When the cold months arrive, having a reliable tool to clear your pathways becomes essential. Grasping the inner workings of this machinery can enhance both performance and longevity. Familiarity with the individual elements not only aids in effective maintenance but also empowers users to tackle potential issues.

Breaking down the structure of your winter device allows for a deeper appreciation of its functionality. Each section plays a critical role, contributing to the overall efficiency and effectiveness of the equipment. Recognizing how these pieces interconnect can lead to more informed decisions during repairs and upgrades.

By delving into the specifics of each component, users can identify what to watch for in terms of wear and tear. Understanding the ultimate relationships between the various sections ensures a smoother operation and enhances your ability to handle any challenges that may arise during use.

Understanding Snowblower Components

In the realm of winter machinery, comprehending the various elements is crucial for effective operation and maintenance. Each component plays a vital role in ensuring efficiency, durability, and performance during snowy conditions.

Key Elements of Operation

Fundamental to the functionality of these machines are the mechanisms that drive movement and facilitate snow removal. The engine provides the necessary power, while the auger works to collect and direct the snow. These core components must work in harmony to achieve optimal results.

Maintenance Considerations

Regular upkeep of the individual elements is essential for longevity. Understanding the functionality of components such as the transmission and belt system can lead to timely interventions, preventing major issues and ensuring smooth operation throughout the winter months.

