When it comes to navigating the open road or tackling rugged terrains, the effectiveness of your vehicle’s directional system is crucial. This section will explore the various elements that contribute to this vital mechanism, ensuring optimal control and responsiveness during your drives.

Every vehicle relies on a complex arrangement of components that work in harmony to facilitate precise movement and handling. Familiarizing yourself with these integral parts can enhance your understanding of how your vehicle operates and aid in maintenance and repair tasks.

From links and connectors to adjustment mechanisms, each element plays a significant role in the overall functionality of the system. By gaining insights into their arrangement and interconnections, you can better appreciate the engineering that goes into making your driving experience both safe and enjoyable.

This section aims to provide a comprehensive overview of the components involved in the directional control assembly of the vehicle, emphasizing their arrangement and functionality. Understanding this layout is crucial for maintenance and troubleshooting, ensuring optimal performance on the road.

In this section, we will explore the following key elements:

- Component Identification

Recognizing each element’s role is essential for effective repairs. Here are the main components to focus on:

- Linkages

- Column assembly

- Knuckles

- Couplings

- Shock absorbers

- Arrangement and Layout

Understanding how these elements fit together can prevent potential issues. Key aspects to consider include:

- Orientation of components

- Connection points

- Angles and geometry

- Clearance requirements

- Functionality and Operation

Each component plays a significant role in the overall system’s effectiveness. Topics to explore:

- How components interact during operation

- Impact of wear and tear

- Indicators of malfunction

By delving into these aspects, readers will gain a thorough understanding of the assembly, facilitating better maintenance and informed decision-making when it comes to repairs or upgrades.

