Understanding the structure and function of various elements in outdoor power tools is crucial for ensuring their efficiency and longevity. These machines, designed for maintaining landscapes and gardens, rely on a harmonious interaction between their numerous components. Proper maintenance and timely replacement of worn-out elements can greatly enhance the overall performance of such equipment.

In this section, we will explore the core elements that make up one of the most commonly used garden tools. By gaining insight into how each piece contributes to the machine’s operation, users can better identify potential issues and maintain their equipment effectively. Whether you’re performing regular upkeep or troubleshooting, recognizing the key elements of your device is essential for achieving optimal results.

Our guide will break down the individual parts and provide clear explanations on how each functions within the system. This knowledge will empower users to handle any necessary repairs or replacements with confidence, ensuring smooth operation during all outdoor tasks.

Understanding the Stihl FS 38 Trimmer Parts

To ensure efficient operation and long-term performance of your garden equipment, it is crucial to familiarize yourself with its individual components. Each element plays a specific role in maintaining smooth functionality and reliability during use. By understanding how these parts work together, you can perform proper maintenance and resolve issues more effectively.

Key Components Overview

The device is made up of various essential elements, all contributing to its functionality. Regular checks and upkeep of these parts can extend the lifespan of the machine and improve its efficiency.

- Engine: The core of the machine, powering its entire operation and ensuring stable performance during use.

- Drive shaft: Transfers energy from the motor to the cutting attachment, playing a pivotal role in ensuring smooth movement.

- Cutting attachment: The essential tool for trimming, designed for optimal cutting and control in different environments.

- Handle:

Key Components of the Stihl FS 38

This section will outline the essential elements that ensure optimal performance and longevity of the equipment. Understanding the core features of the device is crucial for proper handling, maintenance, and troubleshooting.

- Engine: The heart of the tool, providing the necessary power for effective operation. It is responsible for driving the cutting mechanism and requires regular care to maintain efficiency.

- Fuel System: Ensures smooth operation by delivering the right mix of fuel and air. Proper attention to the fuel system is vital for consistent functionality.

- Cutting Mechanism: This component takes care of the primary task. Its sharpness and alignment are key to achieving precise results during use.

- Handle and Control Elements: Designed for comfortable grip and maneuvering, allowing the user to guide the device with accuracy and ease. They also house key control features for starting, stopping, and adjusting the tool.

- How the Trimmer Head Functions

The cutting mechanism operates through a rotating component that efficiently slices through grass and other vegetation. The core of its performance lies in the motion of this unit, which is designed to spin at high speeds, allowing it to perform its task with precision. Its design ensures that vegetation is cleared quickly and evenly, delivering clean and consistent results.

Rotation mechanics are key to the operation. The central hub propels the cutting elements in a circular motion, ensuring steady and even cutting action. This motion is powered by the main motor, transmitting energy to the head and maintaining a consistent rhythm for optimal performance.

Balancing and control are also vital. The structure is engineered to minimize vibrations and maintain stability during use, which not only improves the precision of the cutting process but also reduces fatigue for the user.

Examining the Fuel System Setup

The fuel system is a crucial component in ensuring efficient operation and longevity. This section delves into the arrangement and functionality of key elements responsible for delivering fuel to the engine, focusing on understanding how they interact to maintain optimal performance. A well-maintained fuel system contributes to consistent operation and minimizes potential issues.

Key Components Overview

The main components involved include the fuel tank, lines, and a mechanism to regulate the flow. These elements work together to supply the engine with the necessary mixture for combustion. Keeping these parts clean and properly connected is essential to avoid any disruptions during use.

Common Issues and Maintenance

Frequent issues may arise due to blockages, leaks, or improper sealing within the system. Regular inspection, cleaning, and timely replacement of worn-out elements can prevent major problems. Ensuring the fuel flows smoothly will result in more reliable operation and improved longevity.

The Role of the Ignition System

The ignition system plays a crucial role in ensuring the smooth operation of a variety of outdoor power equipment. Its main function is to create the necessary spark that initiates combustion, allowing the engine to run efficiently. Without this key component, the engine would fail to start or operate properly, causing significant disruptions in performance.

Component Function Spark Plug Generates the spark to ignite the fuel mixture in the engine. Flywheel Stores rotational energy and works with magnets to produce the electric charge needed for ignition. Coil Amplifies the voltage to a high enough level to create a spark at the spark plug. Each of these elements must work together seamlessly to ensure reliable starting and efficient engine performance

Air Filter and Its Importance

The air filter plays a crucial role in the operation of outdoor power equipment, ensuring optimal performance and longevity. By preventing debris, dust, and other contaminants from entering the engine, it helps maintain a clean airflow, which is essential for efficient combustion. A well-functioning filter contributes to better fuel efficiency and reduces emissions, making it an indispensable component of machinery used in landscaping and gardening tasks.