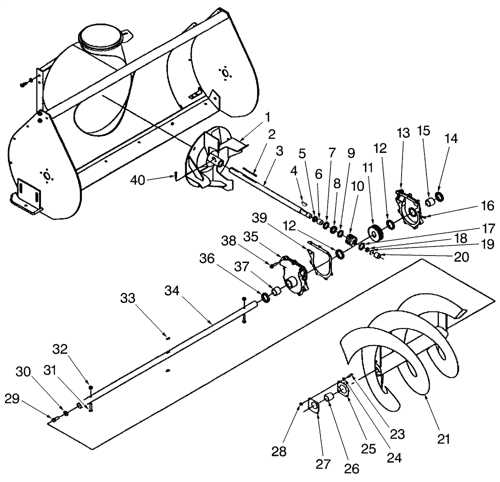

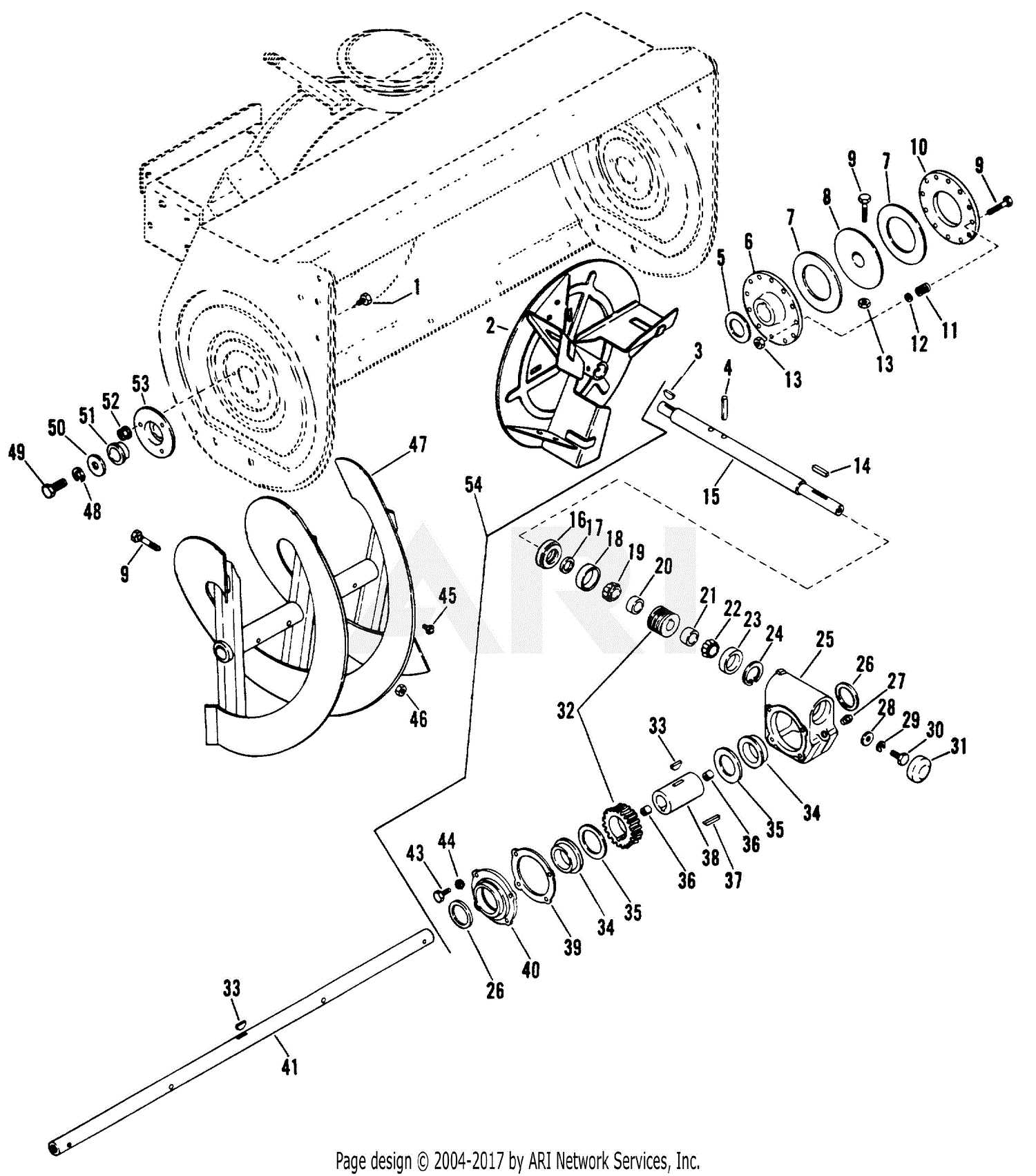

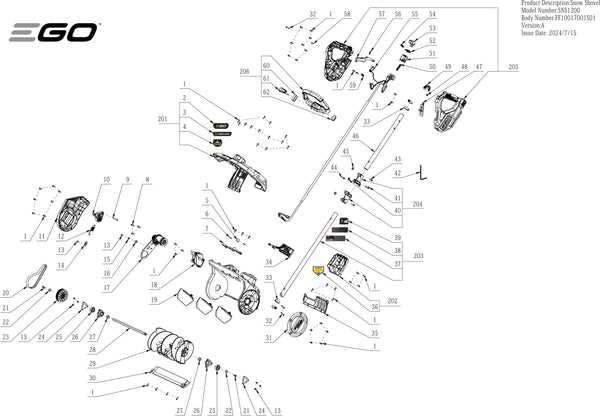

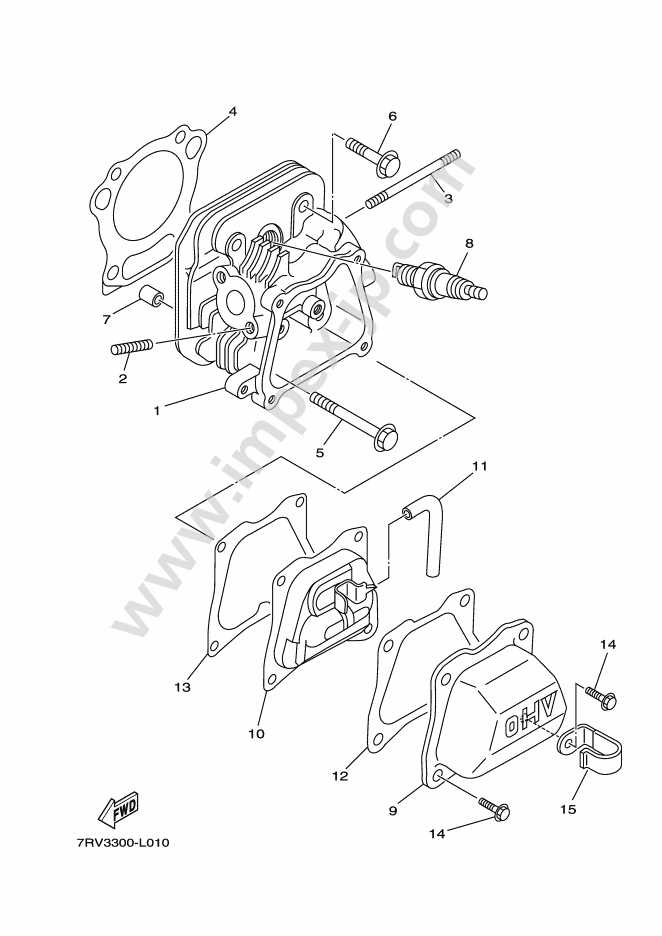

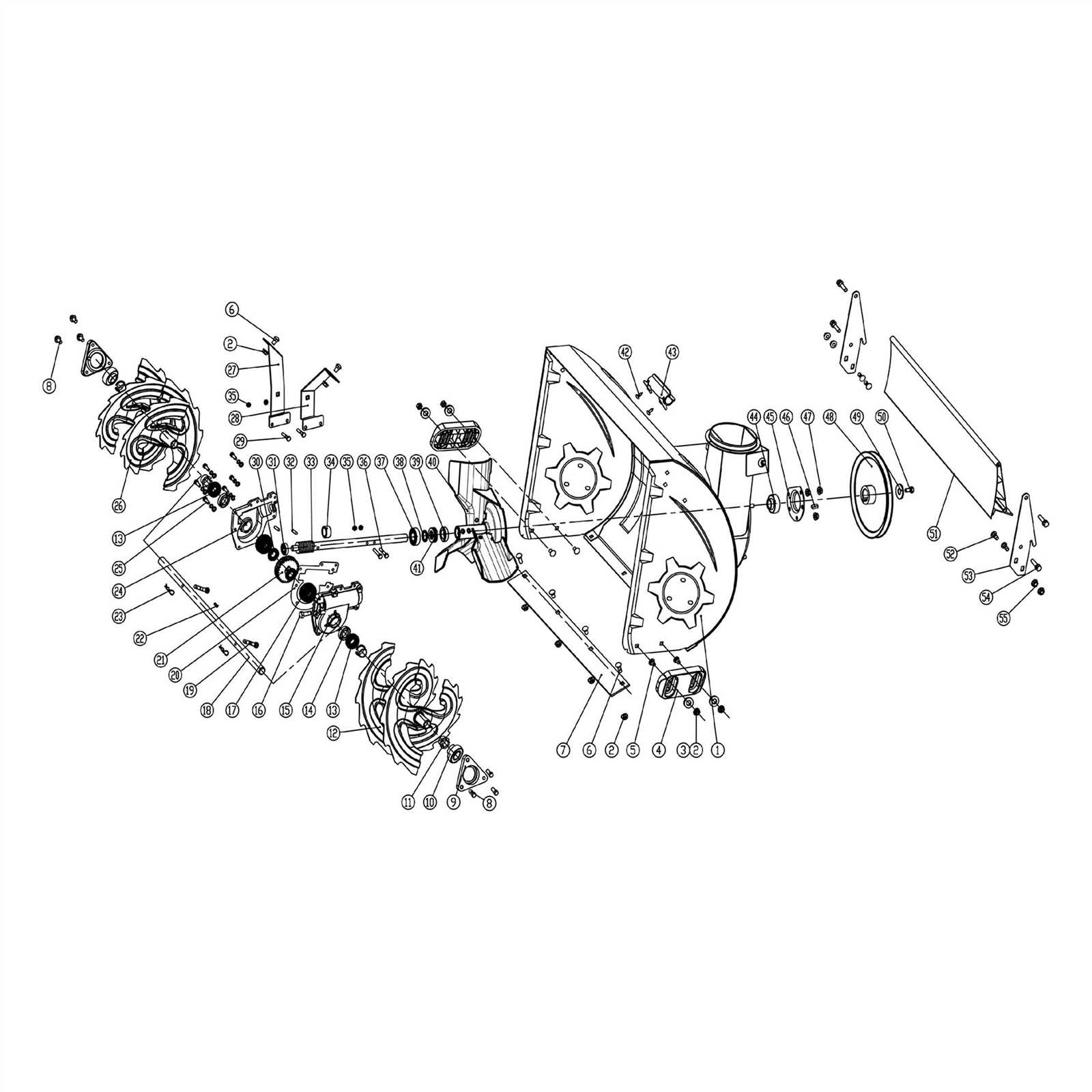

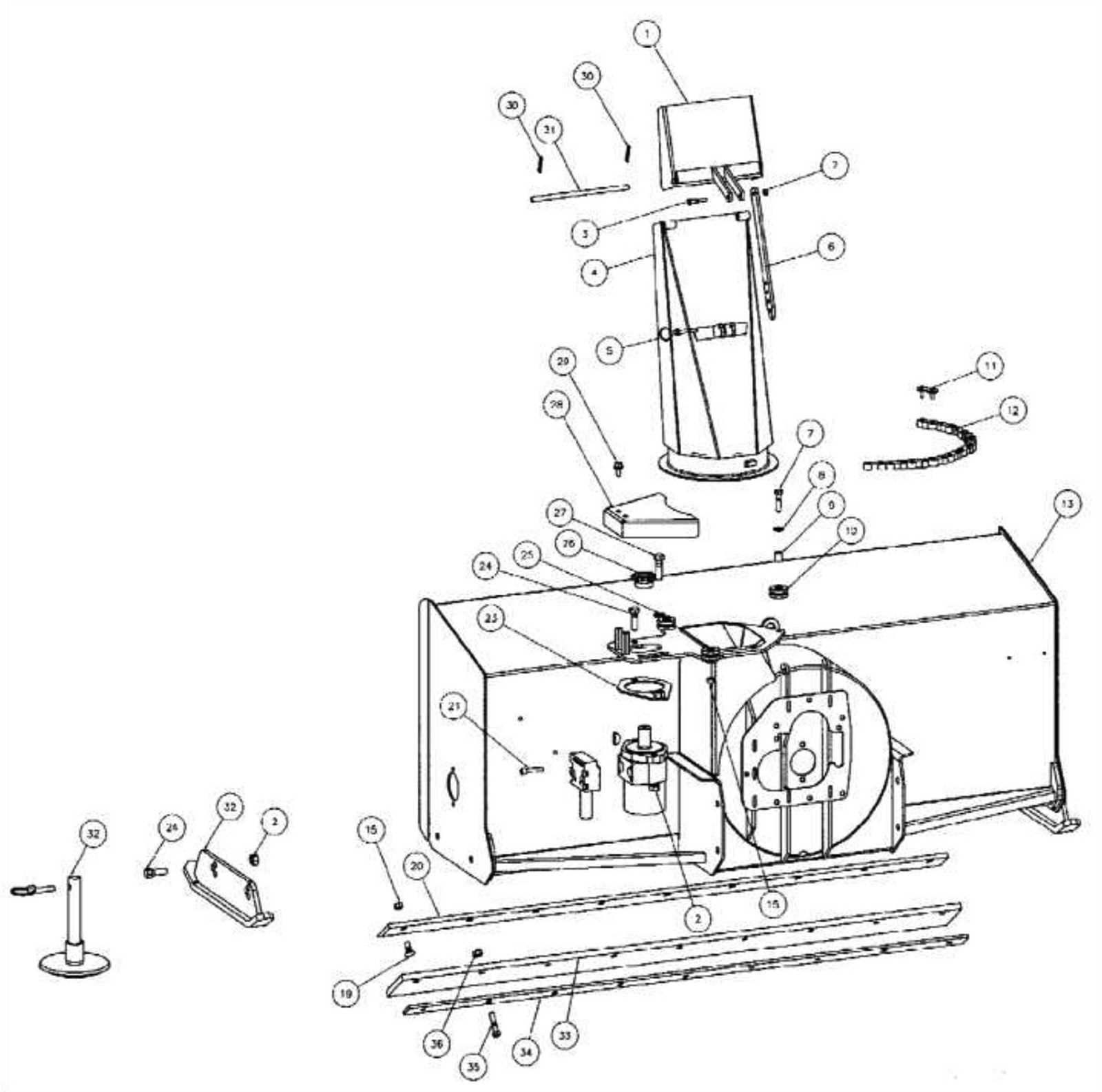

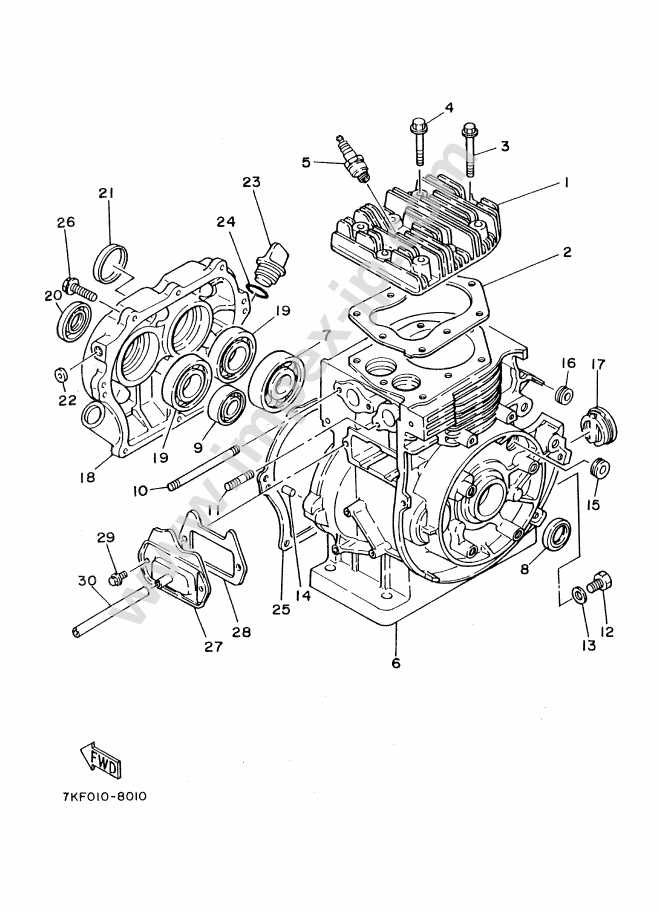

Importance of a Parts Diagram

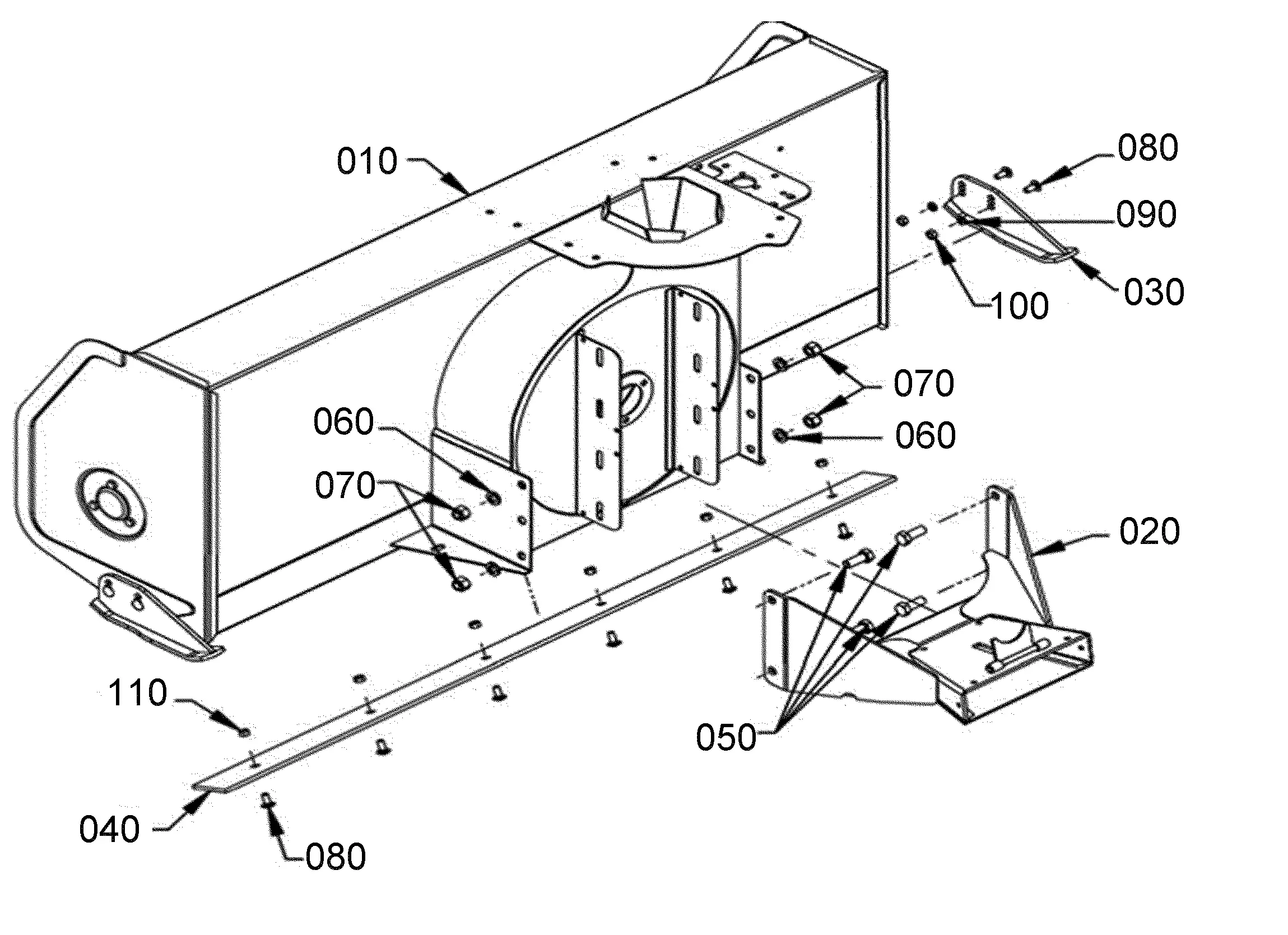

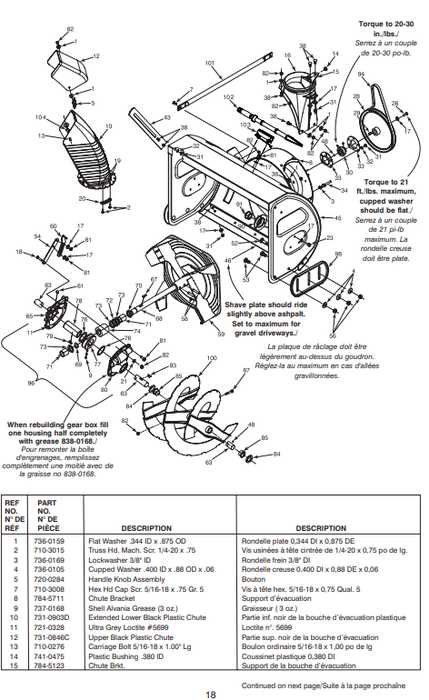

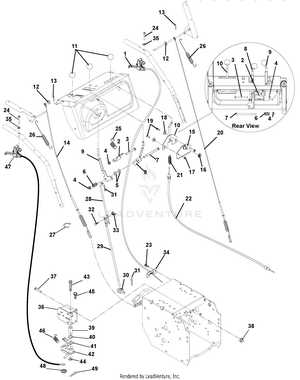

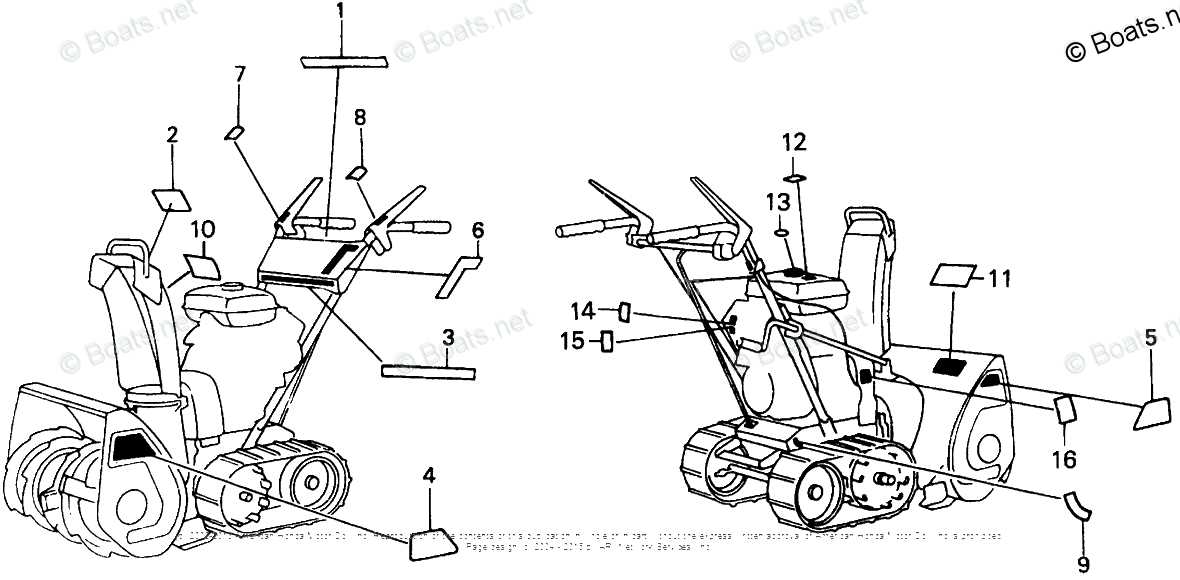

A comprehensive visual representation of components is essential for understanding the assembly and functionality of complex machines. This clarity aids in identifying each element’s role, ensuring that users can effectively maintain and troubleshoot their equipment.

