The efficiency of a grass trimmer heavily relies on its intricate assembly of various elements. Each component plays a crucial role in ensuring the device operates smoothly and effectively, making it essential for users to comprehend how these pieces interact. A detailed visual representation can aid in grasping the relationships and functions of each part, enhancing overall maintenance and repair skills.

For those who seek to optimize the performance of their equipment, recognizing the specific names and functions of individual pieces is vital. This knowledge empowers users to make informed decisions during repairs or upgrades. Furthermore, a thorough understanding of the structure can help identify potential issues before they escalate, ensuring longevity and reliability in usage.

In this section, we will explore a comprehensive overview of the various elements associated with a specific trimmer model. By delving into the arrangement and purpose of each component, we aim to provide valuable insights for both novice and experienced users, fostering a deeper appreciation for the machinery they utilize.

Understanding the Stihl FS 56 Model

The FS 56 model is a well-regarded tool designed for efficient vegetation management and maintenance. Its engineering prioritizes user comfort and reliability, making it suitable for both casual users and professionals. This device is engineered to tackle various tasks, from trimming grass to clearing more dense brush.

Equipped with a powerful engine, this model ensures excellent performance across different terrains. Its lightweight construction enhances maneuverability, allowing users to work for extended periods without excessive fatigue. Additionally, the ergonomic design includes features that promote ease of use, such as adjustable handles and intuitive controls.

In terms of functionality, this model supports various attachments, broadening its application range. Whether for residential upkeep or larger landscaping projects, it provides versatility that appeals to many users. Understanding the features and capabilities of this tool is essential for maximizing its potential in outdoor tasks.

Key Features of the FS 56

The FS 56 is designed to deliver efficient performance for various outdoor tasks. Its innovative features enhance usability and effectiveness, making it a preferred choice among users. With a focus on reliability and power, this model ensures that users can tackle their gardening and landscaping needs with ease.

Power and Efficiency

This model boasts a robust engine that provides ample power for cutting through thick grass and weeds. The efficient fuel consumption allows for longer operation times, reducing the need for frequent refueling. Additionally, the lightweight design enhances maneuverability, making it easier to work in tight spaces.

User-Friendly Design

The FS 56 incorporates ergonomic features that prioritize user comfort. The adjustable handle provides a customized grip, while the anti-vibration technology minimizes strain during extended use. Easy-to-access controls and maintenance points contribute to a hassle-free user experience, allowing operators to focus on the task at hand.

