Maintaining your outdoor power equipment is essential for optimal performance and longevity. A thorough grasp of the internal workings can significantly enhance your ability to troubleshoot and repair any issues that may arise. This knowledge empowers users to undertake maintenance tasks confidently, ensuring that their machinery operates efficiently.

In this section, we will explore a comprehensive visual representation of the various elements that make up your tool. Each component plays a crucial role in the overall functionality, and understanding their arrangement can aid in identifying potential problems. By diving into the intricate layout, you’ll gain insights into how each part interacts within the system.

Whether you’re a seasoned mechanic or a novice user, familiarizing yourself with these components will equip you with the ultimate knowledge for effective upkeep. Recognizing the significance of each piece will enhance your ability to execute repairs and replacements with precision, ultimately prolonging the life of your equipment.

Understanding Stihl 028 Super Components

In the world of outdoor power tools, grasping the intricacies of various elements is crucial for optimal performance. Each component plays a vital role, ensuring the equipment operates smoothly and efficiently. A thorough comprehension of these parts empowers users to maintain and troubleshoot their machinery effectively.

Key Elements of the Equipment

Essential components include the engine, which provides the necessary power, and the cutting system that determines efficiency. Additionally, the fuel delivery mechanism is critical for performance, while the housing ensures protection and durability. Understanding these aspects helps in recognizing potential issues and planning maintenance.

Maintenance and Upkeep

Regular inspections of individual elements are paramount. Users should focus on cleaning air filters, checking fuel lines, and ensuring that blades are sharp. This proactive approach not only extends the lifespan of the machinery but also enhances its overall functionality.

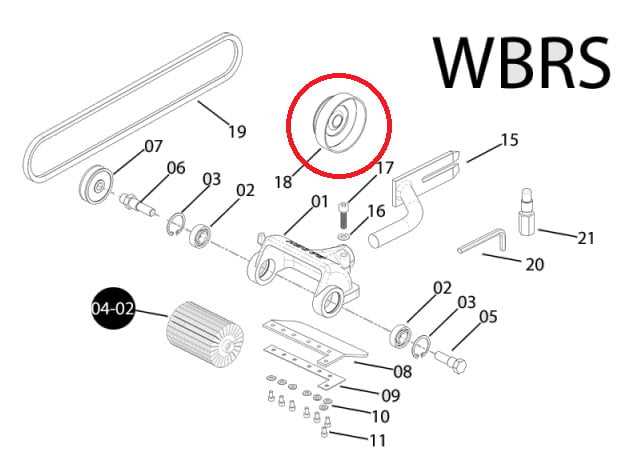

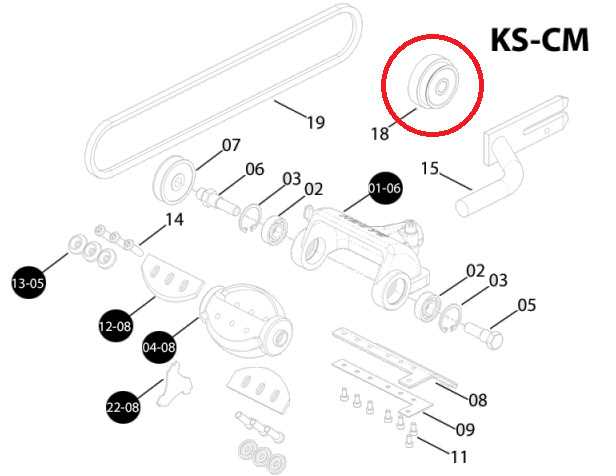

Parts Breakdown for Stihl 028 Super

This section provides a comprehensive overview of the various components essential for the optimal functioning of the equipment. Understanding the individual elements not only aids in maintenance but also enhances the user’s knowledge of the overall mechanism.

Key Elements:

Engine Assembly: Central to operation, it includes vital parts like the crankshaft and cylinder.

Fuel System: Comprising the tank, filter, and lines, this system ensures efficient fuel delivery.

Ignition Components: Essential for starting, this includes the spark plug and ignition coil.

