Understanding how various elements of a machine are arranged and function together is crucial for efficient maintenance and repairs. By examining the structure and connections, you can gain insights into how each component plays a role in the overall performance.

In this section, we will explore the essential elements of a specific mechanical device, focusing on the organization and interaction of its major parts. This will provide a clear understanding of the system’s inner workings and help identify potential areas requiring attention during maintenance or replacements.

Whether you’re dealing with regular upkeep or troubleshooting an issue, having a clear view of how all the key components fit together is invaluable. We will walk you

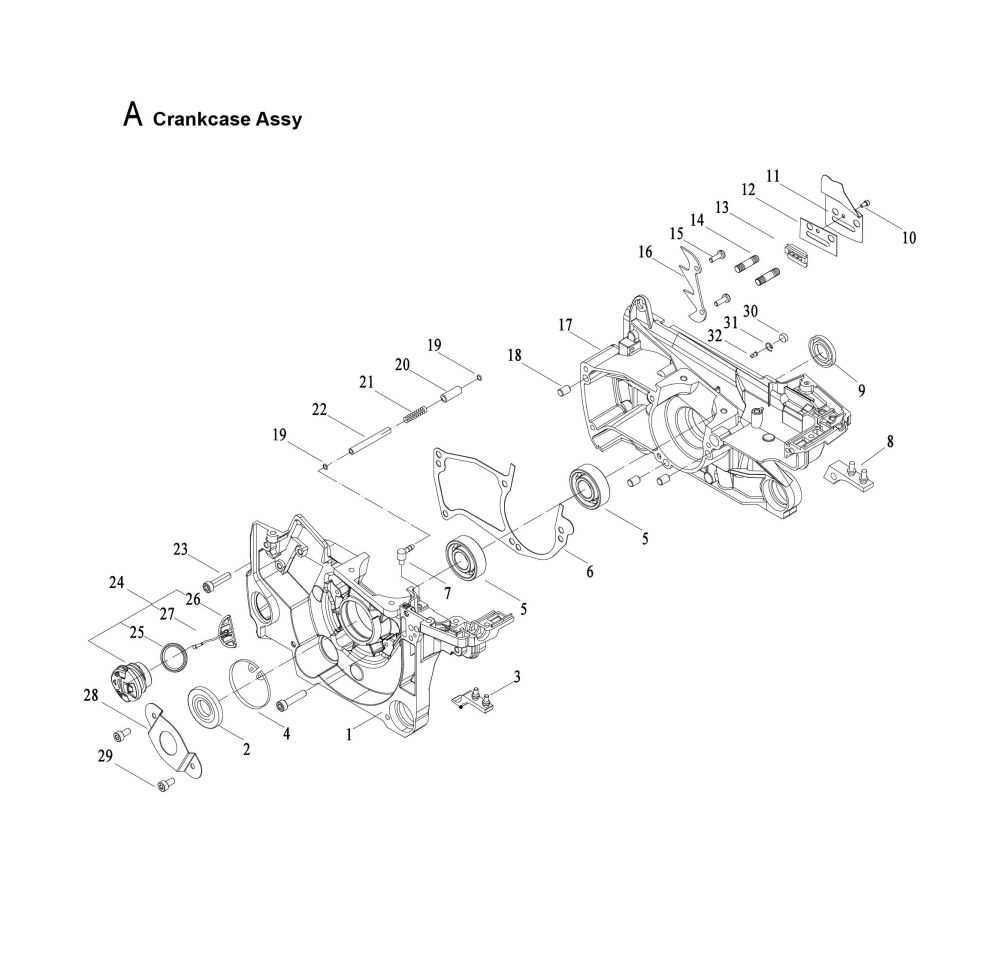

Component Overview for Model 260

This section provides a comprehensive look at the key elements that make up this machine. Understanding how each element works together is essential for ensuring optimal performance and maintenance. We will focus on the most important mechanical pieces and their functions within the system.

Engine Assembly

The core of the machine’s operation is its engine, which drives all functions. It includes several key elements such as the cylinder, piston, and carburetor, which are responsible for fuel combustion and power generation. Regular inspection and cleaning are necessary to maintain efficiency.

