In the realm of outdoor equipment, comprehending the intricate design of a powerful cutting tool is essential for effective maintenance and repair. Each component plays a vital role in the overall functionality, ensuring that the machine operates smoothly and efficiently. Familiarity with the layout and interaction of these elements empowers users to troubleshoot issues and perform necessary upkeep.

Exploring the structure of this particular model reveals a thoughtful arrangement of parts, each meticulously crafted to contribute to its high performance. From the engine assembly to the cutting mechanism, understanding how these components fit together provides valuable insights for both novice and experienced operators.

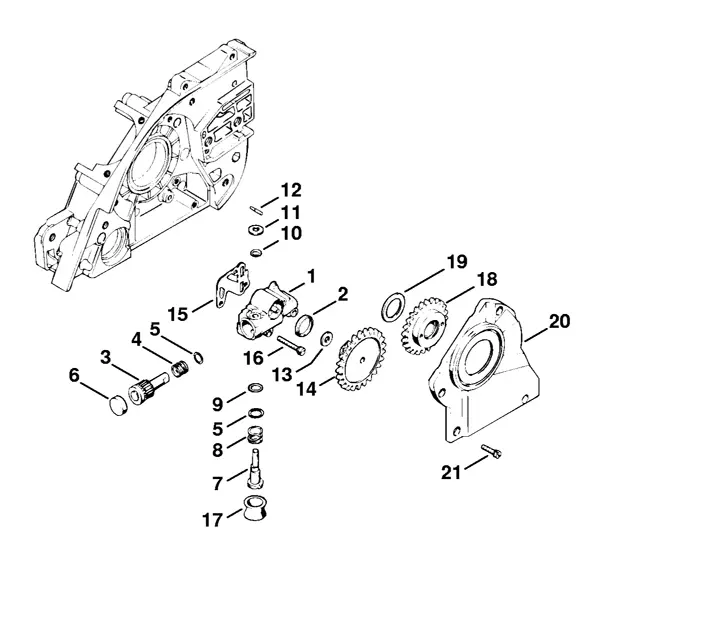

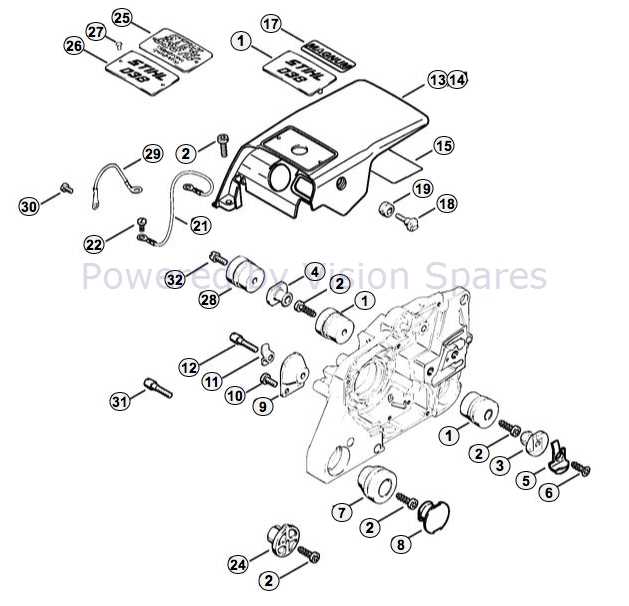

Additionally, having access to a visual representation of the assembly can significantly enhance one’s ability to identify specific elements and their respective functions. This knowledge is crucial when seeking replacements or upgrades, ultimately extending the lifespan of the equipment and optimizing its capabilities.

This section provides a comprehensive overview of a specific model known for its robust performance and reliability in various applications. It highlights the essential features, components, and functionalities that contribute to its effectiveness and user satisfaction.

Key Features

The machine is equipped with several notable characteristics that enhance its usability:

- Powerful engine designed for heavy-duty tasks

- Lightweight frame for easy maneuverability

- Durable construction to withstand tough conditions

- Efficient fuel consumption for prolonged operation

Common Applications

This equipment is widely used in various fields, including:

- Forestry and logging

- Landscaping and garden maintenance

- Construction projects requiring precision cutting

Maintenance Tips

Proper upkeep is crucial for maintaining optimal performance. Consider the following suggestions:

- Regularly check and replace the air filter

- Ensure the cutting chain is well-lubricated

- Inspect the spark plug for wear and replace as needed

- Keep the unit clean to prevent debris buildup

Safety Precautions

When operating this equipment, it’s important to adhere to safety guidelines:

- Always wear appropriate personal protective equipment

- Be aware of your surroundings to prevent accidents

- Follow the manufacturer’s instructions for operation

Replacement Components

For those in need of replacements, several essential components can be sourced, including:

- Chains and bars

- Filters and gaskets

- Fuel and oil lines

Choosing the Right Accessories

Selecting the appropriate accessories can enhance performance:

- Different types of cutting chains for specific tasks

- Protective gear to ensure safe operation

Comparison with Similar Models

Understanding how this model stacks up against competitors can help users make informed choices:

- Evaluate power output and efficiency

- Assess ease of use and comfort features

User Reviews and Feedback

User experiences offer valuable insights into performance and reliability:

- Positive feedback on durability and efficiency

- Common concerns about weight and maneuverability

Where to Buy

Purchasing options include:

- Loc

Key Features and Specifications

This section highlights the essential attributes and technical details of the specified equipment. Understanding these characteristics is crucial for users seeking to optimize performance and ensure longevity. The following information outlines various aspects that define the functionality and usability of this tool.