Cutting Mechanism: Consisting of the chain and bar, this assembly is crucial for effective performance.

Body and Housing: The outer shell that protects internal components while providing ergonomic handling.

Common Issues and Solutions

When operating outdoor power equipment, users may encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems and their potential remedies can significantly enhance the user experience and prolong the life of the machine.

One frequent issue is difficulty in starting the engine. This can often be attributed to a clogged air filter or a faulty spark plug. Regular maintenance, such as cleaning or replacing these components, can resolve the problem and ensure smooth operation.

Another common concern is inconsistent power delivery during use. This may stem from fuel-related issues, such as stale gasoline or an obstructed fuel line. Ensuring that fresh, high-quality fuel is used and that the fuel system is clear can help maintain optimal performance.

Users may also notice excessive vibration or unusual noises while operating their equipment. This could indicate loose or worn-out parts. Conducting routine inspections and tightening or replacing any damaged components can mitigate these issues and enhance safety.

Lastly, overheating can occur if the equipment is overworked or if cooling systems are blocked. Allowing the machine to cool down and checking for obstructions can prevent potential damage and maintain operational integrity.

Maintenance Tips for Your Chainsaw

Proper upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Regular maintenance not only enhances performance but also contributes to safety during operation. By following a few key practices, you can keep your equipment in optimal condition.

Routine Checks

Performing consistent inspections is crucial. Here are some aspects to consider:

- Chain Tension: Ensure the chain is neither too tight nor too loose. Adjust as needed for safe operation.

- Bar Condition: Check for wear and tear on the guide bar. Replace if it shows significant damage.

- Air Filter: Clean or replace the air filter regularly to maintain optimal airflow and engine performance.

Cleaning and Lubrication

Keeping your tool clean is vital for its performance. Follow these steps:

- Clean the Exterior: Remove debris and sawdust from the body to prevent overheating.

- Lubricate Moving Parts: Use the appropriate oil for the chain and other moving components to minimize friction.

- Fuel System Care: Regularly check fuel lines and filters, ensuring they are clean and free from obstructions.

By integrating these practices into your maintenance routine, you can extend the life of your cutting tool and ensure it operates safely and effectively.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. There are various resources available, both online and offline, that cater to enthusiasts and professionals alike. Whether you prefer shopping from the comfort of your home or visiting a local store, options abound to ensure your machinery runs smoothly.

Online Resources

The internet is a treasure trove for sourcing essential components. Websites dedicated to outdoor tools offer extensive catalogs, often featuring detailed descriptions and images to help you identify what you need. Online marketplaces and specialized forums can also connect you with sellers who provide authentic replacements at competitive prices.

Local Dealers and Repair Shops

Visiting a local dealer or repair shop can yield valuable assistance. Knowledgeable staff can guide you to the correct items and might even have them in stock. Additionally, these establishments often provide insight into maintenance and usage, ensuring that your equipment performs at its best.

Assembly Process of Stihl 028 Super

The assembly procedure of a chainsaw requires careful attention to detail and a systematic approach to ensure optimal performance. Each component plays a crucial role in the functionality and safety of the equipment. Understanding the sequence and method of putting together these elements is essential for both maintenance and effective operation.

Initial Preparations

Before starting the assembly, it’s vital to gather all necessary components and tools. Ensuring that each piece is clean and free from debris will prevent any issues during the assembly process. Reviewing the user manual can provide valuable insights into the specific order of assembly and any special instructions related to the components.

Step-by-Step Assembly

The assembly begins with attaching the engine to the chassis, ensuring that all bolts are tightened securely. Next, the guide bar and chain must be installed correctly, following the manufacturer’s specifications. After that, the fuel and oil systems should be assembled, paying close attention to the seals and fittings to avoid leaks. Finally, a thorough inspection of the assembled equipment is necessary to ensure everything is in place and functioning correctly.

Comparative Analysis of Similar Models

This section focuses on evaluating the similarities and differences among various models within the same category. By analyzing features, performance metrics, and user experiences, we aim to provide a comprehensive overview that aids potential buyers in making informed decisions.

Key Features to Consider

- Engine Power: Examine the horsepower and torque specifications.

