Understanding the intricate details of mechanical tools is crucial for effective maintenance and repair. Every element of a device, whether large or small, plays a significant role in its overall function. Having a clear visual guide to the different elements and how they connect allows for efficient troubleshooting and replacement when necessary.

This guide provides a structured breakdown of the essential elements, enabling users to easily identify and manage the internal components. By recognizing the role of each piece, maintenance tasks can be carried out with precision, ensuring the longevity and performance of the equipment.

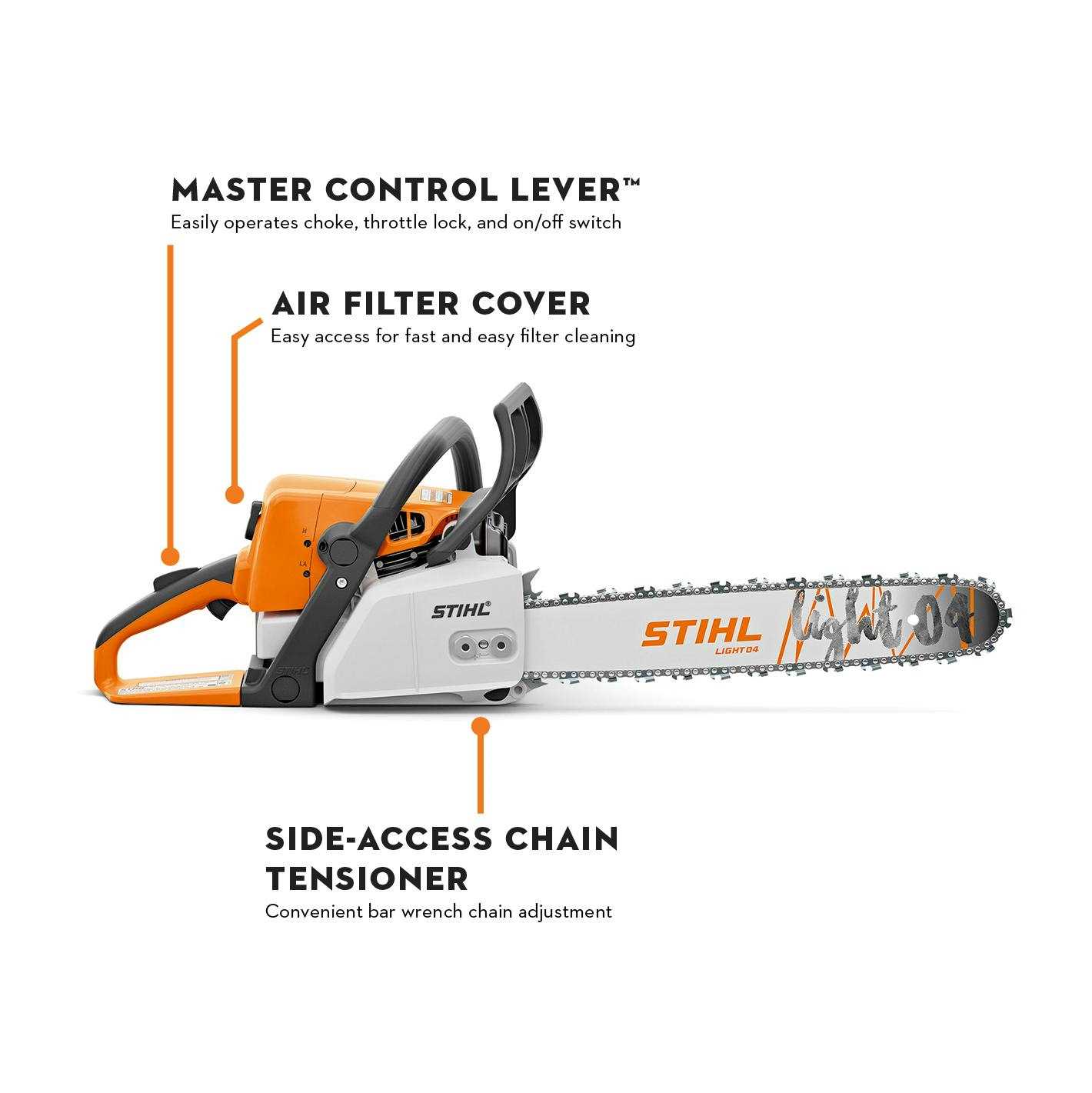

Overview of MS250 Stihl Chainsaw Components

This powerful cutting tool is composed of various essential elements that work together to deliver optimal performance. Understanding the different parts and how they function allows for easier maintenance and repair. Each component plays a vital role in ensuring efficiency, safety, and durability during operation.

