In the world of outdoor machinery, a clear understanding of the intricate structure is essential for effective maintenance and repair. This section delves into the various components that make up a specific model, highlighting their functionality and interconnections. By grasping the organization of these elements, users can enhance their operational knowledge and improve the performance of their equipment.

Additionally, the identification of specific components aids in troubleshooting common issues, ensuring that users can address problems efficiently. This knowledge empowers operators to carry out repairs and replacements with confidence, thereby extending the life of their machinery. Familiarity with the arrangement of essential elements transforms the maintenance process into a manageable task.

Ultimately, comprehending the assembly fosters a deeper appreciation for the technology at hand. As users become more adept at recognizing and understanding each piece’s role, they can optimize their equipment’s functionality, making outdoor tasks more enjoyable and productive.

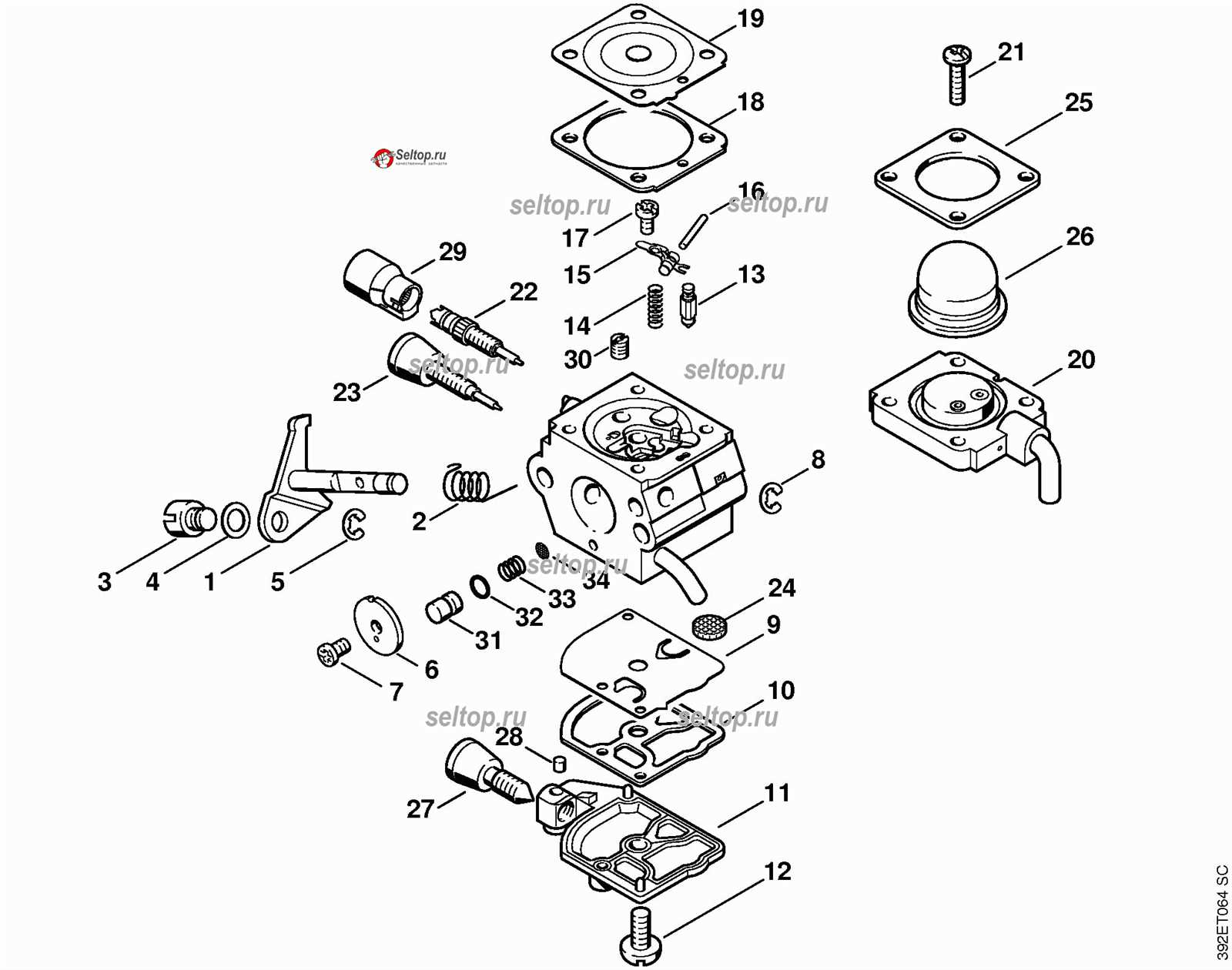

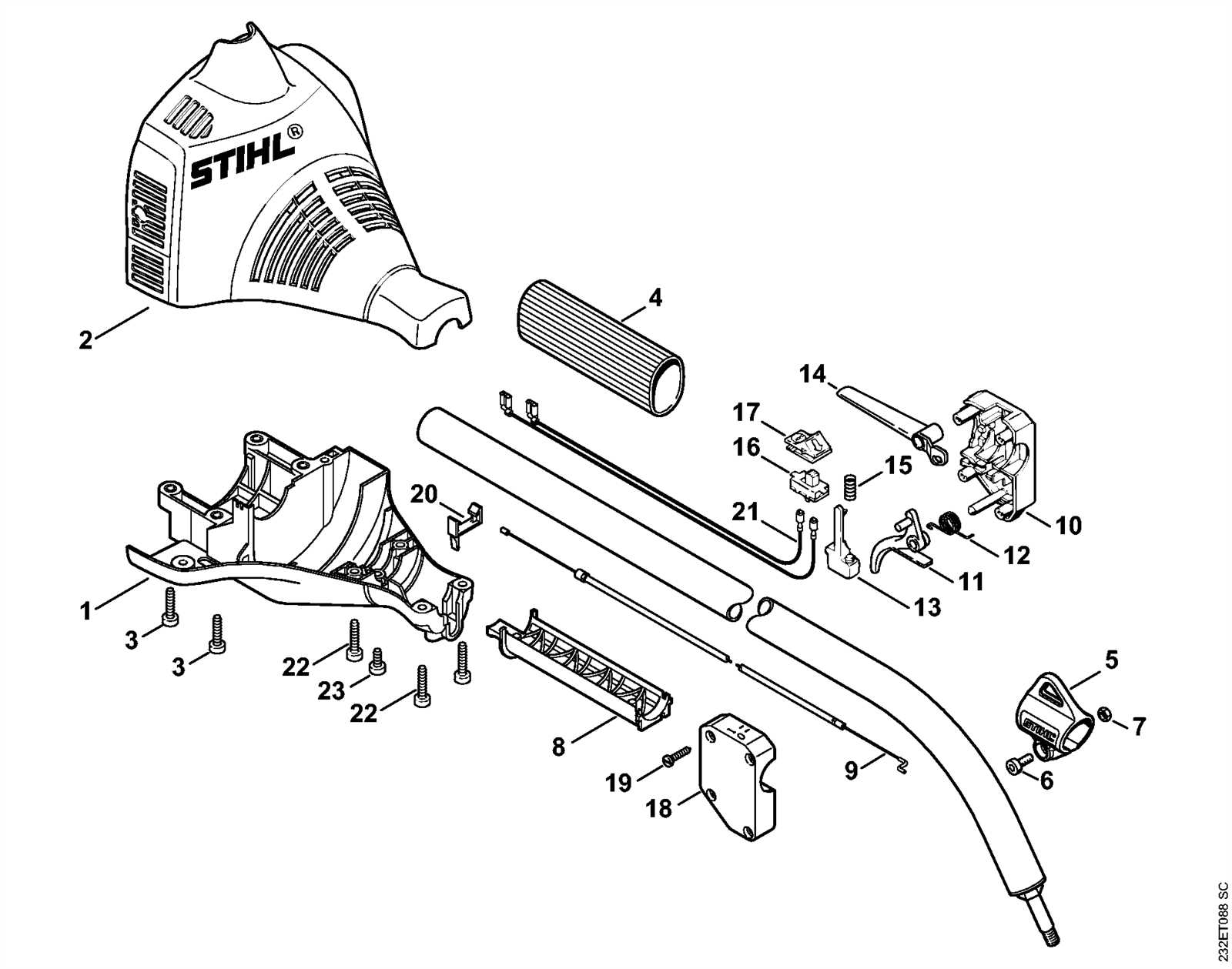

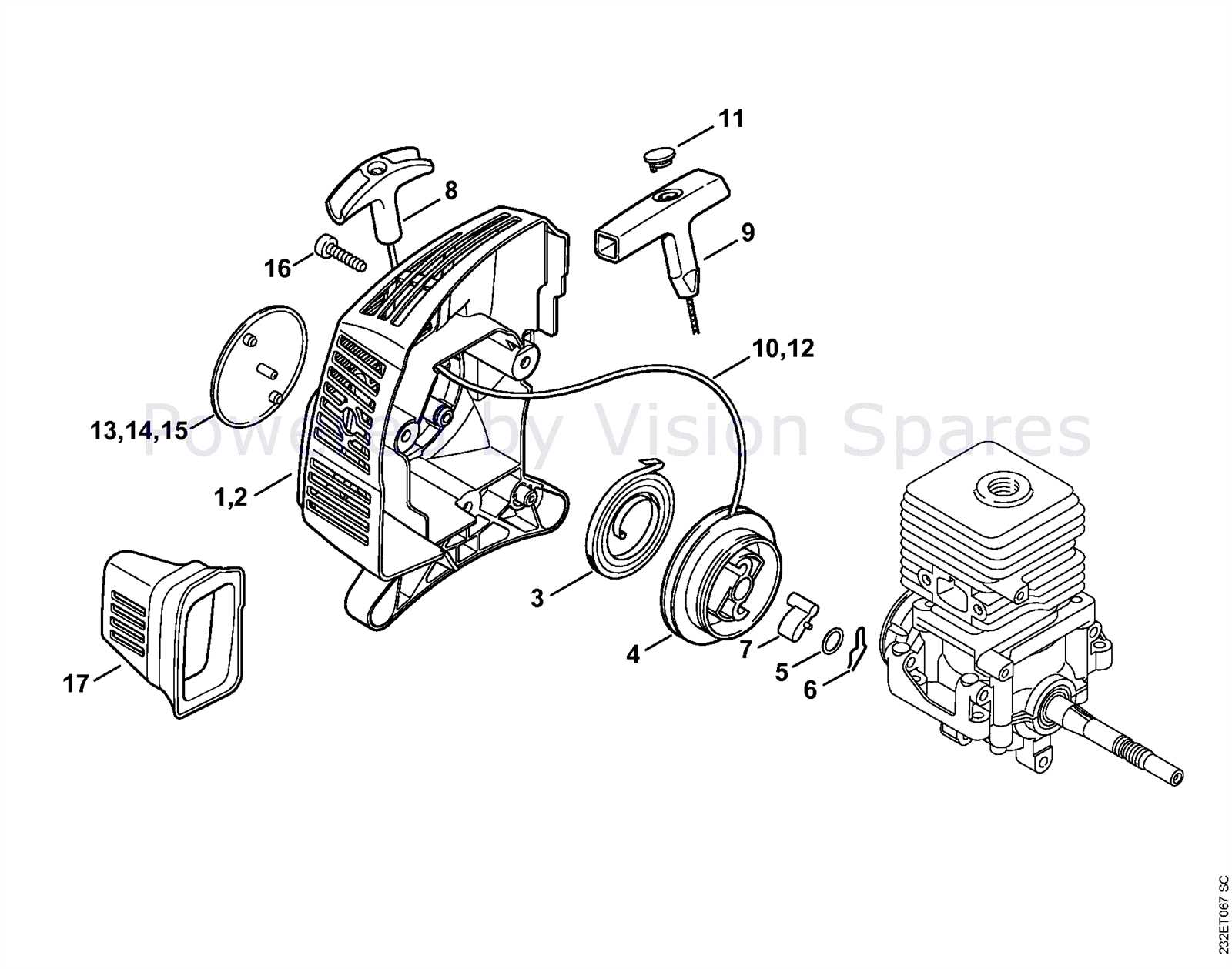

The structure of a specific outdoor power equipment model is essential for understanding its functionality and maintenance. A comprehensive overview can aid users in identifying components, ensuring efficient repairs, and optimizing performance. This section aims to outline various elements of the machine and provide insights into their roles and interconnections.

Key Components Overview

Every assembly consists of critical parts that contribute to its overall operation. Familiarity with these elements enhances a user’s ability to troubleshoot and perform necessary maintenance tasks.

| Component Name | Description |

|---|---|

| Engine | The power source that drives the equipment, converting fuel into mechanical energy. |

| Cutting Head | The part responsible for the actual cutting action, often equipped with a line or blade. |

| Fuel Tank | Stores the necessary fuel for operation, designed for easy filling and secure closure. |

| Handlebar | Provides control over the device, ensuring user comfort and stability during operation. |

| Safety Guard | Protects the user from debris and injury during cutting tasks, enhancing operational safety. |

Interconnectivity of Components

Understanding how these parts work together is crucial for effective operation. Each element interacts with others to ensure the device functions smoothly and efficiently.

Key Components of FS38 Model

The efficiency and performance of this equipment rely on various essential elements. Understanding these crucial components is vital for effective operation and maintenance. Each part plays a significant role in the overall functionality, ensuring optimal use in various tasks.

Major Elements

- Engine: The powerhouse of the machine, responsible for providing the necessary energy to operate.

- Cutter Head: This component is designed to effectively trim grass and weeds, featuring interchangeable lines for versatility.