Feature Specification Engine Type Two-stroke Displacement 61.5 cc Power Output 3.3 kW Weight 5.6 kg Fuel Capacity 0.5 liters Oil Capacity 0.25 liters Bar Length 16 to 20 inches Understanding Parts Functionality

Every machine consists of various components that work together to ensure optimal performance. Recognizing the role of each element is essential for effective operation and maintenance. This knowledge not only aids in troubleshooting but also enhances the overall user experience.

Key Components Overview

Different elements within a device serve distinct purposes. From the engine that powers the machine to the smaller fittings that facilitate seamless operation, each part contributes to the efficiency of the whole system. Understanding how these elements interact can help users maximize the equipment’s capabilities.

Importance of Proper Maintenance

Regular upkeep of individual components is crucial to prolonging the lifespan of any equipment. Neglecting specific elements can lead to malfunctions or decreased efficiency, which may necessitate costly repairs. Familiarity with each component’s functionality enables users to implement appropriate maintenance routines, ensuring longevity and reliability.

Component Function Engine Drives the machine’s overall functionality Fuel System Supplies energy for operation Ignition Initiates the combustion process Air Filter Prevents contaminants from entering the engine Cylinder Houses the combustion process Common Replacement Parts

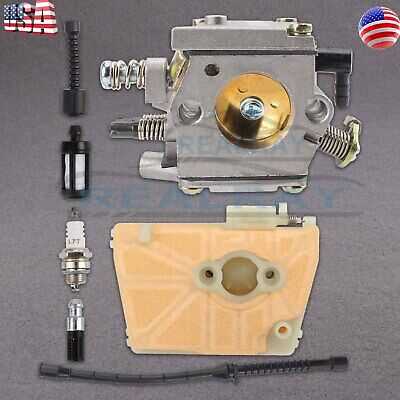

Maintaining outdoor power equipment often requires the replacement of certain components to ensure optimal performance and longevity. Understanding which elements are frequently substituted can aid in efficient repairs and upkeep.

Essential Components

- Air Filter: Keeps debris from entering the engine, ensuring clean airflow.

- Fuel Filter: Prevents impurities from reaching the engine, enhancing performance.

- Spark Plug: Vital for ignition, it should be replaced regularly for efficient engine function.

- Chain: The cutting element that may need replacement due to wear and tear.

Maintenance Items

- Bar: This component supports the chain and requires regular inspection for damage.

- Oil Pump: Ensures proper lubrication of the chain, crucial for preventing overheating.

- Fuel Line: Should be checked for cracks or leaks to maintain fuel efficiency.

Parts Compatibility with Other Models

Understanding the interchangeability of components across various machinery models can significantly enhance repair efficiency and cost-effectiveness. This section explores how certain elements from one model can be utilized in others, providing a practical guide for users seeking to maintain their equipment without the need for original replacements.

Many users often find that specific elements designed for one model are compatible with different versions from the same manufacturer. This can include items like engine components, fuel systems, and ignition parts. Such compatibility not only simplifies maintenance but also expands the options for sourcing necessary elements, enabling users to consider aftermarket solutions or salvaged parts from older machinery.

When selecting replacements, it is essential to consult compatibility charts and diagrams to ensure that the components fit properly and function as intended. This attention to detail helps avoid issues that may arise from mismatched parts, ensuring optimal performance and longevity of the equipment.

In summary, leveraging the compatibility of components among various models can lead to more efficient repairs and maintenance. Users are encouraged to explore these options and verify their choices to keep their machinery in excellent working condition.

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repairs. This guide will provide insights into interpreting these visual representations, ensuring you can identify each element and its function within the assembly.

Familiarize Yourself with the Layout

Start by examining the overall structure of the illustration. Components are typically arranged logically, with related items grouped together. Pay attention to labels, numbers, or letters that correspond to the list of items, as these will aid in identifying specific elements and their locations.

Utilize the Key or Legend

Many illustrations include a key or legend that explains symbols or color codes used in the representation. This key is invaluable for understanding the significance of various markings, making it easier to locate and order the necessary components. Always refer back to this section when in doubt, as it clarifies any confusion regarding the illustration.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure the extended lifespan of your outdoor power equipment. By following a few straightforward practices, you can maintain optimal performance and reliability.

- Regular Cleaning: Keep the equipment free from debris and dirt. After each use, wipe down surfaces and remove any buildup from air filters and cooling fins.

- Routine Inspections: Periodically check components such as the spark plug, fuel lines, and air filters for wear and tear. Replace any damaged parts promptly to prevent further issues.

- Oil Changes: Change the oil according to the manufacturer’s recommendations. Fresh oil helps to lubricate moving parts and reduces friction.