By utilizing such visuals, individuals gain insights into the intricate relationships between various elements, which can enhance repair processes and minimize errors. This knowledge not only improves efficiency but also extends the lifespan of the machinery.

Moreover, having access to a detailed schematic empowers users to undertake repairs with confidence, reducing reliance on professional services. This independence fosters a deeper appreciation for the equipment and its operational mechanics.

Ultimately, a well-structured visual guide serves as a crucial tool for both novice and experienced users, promoting informed decision-making and effective management of their devices.

Key Parts of Snowblowers

Understanding the essential components of a snow-clearing machine is crucial for efficient operation and maintenance. Each element plays a vital role in ensuring optimal performance, especially during harsh winter conditions.

Engine: The heart of the machine, providing the necessary power to drive all functions. A robust engine ensures reliability and efficiency when tackling heavy snowfall.

Auger: This spiral blade system is responsible for breaking up and gathering the snow, facilitating easy movement and disposal. The design and material of the auger significantly influence its effectiveness.

Chute: The directing mechanism that allows the user to control where the cleared snow is thrown. An adjustable chute offers versatility in managing snow placement according to specific needs.

Impeller: Located behind the auger, this component helps propel the snow into the chute and out of the machine. Its shape and speed are crucial for efficient snow discharge.

Drive System: This includes the wheels or tracks that provide mobility. A reliable drive system ensures stability and ease of movement across various terrains.

Controls: User-friendly levers and buttons enable seamless operation. Well-designed controls enhance the overall experience, allowing for quick adjustments while working.

Familiarity with these critical elements not only aids in effective operation but also assists in troubleshooting and maintenance, ultimately prolonging the lifespan of the equipment.

How to Read the Diagram

Understanding technical illustrations can significantly enhance your ability to maintain and repair machinery. A clear interpretation of these visual representations allows for efficient identification and organization of components. Here are key steps to help you navigate these illustrations effectively.

- Familiarize Yourself with Symbols: Each element in the illustration is represented by specific symbols. Take time to review the legend, which typically explains what each symbol means.

- Identify Major Sections: Most illustrations are divided into main areas. Recognizing these sections can help you focus on relevant components for your task.