Engine Assembly

The engine is the heart of the chainsaw, converting fuel into mechanical energy. This section includes the cylinder, piston, and carburetor, which together provide the necessary power for the saw to cut through wood. Proper care of these parts ensures smooth functioning and long-lasting use.

Cutting Mechanism

The cutting system includes the chain and bar, which are responsible for slicing through material. The chain rotates at high speed around the guide bar, making it critical to keep both sharp and well-lubricated for efficient cutting. Regular inspection and adjustment of these components enhance precision and safety.

Guide Bar and Chain Mechanism

The guide bar and chain are essential components in a cutting tool’s operation, ensuring precise and efficient performance. This system is responsible for directing the cutting chain around the bar, allowing it to slice through material smoothly. Regular maintenance and understanding of this mechanism are key to achieving optimal results.

Guide Bar Functionality

The guide bar serves as the backbone of the cutting tool, providing a steady path for the chain to follow. Its design ensures stability during operation, allowing the chain to move with minimal friction. Selecting the right bar length and maintaining its condition are critical for effective cutting and user safety.

Chain Mechanism and Maintenance

The chain, driven by the motor, wraps around the guide bar and performs the actual cutting. Ensuring proper chain tension and sharpening are vital

Fuel System and Carburetor Assembly

The fuel system is responsible for ensuring that the engine receives the right mixture of fuel and air for efficient combustion. This section covers the key components involved in fuel delivery and carburetion, essential for the smooth operation of the engine.

- Fuel Tank: The reservoir where the liquid fuel is stored before being sent to the engine. It’s equipped with a vent to maintain pressure balance.

- Fuel Filter: Positioned inside the tank, the filter prevents debris and impurities from entering the fuel line, protecting the engine from damage.

- Fuel Lines: These flexible tubes transport fuel from the tank to the carburetor. They must be securely connected and free from cracks or leaks.

- Carburetor: This key component mixes fuel with air in the correct ratio before sending it to the combustion chamber. It contains jets and passages that regulate airflow and fuel supply.

- Primer Bulb: A small pump that helps draw fuel into the carburetor, making it easier to start the engine, especially after long periods of inactivity.

Proper maintenance of these components ensures efficient fuel delivery, optimal engine performance, and prolongs the lifespan of the equipment.

Air Filter and Housing Components

The air filter system plays a crucial role in maintaining the engine’s efficiency by preventing dirt and debris from entering. The housing components ensure the filter stays securely in place, providing a protective barrier against harmful particles. Understanding how these elements work together is essential for maintaining optimal performance.

Key Components of the Air Filter System

- Air Filter Element: The main component responsible for trapping particles and ensuring clean air intake.

- Filter Housing: This holds the filter securely and protects it from damage or displacement.

- Air Intake Cover: A removable cover that provides access to the filter for cleaning or replacement.

Maintenance and Replacement Tips

- Regularly inspect the air filter for dirt accumulation and clean it to maintain airflow.

- Replace the filter if it becomes clogged or damaged to ensure the engine receives sufficient clean air.

- Ensure the housing components are intact and

Ignition System and Spark Plug Placement

The ignition mechanism plays a crucial role in ensuring proper engine function by providing the necessary spark to ignite the fuel mixture. The system is responsible for generating the electrical pulse that is transferred to the spark plug, which in turn creates combustion within the engine cylinder. Without a properly functioning ignition setup, the motor will not start or run efficiently.

The placement of the spark plug is key to maintaining optimal performance. It is typically located near the top of the cylinder, allowing for easy access during maintenance. Regular inspection and cleaning of the spark plug are recommended to prevent fouling and ensure consistent firing. Understanding the correct positioning and connection of the ignition components ensures smoother operation and prolonged engine life.

