For enthusiasts and professionals alike, grasping the intricacies of a grass trimmer’s assembly is essential for maintaining optimal performance. Familiarity with the various elements that constitute this machine not only enhances its functionality but also ensures longevity through proper care and repair.

The complexity of these machines necessitates a comprehensive overview of their individual components, each playing a pivotal role in the overall operation. From the cutting mechanism to the engine’s core, every section is designed to work harmoniously, enabling effective trimming and landscaping tasks.

By exploring the arrangement and interconnection of these essential parts, users can gain valuable insights into troubleshooting and maintenance. This knowledge empowers users to make informed decisions regarding repairs and replacements, ultimately enhancing their experience with the equipment.

Understanding Stihl FS 50 C Components

This section explores the essential elements that contribute to the functionality and efficiency of a specific model of handheld equipment. Each component plays a vital role in ensuring optimal performance, enabling the operator to achieve desired outcomes effectively. By gaining insight into these various parts, one can better appreciate their importance and functionality within the overall system.

Key Functional Elements

Numerous components work together to enhance the capabilities of this equipment. Understanding how these elements interact is crucial for effective operation and maintenance.

| Component | Description |

|---|---|

| Engine | The power source that drives the equipment, providing the necessary energy for operation. |

| Cutting Head | Essential for trimming and cutting, this part holds the cutting line or blade. |

| Handle | Designed for user comfort and control, allowing for better maneuverability during use. |

| Fuel Tank | Holds the fuel needed to power the engine, ensuring a steady supply during operation. |

| Starter Mechanism | Facilitates the ignition of the engine, enabling the user to start the equipment easily. |

Maintenance and Care

Proper care of these components is essential for longevity and optimal performance. Regular inspection and maintenance can prevent common issues and ensure reliable operation. Understanding the role of each part aids in identifying potential problems early, leading to effective resolutions.

Key Parts of Stihl Trimmers

The functionality and efficiency of grass-cutting tools rely heavily on their essential components. Understanding these elements enhances user experience and ensures optimal performance during tasks. Each component plays a crucial role in the overall operation, contributing to the reliability and effectiveness of the device.

Among the vital elements is the cutting head, which houses the blade or string line responsible for trimming vegetation. This part directly impacts the tool’s cutting ability and versatility, making it fundamental for various tasks. The power source, whether gas or electric, delivers the necessary energy, influencing performance and runtime.

Additionally, the handle design significantly affects user comfort and control, allowing for better maneuverability during operation. Another crucial component is the guard, which provides safety by shielding users from debris and ensuring a secure working environment. Understanding these key elements allows users to maintain their tools effectively, ensuring longevity and consistent performance.

Importance of Maintenance for Equipment

Regular upkeep is essential for the longevity and performance of machinery. Ensuring that tools and devices are maintained properly can prevent unexpected failures and enhance efficiency. A proactive approach to maintenance not only protects the investment but also contributes to overall productivity.

Key benefits of routine maintenance include:

- Enhanced Performance: Well-maintained equipment operates more smoothly and efficiently, leading to better results.

- Increased Lifespan: Regular care can significantly extend the life of machinery, reducing the need for premature replacements.

- Cost Savings: Preventive measures often cost less than repairs and replacements, ultimately saving money in the long run.

- Safety Assurance: Properly maintained tools are less likely to malfunction, reducing the risk of accidents and injuries.

To achieve optimal performance, consider the following maintenance practices:

- Regularly inspect equipment for wear and tear.

- Keep machinery clean and free from debris.

- Follow manufacturer guidelines for servicing and repairs.

- Schedule routine check-ups to address potential issues early.

By prioritizing maintenance, users can ensure that their equipment remains reliable and effective, facilitating smoother operations in various tasks.

