When it comes to maintaining the efficiency of your outdoor equipment, having a clear understanding of its individual elements is crucial. Each component plays a vital role in the overall functionality, ensuring that your device operates smoothly and effectively. This guide aims to provide insights into the intricate assembly that keeps your machine running at its best.

Proper maintenance begins with familiarization. Knowing the specific functions and interrelationships of each segment allows for timely repairs and replacements, ultimately extending the lifespan of your equipment. By recognizing the significance of each piece, you can better appreciate the engineering behind these powerful tools.

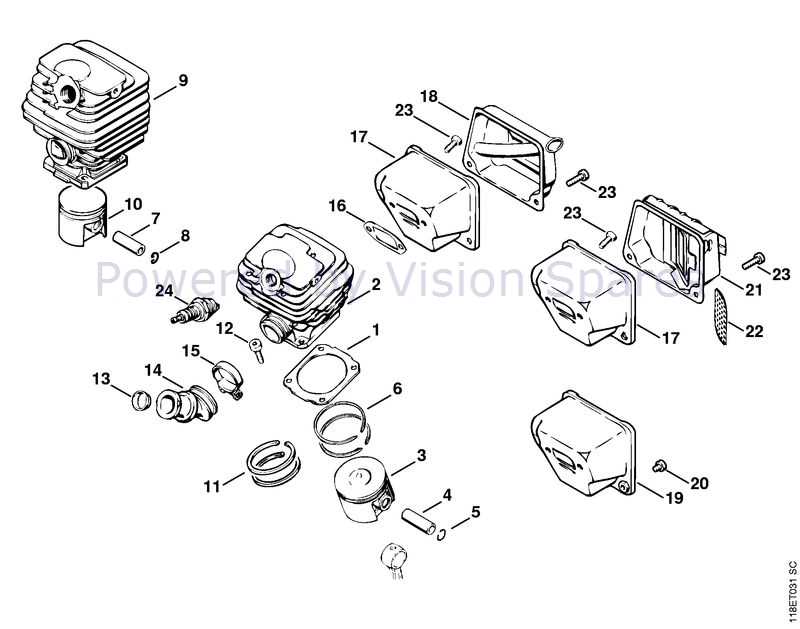

In this article, we will explore a visual representation of the various elements that comprise your cutting apparatus. This resource will assist you in identifying components quickly, making it easier to troubleshoot issues and carry out necessary upkeep. Whether you’re a seasoned user or a newcomer, this information will enhance your understanding and proficiency.

Overview of Stihl 028 AV Wood Boss

This section provides a comprehensive look at a well-regarded cutting tool designed for efficiency and durability. Known for its robust performance, this device has become a favorite among outdoor enthusiasts and professionals alike.

Key features include:

- Powerful engine for optimal cutting performance

- Lightweight design for ease of use

- Advanced vibration reduction system for user comfort

- Durable construction for long-lasting reliability

Maintenance is crucial for preserving functionality. Regular checks and timely replacements of components ensure the tool remains in peak condition. Understanding the anatomy of this machine can greatly enhance the user’s experience.

Key Features of the Stihl 028

This model is renowned for its robust performance and versatility, making it a favorite among users who require reliability and efficiency in their cutting tasks. With a blend of innovative technology and user-centric design, this tool excels in various applications, from light trimming to more demanding forestry work.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a powerful engine that provides optimal cutting speed and torque, enabling efficient operation. |

| Lightweight Design | The ergonomic structure ensures reduced fatigue during extended use, making it suitable for both professionals and hobbyists. |

| Easy Start Mechanism | Incorporates a simple starting system that minimizes effort and time, enhancing user experience. |

| Durability | Constructed with high-quality materials that withstand wear and tear, ensuring a long service life. |

| Adjustable Features | Includes settings for customization according to specific cutting requirements, promoting versatility in usage. |

Common Issues with Stihl 028 Parts

When working with outdoor power tools, various components may present challenges over time. Identifying these common concerns can enhance performance and longevity. Understanding the typical failures allows users to proactively address them, ensuring a smoother operation.

Wear and Tear

Frequent use can lead to wear and tear on vital components, such as the ignition system and fuel lines. These elements may deteriorate due to exposure to harsh conditions, affecting overall efficiency. Regular inspections can help detect issues before they escalate.

Fuel System Problems

Blockages in the fuel system often arise from debris or old fuel. Such issues can result in poor engine performance or starting difficulties. Maintaining a clean fuel supply and timely filter replacements can mitigate these risks effectively.