- Piston and Cylinder – Ensures smooth operation through compression and power transfer.

- Carburetor – Manages the

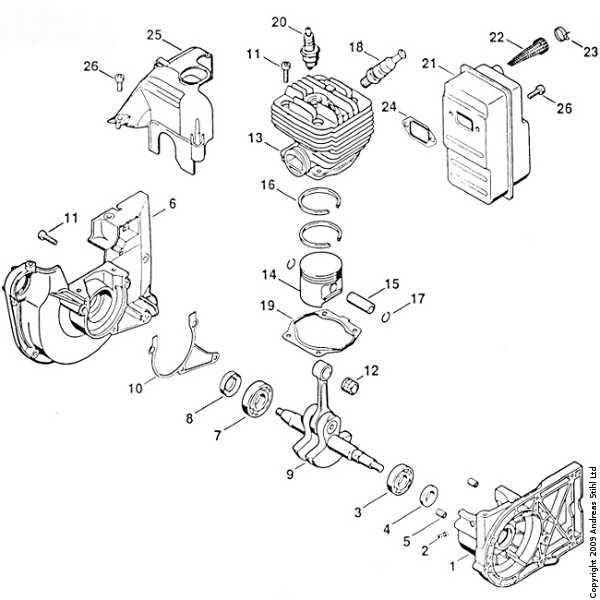

Main Components of Stihl 260 Chainsaw

The internal structure of a chainsaw consists of several crucial elements, each contributing to its overall efficiency and performance. Understanding these key components is essential for maintaining and operating the tool effectively, ensuring its longevity and smooth functioning.

Engine System

The core of any chainsaw is its engine, which powers the cutting process. This system includes a cylinder, piston, and crankshaft, all working together to generate the necessary force. Proper maintenance of these parts ensures consistent performance.

Cutting Mechanism

The cutting system is responsible for the actual sawing process. It comprises the guide bar, chain, and tension

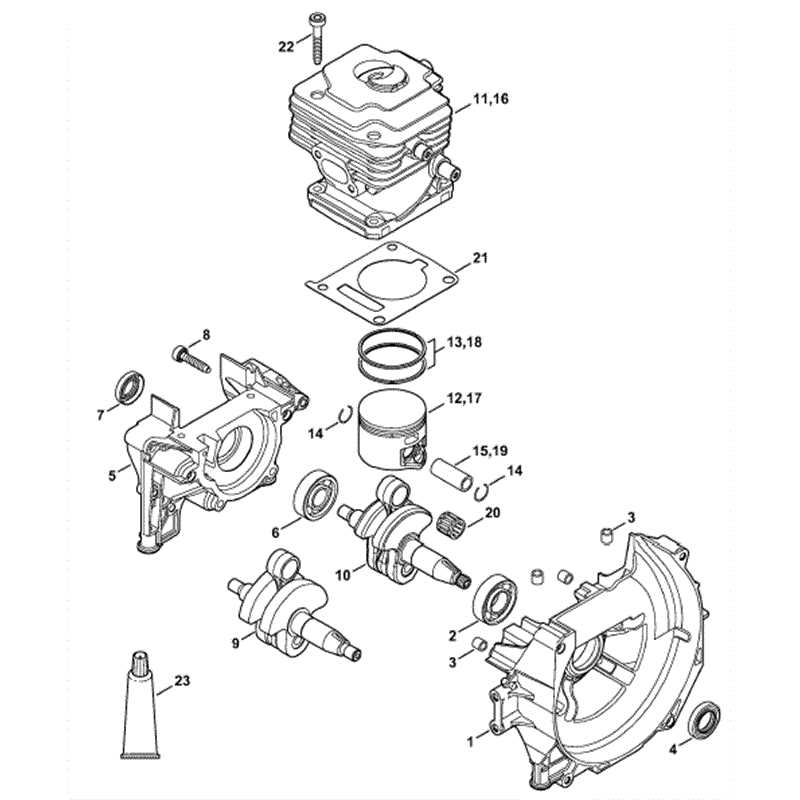

Engine Assembly Breakdown

The internal combustion unit consists of various interconnected components that work together to ensure efficient performance. Each element plays a crucial role in converting fuel into mechanical power, driving the operation of the entire system.