Functionality of the Air Filter

The primary function of the air filter is to trap unwanted particles that could damage internal engine components. By doing so, it enhances the overall efficiency of the engine. When air passes through the filter, it becomes purified, allowing the machinery to operate smoothly. Regular maintenance and timely replacement of the filter are essential practices that ensure uninterrupted operation and protect the engine from potential harm.

Signs of a Clogged Filter

Over time, the air filter can become clogged with dirt and debris, leading to several performance issues. Symptoms of a blocked filter may include reduced power, difficulty starting the engine, and increased fuel consumption. Regularly inspecting and cleaning the air filter is vital to prevent these problems. If the filter shows signs of excessive dirt or damage, it should be replaced promptly to restore optimal functionality.

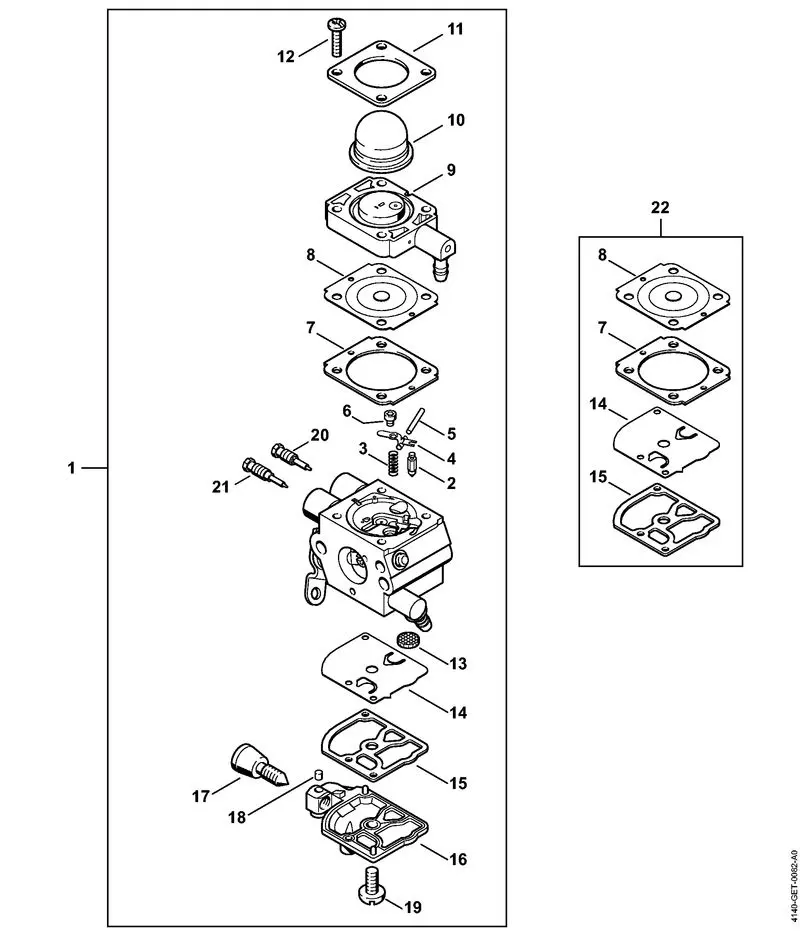

Overview of the Carburetor Mechanism

The carburetor is a vital component of many small engines, playing a crucial role in the fuel-air mixture process. It ensures that the engine receives the optimal blend for efficient combustion, affecting performance and fuel efficiency. Understanding the mechanism of this device is essential for effective maintenance and troubleshooting.

Functionality of the Carburetor

This mechanism operates by mixing fuel with air to create a combustible mixture. The efficiency of this process can directly influence the overall performance of the engine. Here are the main functions:

- Fuel Delivery: The carburetor draws fuel from the tank and delivers it to the combustion chamber.

- Air Intake: It allows the necessary air to mix with the fuel, creating the correct ratio for combustion.

- Throttle Control: It regulates the flow of air and fuel, allowing for acceleration and deceleration of the engine.

Key Components

The mechanism comprises several essential parts that work together to ensure optimal performance:

- Float Chamber: Maintains a steady level of fuel for consistent delivery.

- Venturi: A narrowing in the passage that increases airspeed, helping to draw fuel into the air stream.

- Jet: Controls the flow of fuel into the airstream, ensuring the right mixture is achieved.

- Throttle Valve: Adjusts the amount of air and fuel entering the engine, affecting speed and power output.

Understanding the carburetor’s mechanism and its components is crucial for anyone involved in the maintenance or repair of small engines. Proper knowledge ensures longevity and efficiency, allowing for optimal performance in various applications.

