When it comes to effective winter maintenance, having a clear understanding of the essential elements that comprise your snow clearing machinery is crucial. This knowledge ensures optimal functionality and helps users address any potential issues that may arise during operation.

By familiarizing yourself with the various components, you can enhance your equipment’s performance and longevity. Each element plays a vital role in ensuring smooth operation, making it easier to manage heavy snowfall and maintain safe pathways.

In this section, we will explore the key features of snow clearing machinery, providing insights into how each component works together to deliver reliable results. This information will be invaluable for both novice and experienced users looking to maximize their equipment’s efficiency.

Understanding the key elements of a snow-clearing machine is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring that the equipment functions optimally, making it essential for users to be familiar with these parts.

- Engine: The power source that drives the entire system, providing the necessary energy for operation.

- Auger: This rotating mechanism collects and breaks up the snow, facilitating its movement through the chute.

- Chassis: The framework that supports all components, ensuring structural integrity and stability.

- Transmission: This system transmits power from the engine to the wheels, allowing for controlled movement and maneuverability.

- Chute: Directs the expelled snow away from the working area, helping to maintain a clear path.

Familiarizing oneself with these components can enhance the effectiveness of the equipment and prolong its lifespan.

Common Replacement Parts Overview

Understanding the essential components that may require replacement can greatly enhance the longevity and efficiency of your equipment. Regular maintenance and timely swaps of specific elements can prevent larger issues and ensure optimal performance throughout the winter season.

Belts are crucial for the transmission of power, and worn or damaged belts can lead to decreased efficiency. Additionally, blades play a vital role in clearing snow effectively; sharp and well-maintained blades ensure better results.

Filters should be checked frequently, as they contribute to the overall functionality by ensuring clean air and fuel flow. Finally, spark plugs are essential for reliable ignition, and replacing them can improve starting performance and fuel efficiency.

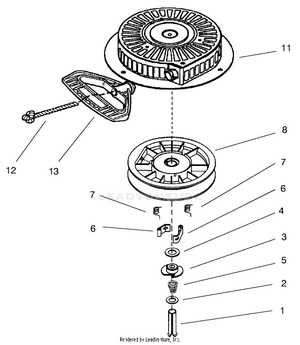

Assembly and Disassembly Instructions

This section provides essential guidelines for the effective assembly and disassembly of the equipment. Proper procedures ensure longevity and optimal performance, minimizing the risk of damage.

- Preparation:

- Gather all necessary tools and components.

- Ensure a clean and spacious work area.

- Assembly Steps:

- Begin with the main structure; secure all bolts tightly.

- Attach additional components, following the specified order.

- Double-check connections for stability.

- Disassembly Steps:

- Start from the last component added, working in reverse order.

- Carefully remove each part, keeping track of all fasteners.

- Store removed components safely to prevent loss.

Following these instructions will facilitate smooth operation and maintenance of your machinery.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. Proper upkeep not only enhances performance but also extends the lifespan of the machine, making it a worthwhile investment.

Regular Inspections

- Check for any signs of wear or damage.

- Inspect belts and cables for fraying.

- Examine the blades for sharpness and integrity.

Proper Cleaning

- Clear debris after each use to prevent buildup.

- Wash components with mild soap and water.

- Lubricate moving parts to reduce friction.

Identifying Wear and Tear Issues

Understanding the signs of deterioration in machinery is essential for maintaining optimal performance. Regular inspection helps in detecting potential problems early, preventing costly repairs and ensuring efficient operation. By familiarizing yourself with common indicators of wear, you can extend the lifespan of your equipment.

Common Indicators of Deterioration

Several factors can signal that components are experiencing wear and require attention. Key signs include:

| Indicator | Description |

|---|---|

| Unusual Noises | Grinding or rattling sounds often indicate loose or damaged parts. |

| Decreased Efficiency | Reduced output performance may suggest worn mechanisms that need replacement. |

| Visual Damage | Cracks, corrosion, or fraying visible on components are clear signs of wear. |

Maintenance Tips

Regular upkeep can help mitigate wear issues. Inspect components frequently, clean the machinery to remove debris, and lubricate moving parts to ensure smooth operation. Following the manufacturer’s recommendations for maintenance schedules will also contribute to the longevity of your equipment.