Main Components of the Engine

At the heart of the assembly lies the cylinder, where fuel combustion occurs. This process powers the piston, which moves up and down within the cylinder. The crankshaft, connected to the piston, converts this linear motion into rotational force, driving the overall system.

Supporting Parts and Functionality

The carburetor, fuel lines, and air filters work together to regulate the mixture of air and fuel, ensuring optimal combustion. Additionally, the exhaust system helps expel gases, while cooling mechanisms prevent the engine

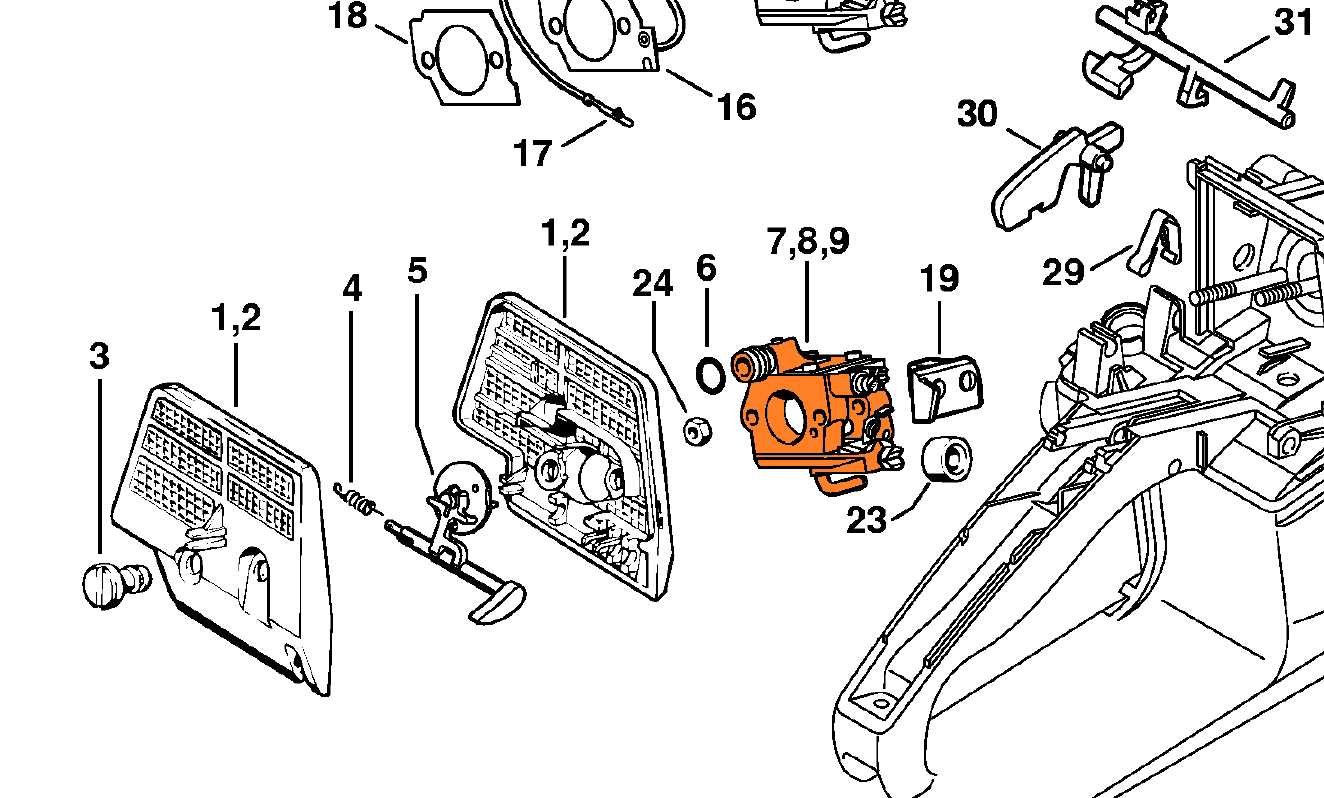

Understanding the Carburetor System

The carburetor is a crucial component that ensures the engine runs smoothly by mixing air and fuel in the right proportions. It plays a significant role in the overall functionality of the engine, making it essential for proper performance and efficiency.