- Handle: Ergonomically designed for comfort and control, it enables the user to maneuver the device with ease.

- Throttle Trigger: This control allows for the adjustment of power output, giving users flexibility depending on the task at hand.

Supporting Features

- Fuel Tank: Stores the fuel needed for operation, designed for easy filling and management.

- Air Filter: Keeps the engine clean by filtering out debris and contaminants, contributing to longevity.

- Safety Guard: Protects the user from debris ejected during operation, enhancing safety.

Importance of Proper Maintenance

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. It involves a systematic approach to inspecting, cleaning, and repairing equipment to prevent potential failures and enhance performance. Neglecting maintenance can lead to significant issues, resulting in costly repairs and downtime.

Key benefits of diligent maintenance include:

- Enhanced Performance: Well-maintained equipment operates more efficiently, delivering optimal results.

- Extended Lifespan: Regular care can significantly prolong the service life of the machinery.

- Safety Assurance: Proper checks reduce the risk of accidents and injuries caused by malfunctioning equipment.

- Cost Savings: Investing time and resources in maintenance minimizes unexpected repair costs.

- Environmental Responsibility: Efficient equipment consumes less energy and produces fewer emissions.

To achieve these benefits, a structured maintenance routine should be established, including:

- Regular inspections to identify wear and tear.

- Cleaning components to prevent debris accumulation.

- Lubricating moving parts to reduce friction.

- Replacing worn-out components promptly to avoid further damage.

- Keeping a maintenance log to track service history and schedules.

By prioritizing systematic upkeep, users can ensure that their machinery operates at peak performance, ultimately leading to better productivity and reliability.

Common Issues with FS38 Parts

Maintaining a cutting tool can present various challenges, particularly concerning its components. Understanding typical complications can significantly enhance performance and longevity. Users often encounter problems that may stem from wear, improper installation, or lack of maintenance.

Frequent Problems:

- Fuel Line Failures: Over time, the fuel delivery system may degrade, leading to insufficient power and efficiency.

- Worn Blades: Dull or damaged blades can hinder cutting performance, resulting in uneven trimming and increased strain on the engine.

- Air Filter Clogs: A dirty air filter can restrict airflow, causing the engine to run poorly or stall unexpectedly.

Addressing Issues:

Regular inspections and timely replacements of affected components are crucial for optimal operation. Keeping the equipment clean and well-maintained will prevent many common issues and enhance overall functionality.

How to Access Parts for Repair

Accessing components for maintenance is essential to ensure the longevity and performance of your equipment. Knowing where to find the necessary elements can simplify the repair process and save time and effort. This section will guide you through various methods to obtain the required pieces effectively.

Identifying Reliable Sources

When seeking replacement items, it’s crucial to identify trustworthy sources. Consider the following options:

- Authorized Dealers: These retailers specialize in original components, ensuring quality and compatibility.

- Online Retailers: Many websites offer a wide range of items, often at competitive prices. Check customer reviews for reliability.

- Local Repair Shops: These establishments may have the necessary items in stock or can assist in ordering them for you.

- Manufacturer’s Website: Official websites often provide a catalog of available components for direct purchase.

Gathering Information

Before making a purchase, gather essential details about the required components:

- Model Information: Ensure you have the correct model details to find the right elements.

- Specifications: Note down the specifications, such as sizes and configurations, to avoid incorrect orders.

- Installation Guides: Reference manuals or online tutorials can provide insight into the installation process, which may affect part selection.

Tools Required for FS38 Maintenance

Proper upkeep of your equipment is essential for optimal performance and longevity. Having the right tools on hand not only simplifies the maintenance process but also ensures that each task is executed efficiently. This section outlines the necessary implements for effective care of your device.

Essential Maintenance Implements

To begin with, a comprehensive toolkit should include various implements that cater to different maintenance needs. The following tools are highly recommended:

- Wrench Set: For loosening and tightening bolts securely.

- Screwdriver Set: Essential for adjusting or replacing screws in different parts.

- Fuel Mixing Bottle: Important for accurately mixing fuel and oil for optimal engine performance.

- Brushes: Useful for cleaning air filters and other components to maintain efficiency.

- Protective Gloves: To ensure safety during maintenance tasks.

Additional Useful Tools

In addition to the essential implements, having a few extra tools can further enhance your maintenance routine:

- Torque Wrench: Ensures that screws and bolts are tightened to the correct specifications.

- Cleaning Solution: Aids in the removal of stubborn dirt and grime from various parts.

- Safety Glasses: Protects your eyes from debris and potential hazards during maintenance.

Equipping yourself with these tools will significantly improve your ability to maintain your equipment effectively, ensuring its reliability and performance over time.