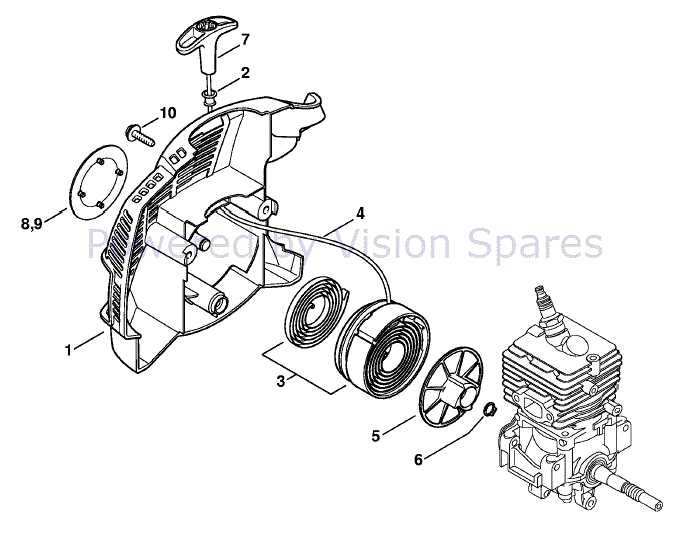

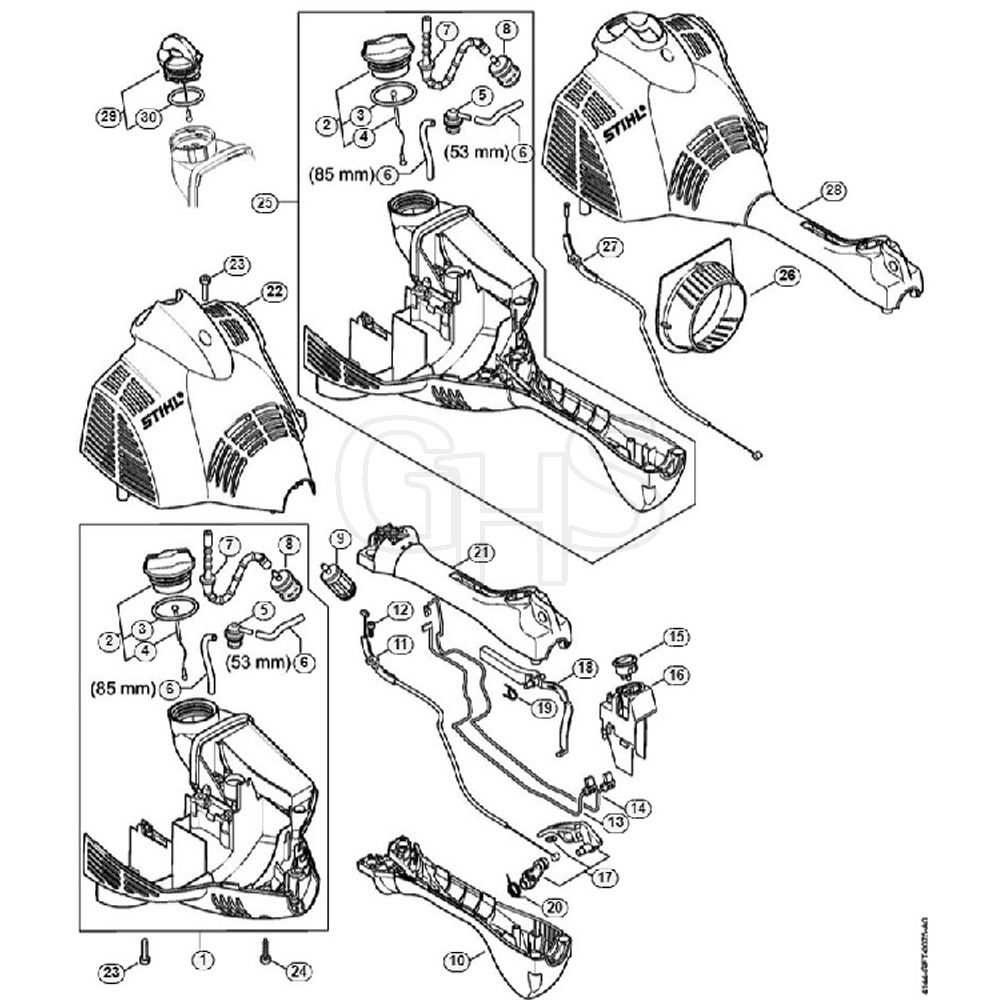

Assembly Guide for Trimmer Parts

This section offers a comprehensive overview of the assembly process for various components of a grass trimming device. Proper assembly is crucial for optimal performance and longevity, ensuring that each element fits securely and functions as intended.

Before starting the assembly, gather all necessary components and tools. Follow these steps to ensure a smooth and efficient process:

- Begin by reviewing the assembly layout to understand the arrangement of components.

- Identify the main body of the trimming unit and ensure it is clean and free of debris.

- Attach the handle to the main frame, securing it with the provided fasteners.

- Connect the cutting mechanism to the shaft, ensuring it is aligned properly.

- Install the protective guard, ensuring it fits snugly over the cutting element.

- Secure all connections, double-checking for any loose components.