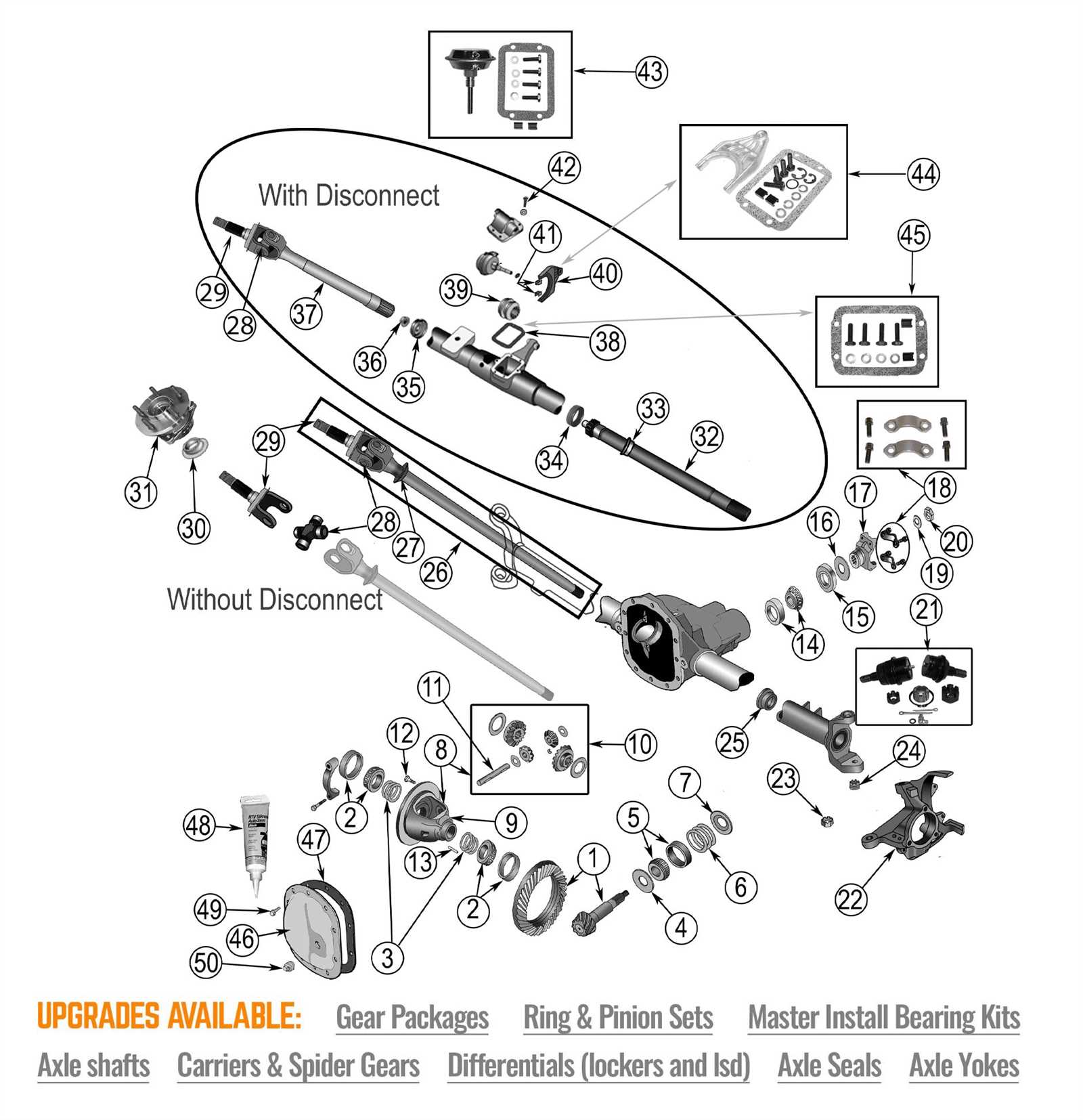

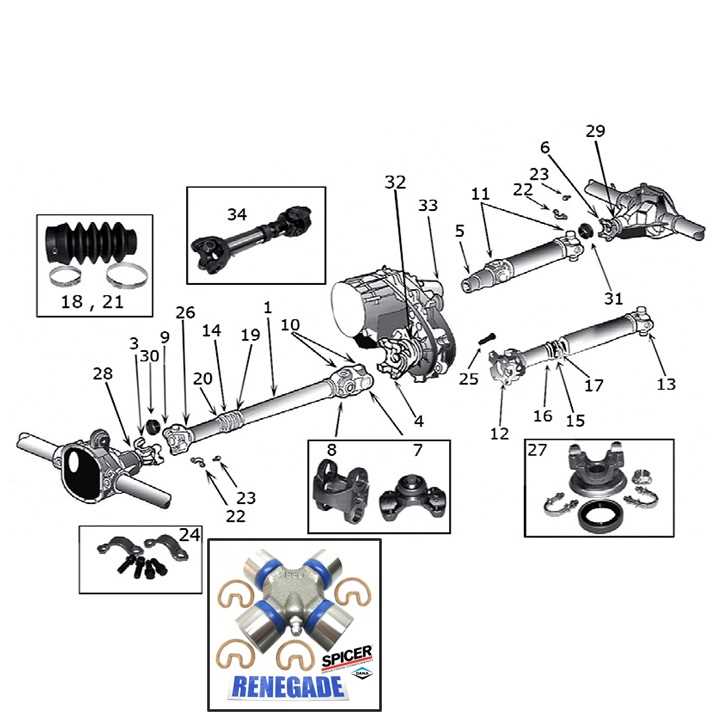

Components of Jeep TJ Steering Assembly

The system responsible for directional control in a vehicle consists of various crucial elements that work together to ensure precise handling and stability. Understanding these components is essential for maintaining optimal performance and safety.

- Rack and Pinion: This mechanism converts rotational motion into linear motion, allowing for efficient turning.

- Control Arms: These components connect the vehicle’s frame to the wheels, facilitating smooth movement and alignment.

- Ball Joints: Acting as pivot points, these joints allow for movement between the suspension and the wheel assembly.

- Linkages: These rods transmit force from the driver’s input to the steering mechanism, ensuring responsive handling.

- Hydraulic System: This system aids in reducing the effort required to turn the wheels, enhancing driver comfort and control.

Each of these elements plays a vital role in the overall functionality of the vehicle’s control system, contributing to a safer and more enjoyable driving experience.

Importance of Steering Parts Maintenance

Regular upkeep of the directional control system is crucial for ensuring vehicle safety and performance. Neglecting this aspect can lead to various issues that not only affect driving comfort but can also compromise overall safety on the road. Proper maintenance helps in identifying potential problems before they escalate, thus preserving the integrity of the vehicle and enhancing its longevity.

Benefits of Regular Inspection

Conducting frequent evaluations allows vehicle owners to detect wear and tear early on. This proactive approach can save time and money in the long run by preventing major repairs. Additionally, well-maintained components contribute to smoother handling, making every journey more enjoyable.

Impact on Safety

Ensuring that all elements of the directional control system are functioning properly significantly reduces the risk of accidents. Faulty mechanisms can lead to unexpected maneuvers or loss of control, creating hazardous situations for both the driver and other road users. Prioritizing maintenance not only safeguards the driver but also promotes a safer environment for everyone.