- Proper Fueling: Use the correct fuel type and mix it according to specifications. Poor fuel quality can lead to engine problems and decreased efficiency.

- Storage Practices: Store the equipment in a dry, sheltered location. If storing for extended periods, drain fuel and consider using a stabilizer to prevent deterioration.

By implementing these maintenance strategies, you can enhance the performance and longevity of your equipment, ensuring it serves you well for many seasons to come.

Where to Buy Replacement Parts

Finding quality components for your equipment is essential for maintaining its performance and longevity. There are various avenues available for sourcing these items, ranging from local suppliers to online marketplaces. Each option presents unique benefits that cater to different preferences and needs.

Local Retailers and Authorized Dealers

Visiting local shops and certified dealers can be a reliable way to obtain necessary components. These establishments often provide knowledgeable staff who can assist in identifying the right items. Additionally, purchasing locally allows for immediate acquisition without shipping delays.

Online Marketplaces

The internet offers a vast array of options for sourcing replacement components. Websites dedicated to tools and machinery often feature competitive pricing and a wide selection. Shopping online also enables easy comparison of prices and customer reviews to ensure quality.

Source Advantages Local Retailers Immediate availability, personal assistance Authorized Dealers Genuine items, expert advice Online Marketplaces Wide selection, competitive prices Cost Considerations for Parts

When maintaining or repairing machinery, understanding the financial implications of replacement components is essential. Various factors can influence the overall expenditure, impacting budget planning and decision-making.

- Quality of Components: Investing in high-quality substitutes may incur higher upfront costs but can lead to long-term savings through durability and performance.

- OEM vs. Aftermarket: Original Equipment Manufacturer items typically come with a premium price tag. However, aftermarket alternatives can provide significant savings, albeit with varying levels of reliability.

- Availability: The accessibility of specific components can affect pricing. Scarcity can drive costs up, while readily available items may be more affordable.

- Volume Discounts: Purchasing in bulk often results in reduced prices per unit. This approach is particularly beneficial for businesses or individuals requiring multiple components.

- Shipping and Handling: When ordering components online, be mindful of additional costs such as shipping fees, which can add to the overall expense.

Understanding these financial aspects can aid in making informed choices, ultimately leading to better maintenance practices and cost management.

Troubleshooting Common Issues

When operating machinery, encountering problems is not uncommon. Identifying and resolving these issues can ensure optimal performance and longevity of the equipment. This section focuses on typical challenges users might face and offers practical solutions to restore functionality.

Frequent Problems and Solutions

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear or damage.

- Verify that the air filter is clean and free of debris.

- Overheating:

- Ensure that cooling fins are not obstructed.

- Check for proper oil levels and quality.

- Inspect the exhaust system for blockages.

Performance Degradation

- Reduced Power:

- Examine the fuel filter for clogs.

- Test the ignition system for faults.

- Evaluate the condition of the carburetor.

- Unusual Noises:

- Listen for rattling sounds which may indicate loose components.

- Inspect for wear on the chain and sprocket.

- Check the muffler for signs of damage or obstruction.

Tips for DIY Repairs

Embarking on do-it-yourself repairs can be a rewarding experience, allowing you to save money while gaining valuable skills. Whether you’re dealing with a malfunctioning tool or performing routine maintenance, understanding some essential tips can significantly enhance your repair efforts.

Gather Necessary Tools

Before starting any repair project, ensure you have all the required tools at hand. This preparation will streamline the process and prevent interruptions. Consider including:

- Screwdrivers of various sizes

- Wrenches

- Pliers

- Safety goggles

- Work gloves

Follow Step-by-Step Instructions

To achieve the best results, adhere to detailed instructions. If available, refer to a manual or online resources that outline the repair process. This approach minimizes errors and enhances the likelihood of success:

- Identify the issue clearly.

- Disassemble the necessary components with care.

- Inspect each part for wear and tear.

- Replace or repair damaged components.

- Reassemble everything and test the tool.

With patience and the right approach, DIY repairs can lead to successful outcomes, ensuring your equipment remains in excellent working condition.

Customer Reviews and Feedback

Customer experiences and opinions play a crucial role in understanding the effectiveness and reliability of any equipment. Users often share their insights based on personal usage, which can significantly aid potential buyers in making informed decisions. Feedback highlights various aspects such as performance, ease of use, and durability, providing a comprehensive overview of the product’s strengths and weaknesses.

Positive feedback frequently emphasizes the exceptional performance and efficiency of the equipment, noting its ability to handle demanding tasks with ease. Many users appreciate its robust construction and longevity, highlighting that it remains effective even after extensive use. The user-friendly design often receives commendations for making operation straightforward and accessible to both novices and seasoned users.

Conversely, constructive criticism from some customers points out areas for improvement. Common concerns may include the weight of the machine, which could be a challenge during prolonged use, or the need for occasional maintenance to ensure optimal functionality. Such insights are valuable for manufacturers looking to enhance future models and for customers considering their purchase.

Overall, customer reviews serve as a vital resource, offering a balanced view of the product that encompasses both advantages and potential drawbacks, assisting buyers in aligning their expectations with real-world performance.