To better grasp how this system works, it’s important to break it down into its key functions and components:

- Regulating airflow into the engine

- Controlling the amount of fuel entering the combustion chamber

- Ensuring the correct air-fuel ratio under different operating conditions

The carburetor system must be well-maintained to prevent common issues such as flooding or poor engine performance. Regular cleaning and adjustments help maint

Ignition System Layout

The ignition system is a critical component that ensures the engine operates efficiently by creating the necessary spark to ignite the fuel mixture. Understanding the overall arrangement of this system can help diagnose issues and maintain the engine’s performance over time. Below is a detailed description of the essential parts and how they are interconnected to provide reliable engine start-up and smooth running.

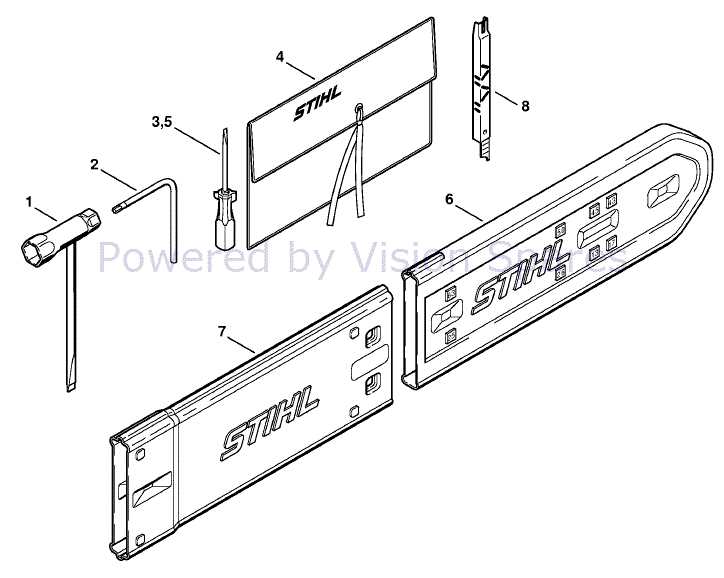

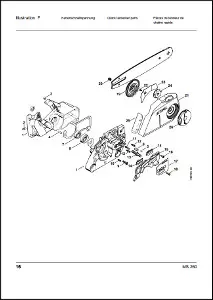

Component Function Flywheel Guide Bar and Chain Details

The guide bar and chain are crucial components of any cutting tool, providing the necessary framework for efficient operation. Understanding their specifications and features is essential for optimal performance and maintenance. This section will explore the various aspects of these elements, including their types, compatibility, and maintenance practices.

Types of Guide Bars

There are several types of guide bars available, each designed for specific tasks. These can vary in length, thickness, and material. For instance, some bars are constructed from high-quality metals, while others may feature lightweight designs for easier handling. Choosing the right guide bar for the intended application ensures enhanced performance and reduced wear on the equipment.

Chain Characteristics

The chain is another integral part of the cutting mechanism, influencing the speed and efficiency of the tool. Chains come in various sizes and configurations, each suited to different guide bar types. Regular inspection and timely replacement of the chain are vital to maintaining cutting efficiency and prolonging the life of the tool.

Fuel System Structure

The fuel system plays a crucial role in the performance and efficiency of any engine. It is responsible for delivering the right amount of fuel to the combustion chamber, ensuring optimal operation and power output. Understanding the components and layout of this system is essential for effective maintenance and troubleshooting.

Key Components

The primary elements of the fuel system include the fuel tank, filter, pump, and carburetor. Each component works in harmony to ensure a smooth flow of fuel. The tank stores the fuel, while the filter removes impurities to protect the engine. The pump facilitates the transfer of fuel, and the carburetor mixes air with the fuel in the correct ratio for combustion.

Flow Process

Fuel is drawn from the tank and passes through the filter, where contaminants are eliminated. The pump then moves the clean fuel to the carburetor, where it is atomized and mixed with air. This mixture is then directed to the engine, where combustion occurs. This entire process must function seamlessly for optimal engine performance.