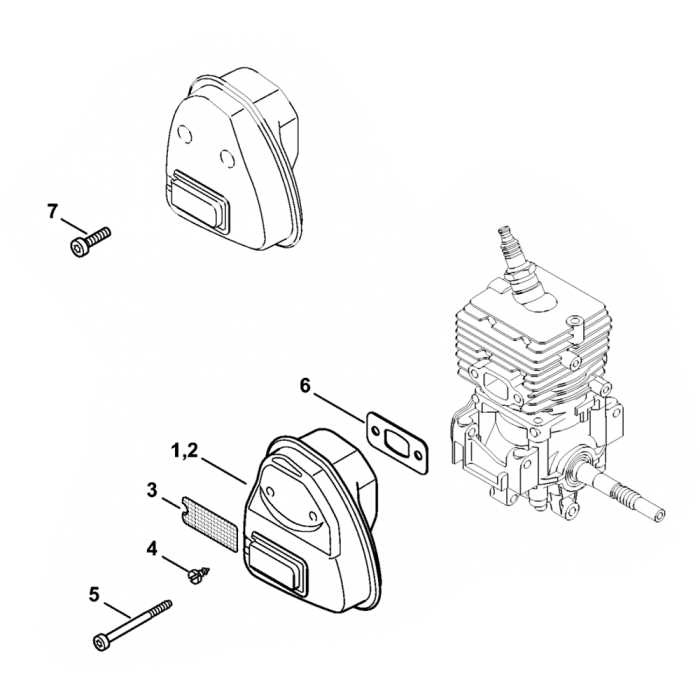

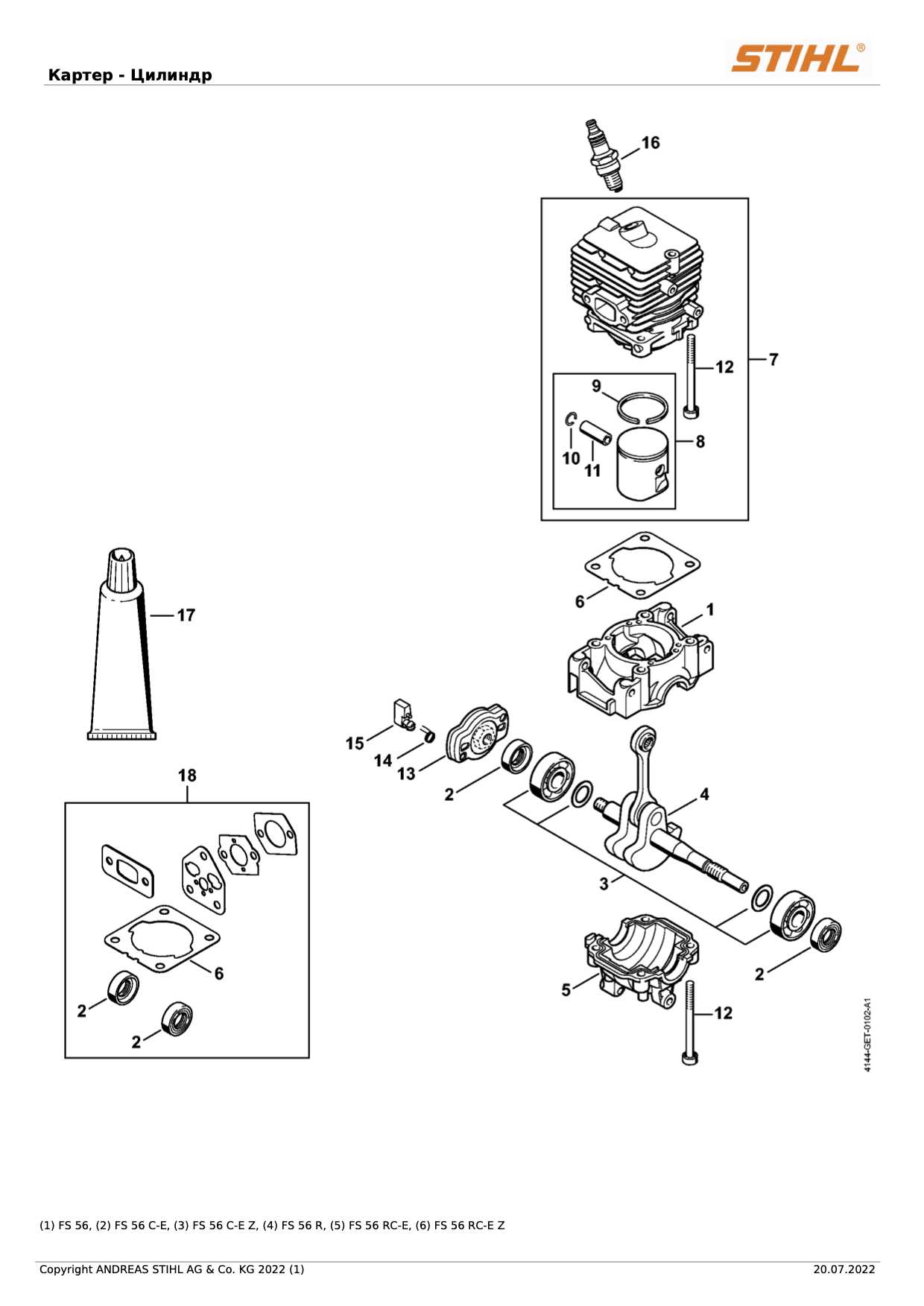

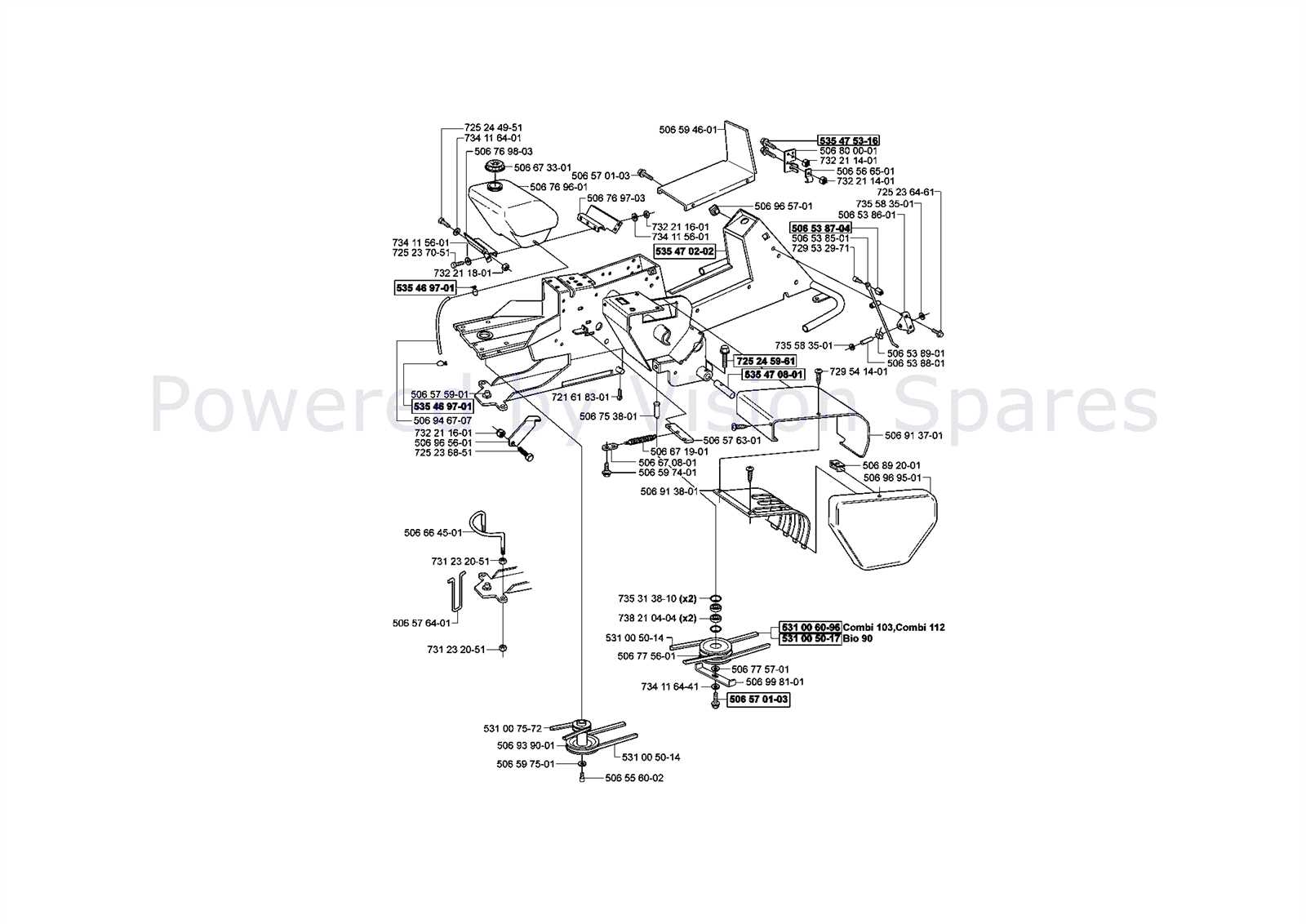

Importance of a Parts Diagram

Understanding the components of any machinery is essential for effective maintenance and repair. A visual representation of the individual elements facilitates the identification of each piece and its function within the overall system. This clarity is crucial for both novice and experienced users, enabling them to address issues more efficiently.

Having access to such a visual guide simplifies the troubleshooting process, allowing users to pinpoint where problems may arise. It enhances the ability to locate specific components quickly, making repairs more manageable and reducing downtime. Moreover, it serves as a valuable reference for reassembly, ensuring that every element is correctly positioned and connected.

In addition, these visual aids play a significant role in facilitating communication between users and service technicians. When discussing repairs or maintenance, having a clear image helps convey information accurately, preventing misunderstandings. This is particularly beneficial when ordering replacement components, as users can refer to the guide to specify the exact item needed.

