In the realm of precision machinery, comprehending the arrangement of individual elements is crucial for effective operation and maintenance. A well-organized overview can enhance one’s ability to identify specific functionalities, ensuring that the equipment performs optimally. Such insights not only facilitate repairs but also promote a deeper understanding of how these intricate devices operate.

Exploring the configuration of components reveals the thoughtful design behind each element, which contributes to the overall efficiency of the tool. Familiarity with these layouts empowers users to troubleshoot issues effectively and implement necessary adjustments with confidence. This knowledge serves as a foundation for both novice users and seasoned professionals alike, ensuring that the machinery remains in peak condition.

Moreover, recognizing the significance of each part allows for informed decisions regarding upgrades and replacements. By appreciating the interconnected nature of these components, users can maximize the longevity and performance of their tools. Ultimately, this understanding fosters a proactive approach to equipment management, promoting a culture of care and expertise.

Understanding Stihl Cut Off Saw Parts

Exploring the various components of cutting tools can significantly enhance your comprehension of their functionality and maintenance. Each element plays a vital role in the overall performance, contributing to efficiency and safety during operation.

Key components include:

- Engine: The power source that drives the tool, providing necessary energy for cutting tasks.

- Blade: A crucial element responsible for the actual cutting action, varying in size and type for different materials.

- Handle: Designed for user control, ensuring comfort and stability while working.

- Guard: A safety feature that protects users from debris and accidents during operation.

- Throttle: Allows the operator to control the speed and power output as needed.

Understanding these components not only aids in effective use but also in identifying issues that may arise, leading to better maintenance practices and extended tool lifespan.

Key Components of the Saw

This section delves into the essential elements that contribute to the functionality and efficiency of the cutting tool. Understanding these components is vital for effective operation and maintenance.

Overview of Main Elements

Every cutting instrument consists of several critical components that work in unison. Familiarity with these elements enhances the user’s ability to handle and care for the equipment.

Detailed Component Table

| Component | Description |

|---|---|

| Blade | The primary element responsible for cutting through various materials. |

| Engine | Provides the necessary power to drive the blade and perform the cutting action. |

| Guard | Ensures safety by covering the blade during operation. |

| Handle | Allows the user to grip and maneuver the device effectively. |

Identifying the Function of Each Part

Understanding the purpose of each component in a power tool is essential for effective operation and maintenance. This knowledge not only enhances performance but also prolongs the lifespan of the equipment. By recognizing how different elements work together, users can troubleshoot issues more efficiently and ensure optimal functionality.

Main Components Overview

Each section of the device serves a specific role, contributing to the overall efficiency and effectiveness of the machine. Key elements include the motor, which provides power; the handle, designed for user control; and the cutting mechanism, which performs the primary task of material removal. Familiarity with these functionalities aids in performing repairs and upgrades.

Safety Features and Their Importance

In addition to the main components, safety mechanisms play a critical role in ensuring user protection. Features such as guards and emergency stops are designed to prevent accidents and injuries. Understanding these safety elements is crucial for safe operation and compliance with operational guidelines.

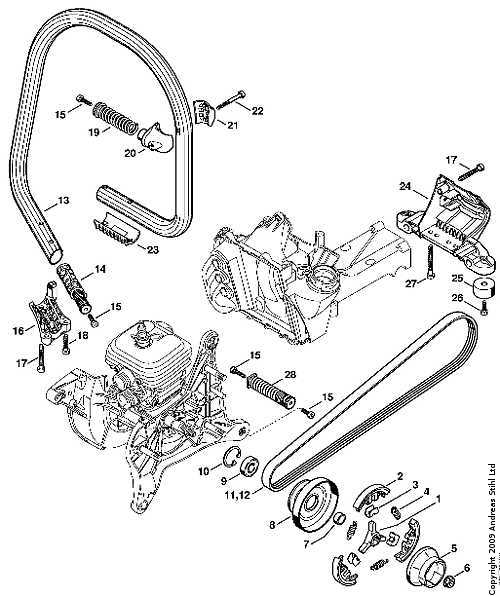

How to Read the Parts Diagram

Understanding a technical illustration is essential for effective maintenance and repairs. Such illustrations provide a visual representation of components, allowing users to identify and locate each element clearly. Grasping how to interpret these visuals can significantly enhance your overall efficiency when working on equipment.

Identify Key Components

Begin by familiarizing yourself with the primary elements shown in the illustration. Each segment is usually labeled with a corresponding number or letter, which connects it to a detailed list. This list typically provides specifications and details about each component, helping you understand their functions and interrelations.

Follow the Assembly Flow

Next, observe how the components are organized. Often, the illustration will follow a logical sequence, illustrating how parts fit together. Recognizing this flow can guide you in disassembly or assembly, ensuring that each piece is placed correctly and functions as intended.

Common Replacement Parts Overview

Understanding the key components that may require replacement during maintenance is essential for optimal performance. These elements play a crucial role in ensuring the device operates smoothly and efficiently.