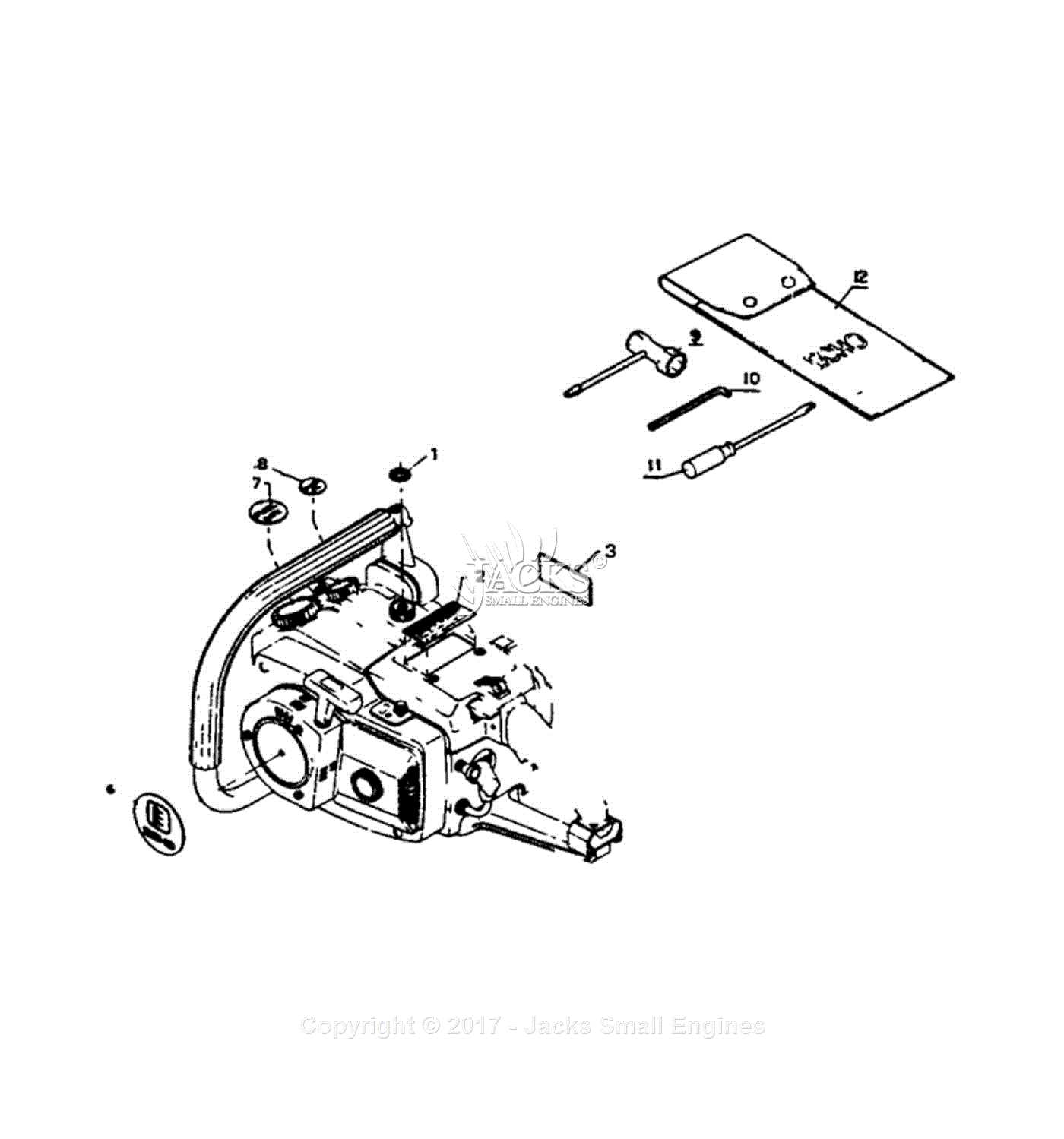

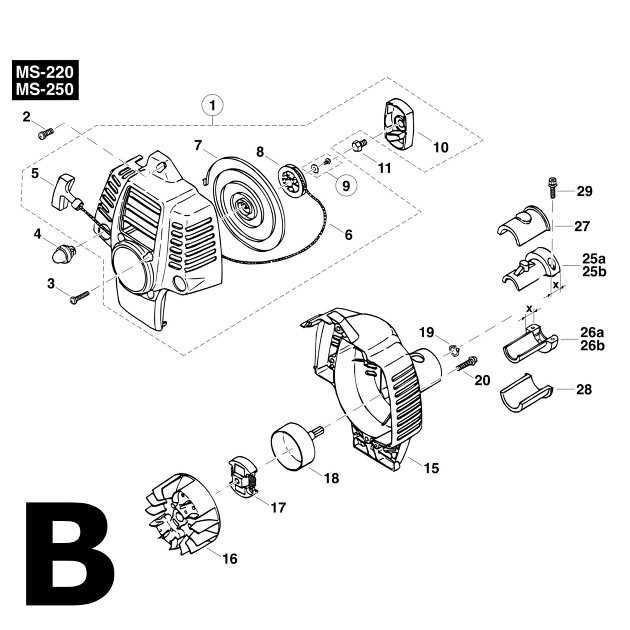

Recoil Starter and Mechanism Parts

The recoil starter system is a vital component in many outdoor power equipment, facilitating the ignition of the engine through a series of mechanical interactions. This assembly typically consists of several essential elements that work together seamlessly to ensure reliable engine startup.

Key Components of the Recoil Starter

At the heart of the recoil starter is the pulley, which is connected to the starter rope. When the rope is pulled, the pulley rotates, engaging the engine flywheel. Additionally, the spring mechanism within the assembly plays a crucial role in retracting the rope after the initial pull, allowing for subsequent starts without manual adjustment.

Common Issues and Maintenance

Regular inspection of the recoil starter components is important to maintain functionality. Common problems include frayed starter ropes or a malfunctioning spring. Ensuring that these components are in good condition will enhance the overall performance and longevity of the equipment.

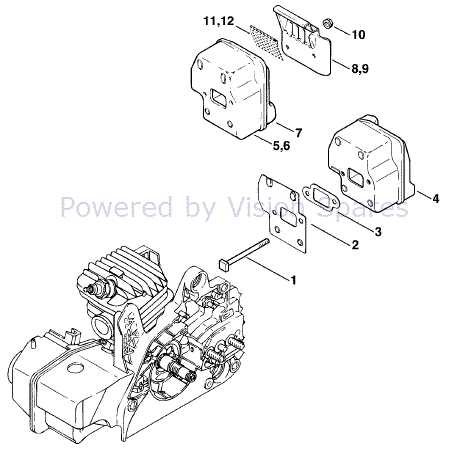

Exhaust System and Muffler Details

The exhaust system plays a crucial role in managing the emissions produced during the operation of small engines. This system not only directs harmful gases away from the engine but also helps to minimize noise levels, ensuring a quieter and more efficient performance.

The muffler is a vital component within the exhaust system. Its primary function is to reduce engine noise by dissipating sound waves generated during combustion. Additionally, the muffler contributes to the overall efficiency of the engine by maintaining optimal back pressure, which is essential for effective exhaust flow.