Air Filter Configuration

The air filtration system plays a crucial role in ensuring optimal performance and longevity of outdoor power equipment. Proper arrangement and maintenance of the filter help in preventing dirt and debris from entering the engine, thereby enhancing its efficiency and reliability.

Importance of Air Filtration

A well-functioning air filter is essential for the proper combustion process within the engine. It ensures a clean air supply, which is vital for efficient fuel combustion. Regular inspection and replacement of the filter contribute to improved fuel economy and reduced emissions.

Configuration Guidelines

When configuring the air filter, ensure that it fits securely within its housing. Follow the manufacturer’s specifications for installation to avoid any leaks. Regular cleaning and replacement, based on usage conditions, will maintain the equipment’s performance and extend its operational life.

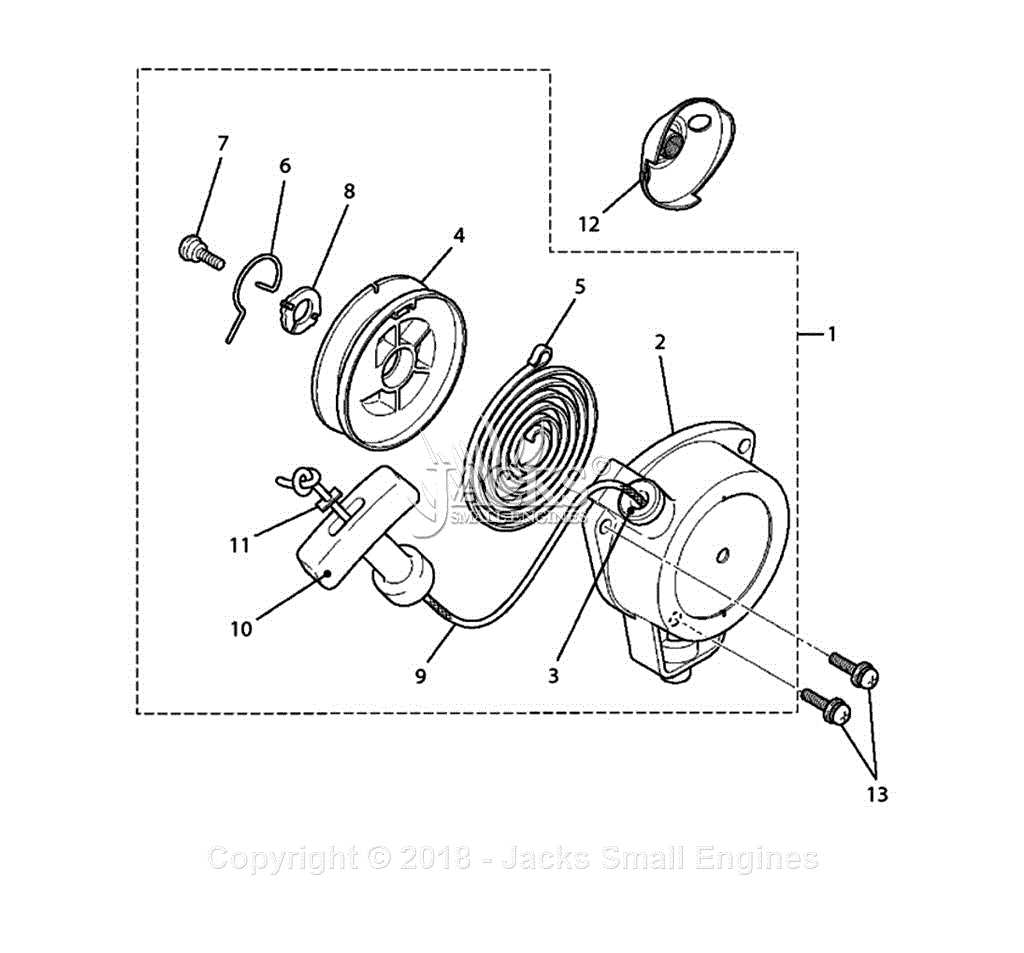

Recoil Starter Assembly

The recoil starter assembly is a crucial component in the operation of outdoor power equipment. It serves the purpose of initiating the engine’s operation by utilizing a spring mechanism to retract the starter rope. Understanding the structure and function of this assembly can significantly aid in maintenance and troubleshooting.