Ultimately, a comprehensive visual representation of machine elements not only supports effective maintenance practices but also extends the life of the equipment by promoting proper care and handling. It empowers users with the knowledge to maintain their tools, leading to improved performance and efficiency.

Components of the FS 56 System

The efficiency and functionality of the FS 56 model rely on a variety of essential elements working in harmony. Each component plays a crucial role in ensuring optimal performance, from the power source to the cutting mechanism. Understanding these individual parts allows for better maintenance and troubleshooting, contributing to the longevity of the equipment.

Power Source

The power source is fundamental to the operation of the system. It provides the necessary energy to drive the cutting mechanism and is typically a high-performance engine designed for durability and reliability. Regular checks and maintenance of this component are vital to prevent operational failures.

Cutting Mechanism

Another key aspect of the system is the cutting mechanism, which includes various attachments designed for specific tasks. These attachments enable users to switch between different cutting styles, enhancing versatility. Proper alignment and maintenance of these elements are essential to ensure efficiency and safety during use.

Identifying Replacement Parts

When maintaining outdoor equipment, knowing how to recognize and source necessary components is crucial for optimal performance. This knowledge not only extends the life of the machine but also ensures that it operates efficiently. Understanding the various elements involved allows users to make informed decisions when it comes to repairs and replacements.

Begin by familiarizing yourself with the essential components of the machine. Each segment plays a specific role in functionality, and understanding these roles can aid in identifying which parts may need attention. It is beneficial to consult the user manual or reference guides that outline the various elements and their functions.

In addition, utilizing online resources or retailer catalogs can provide visual references that help in pinpointing the correct components. Many suppliers offer detailed illustrations that can assist in recognizing specific items. Take note of the part numbers, as they are vital for accurate ordering and replacement.

Finally, keeping track of wear and tear can guide you in anticipating which components might need replacement soon. Regular inspections and maintenance routines can prevent unexpected failures and ensure that your equipment remains in peak condition.

Common Issues and Solutions

When operating garden maintenance tools, users may encounter various challenges that can hinder performance. Understanding these common problems and their respective solutions can enhance the efficiency and longevity of the equipment. Below are some prevalent issues along with practical remedies.

1. Engine Fails to Start

This is a frequent concern that can stem from several factors:

- Fuel Issues: Check for stale or contaminated fuel. Replace it with fresh gasoline mixed with the appropriate oil.

- Air Filter Blockage: A clogged air filter can prevent proper airflow. Clean or replace the filter as needed.

- Spark Plug Problems: Inspect the spark plug for wear or damage. Cleaning or replacing the spark plug can often resolve starting issues.

2. Reduced Cutting Efficiency

When the tool struggles to cut effectively, it can be frustrating. Possible causes include:

- Dull Cutting Head: Ensure the cutting head is sharp. Regularly sharpen or replace blades for optimal performance.

- Line Feed Problems: Check if the cutting line is properly fed. Reload or adjust the line as necessary.

- Incorrect Operating Speed: Use the appropriate throttle settings. Running the engine at the right speed enhances cutting capability.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your outdoor power equipment. Regular maintenance not only enhances performance but also reduces the likelihood of breakdowns. Implementing a few simple practices can significantly improve the durability and efficiency of your machinery.

1. Clean After Use: Always remove debris, dirt, and grass clippings after every session. This helps prevent corrosion and keeps components functioning optimally.

2. Check Fuel and Oil Levels: Regularly inspect fuel and oil levels, ensuring they meet recommended specifications. Fresh fuel and clean oil contribute to smooth operation and prevent damage to internal parts.

3. Inspect Cutting Tools: Regularly examine blades and cutting implements for wear and damage. Keeping them sharp not only improves cutting efficiency but also reduces strain on the engine.

4. Replace Air Filters: Clogged air filters can hinder performance. Change or clean the air filter according to the manufacturer’s guidelines to ensure proper airflow and engine efficiency.

5. Store Properly: When not in use, store your equipment in a dry, sheltered area. Protecting it from harsh weather conditions can prevent rust and other forms of deterioration.

6. Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and recommendations provided by the manufacturer. This ensures you are performing the right checks and replacements at appropriate intervals.

By implementing these straightforward maintenance practices, you can significantly enhance the longevity and performance of your outdoor equipment.