Common Issues with Steering Mechanisms

Understanding the typical problems that may arise in directional control systems is essential for maintaining optimal vehicle performance. These mechanisms are crucial for ensuring that drivers can navigate safely and effectively.

- Excessive Play: Over time, components may wear down, leading to increased looseness in the connection, which can affect handling precision.

- Unusual Noises: Squeaking or grinding sounds during operation often indicate underlying issues such as worn bearings or insufficient lubrication.

- Difficulty in Maneuvering: A noticeable struggle while turning can suggest issues with the linkage or hydraulic systems that need attention.

- Pulling to One Side: If the vehicle tends to drift left or right, it may be a sign of misalignment or uneven tire pressure that must be addressed.

- Fluid Leaks: Leaking fluid from hydraulic systems can lead to decreased efficiency and requires immediate investigation.

Regular inspections and maintenance can help identify these issues early, ensuring a smoother and safer driving experience.

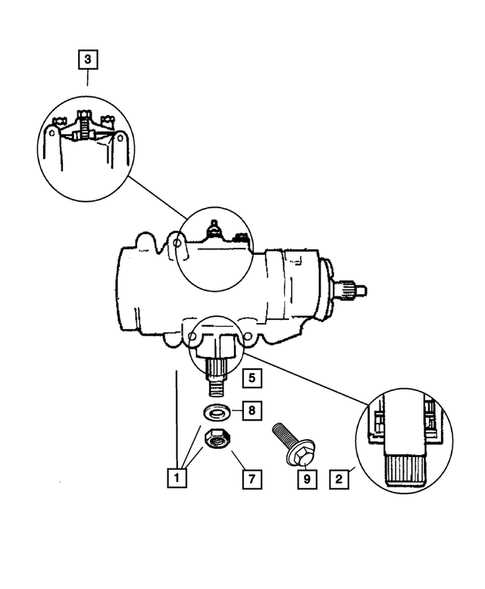

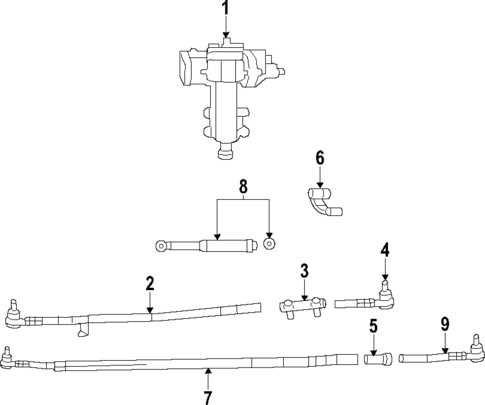

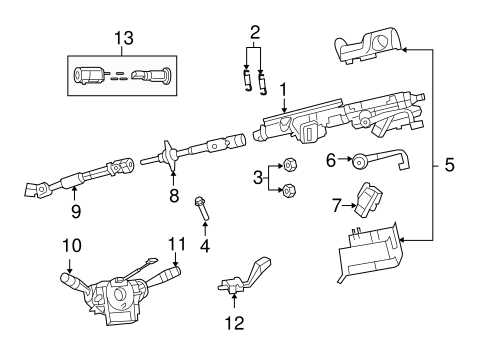

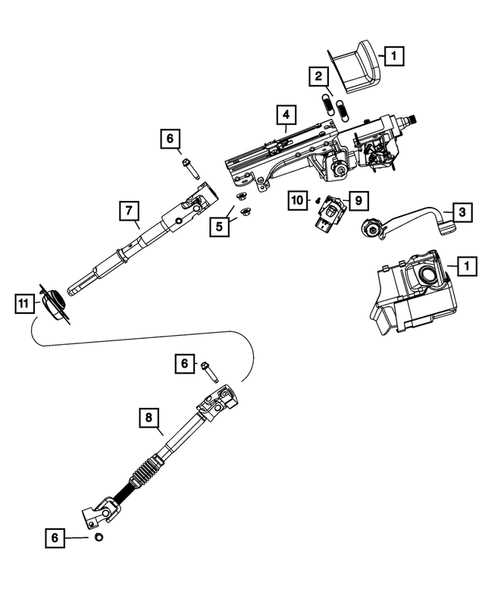

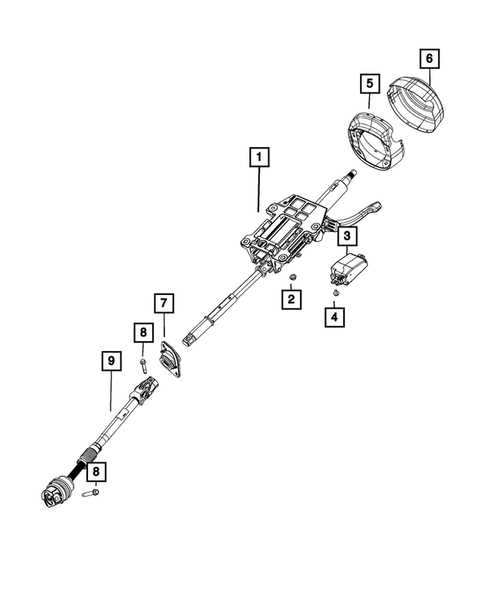

Identifying Parts in Steering Diagrams

Understanding the components involved in directional control systems is essential for effective maintenance and repair. By familiarizing oneself with the various elements illustrated in schematic representations, individuals can more easily diagnose issues and implement solutions. This section aims to guide readers through the process of recognizing and interpreting these components.

When examining visual representations, it is crucial to note the layout and connections between different elements. Each component plays a specific role in the overall function, contributing to the maneuverability and responsiveness of the system. The following table outlines common components and their functions:

| Component Name | Description |

|---|---|

| Control Arm | A pivotal element that connects the wheel assembly to the frame, allowing for smooth turning movements. |

| Linkage | Structures that transmit motion from one component to another, facilitating directional changes. |

| Column Assembly | The vertical component that houses controls and connects to the wheel, enabling user input. |

| Rack and Pinion | A mechanism converting rotational motion into linear motion, providing responsiveness in directional adjustments. |

| Steering Box | A housing that contains gears, which assist in amplifying the force applied by the driver. |