Regular maintenance of the exhaust system and muffler is necessary to ensure proper functionality. This includes checking for signs of wear, rust, or blockage, which can hinder performance. By ensuring that these components are in good condition, one can achieve better fuel efficiency and prolong the engine’s lifespan.

Oil Pump and Lubrication System

The lubrication system is essential for ensuring the efficient operation of the equipment, providing necessary protection to moving parts. This system relies on an oil pump to deliver lubrication fluid, which helps reduce friction, wear, and overheating during operation. Understanding the components and functionality of the lubrication mechanism is crucial for maintaining optimal performance.

Components of the Lubrication System

The lubrication system consists of several key elements that work together to deliver oil to the engine’s vital parts. The primary components include:

- Oil Pump

- Oil Filter

- Oil Reservoir

- Oil Lines

- Lubrication Points

Functionality of the Oil Pump

The oil pump plays a pivotal role in circulating lubrication fluid throughout the system. It draws oil from the reservoir and pumps it under pressure to various parts of the engine. The flow rate can often be adjusted to ensure sufficient lubrication according to operating conditions.

Component Function Oil Pump Circulates lubrication fluid under pressure Oil Filter Removes contaminants from the lubrication fluid Oil Reservoir Holds lubrication fluid for the system Oil Lines Transport lubrication fluid to various parts Lubrication Points Receive oil to minimize friction and wear Clutch and Sprocket Assembly