After completing the assembly, perform a thorough inspection to ensure everything is properly secured and aligned. This attention to detail will enhance the performance and safety of your trimming tool.

Common Issues and Solutions

Equipment can sometimes experience challenges that affect its performance and reliability. Understanding these common problems and their potential fixes can help ensure optimal operation and longevity.

1. Difficulty Starting: A frequent issue involves the inability to start the machine. This may stem from an empty fuel tank, clogged fuel lines, or a faulty ignition system. Regular maintenance, such as checking the fuel level and ensuring clean connections, can mitigate this problem.

2. Overheating: Excessive heat generation can lead to operational failures. Insufficient lubrication or a blocked cooling system often causes overheating. Regularly inspecting the cooling fins and ensuring proper oil levels can help maintain an appropriate temperature.

3. Uneven Cutting: When the equipment fails to provide a consistent cut, it may indicate dull blades or incorrect height adjustments. Regular sharpening of blades and proper height settings can enhance cutting efficiency.

4. Vibration Issues: Unusual vibrations may signal loose components or imbalanced parts. Tightening screws and ensuring all components are secure can alleviate excessive vibrations and enhance user comfort.

By being proactive and addressing these common challenges, users can enhance the reliability and efficiency of their equipment.

Identifying Replacement Parts Easily

Finding suitable components for maintenance or repairs can often be a challenge. However, having a clear understanding of the various elements involved makes the process smoother. By familiarizing oneself with the essential features and attributes of these components, individuals can ensure that they select the right replacements efficiently.

Understanding Component Terminology

Before embarking on the search for new components, it is beneficial to grasp the terminology commonly used. Knowledge of specific terms can simplify discussions with suppliers or during online research. Here are some key terms to consider:

| Term | Description |

|---|---|

| Assembly | A collection of various items that function together. |

| Compatible | Items that can work together without issues. |

| Aftermarket | Products made by companies other than the original manufacturer. |

| OEM | Original equipment manufacturer; products made by the original company. |

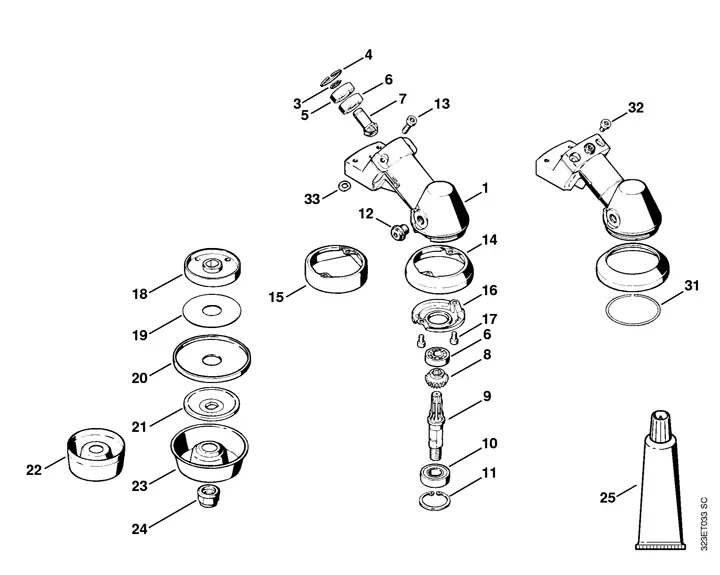

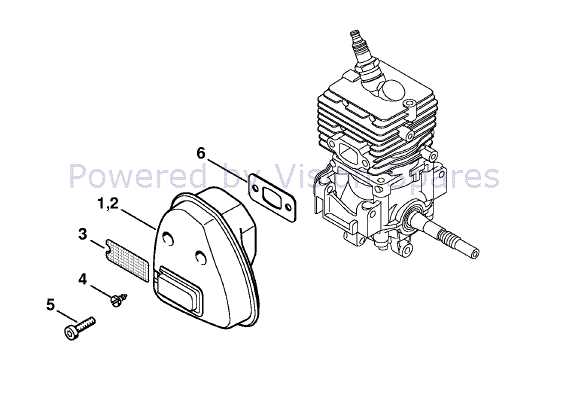

Utilizing Visual Guides

Employing visual aids can significantly enhance the identification process. Exploded views or schematic representations allow for easy recognition of each element’s placement and function. These illustrations provide valuable context, making it simpler to pinpoint the necessary components during maintenance tasks.