- Weight: Consider the portability and ease of use.

- Fuel Efficiency: Compare consumption rates during operation.

- Maintenance Needs: Assess how often servicing is required.

User Experiences and Feedback

- Durability: How well does each model withstand heavy use?

- Ease of Use: User-friendliness and ergonomic design.

- Availability of Accessories: Options for customization and enhancement.

- Customer Support: Evaluate the responsiveness and helpfulness of service teams.

Tools Required for Repairs

When embarking on maintenance or repair tasks, having the right equipment is essential for efficiency and effectiveness. The following tools are commonly needed to ensure a smooth process.

- Wrenches: For loosening and tightening various fasteners.

- Screwdrivers: A set of flat and Phillips screwdrivers is crucial.

- Pliers: Useful for gripping and manipulating components.

- Torque wrench: To apply precise torque settings when necessary.

- Chain saw file: For sharpening the cutting chain.

Additionally, having a clean workspace and safety gear can enhance the repair experience and protect against accidents.

Expert Recommendations for Longevity

To ensure the extended lifespan and optimal performance of your equipment, implementing a few key practices can make a significant difference. By focusing on regular maintenance, proper usage, and timely replacements, you can prevent premature wear and keep your machine running smoothly for years to come.

| Recommendation | Description |

|---|---|

| Regular Maintenance | Perform routine checks and cleanings to remove debris and prevent buildup, which can cause overheating and malfunction. |

| Proper Storage | Store your equipment in a dry, cool place to protect it from moisture and temperature fluctuations that can damage components. |

| Use Quality Fuel | Opt for high-grade fuel to minimize deposits and ensure efficient combustion, enhancing overall performance. |

| Inspect and Replace Worn Parts | Regularly check for signs of wear and replace any damaged or worn components to prevent further issues. |

| Follow Manufacturer Guidelines | Adhere to the recommended maintenance schedule and usage instructions provided by the manufacturer for best results. |

Safety Guidelines for Chainsaw Use

Operating a cutting tool requires attention and adherence to safety measures to prevent accidents and injuries. Understanding and implementing these guidelines is crucial for both novice and experienced users, ensuring a secure working environment while maximizing efficiency.

Before using a chainsaw, it is essential to familiarize yourself with the equipment and its features. Always wear appropriate personal protective equipment (PPE) to minimize risks associated with the operation.

| Safety Equipment | Description |

|---|---|

| Helmet | Protects the head from falling debris. |

| Eye Protection | Prevents injury from flying particles. |

| Ear Protection | Reduces noise exposure that can lead to hearing loss. |

| Gloves | Offers a better grip and protects hands from cuts. |

| Chainsaw Chaps | Provides leg protection against accidental cuts. |

| Sturdy Boots | Ensures foot protection and stability during operation. |

Before starting the machine, inspect it for any defects. Ensure that the chain is sharp and properly tensioned, and that safety features are functional. When operating, maintain a firm grip and keep both hands on the tool, maintaining a balanced stance.

Always be aware of your surroundings, avoiding work near electrical lines or in high-traffic areas. Communicate clearly with anyone nearby to ensure that they are aware of your activities. If fatigue sets in, take breaks to avoid compromising safety.

FAQs About Stihl 028 Super Parts

This section aims to address common inquiries regarding components for a specific model of chainsaw, ensuring users can find the information they need efficiently. From replacement options to maintenance tips, these FAQs provide valuable insights for both novice and experienced operators.

Common Questions

| Question | Answer |

|---|---|

| What should I do if a part is damaged? | Inspect the component carefully and consider replacing it with a compatible item to ensure optimal performance. |

| Where can I find replacement components? | Authorized dealers and various online retailers offer a wide range of replacement options for your equipment. |

| How often should I replace worn components? | It is recommended to check parts regularly and replace them as needed, especially after heavy usage. |

| Are aftermarket components reliable? | Many aftermarket options are of good quality, but always verify compatibility and reviews before purchasing. |

Maintenance Tips

Regular maintenance can extend the life of your equipment. Keep components clean and check for any signs of wear or damage to ensure safe operation.