- Blades: Essential for cutting, these come in various sizes and materials, catering to different applications.

- Filters: Air and fuel filters help maintain cleanliness and efficiency by preventing contaminants from entering the system.

- Spark Plugs: Crucial for ignition, ensuring they are in good condition contributes to reliable starts and efficient combustion.

- Fuel Lines: These transport fuel from the tank to the engine and should be checked for wear to prevent leaks.

- Starter Mechanism: This component is vital for initiating the engine and may need adjustment or replacement over time.

Regular inspection and timely replacement of these elements can enhance the longevity and functionality of your equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires diligent care and regular attention. By adopting proper practices, users can enhance performance and minimize wear over time.

Regular Cleaning: Keep the exterior and internal components free from debris. A clean machine not only functions better but also reduces the risk of damage.

Routine Inspections: Frequently check for any signs of wear or malfunction. Early detection of issues can prevent costly repairs and ensure smooth operation.

Proper Lubrication: Use appropriate lubricants to keep moving parts functioning efficiently. This minimizes friction and prolongs the life of critical components.

Storage Conditions: Store the equipment in a dry, sheltered environment to protect it from environmental elements that may cause rust or corrosion.

Follow Manufacturer Guidelines: Adhering to recommended maintenance schedules and using suggested replacement components ensures optimal performance and reliability.

Tools Needed for Repairs

When tackling maintenance tasks, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-equipped workspace facilitates smooth operations, minimizes complications, and promotes safety.

Essential Hand Tools

Basic hand tools like wrenches, screwdrivers, and pliers are fundamental for most repair activities. These instruments enable precise adjustments and disassembly, allowing access to intricate components.

Power Tools and Accessories

In addition to hand tools, incorporating power tools can significantly expedite the repair process. Drills and grinders can assist in more challenging tasks, while various bits and blades enhance versatility for different applications.

Assembly Instructions for the Saw

Proper assembly is crucial for optimal performance and safety of the equipment. This section provides a comprehensive guide to ensure each component is correctly installed, enabling seamless operation.

- Begin by gathering all necessary tools and components.

- Refer to the manual for a detailed list of items needed for assembly.

- Identify and organize the components to facilitate the assembly process.

Follow these steps for a successful assembly:

- Attach the primary housing unit securely.

- Install the motor assembly, ensuring all connections are tight.

- Connect the power supply, double-checking polarity and secure fit.

- Assemble the cutting mechanism, aligning all parts according to the manual.

- Verify that all screws and bolts are tightened properly to prevent any movement.

Once the assembly is complete, conduct a thorough inspection before use to ensure everything is in place and functioning correctly.

Troubleshooting Common Issues

When working with power tools, encountering difficulties is not uncommon. Identifying and addressing these challenges promptly can enhance performance and prolong the life of the equipment. Understanding the typical problems that may arise is crucial for effective maintenance and repair.

Identifying Performance Issues

Frequent stalling or reduced power may indicate fuel flow problems or air filter obstructions. Checking these components can help restore optimal functionality. Additionally, ensuring that the cutting mechanism is sharp and free of debris will contribute to improved operation.

Resolving Starting Difficulties

If the equipment fails to start, it could be due to a drained battery or spark plug malfunctions. Inspecting the ignition system and ensuring proper connections can often resolve these issues. Furthermore, examining the fuel mixture is essential, as an improper blend can lead to starting complications.

Safety Precautions During Repairs

When performing maintenance or troubleshooting tasks, prioritizing safety is essential to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the safety of the work environment.

Preparation Before Starting Work

- Ensure you are wearing appropriate personal protective equipment, including gloves, goggles, and ear protection.

- Clear the workspace of any unnecessary tools or materials that could create hazards.

- Familiarize yourself with the equipment and its components to avoid mistakes during repairs.

During the Repair Process

- Always disconnect the power source before attempting any maintenance.

- Keep hands and tools away from moving parts to prevent injury.

- Utilize tools correctly and according to the manufacturer’s guidelines to avoid accidents.

Where to Purchase Spare Parts

Acquiring replacement components for your equipment is essential for maintaining optimal performance. There are various reliable sources where enthusiasts and professionals can find quality items to ensure their tools function efficiently. Exploring multiple options can lead to both cost-effective solutions and genuine products.

Authorized Dealers

Visiting certified distributors is often the best choice for obtaining authentic components. These establishments offer a range of items and usually have knowledgeable staff ready to assist you in finding what you need.

Online Retailers

Several websites specialize in selling replacement components, often providing a wider selection than local stores. Make sure to check customer reviews and ratings to ensure a satisfactory purchase experience.

| Source Type | Benefits |

|---|---|

| Authorized Dealers | Genuine items, expert assistance |

| Online Retailers | Convenience, variety, competitive pricing |

| Local Shops | Immediate access, personalized service |