Essential Tools for Assembly Tasks

Effective assembly relies on a set of fundamental instruments that streamline the process and enhance efficiency. These tools are designed to simplify various tasks, ensuring that components fit together seamlessly and securely.

Wrenches are vital for tightening and loosening fasteners, allowing for precise adjustments. Screwdrivers in different sizes and types are crucial for handling screws of various designs, while pliers provide the necessary grip for manipulating parts and securing connections.

Additionally, a reliable utility knife can assist in cutting through packaging and trimming materials, while a measuring tape ensures accurate dimensions during assembly. Having these essential instruments on hand can significantly improve the assembly experience, contributing to successful outcomes.

Differences Between Similar Models

When comparing various models within a specific line of equipment, it’s essential to recognize the nuances that set them apart. While some features may seem similar at first glance, a closer examination reveals distinct variations in specifications, functionality, and intended applications. Understanding these differences can guide users in selecting the most suitable option for their needs.

Comparative Features

One of the primary areas where variations occur is in the features offered by each model. These can include engine power, weight, and ergonomic design. Depending on the intended use, users may find certain specifications more beneficial than others.

Intended Applications

Different models may also be tailored for specific tasks or environments. This could range from casual residential use to more demanding commercial applications. Evaluating the intended applications can help users determine which model aligns best with their requirements.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power (cc) | 25 | 30 | 35 |

| Weight (lbs) | 10 | 11 | 12 |

| Ergonomic Design | Standard | Enhanced | Advanced |

| Intended Use | Residential | Light Commercial | Heavy Duty |

Step-by-Step Repair Instructions

Maintaining your equipment is essential for optimal performance and longevity. The following guide offers a structured approach to troubleshooting and restoring functionality to your machine. By following these detailed steps, you can effectively address common issues, ensuring reliable operation.

| Step | Description |

|---|---|

| 1 | Begin by disconnecting the power source to prevent any accidental start-up during the repair process. |

| 2 | Inspect all visible components for signs of wear or damage, noting any areas that require attention. |

| 3 | Remove the affected parts carefully, using appropriate tools to avoid damaging surrounding areas. |

| 4 | Replace any worn or broken components with high-quality replacements that meet the required specifications. |

| 5 | Reassemble the unit, ensuring that all screws and fasteners are securely tightened. |

| 6 | Reconnect the power source and conduct a thorough test to verify that the equipment functions as intended. |

Where to Find Original Parts

Locating authentic components for your equipment is essential for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality items that meet the manufacturer’s standards. Whether you are looking for replacement pieces or accessories, knowing where to search can simplify the process significantly.

Authorized Dealers and Retailers

One of the most trustworthy methods to acquire genuine components is through authorized dealers. These retailers specialize in equipment and often carry a comprehensive selection of original items. They can provide expert guidance and assist with any inquiries regarding compatibility or installation.

Online Marketplaces

Another effective avenue for finding authentic components is through reputable online platforms. Many websites specialize in offering a wide array of products from recognized brands. Ensure to check customer reviews and seller ratings to confirm the legitimacy of the items being offered.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the proper functioning of the equipment. By adhering to specific guidelines, individuals can mitigate risks and create a safer work environment.

Before commencing any maintenance activities, consider the following precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is clean and organized to prevent accidents.

- Disconnect the power source to avoid unintended activation of the equipment.

It is also important to be mindful of the following practices:

- Review the manufacturer’s guidelines and recommendations to understand specific safety measures.

- Utilize the correct tools for each task to prevent injuries and damage.

- Keep a first-aid kit accessible in case of emergencies.

By following these safety measures, individuals can carry out repairs effectively while minimizing hazards associated with maintenance tasks.

Optimizing Performance with Quality Parts

Achieving optimal functionality in any machine requires careful attention to the components that drive its performance. Utilizing high-grade materials can significantly enhance efficiency and longevity, ensuring that the equipment operates at its best. Understanding the importance of quality elements is essential for maintaining reliability and effectiveness in various tasks.

Key Benefits of Using Quality Components

- Improved Durability: Premium materials are less likely to wear out quickly, extending the lifespan of the equipment.

- Enhanced Efficiency: Superior components can boost overall performance, reducing operational downtime.

- Better Compatibility: High-quality elements often offer more precise fits, minimizing issues during assembly and operation.

Considerations When Selecting Components

- Research the Manufacturer: Choose reputable brands known for their commitment to quality.

- Check Compatibility: Ensure that the selected components are suitable for the specific model to prevent functionality issues.

- Evaluate Reviews: Look for feedback from other users to gauge the reliability of the components.