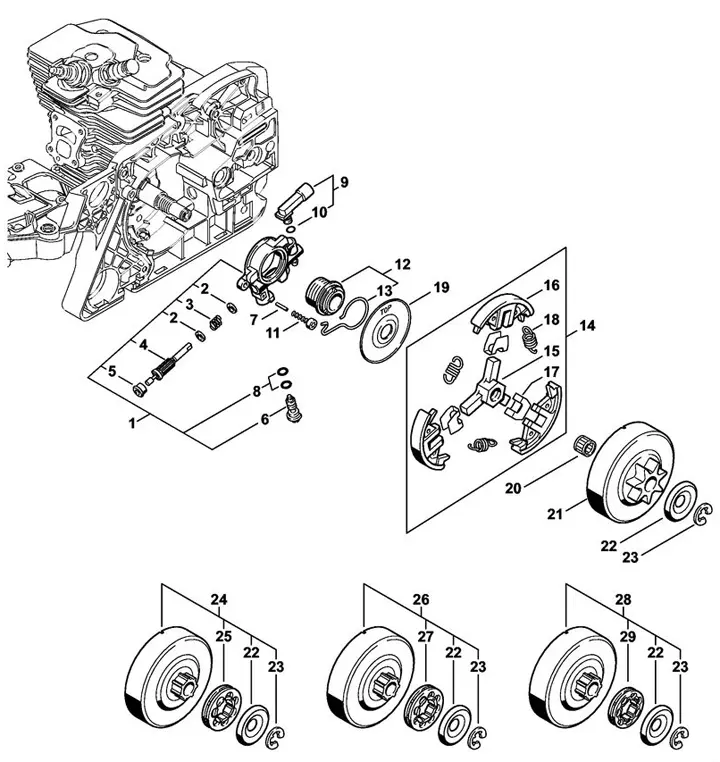

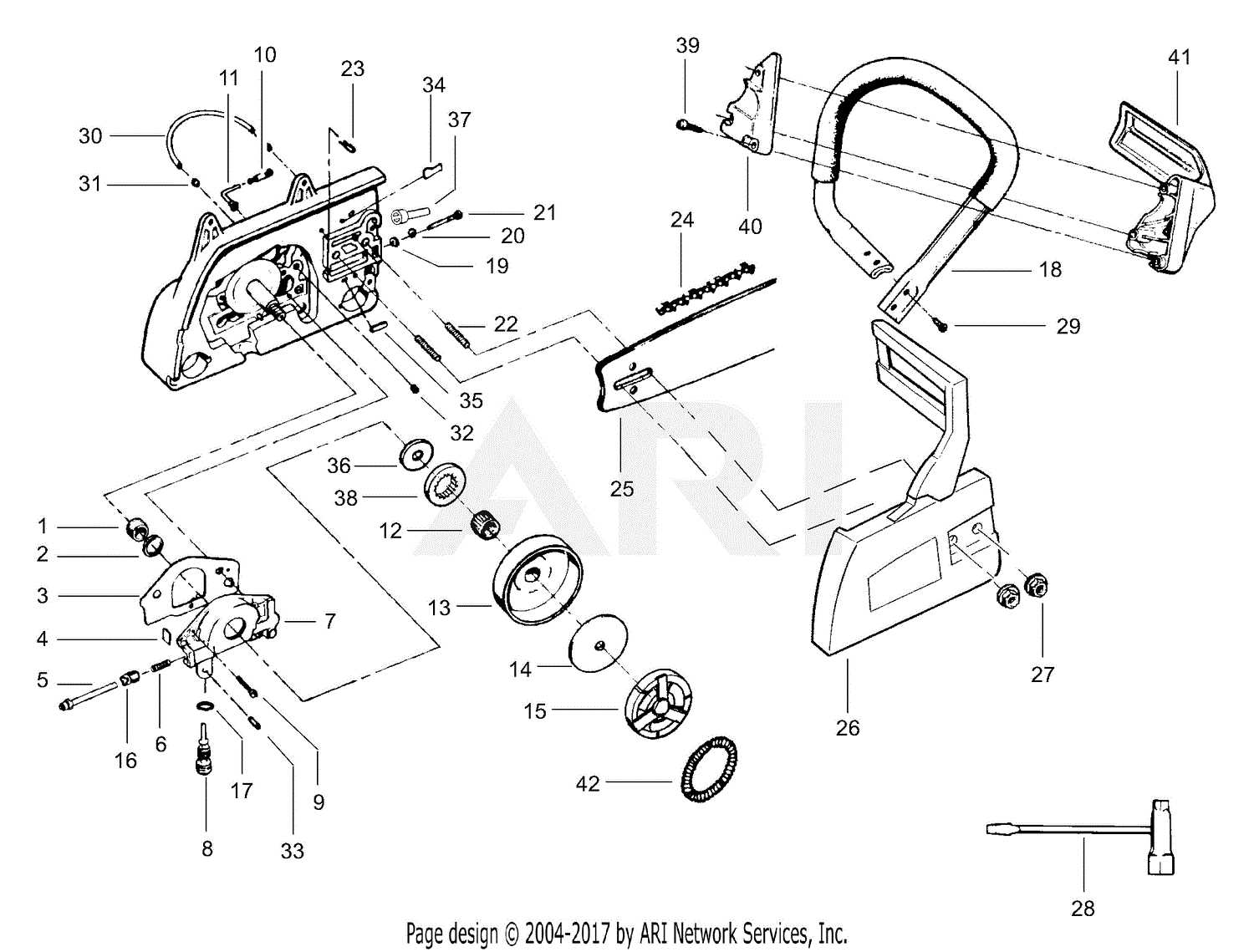

The clutch and sprocket assembly is a crucial component in ensuring the efficient transfer of power from the engine to the cutting tool. This assembly plays a vital role in the operational efficiency of the machine, allowing for smooth engagement and disengagement during use.

Components Overview

This assembly typically consists of several key elements, including the clutch drum, drive sprocket, and bearings. Each component works in harmony to facilitate effective rotation and torque transmission, contributing to the overall performance of the device.

Maintenance Tips

Regular maintenance of the clutch and sprocket assembly is essential for optimal functionality. Inspect the components for wear and tear, and ensure that lubrication is applied appropriately. Replacing worn parts promptly can prevent more significant issues and extend the lifespan of the equipment.