Engine Parts and Their Maintenance

Understanding the components of a powerhead is essential for ensuring optimal performance and longevity. Regular care and maintenance of these elements can significantly enhance the efficiency of your equipment. This section will explore the critical components within the engine assembly and provide guidance on their upkeep.

Key Components of the Engine

- Crankshaft: Responsible for converting linear motion into rotational motion.

- Piston: Moves up and down within the cylinder, compressing the fuel-air mixture.

- Cylinder: Houses the piston and provides the space for combustion.

- Carburetor: Mixes fuel and air in the correct ratio for combustion.

- Ignition System: Generates a spark to ignite the fuel-air mixture.

Maintenance Tips

- Regular Cleaning: Keep the exterior clean to prevent dirt and debris from entering the engine.

- Oil Changes: Check and replace the oil at recommended intervals to ensure smooth operation.

- Air Filter Replacement: Change the air filter regularly to maintain airflow and performance.

- Inspect Fuel System: Regularly check for leaks and ensure that fuel lines are in good condition.

- Check Spark Plug: Inspect and replace the spark plug as needed for optimal ignition.

Drive Shaft and Its Functions

The drive shaft is a crucial component that plays a vital role in the operation of various outdoor power equipment. It serves as a mechanical link that transmits rotational energy from the engine to the cutting mechanism, ensuring efficient performance during use. Understanding its functions and characteristics is essential for maintenance and troubleshooting.

Key Functions of the Drive Shaft

- Energy Transmission: The primary role of the drive shaft is to transfer power generated by the engine to the cutting head, allowing for effective cutting and trimming.

- Vibration Dampening: This component helps absorb vibrations produced during operation, contributing to smoother performance and reducing operator fatigue.

- Durability: Designed to withstand significant wear and tear, the drive shaft is constructed from robust materials to ensure longevity and reliability.

Maintenance Tips

- Regularly inspect the drive shaft for signs of wear or damage.

- Keep the connection points clean to prevent build-up that could impede performance.

- Lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

Handle Assembly and Comfort Features

The handle assembly plays a crucial role in enhancing the overall user experience of garden maintenance equipment. A well-designed grip not only ensures better control but also contributes to reduced fatigue during prolonged usage. Various comfort features are incorporated to provide a more ergonomic and user-friendly experience.

- Ergonomic Design: The handle is shaped to fit comfortably in the user’s hand, minimizing strain during operation.

- Adjustable Height: Many models allow for height adjustment, enabling users of different statures to find their ideal working position.

- Soft Grip Material: A soft, textured surface enhances grip security and comfort, particularly in wet or humid conditions.

- Shock Absorption: Some assemblies incorporate technology that absorbs vibrations, making extended use less taxing on the body.

- Easy-to-Reach Controls: Controls are strategically placed for convenience, allowing users to operate the equipment without having to stretch or reposition their hands.

Incorporating these features significantly enhances usability, making outdoor tasks more enjoyable and efficient.

Understanding the Cutting Attachments

In the realm of outdoor maintenance, the selection of cutting implements plays a crucial role in achieving efficiency and effectiveness. Each attachment serves a distinct purpose, tailored to tackle various types of vegetation and terrain. By comprehending these tools, users can optimize their equipment’s performance and ensure a seamless experience during operation.

Types of Cutting Implements

There are several varieties of cutting tools available, each designed to cater to specific tasks. For instance, line heads are ideal for managing grass and light weeds, while metal blades excel in handling thicker, tougher vegetation. This versatility allows users to adapt their equipment based on the challenges presented by their surroundings.

Choosing the Right Attachment

Selecting the appropriate implement is essential for achieving the best results. Factors such as the density of the foliage, the area to be covered, and the desired outcome should influence the decision-making process. Understanding these elements ensures that users can efficiently manage their outdoor spaces while maintaining the longevity of their equipment.

Common Part Replacements for FS 38

Maintaining your equipment is essential for optimal performance and longevity. Certain components may require regular attention due to wear and tear, ensuring your machine operates smoothly and efficiently. This section highlights the most frequently replaced elements that enhance functionality and reliability.

Frequently Changed Components

Regular maintenance involves the timely replacement of specific elements. These replacements can significantly improve the overall performance and durability of your device.

Component Description Frequency of Replacement Cutting Line Essential for effective trimming; may fray or break with use. Every few uses, depending on density of grass. Spool Holds the cutting line; may crack or wear over time. Annually or as needed based on wear. Filter Prevents debris from entering the engine, ensuring efficiency. Every 10-20 hours of operation. Plug Ignition component that can degrade with usage. Every season or 50 hours of use. Maintenance Tips

To ensure longevity, regularly inspect and replace worn components. Keeping spare parts on hand can prevent downtime and enhance performance, allowing for efficient operation throughout the season.