Components of the Recoil Starter

This assembly comprises several key elements that work together to ensure effective starting. The primary components include the starter rope, recoil spring, pulley, and housing. Each part plays a vital role in facilitating the smooth engagement of the starter mechanism.

Maintenance Tips

Regular inspection and maintenance of the recoil starter assembly can enhance its lifespan and efficiency. It is essential to check for wear and tear on the rope and spring, as well as ensuring that the pulley rotates freely. If any components show signs of damage, they should be replaced promptly to avoid starting difficulties.

Component Description Starter Rope A durable cord that is pulled to initiate the engine start. Recoil Spring A spring that allows the rope to retract after being pulled. Pulley Rotates to wind the starter rope when pulled. Housing The outer shell that protects the internal components. Clutch Mechanism Explanation

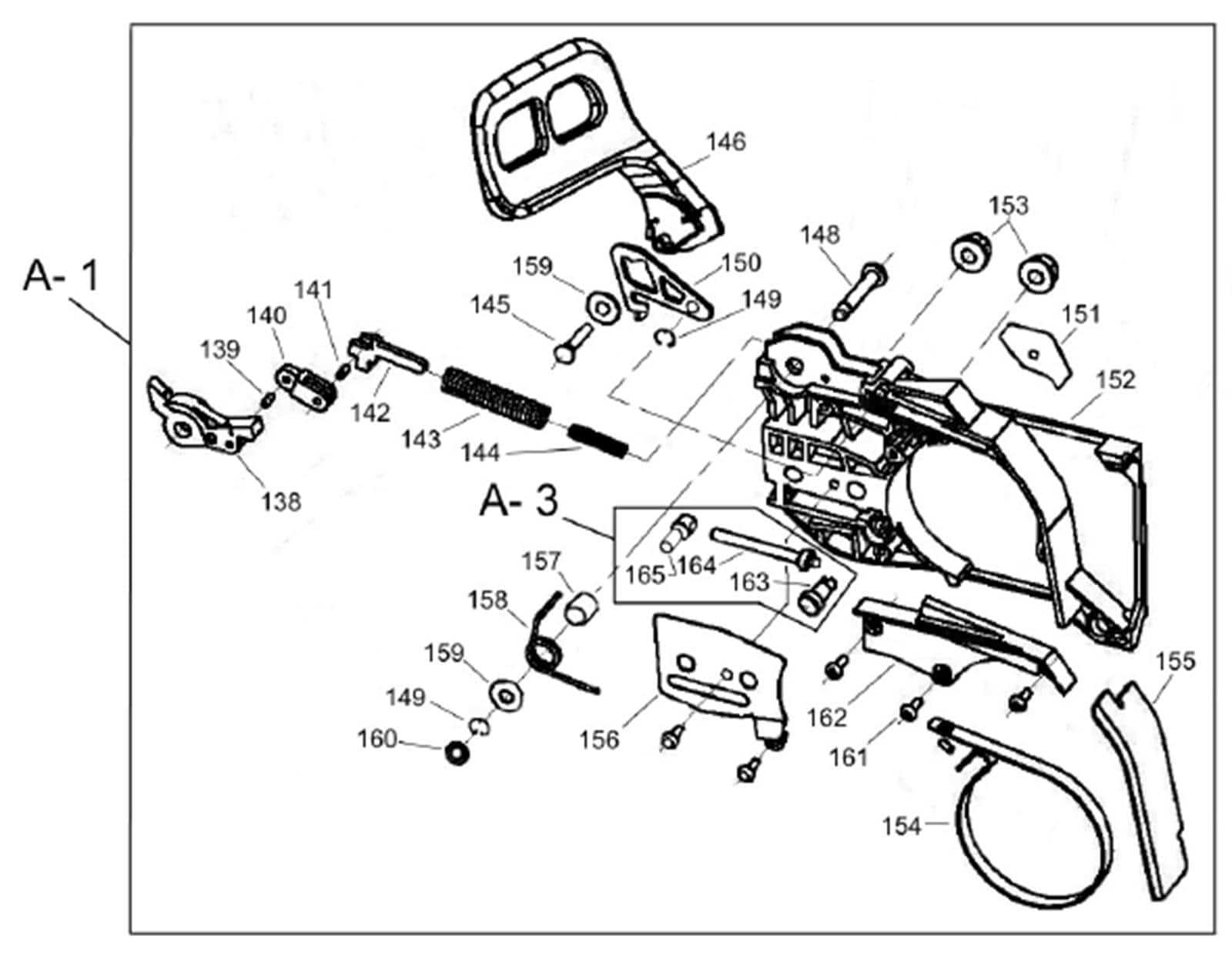

The clutch mechanism is a crucial component in power tools that allows for the engagement and disengagement of the engine’s power to the cutting equipment. Understanding how this mechanism operates is essential for maintaining optimal performance and ensuring safety during use.

Functionality of the Clutch

The primary function of the clutch is to transfer power from the engine to the driven tool while preventing damage during overload situations. When the engine reaches a certain speed, the clutch engages, allowing the tool to operate effectively. Conversely, when the tool encounters resistance, the clutch disengages, protecting the engine from potential damage.

Components of the Clutch Mechanism

- Drive Plate: This component connects directly to the engine and rotates when the engine is running.

- Driven Plate: This part is connected to the cutting tool and engages with the drive plate to transmit power.

- Springs: These components maintain tension and control the engagement and disengagement of the clutch.

- Friction Material: Often found on the driven plate, this material provides the necessary grip for power transfer.

Regular inspection and maintenance of the clutch mechanism can significantly enhance the longevity and efficiency of the tool. Ensuring that components are in good condition and free from wear will prevent operational failures and improve performance.

Muffler and Exhaust System

The muffler and exhaust assembly play a crucial role in the overall performance and efficiency of the engine. These components work together to direct the flow of exhaust gases away from the power unit while minimizing noise and emissions. A well-functioning exhaust system not only enhances the operational capabilities but also ensures compliance with environmental regulations.