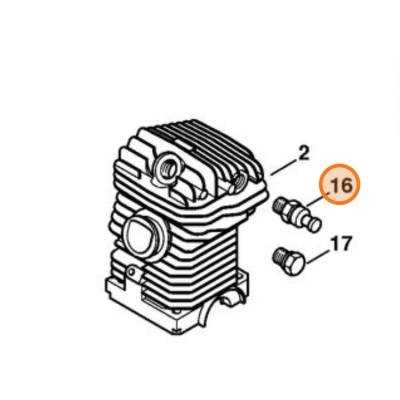

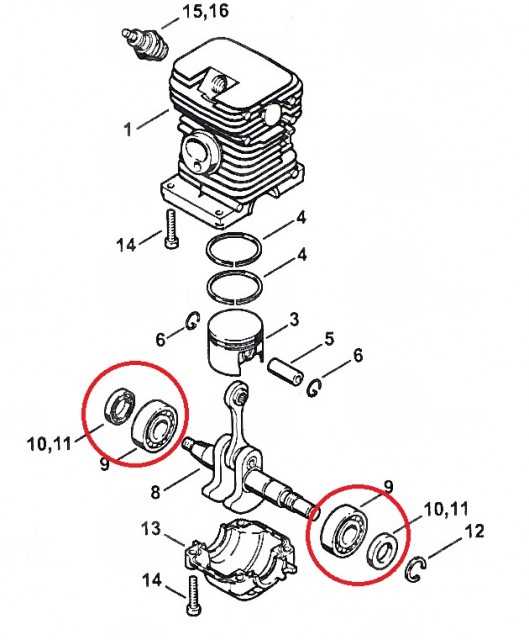

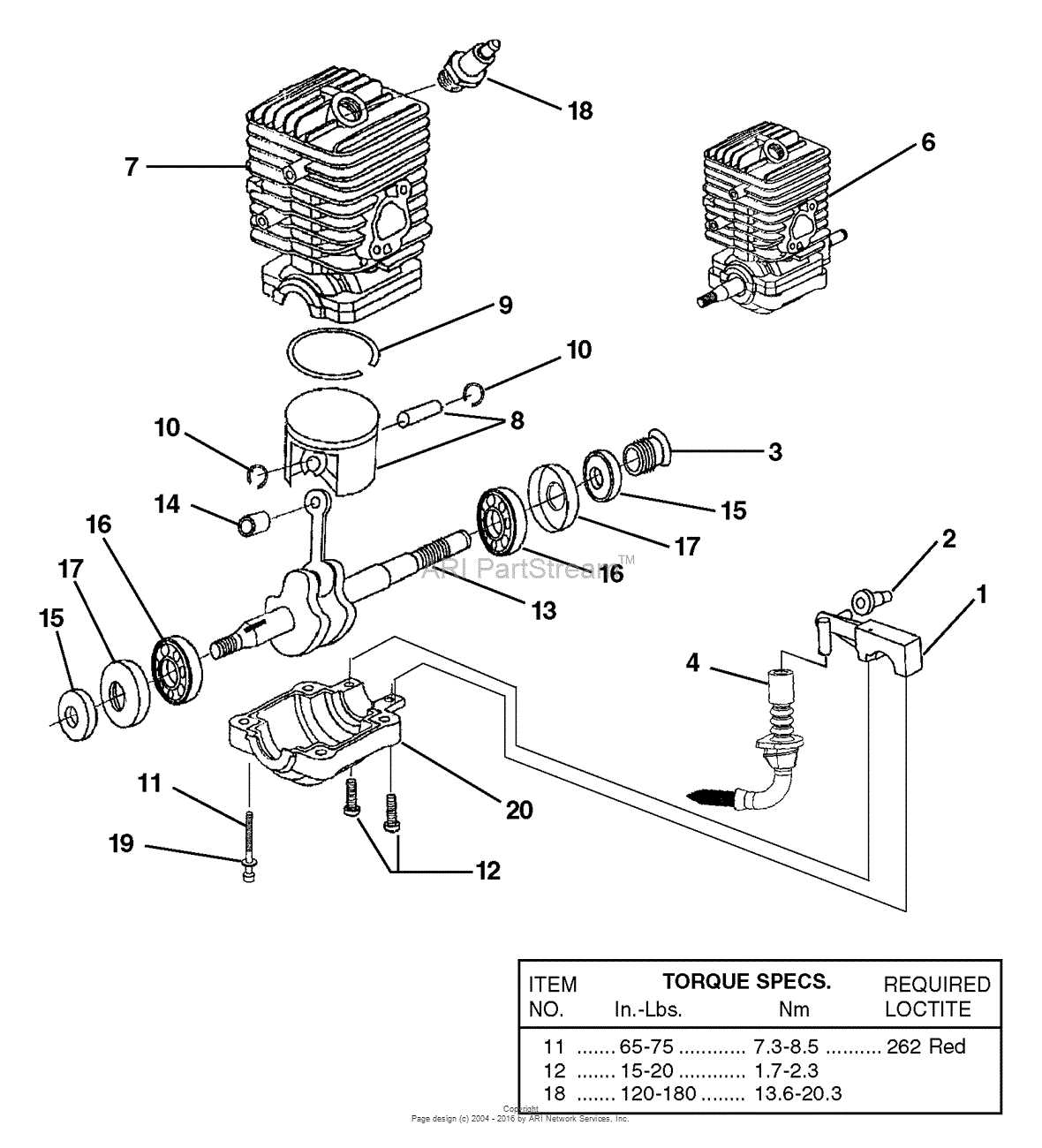

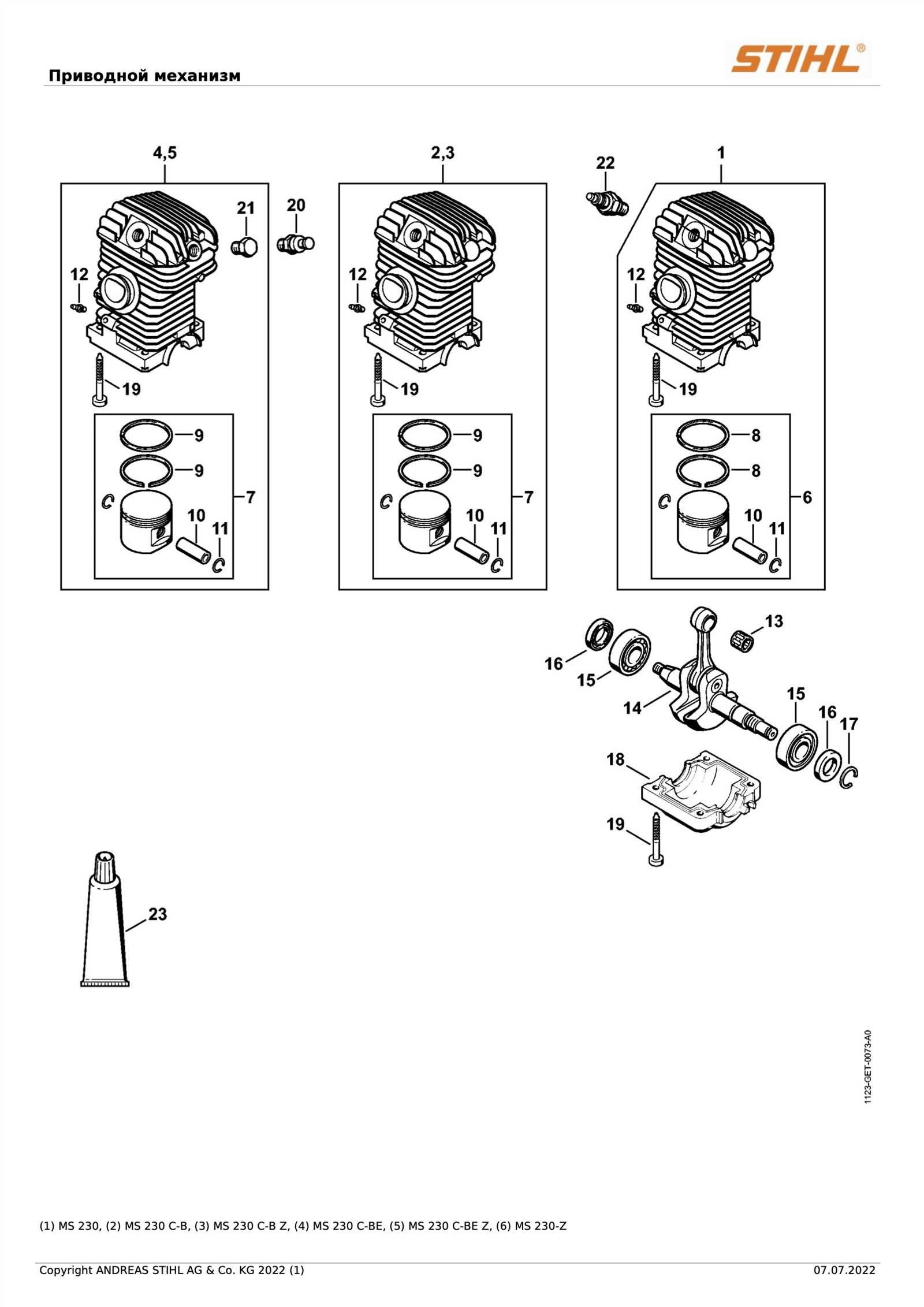

Cylinder and Piston Arrangement

The configuration of the cylinder and piston plays a crucial role in the performance and efficiency of any engine. This arrangement is essential for the compression of the fuel-air mixture, enabling effective combustion and energy production. Understanding how these components interact can provide valuable insights into the engine’s functionality.

Component Description Cylinder A cylindrical chamber where the piston moves, facilitating the intake and exhaust processes. Piston A moving component that compresses the fuel-air mixture within the cylinder, transferring force to the crankshaft. Piston Rings Seals the gap between the piston and cylinder wall, preventing gas leakage and ensuring proper lubrication. Cylinder Head The top part of the cylinder that houses the combustion chamber and valves, crucial for controlling air and fuel flow. Handlebar and Vibration Dampening System