Seasonal Preparation Guidelines

Preparing equipment for seasonal changes is essential to ensure optimal performance during cold months. Proper maintenance and readiness can significantly extend the lifespan of machinery, making tasks more efficient and manageable.

Essential Maintenance Steps

Before the onset of winter, follow these critical maintenance steps to enhance functionality:

| Task | Description |

|---|---|

| Fuel System Check | Inspect and replace old fuel to prevent issues related to moisture and degradation. |

| Blade Inspection | Examine cutting edges for wear and ensure they are sharp for effective operation. |

| Battery Maintenance | Test and charge the battery to guarantee reliable starts in low temperatures. |

Storage Recommendations

Proper storage practices are crucial for maintaining equipment in optimal condition. Store in a dry, sheltered area to prevent rust and corrosion.

Tools Required for Repairs

When performing maintenance or fixing equipment, having the right instruments is essential for a successful outcome. The appropriate tools not only facilitate the repair process but also ensure that the job is done efficiently and safely.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are crucial for disassembling and reassembling components. A socket set is particularly useful for loosening or tightening various fasteners. Always ensure that the tools are of good quality to prevent any damage during the repair process.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be required for specific repairs. Items like torque wrenches or diagnostic tools can help in accurately measuring and assessing the functionality of parts. Utilizing the right equipment can significantly reduce the time and effort needed for repairs, leading to a more satisfactory result.

Where to Purchase Parts

Finding reliable sources for components can greatly enhance the maintenance and performance of your equipment. Whether you’re looking for original replacements or compatible alternatives, several options are available to ensure you get what you need.

Online Retailers

- Many dedicated websites offer a wide range of components for various models, often with detailed specifications.

- Popular e-commerce platforms may also have listings from various sellers, allowing for price comparisons.

Local Suppliers

- Local hardware stores may carry a selection of essential components and can order specific items upon request.

- Authorized dealers can provide original parts and expert advice on compatibility.

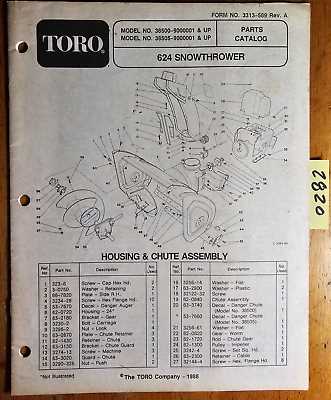

Diagram Interpretation for Users

This section aims to assist users in understanding the layout and components of their equipment effectively. A clear representation can enhance familiarity with the device, ensuring proper operation and maintenance.

Users should familiarize themselves with the various elements depicted in the illustration, as each part plays a vital role in functionality. Recognizing these components will facilitate better handling and troubleshooting.

| Component | Description |

|---|---|

| Handle Assembly | The control area for operation. |

| Auger | Responsible for gathering and moving snow. |

| Chassis | The main body supporting all components. |

| Engine | Powers the entire unit for effective performance. |

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of outdoor equipment. Here, users can find helpful insights to enhance their understanding and usage of their machinery.

- What maintenance is required for optimal performance?

Regular checks and cleanings are essential to ensure longevity and efficiency. Always refer to the manufacturer’s recommendations for specific guidelines.

- How can I identify malfunctioning components?

Signs of wear may include unusual noises, reduced performance, or visible damage. It’s important to inspect the equipment periodically for any irregularities.

- Where can I find replacement components?

Replacement parts can often be sourced from authorized dealers or reputable online retailers. Ensure compatibility with your specific model before purchasing.

- Are there troubleshooting tips for common issues?

Yes, many common problems have straightforward solutions. Consulting the user manual or online forums can provide valuable assistance in troubleshooting.