Regular maintenance of the muffler and exhaust system is essential for optimal engine function. Over time, these parts may accumulate debris or suffer from wear, leading to reduced efficiency and increased noise levels. Inspections should focus on identifying any signs of damage or blockages that could impact performance.

Component Description Function Muffler A device that reduces engine noise. Minimizes sound produced during operation. Exhaust Pipe A pipe that channels exhaust gases away from the engine. Facilitates the exit of gases while preventing back pressure. Exhaust Gasket A seal that ensures a tight connection between components. Prevents leaks of exhaust gases and maintains efficiency. Heat Shield A protective barrier that shields surrounding components from heat. Reduces the risk of heat-related damage. Handle Assembly Overview

The handle assembly is a crucial component of power tools, providing the user with control and stability during operation. This section explores the essential elements that make up this assembly, emphasizing its significance in ensuring safety and functionality.

Components within the handle assembly typically include the grip, throttle control, and trigger mechanism. Each part plays a vital role in facilitating smooth operation and enhancing the user experience.

Maintenance of the handle assembly is essential for optimal performance. Regular inspections can help identify any wear or damage, ensuring that the tool remains safe and effective during use.

Understanding the structure and function of the handle assembly allows users to make informed decisions regarding repairs and upgrades, ultimately leading to improved efficiency and longevity of their equipment.

Oil Pump and Lubrication System

The lubrication mechanism plays a crucial role in the performance and longevity of any power tool. It ensures that all moving components operate smoothly, minimizing friction and wear. This system is designed to deliver the appropriate amount of lubricant to essential parts, thus maintaining optimal functionality during operation.

Functionality of the Oil Pump

The oil pump is responsible for transporting lubricant from the reservoir to the various moving elements. By maintaining consistent pressure, it ensures that the oil reaches every necessary area, preventing overheating and excessive wear. A reliable pump is vital for the overall efficiency of the equipment.

Importance of Proper Lubrication

Effective lubrication is essential for maximizing the lifespan of the machinery. Without adequate oil flow, components can experience increased friction, leading to potential failure. Regular maintenance and timely checks of the lubrication system are recommended to ensure seamless operation and prevent costly repairs.