Identifying Replacement Components

Understanding the key elements of a power tool is crucial for maintaining its performance and longevity. When it comes to repairs or upgrades, recognizing the specific components needed can make the process more efficient. This guide aims to simplify the identification of essential parts to ensure optimal functionality.

Common Elements to Consider

Begin by examining the core structure of the tool. Elements such as the engine, fuel system, and cutting mechanisms play pivotal roles. Familiarizing yourself with these components allows for a more precise selection of replacements.

Resources for Identification

Utilize various resources like manuals and online forums dedicated to power tools. These platforms often provide detailed information and diagrams that can assist in pinpointing the exact components required for replacement.

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and repair. A visual representation helps users identify each element’s function and relationship, facilitating easier troubleshooting and assembly.

Importance of Familiarity

Being acquainted with the arrangement allows for quicker identification of issues. It enhances the overall efficiency of repairs, ensuring that each piece is correctly handled and replaced when necessary.

How to Utilize the Visual Guide

To make the most of the visual guide, start by studying each section closely. Pay attention to labels and references that indicate the specific roles of each component, aiding in better understanding and execution of maintenance tasks.

Importance of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring optimal performance and longevity. Neglecting routine care can lead to inefficiencies and costly repairs, ultimately impacting productivity. Regular attention not only enhances functionality but also promotes safety during use.

Benefits of Routine Care

- Increased lifespan of the machine

- Improved efficiency and performance

- Reduced risk of unexpected failures

- Enhanced safety for the operator

Key Maintenance Practices

- Regularly clean components to prevent debris buildup.

- Inspect and replace worn parts as needed.

- Check fluid levels and change them according to guidelines.

- Sharpen blades and tools to ensure effective operation.

Where to Find Stihl 028 Parts

Locating components for your chainsaw can seem daunting, but there are several reliable avenues to explore. From authorized dealers to online marketplaces, options abound for those in need of replacement pieces. This section provides insights into the best sources for obtaining what you require.

Authorized Dealers

Visiting an authorized dealer is one of the most dependable ways to find high-quality components. Here’s what you can expect:

- Genuine parts that ensure compatibility and performance.

- Expert advice from knowledgeable staff.

- Access to the latest updates and products.

Online Marketplaces

The internet offers a wealth of options for purchasing components. Consider these platforms:

- eBay: A vast selection of new and used items, often at competitive prices.

- Amazons: Reliable shipping and customer service with a wide variety of options.

- Specialized Websites: Numerous online retailers focus on outdoor power equipment, providing detailed listings and specifications.

Tips for Installing New Parts

When replacing components in machinery, careful attention ensures optimal performance and longevity. Following specific guidelines can facilitate a smooth installation process, reducing the risk of future issues.

Preparation is Key

Before beginning the installation, gather all necessary tools and new components. Consulting the manual can provide valuable insights into the assembly process. Ensure the work area is clean and well-lit to prevent any distractions.

Follow a Step-by-Step Approach

Take your time and follow a methodical approach to avoid mistakes. Double-check each step to ensure proper alignment and secure fitting. Regularly inspect your work to catch any potential errors early on.

Comparison with Other Chainsaws

When evaluating various cutting machines, it’s essential to explore how different models stack up against each other. This analysis highlights key features, performance metrics, and user experiences, providing insights into their relative strengths and weaknesses.

Performance Metrics

In terms of power output and efficiency, some machines stand out for their robust engines and enhanced cutting capabilities. For instance, several competitors offer superior torque, making them ideal for heavier tasks. Weight is another critical factor; lighter options can improve maneuverability, especially for prolonged use.

User Experience

Comfort and ease of use vary significantly among different brands. Many users appreciate ergonomic designs that reduce fatigue during extended cutting sessions. Additionally, maintenance requirements can differ; some models are lauded for their straightforward upkeep, while others may require more frequent attention. Ultimately, understanding these differences can help consumers make informed decisions tailored to their specific needs.

User Reviews and Experiences

This section provides insights into the opinions and feedback of individuals who have utilized this particular equipment. By sharing their encounters, users can highlight strengths and potential areas for improvement, aiding prospective buyers in making informed decisions.

| User | Experience | Rating |

|---|---|---|

| John D. | Excellent performance, handles tough jobs effortlessly. | 5/5 |

| Lisa M. | Great value, but a bit heavy for long sessions. | 4/5 |

| Mark T. | Durable design, easy maintenance, highly recommend! | 5/5 |

| Sarah P. | Reliable for small tasks, but lacks power for larger projects. | 3/5 |