacement, perform a thorough check of the entire assembly to confirm everything is in order. This diligence not only prolongs the life of your equipment but also ensures safe operation for future use.

Tools Needed for Snow Blower Repairs

Maintaining and fixing outdoor equipment requires a selection of essential implements. Understanding which tools to have on hand can significantly simplify the repair process and enhance efficiency. Whether performing routine maintenance or addressing specific issues, the right equipment is crucial for effective troubleshooting and repairs.

Basic Hand Tools: A set of screwdrivers, wrenches, and pliers are indispensable for disassembling components and making necessary adjustments. Ensure you have both flathead and Phillips screwdrivers, along with various sizes of wrenches to accommodate different fasteners.

Specialty Tools: Some repairs may necessitate unique tools such as a torque wrench, which is essential for tightening bolts to the manufacturer’s specifications. Additionally, having a spark plug socket can make replacing ignition components easier.

Safety Gear: Prioritizing safety during repairs is paramount. Equip yourself with safety goggles, gloves, and a dust mask to protect against debris and hazardous materials.

Cleaning Supplies: Keeping the equipment clean is vital for its longevity. Brushes, rags, and cleaning solutions help remove dirt and grime, ensuring smooth operation.

Equipped with these tools and accessories, you will be well-prepared to tackle any repair tasks that arise, ensuring your outdoor equipment remains in optimal working condition.

When to Consult a Professional

Knowing when to seek the expertise of a trained technician can be crucial for maintaining the functionality of your equipment. While some issues can be resolved through basic troubleshooting and minor repairs, others may require specialized knowledge and tools to ensure proper resolution.

Identifying Complex Issues

If you encounter problems that are beyond your understanding or require intricate repairs, it’s advisable to consult a professional. This is particularly important when you notice unusual noises, performance drops, or any malfunction that persists despite your attempts at resolution.

Safety Considerations

Safety should always be a priority when handling machinery. If you’re unsure about the safety protocols or if a task involves potentially hazardous components, it’s best to defer to a qualified technician. This ensures not only your well-being but also the integrity of your equipment.

| Signs to Seek Help | Possible Implications |

|---|---|

| Unusual Noises | Could indicate mechanical failure |

| Frequent Breakdowns | May signal deeper systemic issues |

| Inconsistent Performance | Suggests possible underlying faults |

| Complex Repairs Needed | Requires expertise beyond basic maintenance |

Seasonal Maintenance Tips for Performance

Regular upkeep is essential for ensuring optimal functioning of your outdoor equipment throughout the changing seasons. By following a structured maintenance routine, you can enhance reliability, extend the lifespan of your machine, and ensure it operates at peak efficiency when needed the most.

Begin by inspecting all mechanical components for wear and tear, addressing any issues before they escalate. Lubrication of moving parts is crucial to reduce friction and prevent premature damage. Additionally, cleaning debris from critical areas will help maintain airflow and overall performance.

It is also advisable to check fluid levels, including oil and fuel, ensuring they meet the manufacturer’s recommendations. Replace filters as necessary to promote cleanliness and efficient operation. Furthermore, sharpen or replace cutting elements as needed to maximize effectiveness during use.

Finally, store your equipment in a dry, sheltered location when not in use. Protecting it from harsh environmental conditions can prevent rust and corrosion, ensuring it remains ready for action when the time comes.

Finding Replacement Parts Online

Locating components for your equipment has become increasingly convenient thanks to the vast resources available on the internet. By utilizing online platforms, users can effortlessly search for specific items that match their requirements. This section will guide you through effective strategies for acquiring essential components efficiently.

When beginning your search, consider the following steps:

- Identify the model and specifications of your equipment to ensure compatibility.

- Utilize reputable websites that specialize in equipment components, as they often provide detailed listings and diagrams.

- Read customer reviews and ratings to gauge the reliability of the seller and the quality of the products.

- Take advantage of online forums and communities where fellow users share their experiences and recommendations.

Key aspects to keep in mind during your search include:

- Price comparison across multiple platforms to find the best deals.

- Checking for warranties or return policies to safeguard your purchase.

- Ensuring that the website has secure payment options to protect your personal information.

- Looking for additional resources, such as installation guides or videos, to aid in the replacement process.

By following these guidelines, you can streamline your search for necessary components and enhance the performance and longevity of your equipment.

Upgrades to Enhance Snow Blower Efficiency

Improving the performance of your equipment can significantly increase its productivity and longevity. By incorporating specific enhancements, you can ensure that your machine operates at peak efficiency, ultimately saving time and effort during winter tasks. Below are some recommended upgrades that can make a substantial difference in performance.

- High-Quality Blades: Upgrading to superior blades can enhance cutting efficiency, allowing for smoother operation and better snow clearance.

- Enhanced Engine Oil: Using synthetic oil can improve engine performance and reduce wear, especially in colder temperatures.

- Improved Tire Traction: Installing tires with better grip will provide increased stability and control on icy surfaces.

- Electric Start Feature: Adding an electric start mechanism can simplify the ignition process, especially in frigid conditions.

- Adjustable Chute: A chute with adjustable angles allows for more precise snow discharge, helping to direct snow away from driveways and walkways.

Implementing these upgrades not only enhances the functionality of your equipment but also contributes to a more efficient and enjoyable experience during winter maintenance. Regularly assessing and upgrading components can lead to improved results and less downtime.