Identifying Original Stihl Parts

Recognizing authentic components for outdoor equipment is crucial for maintaining optimal performance and longevity. Genuine parts ensure that the machinery operates effectively and safely, preventing potential damage or malfunction. Understanding the features that distinguish original items from replicas can help users make informed purchasing decisions.

To ascertain the authenticity of a component, one should examine the packaging and labeling closely. Original items often include specific branding elements, including holograms, serial numbers, or part codes that can be verified with the manufacturer. Additionally, the quality of the material and construction can serve as indicators; genuine products typically exhibit superior craftsmanship and durability.

Consulting official documentation or resources from the manufacturer can provide further assurance. Many companies offer detailed catalogs or online tools that allow users to cross-reference parts with their equipment model. Engaging with authorized dealers or service centers can also provide valuable insights and support in identifying original components.

Step-by-Step Assembly Guide

Assembling your equipment efficiently requires a clear understanding of the various components and their interactions. This section will provide a structured approach to reassembling your device, ensuring each piece is correctly positioned for optimal performance. Following these steps will help avoid common pitfalls and streamline the process.

1. Gather Your Tools

Before starting, ensure you have all necessary tools on hand. This includes wrenches, screwdrivers, and any specialized equipment needed for assembly. Having everything ready will prevent interruptions during the process.

2. Identify All Components

Carefully lay out each element of your device. Familiarize yourself with their functions and how they fit together. This will provide clarity and confidence as you progress through the assembly.

3. Follow the Sequence

Start with the base assembly and work your way up. Attach larger components first, followed by smaller ones. Refer to your documentation to ensure you’re following the correct order.

4. Secure Connections

As you connect each part, make sure they are tightly secured. Loose components can lead to malfunction or damage over time. Check each connection before proceeding to the next step.

5. Final Inspection

Once assembly is complete, conduct a thorough inspection. Look for any missed connections or components that appear misaligned. Ensure everything is in its proper place before attempting to operate the device.

By following this structured approach, you can ensure a smooth assembly process, enhancing the reliability and longevity of your equipment.

Safety Precautions for Handling Parts

Ensuring safety while managing components is crucial to prevent accidents and maintain effective operations. Familiarizing yourself with appropriate practices can significantly reduce the risks associated with mishandling and improper usage. Adopting a proactive approach toward safety not only protects individuals but also enhances the longevity of equipment.

Before engaging with any components, it is essential to consider the following precautions:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear suitable gear such as gloves, goggles, and sturdy footwear to shield against injuries. |

| Workspace Organization | Keep your workspace tidy and free from clutter to minimize the risk of tripping or accidents. |

| Tool Familiarity | Understand the tools and components you are working with to prevent misuse and potential hazards. |

| Proper Lifting Techniques | Use correct lifting methods to avoid strain or injury when handling heavy items. |

| Disposal of Defective Components | Ensure that damaged or worn-out parts are disposed of safely to avoid accidents. |

Resources for FS38 Repair Manuals

Accessing comprehensive guides for maintenance and repair is essential for keeping outdoor equipment in optimal condition. These resources provide valuable insights and instructions for users, allowing them to effectively troubleshoot issues and perform necessary repairs. Whether you are a novice or an experienced technician, having access to detailed documentation can significantly enhance your understanding and efficiency in handling machinery.

Official Manufacturer Guides

Official manufacturer publications are often the most reliable sources of information. These documents typically include schematics, service procedures, and specifications that are crucial for effective repairs. They ensure that users follow recommended practices and use the correct methods for disassembly and reassembly.

Online Community Forums

In addition to formal manuals, online community forums serve as a rich resource for shared knowledge and experiences. Users can find tips, troubleshooting advice, and insights from fellow equipment owners. Engaging with these communities can provide practical solutions and innovative ideas that are not always found in official documentation.

Customer Support and Replacement Options

When it comes to maintaining outdoor equipment, having reliable assistance and quality components is essential for optimal performance. Users often seek guidance on the best practices for upkeep and sourcing replacement items. Understanding available resources can greatly enhance the experience and extend the lifespan of the equipment.

Customer service is a crucial aspect that provides users with the necessary support. Many manufacturers offer dedicated helplines, online chat options, and comprehensive websites where users can find helpful information. These resources often include troubleshooting tips, maintenance guidelines, and instructional videos to aid in resolving common issues.

Additionally, replacement options are widely available through various channels. Authorized dealers and online marketplaces provide a vast array of components, ensuring users can find what they need efficiently. Investing in high-quality substitutes not only guarantees compatibility but also enhances the overall functionality of the machinery.