Where to Find Genuine Parts

Locating authentic components for your equipment is crucial for ensuring optimal performance and longevity. When it comes to sourcing these essential elements, reliability and quality are paramount. There are various avenues to explore that can provide the assurance you need in your search for genuine items.

One of the most effective ways to obtain original items is through authorized dealers. These vendors typically maintain a comprehensive inventory of high-quality products that adhere to the manufacturer’s standards. Additionally, they can offer expert guidance on selecting the appropriate components for your model.

Online marketplaces also serve as valuable resources. Reputable e-commerce websites often feature sections dedicated to authentic merchandise, enabling customers to browse and compare different options conveniently. Be sure to read reviews and check seller ratings to ensure the legitimacy of the items being offered.

Another option is to explore local repair shops that specialize in outdoor equipment. Many of these establishments have access to genuine components and can provide installation assistance. Establishing a relationship with a trusted technician can lead to personalized service and insights into maintaining your equipment effectively.

Lastly, consider reaching out directly to the manufacturer’s customer service for assistance. They can provide information on authorized retailers and may even offer direct sales options. This approach guarantees that you receive authentic components designed specifically for your equipment.

Assembling the FS 56 Correctly

Proper assembly of your equipment is essential for optimal performance and longevity. Each component plays a crucial role in ensuring that the machine operates smoothly and effectively. Following the correct procedures not only enhances functionality but also reduces the risk of damage and maintenance issues.

Step-by-Step Assembly Instructions

Begin by gathering all the necessary components and tools. This preparation allows for a smoother assembly process. Refer to the user manual to identify each piece and its designated location. Start with the base unit, ensuring that it is securely positioned on a stable surface. Attach the handle, making sure to align it properly with the designated slots. Tighten the screws firmly but avoid overtightening, which can lead to damage.

Final Checks and Testing

Once the assembly is complete, perform a thorough inspection of all connections and fittings. Ensure that each part is secure and correctly aligned. After confirming that everything is in place, proceed to test the equipment. Start it up and observe its operation. If any unusual sounds or movements occur, turn it off immediately and recheck the assembly. Making adjustments early can prevent further complications.

Tools Needed for Repairs

Performing maintenance and fixing issues with your equipment requires a variety of essential instruments. Having the right tools at your disposal not only streamlines the process but also ensures that repairs are carried out effectively and safely. Below are some of the fundamental tools that will aid in achieving optimal results during repairs.

Wrench Set: A comprehensive set of wrenches is crucial for loosening and tightening various nuts and bolts. Ensure you have both standard and metric sizes to accommodate different components.

Screwdriver Set: A good selection of screwdrivers, including flathead and Phillips types, is necessary for removing and securing screws in various parts of the machinery.

Plier Set: Pliers are versatile tools that can assist in gripping, twisting, and cutting wires or other materials, making them indispensable during repairs.

Torque Wrench: This tool is essential for applying a specific torque to fasteners, ensuring they are tightened to the manufacturer’s specifications without risking damage.

Safety Equipment: Always prioritize safety by using gloves, goggles, and ear protection when conducting repairs. This equipment helps prevent injuries while working with tools and machinery.

Cleaning Tools: Keeping components clean is vital for proper functioning. Brushes, cloths, and solvents can help remove debris and ensure all parts are in good condition before reassembly.

Equipped with these tools, you’ll be well-prepared to handle repairs efficiently, ultimately extending the life and performance of your equipment.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of a popular outdoor power tool. Whether you are a new user or an experienced operator, understanding these topics can enhance your knowledge and ensure optimal performance.

| Question | Answer |

|---|---|

| What should I do if my equipment won’t start? | Check the fuel, ensure the ignition switch is on, and inspect the air filter for blockages. |

| How often should I replace the cutting line? | Replace the line when it appears frayed or worn, typically after several uses depending on the thickness of the material being cut. |

| What type of fuel is recommended for this machine? | A mixture of unleaded gasoline and two-stroke oil is advised. Refer to the manufacturer’s instructions for the correct ratio. |

| How can I maintain the cutting head? | Regularly clean the cutting head and replace the line as needed. Ensure the head is free of debris to avoid damage. |

| Is there a specific way to store the tool? | Store in a cool, dry place away from direct sunlight. Ensure it is cleaned and the fuel is drained if not used for an extended period. |