- Follow Numbering Systems: Many illustrations employ a numbering system for clarity. Follow this sequence to trace connections and relationships between different elements.

As you study the visual representation, pay attention to:

- Connections: Look for lines indicating how parts are connected. These lines often signify mechanical or electrical links.

- Scale: Understanding the scale can provide insights into the size and proportion of components relative to one another.

- Notes and Annotations: Often, additional notes provide crucial information about installation or maintenance procedures.

By applying these strategies, you can enhance your comprehension of technical illustrations, making repairs and maintenance tasks more manageable.

Common Snowblower Issues

| Issue | Possible Causes | Solutions |

|---|---|---|

| Not Starting | Fuel issues, battery failure, or spark plug problems | Check fuel levels, replace or charge the battery, inspect and clean or replace the spark plug |

| Uneven Clearing | Dull blades, improper height adjustment, or clogged chute | Sharpen or replace the blades, adjust the height, and clear any obstructions |

| Stalling | Overloading, fuel contamination, or air filter blockage | Avoid overloading, use fresh fuel, and clean or replace the air filter |

| Excessive Vibrations | Loose components or damaged auger | Tighten loose parts and inspect the auger for any damage |

Addressing these issues promptly can significantly enhance the efficiency and longevity of your equipment, ensuring that it performs well throughout the winter season.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor equipment requires regular upkeep and attention to detail. Proper maintenance not only enhances performance but also extends the lifespan of the machine, saving you time and money in the long run.

Regular Cleaning: After each use, clean the exterior to remove debris and dirt. This prevents buildup that can lead to rust and wear over time.

Check Fluids: Regularly inspect and replace necessary fluids, as they play a crucial role in lubrication and cooling. Keeping them at optimal levels ensures smooth operation.

Inspect Belts and Cables: Examine belts and cables for wear and tear. Replacing frayed components promptly can prevent more significant issues down the road.

Sharpen Cutting Edges: Maintain sharp edges for efficient performance. Dull blades strain the engine and reduce effectiveness.

Store Properly: When not in use, store the equipment in a dry place, free from moisture. Covering it can protect it from dust and environmental damage.

By following these guidelines, you can delve into the ultimate maintenance practices that will keep your machinery running smoothly for years to come.

Identifying Worn-Out Parts

Recognizing when components have deteriorated is crucial for maintaining optimal performance. Regular inspection can help detect signs of wear that might otherwise go unnoticed, leading to inefficiency or even breakdown. Knowing what to look for ensures that machinery operates smoothly and effectively.

Common Signs of Wear

One of the primary indicators of component fatigue is unusual noise during operation. If you hear grinding, rattling, or clanking sounds, it may signal that certain elements need attention. Additionally, visual inspection can reveal cracks, rust, or significant wear on surfaces. Inspecting belts and blades for fraying or dullness is essential, as these issues can severely impact functionality.

Impact on Performance

When parts begin to fail, the overall efficiency of the equipment is compromised. Reduced effectiveness can lead to increased energy consumption and operational delays. It’s important to address these issues promptly to avoid further damage and to ensure that your equipment remains reliable and effective.

Finding Replacement Components

When it comes to maintaining your outdoor equipment, locating suitable replacements is essential for optimal performance. Understanding where to search and what to consider can greatly enhance your repair experience.

Where to Look

- Authorized Dealers: They offer genuine items and reliable service.

- Online Retailers: A convenient option with extensive selections.

- Local Hardware Stores: Often stock common replacements for quick access.

- Second-Hand Shops: Can have affordable options if you’re on a budget.

Key Considerations

- Compatibility: Ensure components fit your specific model.

- Quality: Look for reputable brands to ensure durability.

- Warranty: Check if replacements come with a guarantee.

- Price: Compare costs to find the best value.

Assembly and Disassembly Guide

This section provides essential insights into the process of assembling and disassembling your equipment. Understanding the correct methods ensures optimal functionality and longevity. By following this guide, you can tackle maintenance tasks with confidence.

Disassembly Steps: Start by gathering the necessary tools. Ensure the machine is powered down and disconnected from any power source. Carefully remove any protective covers, noting the order of components. Detach parts methodically, keeping track of screws and fasteners for easy reassembly.

Assembly Steps: Begin by positioning the primary components in their designated locations. Refer to your reference material for guidance on the correct order. Secure each piece tightly, ensuring no loose connections. Finally, replace any protective covers and perform a thorough inspection to confirm everything is in place.

Proper execution of these procedures not only enhances performance but also prolongs the life of your machinery.

Safety Precautions During Repair

When engaging in maintenance or troubleshooting tasks on machinery, ensuring safety is of utmost importance. Proper precautions help prevent accidents and injuries, enabling a smooth and efficient repair process. Being aware of potential hazards and taking the necessary steps to mitigate risks can lead to a safer working environment.