The handlebar and vibration dampening mechanism play a crucial role in the operation of outdoor power equipment. These components ensure a comfortable grip and minimize the transfer of vibrations to the user, enhancing overall handling and reducing fatigue during prolonged use.

The design of the handlebar is essential for achieving optimal control and stability while operating the machine. It allows the user to maneuver the equipment effectively, providing a secure hold even in challenging conditions. The vibration dampening system further contributes to user comfort by absorbing shocks and vibrations generated during operation, promoting a smoother experience.

Component Description Handlebar Provides a stable grip and control for the operator. Dampening Mounts Absorb vibrations and reduce the impact on the user’s hands. Grip Enhances comfort and prevents slippage during use. Adjustment Mechanism Allows for customizing the handlebar height and angle for better ergonomics. Throttle and Control Lever Functionality

The throttle and control lever play a crucial role in the operation of handheld power tools, enabling the user to manage engine speed and overall performance. Understanding their functionality is essential for effective usage and maintenance.

When engaged, the throttle lever regulates the amount of fuel and air mixture that enters the engine, influencing its power output. This mechanism allows users to adjust the tool’s speed according to the specific task at hand, providing greater control and efficiency.

Function Description Throttle Control Adjusts the engine speed by controlling the fuel-air mixture. Safety Mechanism Prevents accidental acceleration, ensuring safe operation. Ergonomic Design Facilitates comfortable and intuitive handling for extended use. Response Time Ensures quick and accurate adjustment to user commands.