By learning to identify these elements, one can better navigate the intricacies of maintenance and enhancements, leading to improved vehicle performance and safety.

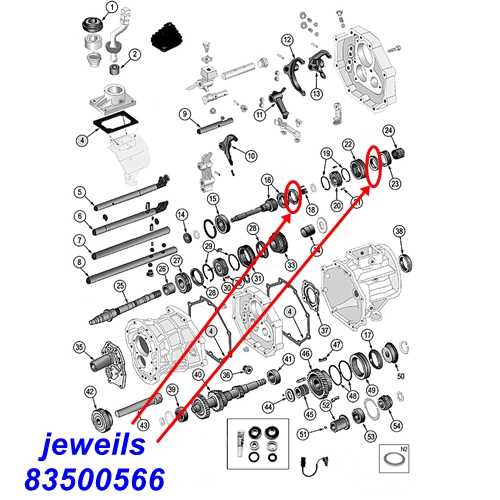

How to Read Steering System Schematics

Understanding the layout and connections within a vehicle’s directional control system is essential for effective maintenance and troubleshooting. By familiarizing yourself with the visual representations of these components, you can gain valuable insights into their functions and relationships.

When examining a schematic, consider the following key aspects:

- Symbols: Each element in the illustration is represented by a specific symbol. Learn the common symbols used for various components such as pumps, linkages, and sensors.

- Connections: Pay attention to the lines connecting the symbols, as they indicate how different elements interact. Solid lines usually represent direct connections, while dashed lines may denote alternative paths or optional components.

- Labels: Look for labels that provide additional information, such as part numbers, functions, or flow directions. These annotations can guide you in identifying each component’s role within the system.

By mastering these fundamental principles, you can effectively interpret schematics and enhance your understanding of vehicle control mechanisms.

Upgrading Steering Components Effectively

Enhancing the maneuverability and responsiveness of your vehicle involves a strategic approach to replacing key components. This process not only improves overall handling but also contributes to a more enjoyable driving experience. By selecting high-quality upgrades, you can achieve better performance and longevity.

Here are some effective steps to consider when undertaking this enhancement:

- Assess Current Components:

Begin by evaluating the existing system for any signs of wear or damage. This evaluation will help identify which components require replacement.

- Select Quality Upgrades:

Research and choose components that are known for their durability and performance. Look for reputable manufacturers that offer warranties.

- Consider Compatibility:

Ensure that the new components are compatible with your vehicle’s specifications. This is crucial for maintaining optimal functionality.

- Installation:

Follow manufacturer guidelines for installation. If necessary, consult with a professional to ensure proper fitting and alignment.

- Testing:

After installation, conduct thorough tests to evaluate the enhancements. Pay attention to handling, responsiveness, and overall performance.

By carefully considering these factors, you can effectively elevate the control and responsiveness of your vehicle, leading to a safer and more pleasurable driving experience.