Wear Protective Gear

Before starting any repair work, it is essential to equip yourself with appropriate protective gear. This includes gloves to shield your hands from sharp edges, safety goggles to protect your eyes from debris, and sturdy footwear to prevent slips and falls. Each of these items plays a vital role in ensuring your personal safety throughout the repair process.

Work in a Well-Ventilated Area

Another critical safety measure is to ensure that the workspace is well-ventilated. This is particularly important when working with any substances that may emit harmful fumes. If possible, work outdoors or in a space with sufficient airflow. If working indoors, consider using fans or exhaust systems to enhance ventilation and reduce the risk of inhalation hazards.

Upgrading Your Snowblower Parts

Enhancing the functionality and efficiency of your winter machinery can significantly improve its performance and lifespan. By selecting high-quality components and integrating modern technology, you can ensure that your equipment operates at peak efficiency, even in the harshest conditions. This process not only maximizes productivity but also minimizes potential breakdowns, allowing you to tackle heavy snowfall with ease.

Choosing Quality Components

When considering upgrades, focus on durability and performance. Investing in premium materials can make a noticeable difference in how your machine handles tough tasks. Look for options that offer enhanced resistance to wear and tear, as well as improved operational efficiency. Researching brands with a solid reputation can guide you towards reliable choices that stand the test of time.

Incorporating New Technologies

Modern advancements can provide significant advantages over older models. Features such as electric start mechanisms, adjustable chute angles, and improved engine designs can enhance your machine’s usability. Exploring these innovations can lead to a more effortless and efficient experience, allowing you to manage snow removal tasks with greater ease.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments on hand is essential for effective and efficient repairs. Proper tools not only facilitate the process but also ensure safety and longevity of the machinery. Below, we outline some key implements you may need for a successful repair job.

Essential Hand Tools

Basic hand tools are crucial for any repair task. A reliable set of wrenches and screwdrivers are fundamental for loosening and tightening components. Additionally, pliers can assist in gripping and twisting various parts. A good quality hammer may also come in handy for adjusting misaligned elements.

Power Tools and Accessories

In more complex scenarios, power tools can significantly enhance efficiency. A drill with the appropriate bits can expedite the process of removing and installing screws and bolts. Furthermore, having a socket set allows for easier access to hard-to-reach areas, making it an indispensable addition to your toolkit. Always remember to use the right protective gear when operating power tools to ensure your safety during repairs.

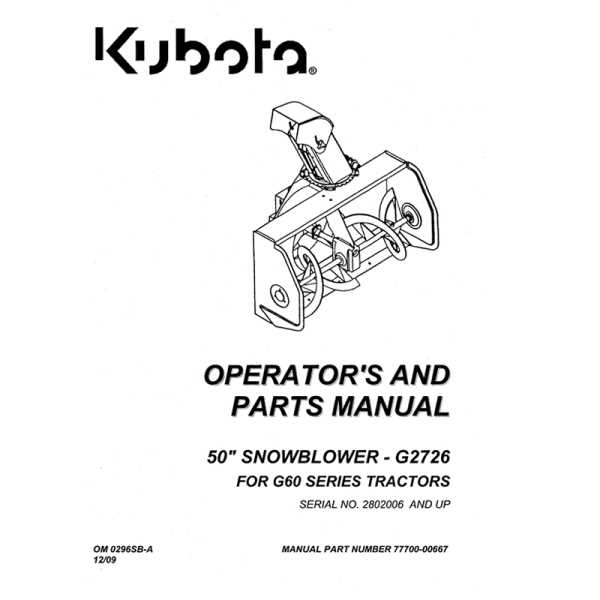

Resources for Parts Diagrams

Finding the right resources to assist with mechanical assemblies can greatly enhance your repair and maintenance efforts. Whether you’re looking for visual guides or detailed breakdowns, various platforms offer comprehensive information to simplify your search for components and their arrangements.

Online Databases: Numerous websites provide extensive catalogs where users can browse through different models and their respective elements. These platforms often feature high-quality images and user-friendly interfaces, allowing for easy navigation and identification of necessary items.

Manufacturer Manuals: Official documentation from manufacturers serves as a valuable source of information. These manuals typically include assembly instructions and visual representations, ensuring that users have access to accurate and reliable details about each unit.

Community Forums: Engaging with online communities can provide insights and shared experiences from fellow users. Forums and discussion boards often contain valuable tips, troubleshooting advice, and links to relevant resources, fostering a collaborative environment for enthusiasts and professionals alike.

Video Tutorials: Many individuals turn to video platforms for practical demonstrations. Visual walkthroughs can be particularly helpful in understanding the installation and maintenance processes, making complex tasks more approachable.

Leveraging these diverse resources can empower you to confidently navigate the intricacies of your equipment, ensuring efficient repairs and upkeep.