Tools Needed for Steering Repairs

When addressing issues related to the directional control system of your vehicle, having the right tools at hand is crucial for a successful repair process. Various tasks may require specific instruments to ensure proper adjustments, replacements, and maintenance, enhancing the overall performance and safety of the vehicle.

Essential Tools

- Socket and Ratchet Set

- Wrenches (Open-End and Box-End)

- Torque Wrench

- Ball Joint Separator

- Steering Wheel Puller

- Pry Bar

- Hammer (Dead Blow or Rubber)

Additional Equipment

- Jack and Jack Stands

- Brake Cleaner

- Grease Gun

- Measuring Tape

- Shop Manual (for reference)

- Safety Gear (Gloves and Goggles)

Having these tools readily available can significantly ease the process of maintaining or replacing components within the directional control system, ensuring that all adjustments are made correctly and efficiently.

Signs of Worn Steering Parts

As vehicles age, certain components can experience wear and tear, affecting overall handling and safety. Recognizing the signs of deterioration in these critical elements is essential for maintaining optimal performance. Early detection can prevent further damage and costly repairs, ensuring a smoother and safer driving experience.

Common Indicators of Wear

There are several observable symptoms that may indicate a decline in the functionality of essential components responsible for directional control. Drivers should be aware of these warning signs:

| Symptom | Description |

|---|---|

| Loose Handling | Difficulty in maintaining a straight line, requiring constant correction. |

| Noisy Operation | Unusual sounds such as clunking or grinding when turning. |

| Vibration | Excessive shaking in the wheel or cabin during movement. |

| Uneven Tire Wear | Noticeable differences in tread wear patterns across tires. |

Preventive Measures

Regular inspections and maintenance can significantly extend the lifespan of these crucial elements. Addressing minor issues promptly can lead to improved performance and safety on the road.

Best Practices for Installation and Replacement

Proper techniques during the installation and replacement of components can significantly enhance the performance and longevity of your vehicle’s handling system. Adhering to best practices ensures a seamless process while minimizing the risk of future issues.

Preparation Steps

Before starting the process, it is essential to gather the necessary tools and components. Thoroughly inspect the area where work will be performed, ensuring cleanliness and accessibility. Proper planning can save time and prevent potential complications.

Installation Guidelines

During the installation phase, follow the manufacturer’s specifications carefully. Ensure that all components fit correctly and are aligned properly. Tighten bolts and fasteners to the recommended torque settings to avoid any loosening during operation.

| Step | Action | Notes |

|---|---|---|

| 1 | Gather Tools | Wrenches, sockets, torque wrench, etc. |

| 2 | Inspect Components | Look for wear or damage |

| 3 | Align Parts | Ensure proper positioning |

| 4 | Tighten Fasteners | Use correct torque specifications |

By following these guidelines, you can enhance the reliability of your vehicle’s handling system and enjoy a smoother driving experience.

Resources for Steering Parts Information

Accessing comprehensive information about essential components in the control mechanism of a vehicle can significantly enhance your understanding and maintenance of the system. Various resources are available to assist enthusiasts and professionals alike in identifying and sourcing these critical elements.

Online Forums and Communities

Engaging with online forums and communities dedicated to automotive enthusiasts is a valuable way to gather insights and experiences. Platforms such as dedicated automotive forums often feature sections where members share knowledge about specific components, troubleshooting techniques, and modifications. Participating in discussions or browsing through past threads can provide practical advice and recommendations.

Manufacturer Websites and Manuals

Consulting the official websites of manufacturers can yield detailed specifications and guidelines related to the components of interest. Many manufacturers provide downloadable manuals that outline installation procedures, maintenance tips, and parts compatibility. These resources are crucial for ensuring that the elements you are working with meet the necessary standards for safety and performance.

Choosing Quality Replacement Components

When it comes to maintaining and upgrading your vehicle’s functionality, selecting high-quality replacement elements is crucial. This decision can significantly impact performance, safety, and longevity. Investing time in understanding the available options ensures that you choose components that meet the required standards and specifications.

Importance of Material and Construction

Pay close attention to the materials used in the fabrication of replacement components. Durable materials, such as high-grade metals and composites, can enhance strength and resistance to wear. Additionally, ensure that the construction methods adhere to industry standards, as this contributes to overall reliability and performance.

Research and Recommendations

Before making a purchase, it is advisable to conduct thorough research. Consult with experienced professionals and read customer reviews to gather insights on different brands and their reputations. Quality assurance from reputable manufacturers can provide peace of mind, knowing that you are investing in components that will perform effectively over time.